1.9" Diameter Conveyor Rollers

Replace damaged rollers or use multiple rollers to build a custom conveyor.

For technical drawings and 3-D models, click on a part number.

Roller | |||||||

|---|---|---|---|---|---|---|---|

| For Between Frame Wd. | Wd. | Gauge | Cap., lbs. | Overall Wd. | Temp. Range, °F | Each | |

7/16" Hex Axle | |||||||

1.9" Dia. Galvanized Steel Roller | |||||||

| 38" | 37 19/32" | 16 | 250 | 39 1/4" | -20° to 300° | 00000000 | 000000 |

1/4" Round Axle | |||||||

1.9" Dia. Galvanized Steel Roller | |||||||

| 38" | 37 1/2" | 16 | 125 | 39" | -15° to 220° | 00000000 | 00000 |

3/8" Round Axle | |||||||

1.9" Dia. Galvanized Steel Roller | |||||||

| 38" | 37 7/8" | 16 | 40 | 39" | 0° to 150° | 00000000 | 00000 |

1/2" Round Axle | |||||||

1.9" Dia. Galvanized Steel Roller | |||||||

| 38" | 37 19/32" | 16 | 265 | 39 1/4" | -20° to 140° | 00000000 | 00000 |

Large-Diameter Conveyor Rollers

Steel rollers are stronger than aluminum rollers.

For technical drawings and 3-D models, click on a part number.

Roller | |||||||

|---|---|---|---|---|---|---|---|

| For Between Frame Wd. | Wd. | Gauge | Cap., lbs. | Overall Wd. | Temp. Range, °F | Each | |

11/16" Hex Axle | |||||||

2 1/2" Dia. Steel Roller | |||||||

| 38" | 37" | 11 | 750 | 39 1/4" | 0° to 150° | 00000000 | 0000000 |

1 1/16" Hex Axle | |||||||

3 1/2" Dia. Steel Roller | |||||||

| 38" | 37 3/8" | 5 | 1,100 | 39 1/2" | -10° to 220° | 00000000 | 000000 |

1/4" Round Axle | |||||||

2" Dia. Steel Roller | |||||||

| 38" | 37 1/2" | 12 | 190 | 39" | -15° to 220° | 00000000 | 00000 |

Small-Diameter Corrosion-Resistant Conveyor Rollers

Roller | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Between Frame Wd. | Wd. | Gauge | Cap., lbs. | Overall Wd. | Bearing Material | Temp. Range, °F | Each | |

1/4" Round Axle | ||||||||

1 3/8" Dia. Stainless Steel Roller | ||||||||

| 38" | 37 3/8" | 16 | 95 | 39" | Plastic | -30° to 165° | 00000000 | 0000000 |

1.9" Diameter Corrosion-Resistant Conveyor Rollers

Made from stainless steel, these rollers are suitable for washdown applications.

For technical drawings and 3-D models, click on a part number.

Roller | |||||||

|---|---|---|---|---|---|---|---|

| For Between Frame Wd. | Wd. | Gauge | Cap., lbs. | Overall Wd. | Temp. Range, °F | Each | |

7/16" Hex Axle | |||||||

1.9" Dia. Stainless Steel Roller | |||||||

| 38" | 37 3/8" | 16 | 80 | 39" | 10° to 150° | 0000000 | 0000000 |

1.9" Diameter Dent-Resistant Conveyor Rollers

Rollers are made from thick, 12-ga. steel so they're less likely to dent than standard 16-ga. rollers.

Shielded bearings keep out dirt and debris.

For technical drawings and 3-D models, click on a part number.

