About Heat-Shrink Tubing

More

Protective Covers for Conveyor Rollers

Reduce noise, absorb impact, and extend roller life. The higher the hardness rating, the longer the covers will protect rollers in demanding applications.

Heat-shrink covers conform to the shape of your roller when heated. Slide-on covers slip over the roller. For easier installation, use lubricant and an air nozzle.

PVC is for use in corrosive environments. Polyurethane has a high-friction surface for high speeds and inclines.

FDA-compliant covers are safe to use for conveying food and beverages

Lubricant is water based and loses its lubrication properties upon drying to ensure covers retain a snug fit.

Connect air nozzles to a source of compressed air to create a cushion for sliding covers onto the roller.

| For Roller Dia. | For Tapered Roller Dia. | Wd., ft. | Thick. | Min. Shrink Temperature, °F | Hardness | Hardness Rating | Specifications Met | Pkg. Qty. | Pkg. | |

PVC Plastic | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Black | ||||||||||

| 1 3/8" | __ | 5 | 0.05" | 212° | Durometer 85A | Hard | __ | 1 | 0000000 | 000000 |

| 1.9" | __ | 5 | 0.05" | 212° | Durometer 85A | Hard | __ | 1 | 0000000 | 00000 |

| 2" | __ | 5 | 0.05" | 212° | Durometer 85A | Hard | __ | 1 | 0000000 | 00000 |

| 2 1/2" | __ | 5 | 0.05" | 212° | Durometer 85A | Hard | __ | 1 | 0000000 | 00000 |

| __ | 1 1/2"-2 1/2" | 5 | 0.05" | 212° | Durometer 85A | Hard | __ | 1 | 0000000 | 00000 |

Orange | ||||||||||

| 1 3/8" | __ | 5 | 0.05" | 212° | Durometer 85A | Hard | __ | 1 | 0000000 | 00000 |

| 1.9" | __ | 1 | 0.05" | 212° | Durometer 85A | Hard | __ | 5 | 0000000 | 00000 |

| 1.9" | __ | 2 | 0.05" | 212° | Durometer 85A | Hard | __ | 5 | 0000000 | 00000 |

| 1.9" | __ | 5 | 0.05" | 212° | Durometer 85A | Hard | __ | 1 | 0000000 | 00000 |

| 2" | __ | 5 | 0.05" | 212° | Durometer 85A | Hard | __ | 1 | 0000000 | 00000 |

| 2 1/2" | __ | 5 | 0.05" | 212° | Durometer 85A | Hard | __ | 1 | 0000000 | 00000 |

| __ | 1 1/2"-2 1/2" | 5 | 0.05" | 212° | Durometer 85A | Hard | __ | 1 | 0000000 | 00000 |

White | ||||||||||

| 1 3/8" | __ | 5 | 0.05" | 212° | Durometer 85A | Hard | FDA Compliant 21 CFR 177.1980 | 1 | 0000000 | 00000 |

| 1.9" | __ | 5 | 0.05" | 212° | Durometer 85A | Hard | FDA Compliant 21 CFR 177.1980 | 1 | 0000000 | 00000 |

| 2" | __ | 5 | 0.05" | 212° | Durometer 85A | Hard | FDA Compliant 21 CFR 177.1980 | 1 | 0000000 | 00000 |

| 2 1/2" | __ | 5 | 0.05" | 212° | Durometer 85A | Hard | FDA Compliant 21 CFR 177.1980 | 1 | 0000000 | 00000 |

| __ | 1 1/2"-2 1/2" | 5 | 0.05" | 212° | Durometer 85A | Hard | FDA Compliant 21 CFR 177.1980 | 1 | 0000000 | 00000 |

Covers | Air Nozzles | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Roller Dia. | Wd., ft. | Thick. | Hardness | Hardness Rating | Specifications Met | Pkg. Qty. | Pkg. | Each | ||

