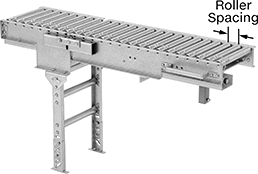

High-Capacity Large-Diameter Roller Conveyors

For more demanding shipping and assembly applications, these conveyors can carry heavy loads.

Lift gate conveyors can be lifted up to let workers quickly and safely pass through, so they don’t have to walk around or climb stairs over conveyors to navigate their facility. In constrained environments, these conveyors give you flexibility in conveyor placement.

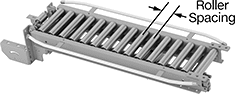

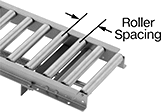

Note: Capacities are based on an evenly distributed load with at least one stand at each end for straight conveyors, and an additional stand in the center for curved conveyors. You can increase the capacity of a 10-ft. straight conveyor by adding a stand in the center. The length of the material you’re conveying should be at least three times the roller spacing.

Wd. | 3" Roller Spacing | |||||||

|---|---|---|---|---|---|---|---|---|

| O'all | Between Frame | Lg., ft. | Opening Lg., ft. | Cap. (No. of Stands Required) | No. of Stands Included | Features | Each | |

2 1/2" Dia. Steel Rollers—11/16" Hex Axle | ||||||||

| 10" | 7" | 4 | 3 1/2 | 800 lbs./ft. (2) | None | Connecting Plates | 00000000 | 0000000 |

| 12" | 9" | 4 | 3 1/2 | 800 lbs./ft. (2) | None | Connecting Plates | 00000000 | 000000 |

| 18" | 15" | 4 | 3 1/2 | 800 lbs./ft. (2) | None | Connecting Plates | 00000000 | 000000 |

| 24" | 21" | 4 | 3 1/2 | 800 lbs./ft. (2) | None | Connecting Plates | 00000000 | 00000000 |

| 30" | 27" | 4 | 3 1/2 | 800 lbs./ft. (2) | None | Connecting Plates | 00000000 | 00000000 |

| 36" | 33" | 4 | 3 1/2 | 800 lbs./ft. (2) | None | Connecting Plates | 00000000 | 00000000 |

High-Capacity Roller Conveyors

For moving heavy products on shipping and assembly lines, these have three times the load capacity of our standard roller conveyors. Whether you’re creating a straight line, a curve to route items around equipment, or a decline to lower them into a truck trailer, mixing and matching conveyors and stands lets you customize your system as needed. These conveyors have rollers that transfer items with flat or uneven bottoms, such as boxes or shipping tubes.

Because these conveyors don’t run on electricity, their rollers require momentum from gravity, a push, or a powered conveyor to move. Since they’re not wired, they’re quick to set up and easy to maintain. This makes them handy if another conveyor unexpectedly shuts down or you need to extend an existing line in a pinch. However, these high-capacity conveyors weigh about twice as much as standard ones, so they require more effort to move around.

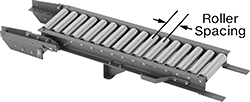

Choose a small roller spacing when conveying small items to prevent them from getting stuck between rollers. For large items, a large roller spacing helps minimize friction between your material and the rollers.

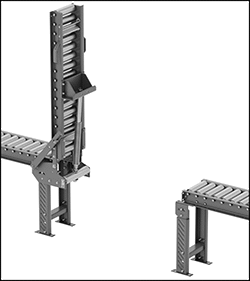

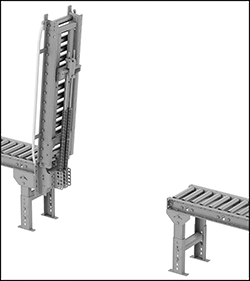

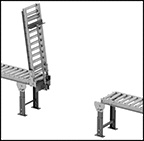

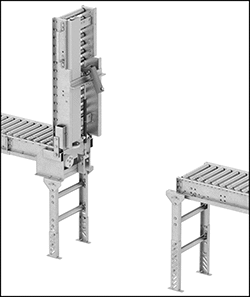

Lift gate conveyors can be raised up like a drawbridge, so you can quickly and safely pass through instead of walking around or using stairs to climb over. This gives you more flexibility in placing your conveyor, especially in cramped working environments. They’re spring loaded for easy lifting. Connect them to existing conveyors and a lift gate stand using their mounting plate.

Note: Capacities are based on an evenly distributed load. The length of the material you’re conveying should be at least three times the roller spacing.