Roller | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Between Frame Wd. | Wd. | Gauge | Cap., lbs. | Overall Wd. | Bearing Seal Type | Temp. Range, °F | Each | |

7/16" Hex Axle | ||||||||

1.9" Dia. Steel Roller | ||||||||

| 38" | 37 7/8" | 12 | 150 | 39" | Shielded | -15° to 250° | 0000000 | 000000 |

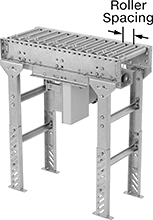

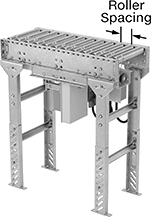

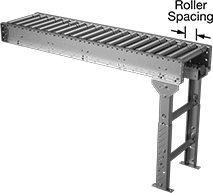

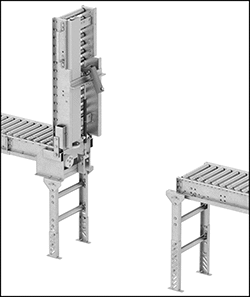

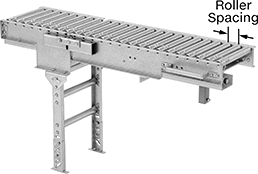

Motorized Roller Conveyors

Also known as line-shaft conveyors, these conveyors are driven by a drive shaft and round belts. Unlike belt conveyors, these have built-in accumulation, so packages can build up without crashing into one another or falling off the conveyor. The rollers are designed to smoothly transfer totes, packages, and other lightweight material. Shipping tubes, drums, and pails are less likely to get stuck in between rollers than between skate wheels.

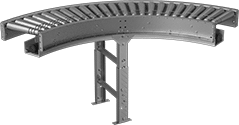

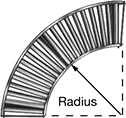

Mix and match stands and conveyors to form straight lines, curve around obstacles, or create inclines. Only straight conveyor sections contain a motor, but they can power up to 60 ft. of conveyor extensions on either side. The motor can be reversed to send material in either direction.

Fixed-speed conveyors travel at 60 fpm, a common industry rate, to move material. Those with three-phase motors balance power more evenly than single-phase motors, so they can handle heavier loads. While a conveyor with a single-phase motor may lag when a heavy load reaches the conveyor, a conveyor with a three-phase motor will continue smoothly.

Variable-speed conveyors adjust from standard conveyor speeds down to 25 fpm, so they’re often used to slow material flow for quality checks.

90° curved conveyors have tapered rollers that keep packages centered.

Lift gate conveyors can be raised up like a drawbridge, so you can quickly and safely pass through your line. Install them in areas that don’t have room for crossover bridges to skip the long walk around. They’re spring-loaded, so they’re easier to lift than manual gates. Choose a lift gate with a drive shaft mounted to the same side as the conveyor you’re connecting it to. The drive shaft on curved conveyors is always mounted to the inside curve.

Note: Capacities are based on an evenly distributed load. The length of the material you’re conveying should be at least three times the roller spacing.

For technical drawings and 3-D models, click on a part number.

Wd. | Roller | Ht. | No. of Stands | 3 ft. Lg. | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| O'all | Between Frame | Spacing | Projection | Frame | O'all | Power, hp | Speed, fpm | Cap., lbs./ft. | Required | Included | Features | Each | |

1.9" Dia. Galvanized Steel Rollers—7/16" Hex Axle | |||||||||||||

120V AC—Single Phase (Plug In) | |||||||||||||

| 41" | 38" | 3" | 1/4" | 5 1/2" | 36"-48" | 1/2 | 60 | 40 | 2 | 2 | Connecting Plates, On/Off Switch | 00000000 | 000000000 |

240/460V AC—Three Phase (Hardwire) | |||||||||||||

| 41" | 38" | 3" | 1/4" | 5 1/2" | 36"-48" | 1/2 | 60 | 40 | 2 | 2 | Connecting Plates | 00000000 | 00000000 |

Wd. | Roller | Ht. | No. of Stands | 3 ft. Lg. | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| O'all | Between Frame | Spacing | Projection | Frame | O'all | Power, hp | Speed, fpm | Cap., lbs./ft. | Required | Included | Features | Each | |