Polyurethane Rubber | ||||||||||

Black | ||||||||||

| 1 3/8" | 5 | 1/8" | Durometer 85A | Hard | __ | 1 | 0000000 | 000000 | 0000000 | 0000000 |

| 1.9" | 5 | 1/16" | Durometer 85A | Hard | __ | 1 | 00000000 | 00000 | 0000000 | 000000 |

| 1.9" | 5 | 1/8" | Durometer 70A | Hard | FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 1 | 00000000 | 00000 | 0000000 | 000000 |

| 1.9" | 5 | 1/8" | Durometer 85A | Hard | __ | 1 | 0000000 | 00000 | 0000000 | 000000 |

| 2" | 5 | 1/8" | Durometer 85A | Hard | __ | 1 | 0000000 | 00000 | 0000000 | 000000 |

| 2 1/2" | 5 | 1/8" | Durometer 85A | Hard | __ | 1 | 0000000 | 00000 | 0000000 | 000000 |

| 2 3/4" | 5 | 1/8" | Durometer 85A | Hard | __ | 1 | 00000000 | 00000 | 00000000 | 000000 |

Orange | ||||||||||

| 3/4" | 5 | 1/8" | Durometer 85A | Hard | __ | 1 | 0000000 | 00000 | 0000000 | 000000 |

| 1 3/8" | 5 | 1/8" | Durometer 85A | Hard | __ | 1 | 0000000 | 00000 | 0000000 | 000000 |

| 1.9" | 5 | 1/16" | Durometer 85A | Hard | __ | 1 | 00000000 | 00000 | 0000000 | 000000 |

| 1.9" | 5 | 1/8" | Durometer 85A | Hard | __ | 1 | 0000000 | 00000 | 0000000 | 000000 |

| 1.9" | 5 | 1/4" | Durometer 85A | Hard | __ | 1 | 00000000 | 00000 | 0000000 | 000000 |

| 2" | 5 | 1/8" | Durometer 85A | Hard | __ | 1 | 0000000 | 00000 | 0000000 | 000000 |

| 2 1/2" | 5 | 1/8" | Durometer 85A | Hard | __ | 1 | 0000000 | 00000 | 0000000 | 000000 |

| 2 1/2" | 5 | 1/4" | Durometer 85A | Hard | __ | 1 | 00000000 | 000000 | 0000000 | 000000 |

| 3 1/2" | 5 | 1/8" | Durometer 85A | Hard | __ | 1 | 0000000 | 00000 | 0000000 | 000000 |

Green | ||||||||||

| 1.9" | 5 | 1/8" | Durometer 85A | Hard | __ | 1 | 00000000 | 00000 | 0000000 | 000000 |

| 2 1/2" | 5 | 1/8" | Durometer 85A | Hard | __ | 1 | 00000000 | 00000 | 0000000 | 000000 |

PVC Plastic | ||||||||||

Black | ||||||||||

| 1 1/2" | 5 | 3/16" | Durometer 60A | Medium Hard | __ | 1 | 00000000 | 00000 | 00000000 | 000000 |

Gray | ||||||||||

| 1.9" | 5 | 1/8" | Durometer 60A | Medium Hard | __ | 1 | 0000000 | 00000 | 0000000 | 000000 |

| 2 1/2" | 5 | 1/8" | Durometer 60A | Medium Hard | __ | 1 | 0000000 | 00000 | 0000000 | 000000 |

Blue | ||||||||||

| 1.9" | 5 | 1/8" | Durometer 90A | Extra Hard | __ | 1 | 00000000 | 00000 | 0000000 | 000000 |

| 2 1/2" | 5 | 1/8" | Durometer 90A | Extra Hard | __ | 1 | 00000000 | 00000 | 0000000 | 000000 |

| Lubricant (32 oz. Spray Bottle) | 0000000 | Each | 000000 |

Loose-Fitting Protective Covers for Conveyor Rollers

Covers fit loosely over the roller to allow packages to accumulate. Rollers can continue spinning inside the cover without causing damage to packages.