Wd. | 3" Roller Spacing | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| O'all | Between Frame | Lg., ft. | Opening Lg., ft. | Roller Projection | Frame Ht. | Cap. (No. of Stands Required) | No. of Stands Included | Each | |

1.9" Dia. Steel Rollers—7/16" Hex Axle | |||||||||

| 13" | 10" | 4 | 3 1/2 | 1/4" | 3 1/2" | 620 lbs./ft. (2) | None | 0000000 | 000000000 |

| 16" | 13" | 4 | 3 1/2 | 1/4" | 3 1/2" | 620 lbs./ft. (2) | None | 0000000 | 00000000 |

| 18" | 15" | 4 | 3 1/2 | 1/4" | 3 1/2" | 620 lbs./ft. (2) | None | 0000000 | 00000000 |

| 20" | 17" | 4 | 3 1/2 | 1/4" | 3 1/2" | 620 lbs./ft. (2) | None | 0000000 | 00000000 |

| 24" | 21" | 4 | 3 1/2 | 1/4" | 3 1/2" | 620 lbs./ft. (2) | None | 0000000 | 00000000 |

| 36" | 33" | 4 | 3 1/2 | 1/4" | 3 1/2" | 620 lbs./ft. (2) | None | 0000000 | 00000000 |

| 40" | 37" | 4 | 3 1/2 | 1/4" | 3 1/2" | 620 lbs./ft. (2) | None | 0000000 | 00000000 |

| 42" | 39" | 4 | 3 1/2 | 1/4" | 3 1/2" | 620 lbs./ft. (2) | None | 0000000 | 00000000 |

Roller Conveyors

Mix and match conveyors and stands to design a conveyor system that moves parts exactly where they need to go. These conveyors have rollers that transfer items with flat or uneven bottoms, such as boxes or shipping tubes. They’re more durable and carry heavier loads than belt and skate wheel conveyors.

These conveyors don’t run on electricity, so their rollers require momentum from gravity, a push, or a powered conveyor to move. Since they’re not wired, they’re quick to set up and easy to maintain. This makes them handy if another conveyor unexpectedly shuts down or you need to extend an existing line in a pinch.

Lift gate conveyors can be raised like a drawbridge, so you can safely walk through your line. Install them in areas that don’t have room for crossover bridges to skip the long walk around your conveyor. The gate is spring loaded, which makes it easy to lift without effort. These conveyors have a mounting plate to connect to an existing conveyor.

Galvanized steel conveyors carry heavier loads than aluminum conveyors.

Note: Capacities are based on an evenly distributed load. The length of the material you’re conveying should be at least three times the roller spacing.

Wd. | 3" Roller Spacing | |||||||

|---|---|---|---|---|---|---|---|---|

| O'all | Between Frame | Lg., ft. | Opening Lg., ft. | Frame Ht. | Cap. (No. of Stands Required) | No. of Stands Included | Each | |

1 3/8" Dia. Galvanized Steel Rollers—1/4" Round Axle | ||||||||

| 12" | 10" | 3 | 2 1/2 | 2 1/2" | 200 lbs./ft. (None) | None | 0000000 | 0000000 |

| 18" | 16" | 3 | 2 1/2 | 2 1/2" | 200 lbs./ft. (None) | None | 0000000 | 000000 |

| 24" | 22" | 3 | 2 1/2 | 2 1/2" | 200 lbs./ft. (None) | None | 0000000 | 000000 |

Motorized Roller Conveyors

Also known as line-shaft conveyors, these conveyors are driven by a drive shaft and round belts. Unlike belt conveyors, these have built-in accumulation, so packages can build up without crashing into one another or falling off the conveyor. The rollers are designed to smoothly transfer totes, packages, and other lightweight material. Shipping tubes, drums, and pails are less likely to get stuck in between rollers than between skate wheels.

Mix and match stands and conveyors to form straight lines, curve around obstacles, or create inclines. Only straight conveyor sections contain a motor, but they can power up to 60 ft. of conveyor extensions on either side. The motor can be reversed to send material in either direction.

Lift gate conveyors can be raised up like a drawbridge, so you can quickly and safely pass through your line. Install them in areas that don’t have room for crossover bridges to skip the long walk around. They’re spring-loaded, so they’re easier to lift than manual gates. Choose a lift gate with a drive shaft mounted to the same side as the conveyor you’re connecting it to. The drive shaft on curved conveyors is always mounted to the inside curve.

Note: Capacities are based on an evenly distributed load. The length of the material you’re conveying should be at least three times the roller spacing.