1.9" Dia. Galvanized Steel Rollers—7/16" Hex Axle | |||||||||||||

120V AC—Single Phase (Plug In) | |||||||||||||

| 41" | 38" | 3" | 1/4" | 5 1/2" | 36"-48" | 1/2 | 25-60 | 40 | 2 | 2 | Connecting Plates, On/Off Switch | 0000000 | 000000000 |

Wd. | Roller | Ht. | |||||||

|---|---|---|---|---|---|---|---|---|---|

| O'all | Between Frame | Spacing | Projection | Frame | O'all | Cap., lbs./ft. | Features | Each | |

3 ft. Lg. | |||||||||

1.9" Dia. Galvanized Steel Rollers—7/16" Hex Axle | |||||||||

| 41" | 38" | 3" | 1/4" | 5 1/2" | 36"-48" | 40 | Connecting Plates | 00000000 | 0000000 |

4 ft. Lg. | |||||||||

1.9" Dia. Galvanized Steel Rollers—7/16" Hex Axle | |||||||||

| 41" | 38" | 3" | 1/4" | 5 1/2" | 36"-48" | 40 | Connecting Plates | 00000000 | 000000 |

5 ft. Lg. | |||||||||

1.9" Dia. Galvanized Steel Rollers—7/16" Hex Axle | |||||||||

| 41" | 38" | 3" | 1/4" | 5 1/2" | 36"-48" | 40 | Connecting Plates | 00000000 | 00000000 |

7 ft. Lg. | |||||||||

1.9" Dia. Galvanized Steel Rollers—7/16" Hex Axle | |||||||||

| 41" | 38" | 3" | 1/4" | 5 1/2" | 36"-48" | 40 | Connecting Plates | 00000000 | 00000000 |

8 ft. Lg. | |||||||||

1.9" Dia. Galvanized Steel Rollers—7/16" Hex Axle | |||||||||

| 41" | 38" | 3" | 1/4" | 5 1/2" | 36"-48" | 40 | Connecting Plates | 00000000 | 00000000 |

10 ft. Lg. | |||||||||

1.9" Dia. Galvanized Steel Rollers—7/16" Hex Axle | |||||||||

| 41" | 38" | 3" | 1/4" | 5 1/2" | 36"-48" | 40 | Connecting Plates | 00000000 | 00000000 |

Wd. | Ht. | No. of Stands | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| O'all | Between Frame | Roller Projection | Frame | O'all | Cap., lbs./ft. | Required | Included | Features | Each | |

1.9" Dia. Galvanized Steel Rollers—7/16" Hex Axle | ||||||||||

| 41" | 38" | 1/4" | 5 1/2" | 36"-48" | 40 | 3 | 1 | Connecting Plates | 00000000 | 000000000 |

Wd. | Roller | Ht. | No. of Stands | 6 ft. Lg. | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| O'all | Between Frame | Spacing | Projection | Frame | O"all | Cap., lbs./ft. | Required | Included | Features | Choose a Drive Location | Each | |

1.9" Dia. GalvanizedSteel Rollers—7/16" Hex Axle | ||||||||||||

| 41" | 38" | 3" | 1/4" | 5 1/2" | 36"-48" | 40 | 2 | 1 | Connecting Plates | 00000000 | 000000000 | |

Conveyor Mount. Slot | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ht. | Conveyor Mount. Fasteners Included | No. of Conveyor Mount. Holes | Lg. | Wd. | Mount. Hole Ctr.-to-Ctr. | Floor Mount. Fasteners Included | No. of Floor Mount. Holes | Floor Mount. Hole Dia. | Each | |

For 16" Overall Wd. | ||||||||||

| 30 1/4" to 42 1/4" | Yes | 4 | 1" | 7/16" | 4" | No | 4 | 9/16" | 00000000 | 0000000 |

For 41" Overall Wd. | ||||||||||

| 30 1/4" to 42 1/4" | Yes | 4 | 1" | 7/16" | 4" | No | 4 | 9/16" | 00000000 | 000000 |