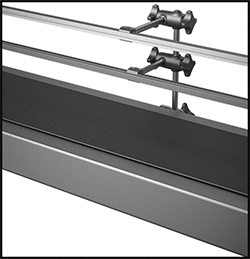

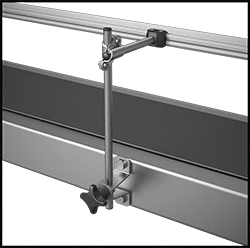

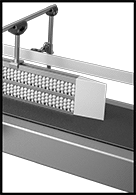

Conveyor Guides

|  H |

J |

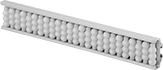

Conveyor guides direct and position material.

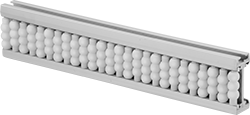

Rollers keep things moving where items tend to jam. They help maintain proper alignment and prevent items from moving off course. Attach them to threaded mounting rods or brackets with a 5/16”-18 bolt (mounting bolt sold separately for Style H). Style H rollers are made of FDA listed material for use in food and beverage conveying applications.

For technical drawings and 3-D models, click on a part number.

Ht. | 2 ft. Lg. | |||||||

|---|---|---|---|---|---|---|---|---|

| Style | O'all | Roller | Roller Color | Mounting Fasteners Included | Max. Temp., °F | Specifications Met | Each | |

Acetal Plastic with Aluminum Channel | ||||||||

| H | 1.9" | 1.45" | White | No | 180° | FDA Compliant 21 CFR 177.1520 | 00000000 | 0000000 |

| H | 3.78" | 3.26" | White | No | 180° | FDA Compliant 21 CFR 177.1520 | 00000000 | 000000 |

| J | 1.9" | 1.45" | Gray | Yes | 180° | __ | 00000000 | 000000 |

| J | 3.72" | 1.45" | Gray | Yes | 180° | __ | 00000000 | 000000 |

Flexible Conveyor Guides

Bend these guides without any extra equipment and secure them in place to match the corners and curves in your conveyor.

Roller guides keep things moving where items tend to jam. They help maintain proper alignment and prevent items from moving off course.

For technical drawings and 3-D models, click on a part number.

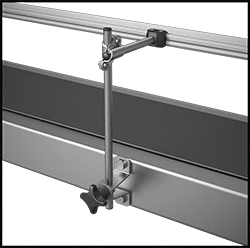

Easy-Adjust Conveyor Guides

An adjustable wear strip makes it easy to quickly position these guides and direct different sizes of material. Loosen the handles to adjust the wear strip and then tighten once the wear strip is in the position you want. These guides fasten to the side of your conveyor with bolts.

For technical drawings and 3-D models, click on a part number.

Overall | Wear Strip | Mounting Hole | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg., ft. | Ht. | Wd. Range | Ht. | Profile | Handle Material | Max. Temp., °F | Mounting Fasteners Included | No. of | Dia. | Features | Each | |

Powder-Coated Steel Wear Strips | ||||||||||||

| 2 | 2 1/2" | 2" to 8" | 1 3/4" | Flat | ABS Plastic | 300° | No | 2 | 3/8" | Locking Handles | 0000000 | 0000000 |

Mounting Rods for Conveyors

Use brackets and connectors to create vertical and horizontal support arms.

Round rods are the most common. However, these rods might cause connectors to slip over time as vibration loosens their hold on the rod. Solid rods are sturdier than hollow rods, so they’re less likely to be knocked out of place by heavy objects on your conveyor.

Stainless steel mounting rods are the most corrosion resistant.

For technical drawings and 3-D models, click on a part number.

Thread | ||||||||

|---|---|---|---|---|---|---|---|---|

| Lg. | Rod Dia. | Size | Lg. | Gender | Material | Each | ||

Solid | ||||||||

| A | 24" | 1/2" | 5/16"-18 | 0.89" | Female | Stainless Steel | 00000000 | 000000 |

Graduated Mounting Rods for Conveyors

Graduated in 1/8" or 1 mm increments, these rods make it easy to align multiple brackets during installation.

Round rods are the most common. However, these rods might cause connectors to slip over time as vibration loosens their hold on the rod. Solid rods are sturdier than hollow rods, so they are less likely to be knocked out of place by heavy objects on your conveyor.

For technical drawings and 3-D models, click on a part number.

Thread | 1/2" Rod Dia. | ||||||

|---|---|---|---|---|---|---|---|

| Lg. | Graduation Marks (Numeric Increments) | Size | Lg. | Gender | Material | Each | |

Solid | |||||||

| 24" | 8ths (1") | 5/16"-18 | 0.89" | Female | Stainless Steel | 00000000 | 000000 |

Roller Lane Dividers for Conveyors

Keep materials orderly and separate products into distinct lanes with guides and nose plows.

Guides provide a barrier between lanes.

For technical drawings and 3-D models, click on a part number.

Roller | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Lg., ft. | Ht. | Wd. | Ht. | Color | Channel Wd. | Mounting Fasteners Included | For Thread Size | Each | ||

UHMW Polyethylene Plastic with Aluminum Channel | ||||||||||

| C | 2 | 2 5/32" | 1" | 1 3/8" | White | 1.44" | No | 5/16"-18 | 0000000 | 0000000 |

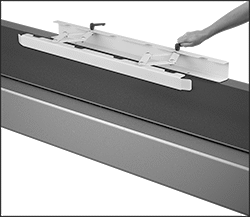

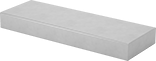

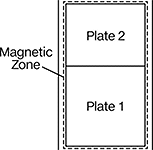

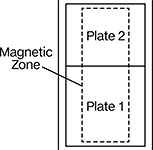

Magnetic Plates for Belt Conveyors

Keep ferrous objects in place as they move along your conveyor belt. These plates install under your conveyor belt to create a magnetic hold. Mount them with nonmagnetic fasteners.

Conveyor plates with full magnetic coverage have a higher magnetic force than conveyor plates with partial magnetic coverage. They have a full magnetic zone throughout the plate, making them best for moving large objects. Position them side-by-side or end-to-end to cover the entire width or length of the belt. All have tapped holes for mounting.

Conveyor plates with partial magnetic coverage have a magnetic zone that runs down the center of the plate's length. They’re typically placed underneath the middle of the belt to pull small objects that are prone to shifting due to vibration, such as lids and fasteners, towards the center of the belt for secure conveying. If used with large objects, only a part of the object will be secured. When installing multiple plates down your conveyor run, be sure the poles are opposite of each other. All have mounting brackets for quick installation.

For technical drawings and 3-D models, click on a part number.

24" Lg. | |||||

|---|---|---|---|---|---|

| Wd. | Thick. | Max. Pull @ Distance | Bracket Material | Each | |

Full Magnetic Coverage | |||||

| 4 1/8" | 1 5/16" | 7 1/2 lbs. @ 1/8" | __ | 00000000 | 000000000 |

| 4 1/8" | 2 5/16" | 9 1/2 lbs. @ 1/8" | __ | 00000000 | 00000000 |

Partial Magnetic Coverage | |||||

| 1 5/8" | 1 5/32" | 2 1/2 lbs. @ 1/8" | Stainless Steel | 00000000 | 000000 |

| 3" | 1 5/32" | 5 lbs. @ 1/8" | Stainless Steel | 00000000 | 000000 |

| 3 5/8" | 1 29/32" | 5 3/4 lbs. @ 1/8" | Stainless Steel | 00000000 | 00000000 |