Transfer Guards for Conveyor Rollers

Keep small items moving smoothly down a roller conveyor. These guards cover the gap between rollers so items don’t fall through or get jammed. They consist of a flat plate with flexible legs that snap in place between your rollers.

To figure out how many guards you need, consider how wide your rollers are. For rollers wider than 12”, you’ll need multiple. Trim guards that are too long using the installation tools (sold separately). Use the leg cutter to remove the leg just past the width you need. This gives you enough room to use the guard cutter to trim the guard down. For a proper fit, you can’t trim these shorter than 4”.

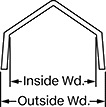

Protective Covers for Conveyors

Protect conveyed material from dust, debris, and other contaminants. All of these covers are FDA compliant for food and beverage conveying.

PETG plastic covers are more chemical resistant than ABS plastic but not as scratch resistant.

Metal-detectable ABS plastic covers are best when metal detection and retrieval are essential, such as in food processing applications. Made with metal additives, they set off metal detectors if any part falls into your line, so it won’t leave your facility.

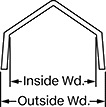

Outside | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Lg., ft. | Wd. | Ht. | Inside Wd. | Thick. | Color | UV Resistant | Specifications Met | Each | |

ABS Plastic | |||||||||

| 4 | 8" | 2 5/8" | 7 1/2" | 0.13" | Yellow | No | FDA Compliant 21 CFR 181.32 | 0000000 | 0000000 |

| 5 | 5 1/2" | 2 1/2" | 5" | 0.13" | Yellow | No | FDA Compliant 21 CFR 181.32 | 0000000 | 000000 |

| 5 | 13" | 3 1/4" | 12 1/2" | 0.13" | Yellow | No | FDA Compliant 21 CFR 181.32 | 0000000 | 000000 |

PETG Plastic | |||||||||

| 5 | 5 1/2" | 2 3/4" | 5" | 0.13" | Clear | No | FDA Compliant 21 CFR 177.1315 | 0000000 | 000000 |

| 5 | 13" | 3 1/4" | 12 1/2" | 0.13" | Clear | No | FDA Compliant 21 CFR 177.1315 | 0000000 | 000000 |

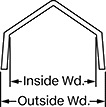

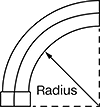

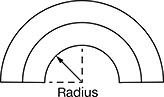

Outside | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Radius | Wd. | Ht. | Inside Wd. | Thick. | Color | UV Resistant | Specifications Met | Each | |

ABS Plastic | |||||||||

| 15 1/2" | 5 1/2" | 2 3/4" | 5" | 0.13" | Yellow | No | FDA Compliant 21 CFR 181.32 | 0000000 | 0000000 |

| 20 1/8" | 8" | 2 5/8" | 7 1/2" | 0.13" | Yellow | No | FDA Compliant 21 CFR 181.32 | 0000000 | 000000 |

| 21 1/2" | 5 1/2" | 2 3/4" | 5" | 0.13" | Yellow | No | FDA Compliant 21 CFR 181.32 | 0000000 | 000000 |

ABS Plastic—Metal Detectable | |||||||||

| 15 1/2" | 5 1/2" | 2 3/4" | 5" | 0.09" | Blue | No | FDA Compliant 21 CFR 181.32 | 0000000 | 000000 |

| 21 1/2" | 5 1/2" | 2 3/4" | 5" | 0.09" | Blue | No | FDA Compliant 21 CFR 181.32 | 0000000 | 000000 |

