Filter by

Roller Material

Bearing Material

Weight Capacity

Width

Axle Grip Type

Maximum Temperature

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Ball Bearing Material

Material Handling

Power Transmission

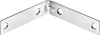

Building and Machinery Hardware