1.9" Diameter Conveyor Rollers

Replace damaged rollers or use multiple rollers to build a custom conveyor.

Roller | Each | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Between Frame Wd. | Wd. | Gauge | Cap., lbs. | Overall Wd. | Temp. Range, °F | 1-24 | 25-99 | 100-Up | |

7/16" Hex Axle | |||||||||

1.9" Dia. Galvanized Steel Roller | |||||||||

| 8" | 7 19/32" | 16 | 265 | 9 1/4" | -20° to 300° | 00000000 | 000000 | 000000 | 00000 |

1/4" Round Axle | |||||||||

1.9" Dia. Galvanized Steel Roller | |||||||||

| 8" | 7 1/2" | 16 | 125 | 9" | -15° to 220° | 00000000 | 00000 | 00000 | 00000 |

3/8" Round Axle | |||||||||

1.9" Dia. Galvanized Steel Roller | |||||||||

| 8" | 7 7/8" | 16 | 180 | 9" | 0° to 150° | 00000000 | 00000 | 00000 | 00000 |

1/2" Round Axle | |||||||||

1.9" Dia. Galvanized Steel Roller | |||||||||

| 8" | 7 19/32" | 16 | 265 | 9 1/4" | -20° to 140° | 00000000 | 00000 | 00000 | 00000 |

Large-Diameter Conveyor Rollers

Steel rollers are stronger than aluminum rollers.

Aluminum rollers are lightweight and corrosion resistant.

Sealed bearings keep out dirt and moisture for longer life.

Roller | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Between Frame Wd. | Wd. | Gauge | Cap., lbs. | Overall Wd. | Bearing Seal Type | Temp. Range, °F | Each | |

7/16" Hex Axle | ||||||||

2" Dia. Steel Roller | ||||||||

| 8" | 7 9/16" | 12 | 300 | 9 1/8" | __ | -15° to 220° | 00000000 | 000000 |

2 1/2" Dia. Steel Roller | ||||||||

| 8" | 7 3/8" | 14 | 280 | 9 1/8" | __ | -15° to 220° | 00000000 | 00000 |

11/16" Hex Axle | ||||||||

2" Dia. Steel Roller | ||||||||

| 8" | 7 5/8" | 11 | 700 | 10" | Shielded | -10° to 225° | 0000000 | 00000 |

2 1/2" Dia. Steel Roller | ||||||||

| 8" | 7" | 11 | 750 | 9 1/4" | __ | 0° to 150° | 00000000 | 00000 |

1 1/16" Hex Axle | ||||||||

3 1/2" Dia. Steel Roller | ||||||||

| 8" | 7 3/8" | 5 | 1,100 | 9 1/2" | Sealed | -10° to 250° | 0000000 | 000000 |

1/4" Round Axle | ||||||||

2" Dia. Steel Roller | ||||||||

| 8" | 7 1/2" | 12 | 190 | 9" | __ | -15° to 220° | 00000000 | 00000 |

2" Dia. Aluminum Roller | ||||||||

| 8" | 7 1/2" | 16 | 65 | 9" | __ | -15° to 220° | 00000000 | 00000 |

Small-Diameter Conveyor Rollers

Galvanized steel rollers are strong and have some corrosion resistance. Aluminum rollers are lightweight and more corrosion resistant than galvanized steel.

Roller | |||||||

|---|---|---|---|---|---|---|---|

| For Between Frame Wd. | Wd. | Gauge | Cap., lbs. | Overall Wd. | Temp. Range, °F | Each | |

1/4" Round Axle | |||||||

3/4" Dia. Galvanized Steel Roller | |||||||

| 8" | 7 3/4" | 20 | 30 | 8 3/4" | -15° to 220° | 0000000 | 000000 |

3/4" Dia. Aluminum Roller | |||||||

| 8" | 7 3/4" | 20 | 20 | 8 3/4" | -15° to 220° | 0000000 | 00000 |

7/8" Dia. Steel Roller | |||||||

| 8" | 7 3/4" | 13 | 45 | 8 3/4" | -15° to 220° | 0000000 | 00000 |

1 3/8" Dia. Galvanized Steel Roller | |||||||

| 8" | 7 1/2" | 18 | 50 | 9" | -15° to 220° | 0000000 | 0000 |

1 3/8" Dia. Aluminum Roller | |||||||

| 8" | 7 1/2" | 18 | 40 | 9" | -15° to 220° | 00000000 | 0000 |

Small-Diameter Corrosion-Resistant Conveyor Rollers

Made from stainless steel, these rollers are suitable for washdown applications.

