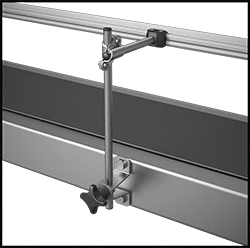

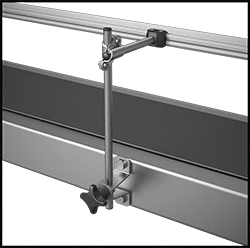

Mounting Rods for Conveyors

Use brackets and connectors to create vertical and horizontal support arms.

Round rods are the most common. However, these rods might cause connectors to slip over time as vibration loosens their hold on the rod.

Hollow rods are lighter than solid rods and easier to move. They’re the best choice for frequent conveyor setup changes.

Stainless steel mounting rods are the most corrosion resistant.

Thread | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Lg. | Rod Dia. | Size | Lg. | Gender | Material | Includes | Each | ||

Hollow | |||||||||

| A | 18" | 1/2" | 5/16"-18 | 3/4" | Female | Stainless Steel | Black Plastic End Cap | 00000000 | 000000 |

Graduated Mounting Rods for Conveyors

Graduated in 1/8" or 1 mm increments, these rods make it easy to align multiple brackets during installation.

Round rods are the most common. However, these rods might cause connectors to slip over time as vibration loosens their hold on the rod. Solid rods are sturdier than hollow rods, so they are less likely to be knocked out of place by heavy objects on your conveyor.

Thread | 1/2" Rod Dia. | ||||||

|---|---|---|---|---|---|---|---|

| Lg. | Graduation Marks (Numeric Increments) | Size | Lg. | Gender | Material | Each | |

Solid | |||||||

| 18" | 8ths (1") | 5/16"-18 | 0.89" | Female | Stainless Steel | 00000000 | 000000 |