Wd. | Roller | Ht. | No. of Stands | 6 ft. Lg. | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| O'all | Between Frame | Spacing | Projection | Frame | O"all | Cap., lbs./ft. | Required | Included | Features | Choose a Drive Location | Each | |

1.9" Dia. GalvanizedSteel Rollers—7/16" Hex Axle | ||||||||||||

| 16" | 13" | 3" | 1/4" | 5 1/2" | 36"-48" | 40 | 2 | 1 | Connecting Plates | 00000000 | 000000000 | |

| 17" | 14" | 3" | 1/4" | 5 1/2" | 36"-48" | 40 | 2 | 1 | Connecting Plates | 00000000 | 00000000 | |

| 19" | 16" | 3" | 1/4" | 5 1/2" | 36"-48" | 40 | 2 | 1 | Connecting Plates | 00000000 | 00000000 | |

| 21" | 18" | 3" | 1/4" | 5 1/2" | 36"-48" | 40 | 2 | 1 | Connecting Plates | 00000000 | 00000000 | |

| 25" | 22" | 3" | 1/4" | 5 1/2" | 36"-48" | 40 | 2 | 1 | Connecting Plates | 00000000 | 00000000 | |

| 29" | 26" | 3" | 1/4" | 5 1/2" | 36"-48" | 40 | 2 | 1 | Connecting Plates | 00000000 | 00000000 | |

| 31" | 28" | 3" | 1/4" | 5 1/2" | 36"-48" | 40 | 2 | 1 | Connecting Plates | 00000000 | 00000000 | |

| 35" | 32" | 3" | 1/4" | 5 1/2" | 36"-48" | 40 | 2 | 1 | Connecting Plates | 00000000 | 00000000 | |

| 41" | 38" | 3" | 1/4" | 5 1/2" | 36"-48" | 40 | 2 | 1 | Connecting Plates | 00000000 | 00000000 | |

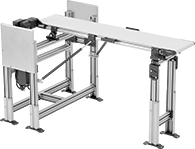

Easy-Access Ready-To-Run Mini Belt Conveyors

Run these conveyors right out of the box—they simply plug into an electrical outlet for power. The belts on these conveyors can move a wide range of small products, including electronic components, molded plastic parts, and other irregularly shaped parts that would catch on rollers and skate wheels. A good choice for quality checks, these conveyors have built-in speed controls and a flat belt surface that keeps objects steady as they move. Reverse the direction of travel with the flip of a switch. They’re small enough to fit in areas with limited space. Open the integrated lift gate for workers, dollies, and other equipment to safely pass through your line rather than going around the conveyor or over stairs. The height is adjustable to help you match existing setups. Continuous T-slots run along the sides of these conveyors for mounting side rails, guides, and custom equipment.

Note: Capacities are based on an evenly distributed load.

Wd. | No. of Stands | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Belt | Frame | O'all Ht. | Cap., lbs. | Required | Included | Voltage | Reversible | Features | Opening Lg. | Each | |

5 ft. Lg. | |||||||||||

10-58 fpm | |||||||||||

| 6" | 6 5/8" | 24"-60" | 30 | 2 | 2 | 120V AC | Yes | On/Off Switch | 36" | 0000000 | 000000000 |

| 8" | 8 5/8" | 24"-60" | 30 | 2 | 2 | 120V AC | Yes | On/Off Switch | 36" | 00000000 | 00000000 |

| 12" | 12 5/8" | 24"-60" | 30 | 2 | 2 | 120V AC | Yes | On/Off Switch | 36" | 00000000 | 00000000 |

7 ft. Lg. | |||||||||||

10-58 fpm | |||||||||||

| 6" | 6 5/8" | 24"-60" | 30 | 2 | 2 | 120V AC | Yes | On/Off Switch | 60" | 0000000 | 00000000 |

| 8" | 8 5/8" | 24"-60" | 30 | 2 | 2 | 120V AC | Yes | On/Off Switch | 60" | 00000000 | 00000000 |

| 12" | 12 5/8" | 24"-60" | 30 | 2 | 2 | 120V AC | Yes | On/Off Switch | 60" | 00000000 | 00000000 |

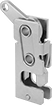

O'all | Mounting Holes | ||||||

|---|---|---|---|---|---|---|---|

| Lg. | Wd. | Mounting Fasteners Included | No. of | Dia. | Material | Each | |

| 3 3/16" | 1 3/4" | Yes | 2 | 9/32" | Zinc-Plated Steel | 0000000 | 000000 |

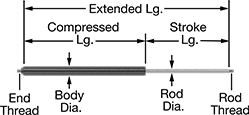

Body | Rod | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Extension Force, lbs. | Compression Force, lbs. | Extended Lg. | Compressed Lg. | Stroke Lg. | Max. Cycles per Minute | Max. Cycles | Dia. | Material | Dia. | Material | Temperature Range, °F | Each | |

M8 Rod and End Thread Size | |||||||||||||

| 25 | 33 | 33.94" | 17.8" | 16.14" | 6 | 25,000 | 0.85" | Steel | 0.39" | Steel | -22° to 176° | 00000000 | 000000 |

| 50 | 66 | 33.94" | 17.8" | 16.14" | 6 | 25,000 | 0.85" | Steel | 0.39" | Steel | -22° to 176° | 00000000 | 00000 |