Rollers with stainless steel bearings are more durable than rollers with plastic bearings.

Conveyor Rollers | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Roller | Replacement Bearings | |||||||||

| For Between Frame Wd. | Wd. | Gauge | Cap., lbs. | Overall Wd. | Bearing Material | Temp. Range, °F | Each | Each | ||

7/16" Hex Axle | ||||||||||

1 5/8" Dia. Stainless Steel Roller | ||||||||||

| 8" | 7 3/8" | 16 | 100 | 9 1/8" | Plastic | 30° to 150° | 0000000 | 000000 | 0000000 | 000000 |

1/4" Round Axle | ||||||||||

3/4" Dia. Stainless Steel Roller | ||||||||||

| 8" | 7 1/8" | 20 | 20 | 9" | Plastic | 30° to 150° | 0000000 | 00000 | 0000000 | 0000 |

1 3/8" Dia. Stainless Steel Roller | ||||||||||

| 8" | 7 7/8" | 16 | 400 | 9" | Stainless Steel | 0° to 150° | 0000000 | 00000 | 000000 | 00 |

1.9" Diameter Corrosion-Resistant Conveyor Rollers

Made from stainless steel, these rollers are suitable for washdown applications.

Sealed bearings keep out dirt and moisture for longer life.

Roller | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Between Frame Wd. | Wd. | Gauge | Cap., lbs. | Overall Wd. | Bearing Seal Type | Temp. Range, °F | Each | |

7/16" Hex Axle | ||||||||

1.9" Dia. Stainless Steel Roller | ||||||||

| 8" | 6 3/4" | 16 | 295 | 9" | Sealed | 10° to 150° | 0000000 | 000000 |

1.9" Diameter Abrasion-Resistant Conveyor Rollers

The nonmarring roller surface protects material better than all-metal rollers.

PVC rollers are for light duty applications.

Polyurethane-coated rollers are the most abrasion resistant.

Rollers with quiet-rolling bearings have maintenance-free, precision bearings to reduce conveyor noise.

Roller | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Between Frame Wd. | Wd. | Thick. | Gauge | Coating Thick. | Cap., lbs. | Overall Wd. | Temp. Range, °F | Features | Each | |

7/16" Hex Axle | ||||||||||

1.9" Dia. PVC Plastic Rollers—Gray | ||||||||||

| 8" | 7 3/8" | 1/8" | __ | __ | 100 | 9 1/8" | 30° to 150° | __ | 00000000 | 000000 |

1.9" Dia. Polyurethane-Coated Steel Rollers—Orange | ||||||||||

| 8" | 7 1/2" | __ | 16 | 0.13" | 250 | 9 1/8" | -20° to 150° | __ | 00000000 | 00000 |

1.9" Dia. Polyurethane-Coated Steel Rollers—Black | ||||||||||

| 8" | 7 7/8" | __ | 16 | 0.1" | 250 | 9" | 0° to 150° | Quiet-Rolling Bearings | 00000000 | 00000 |

Small-Diameter Abrasion-Resistant Conveyor Rollers

These nonmarring, nonmarking PVC plastic rollers protect material better than all-metal rollers.

Roller | |||||||

|---|---|---|---|---|---|---|---|

| For Between Frame Wd. | Wd. | Color | Cap., lbs. | Overall Wd. | Temp. Range, °F | Each | |

1/4" Round Axle | |||||||

0.78" Dia. PVC Plastic Roller | |||||||

| 8" | 7 1/8" | Gray | 10 | 9" | 30° to 150° | 0000000 | 000000 |

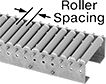

Round-Groove Conveyor Rollers

Rollers are grooved to accommodate round belts on line-shaft conveyors.

Rollers with two grooves can be used with motorized roller conveyors.

Abrasion-Resistant Bench-Top Roller Conveyors

|  |

|

Push glass, painted objects, and other delicate material from one workstation to the next. These conveyors rest on a flat surface instead of a stand, and they have PVC rollers that won’t mark or dent your material. They have two sets of axle holes for the rollers, so you can position the conveying surface 1/8" above the frame or 3/4" below. The frame serves as a guide rail when rollers are mounted below it.

Note: Capacities are based on an evenly distributed load. The length of the material you're conveying should be at least three times the roller spacing.