PETG Plastic | |||||||||

| 15 1/2" | 5 1/2" | 2 3/4" | 5" | 0.13" | Clear | No | FDA Compliant 21 CFR 177.1315 | 0000000 | 000000 |

| 20 1/8" | 8" | 2 5/8" | 7 1/2" | 0.13" | Clear | No | FDA Compliant 21 CFR 177.1315 | 0000000 | 000000 |

| 21 1/2" | 5 1/2" | 2 5/8" | 5" | 0.13" | Clear | No | FDA Compliant 21 CFR 177.1315 | 0000000 | 000000 |

Outside | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Radius | Wd. | Ht. | Inside Wd. | Thick. | Color | UV Resistant | Specifications Met | Each | |

ABS Plastic | |||||||||

| 3 3/8" | 8" | 2 5/8" | 7 3/4" | 0.13" | Yellow | No | FDA Compliant 21 CFR 181.32 | 0000000 | 0000000 |

| 7 1/8" | 8" | 2 5/8" | 7 3/4" | 0.13" | Yellow | No | FDA Compliant 21 CFR 181.32 | 0000000 | 000000 |

PETG Plastic | |||||||||

| 3 3/8" | 8" | 2 5/8" | 7 3/4" | 0.13" | Clear | No | FDA Compliant 21 CFR 177.1315 | 0000000 | 000000 |

| 7 1/8" | 8" | 2 5/8" | 7 3/4" | 0.13" | Clear | No | FDA Compliant 21 CFR 177.1315 | 0000000 | 000000 |

Chemical-Resistant Heat-Shrink Tubing

Use this tubing where wire and cable may be exposed to chemicals, oil, and acids.

PVC plastic tubing is more chemical resistant than rubber. It also resists UV, so it won’t fade or discolor when exposed to sunlight. Store tubing at 70° F or lower to avoid premature shrinkage.

Dielectric strength is the maximum voltage a material can handle before it starts to breakdown. The higher the dielectric strength of a material, the better it is for preventing electricity, heat, or signal from dissipating from wire and cable.

- Shrink Ratio: 2:1

- Dielectric Strength: See Table

- Shrink Temperature: 215° F

- Temperature Range: 0° to 220° F

ID | 1 ft. Lg. | ||||||

|---|---|---|---|---|---|---|---|

| Before Shrinking | Min. After Shrinking | Min. Wall Thick. After Shrinking | Dielectric Strength | Choose a Color | Pkg. Qty. | Pkg. | |

| 0.63" | 0.31" | 0.03" | Not Rated | 5 | 0000000 | 00000 | |

| 0.75" | 0.38" | 0.03" | Not Rated | 5 | 0000000 | 0000 | |

| 1" | 0.5" | 0.04" | Not Rated | 5 | 0000000 | 0000 | |

| 1.5" | 0.75" | 0.04" | Not Rated | 5 | 0000000 | 00000 | |

| 2" | 1" | 0.05" | Not Rated | 3 | 0000000 | 00000 | |

| 3" | 1.5" | 0.07" | Not Rated | 1 | 0000000 | 0000 | |

| 4" | 2" | 0.07" | Not Rated | 1 | 0000000 | 00000 | |

- Shrink Ratio: 2:1

- Dielectric Strength: See Table

- Shrink Temperature: 215° F

- Temperature Range: 0° to 220° F

ID | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Before Shrinking | Min. After Shrinking | Min. Wall Thick. After Shrinking | Dielectric Strength | Choose a Color | 5 ft. Lg. | 25 ft. Lg. | 50 ft. Lg. | 100 ft. Lg. | |

| 0.63" | 0.31" | 0.03" | Not Rated | 00000000 | |||||

| 0.75" | 0.38" | 0.03" | Not Rated | 00000000 | |||||

| 1" | 0.5" | 0.04" | Not Rated | 00000000 | |||||

| 1.5" | 0.75" | 0.04" | Not Rated | 00000000 | |||||

| 2" | 1" | 0.05" | Not Rated | 00000000 | |||||

| 3" | 1.5" | 0.07" | Not Rated | 00000000 | |||||

| 4" | 2" | 0.07" | Not Rated | 00000000 | |||||

| 5" | 2.5" | 0.08" | Not Rated | 00000000 | |||||

High-Strength Heat-Shrink Tubing

With excellent durability and chemical resistance, this tubing withstands demanding use.

FEP tubing is more chemical resistant than PVDF tubing, and withstands higher temperatures. It resists tears from stretching or flexing, but it’s softer than PVDF tubing and less resistant to cuts.

Dielectric strength is the maximum voltage a material can handle before it starts to breakdown. The higher the dielectric strength of a material, the better it is for preventing electricity, heat, or signal from dissipating from wire and cable.

- Shrink Ratio: See Table

- Dielectric Strength: See Table

- Shrink Temperature: See Table

- Temperature Range: See Table

ID | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Before Shrinking | Min. After Shrinking | Min. Wall Thick. After Shrinking | Shrink Temp., °F | Temp. Range, °F | Dielectric Strength | Color | 1 ft. | 2 ft. | 3 ft. | 4 ft. | 6 ft. | 8 ft. | |

1.3:1 Shrink Ratio | |||||||||||||

| 1.1" | 0.88" | 0.02" | 350° | -450° to 400° | 1,400 V/mil | Clear | 00000000 | ||||||

| 1.3" | 1" | 0.02" | 350° | -450° to 400° | 1,400 V/mil | Clear | 00000000 | ||||||

| 1.7" | 1.3" | 0.02" | 350° | -450° to 400° | 1,400 V/mil | Clear | 00000000 | ||||||

| 2.1" | 1.7" | 0.02" | 350° | -450° to 400° | 1,400 V/mil | Clear | 00000000 | ||||||

| 2.6" | 2.1" | 0.02" | 350° | -450° to 400° | 1,400 V/mil | Clear | 00000000 | ||||||

| 2.6" | 2.2" | 0.02" | 420° | -400° to 400° | 2,000 V/mil | Clear | 0000000 | ||||||

| 3.1" | 2.6" | 0.02" | 350° | -450° to 400° | 1,400 V/mil | Clear | 00000000 | ||||||

| 4.2" | 3.5" | 0.02" | 420° | -400° to 400° | 2,000 V/mil | Clear | 0000000 | ||||||

| 4.3" | 3.5" | 0.02" | 350° | -450° to 400° | 1,400 V/mil | Clear | 00000000 | ||||||

| 5.2" | 4.3" | 0.02" | 350° | -450° to 400° | 1,400 V/mil | Clear | 00000000 | ||||||

| 6.2" | 5.2" | 0.02" | 350° | -450° to 400° | 1,400 V/mil | Clear | 00000000 | ||||||

Abrasion-Resistant Rollers

These urethane rollers are nonmarring and wear resistant. Mount them directly onto your shaft or build a custom roller by adding your own hub.

For technical drawings and 3-D models, click on a part number.

Roller | |||||||

|---|---|---|---|---|---|---|---|

| Dia. | Wd. | For Shaft Dia. | Shaft Mount Type | Temperature Range, ° F | Choose a Durometer (Hardness Rating) | Each | |

Urethane Roller | |||||||

| 1" | 1/2" | 1/2" | Press Fit | -40° to 170° | 000000000 | 00000 | |

| 1 1/2" | 1/2" | 3/4" | Press Fit | -40° to 170° | 000000000 | 0000 | |

| 1 1/2" | 3/4" | 1/2" | Press Fit | -40° to 170° | 000000000 | 0000 | |

| 2" | 3/4" | 1" | Press Fit | -40° to 170° | 000000000 | 00000 | |

| 2 1/4" | 1" | 3/4" | Press Fit | -40° to 170° | 000000000 | 00000 | |

| 3" | 1" | 1" | Press Fit | -40° to 170° | 000000000 | 00000 | |

| 4" | 3/4" | 2" | Press Fit | -40° to 170° | 000000000 | 00000 | |