High-Capacity Roller Conveyors

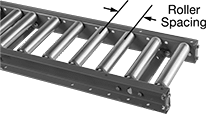

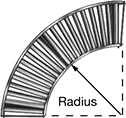

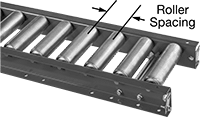

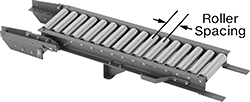

For moving heavy products on shipping and assembly lines, these have three times the load capacity of our standard roller conveyors. Whether you’re creating a straight line, a curve to route items around equipment, or a decline to lower them into a truck trailer, mixing and matching conveyors and stands lets you customize your system as needed. These conveyors have rollers that transfer items with flat or uneven bottoms, such as boxes or shipping tubes.

Because these conveyors don’t run on electricity, their rollers require momentum from gravity, a push, or a powered conveyor to move. Since they’re not wired, they’re quick to set up and easy to maintain. This makes them handy if another conveyor unexpectedly shuts down or you need to extend an existing line in a pinch. However, these high-capacity conveyors weigh about twice as much as standard ones, so they require more effort to move around.

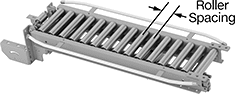

Choose a small roller spacing when conveying small items to prevent them from getting stuck between rollers. For large items, a large roller spacing helps minimize friction between your material and the rollers.

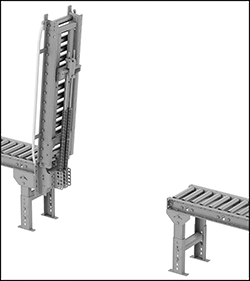

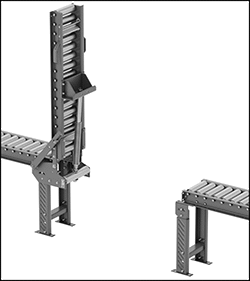

Lift gate conveyors can be raised up like a drawbridge, so you can quickly and safely pass through instead of walking around or using stairs to climb over. This gives you more flexibility in placing your conveyor, especially in cramped working environments. They’re spring loaded for easy lifting. Connect them to existing conveyors and a lift gate stand using their mounting plate.

Stands have adjustable mounting plates, which let you set your conveyor at a decline. They also have an adjustable height, letting you raise or lower sections of your line as needed.

Note: Capacities are based on an evenly distributed load. The length of the material you’re conveying should be at least three times the roller spacing.

Wd. | ||||||||

|---|---|---|---|---|---|---|---|---|

| O'all | Between Frame | Lg., ft. | Roller Projection | Frame Ht. | Cap. (No. of Stands Required) | No. of Stands Included | Each | |

2 1/4" Roller Spacing | ||||||||

1.9" Dia. Steel Rollers—7/16" Hex Axle | ||||||||

| 24" | 21" | 5 | 1/4" | 3 1/2" | 620 lbs./ft. (2) | None | 00000000 | 0000000 |

| 24" | 21" | 10 | 1/4" | 3 1/2" | 620 lbs./ft. (3), 115 lbs./ft. (2) | None | 00000000 | 000000 |

3" Roller Spacing | ||||||||

1.9" Dia. Steel Rollers—7/16" Hex Axle | ||||||||

| 24" | 21" | 3 | 1/4" | 3 1/2" | 620 lbs./ft. (2) | None | 00000000 | 000000 |

| 24" | 21" | 4 | 1/4" | 3 1/2" | 620 lbs./ft. (2) | None | 00000000 | 000000 |

| 24" | 21" | 5 | 1/4" | 3 1/2" | 620 lbs./ft. (2) | None | 0000000 | 000000 |

| 24" | 21" | 8 | 1/4" | 3 1/2" | 620 lbs./ft. (3), 115 lbs./ft. (2) | None | 00000000 | 000000 |

| 24" | 21" | 10 | 1/4" | 3 1/2" | 620 lbs./ft. (3), 115 lbs./ft. (2) | None | 0000000 | 000000 |

4 1/2" Roller Spacing | ||||||||

1.9" Dia. Steel Rollers—7/16" Hex Axle | ||||||||

| 24" | 21" | 5 | 1/4" | 3 1/2" | 620 lbs./ft. (2) | None | 00000000 | 000000 |

| 24" | 21" | 10 | 1/4" | 3 1/2" | 620 lbs./ft. (3), 115 lbs./ft. (2) | None | 0000000 | 000000 |

6" Roller Spacing | ||||||||

1.9" Dia. Steel Rollers—7/16" Hex Axle | ||||||||

| 24" | 21" | 5 | 1/4" | 3 1/2" | 620 lbs./ft. (2) | None | 00000000 | 000000 |

| 24" | 21" | 10 | 1/4" | 3 1/2" | 620 lbs./ft. (3), 115 lbs./ft. (2) | None | 0000000 | 000000 |

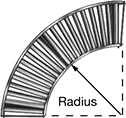

Wd. | ||||||||

|---|---|---|---|---|---|---|---|---|

| O'all | Between Frame | Radius | Roller Projection | Frame Ht. | Cap. (No. of Stands Required) | No. of Stands Included | Each | |

1.9" Dia. Steel Rollers—7/16" Hex Axle | ||||||||

| 24" | 21" | 32 1/2" | 1/4" | 3 1/2" | 620 lbs./ft. (3) | None | 00000000 | 0000000 |

Wd. | 3" Roller Spacing | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| O'all | Between Frame | Lg., ft. | Opening Lg., ft. | Roller Projection | Frame Ht. | Cap. (No. of Stands Required) | No. of Stands Included | Each | |

1.9" Dia. Steel Rollers—7/16" Hex Axle | |||||||||

| 24" | 21" | 4 | 3 1/2 | 1/4" | 3 1/2" | 620 lbs./ft. (2) | None | 0000000 | 000000000 |

Conveyor Mount. Slot | Floor Mount. Slot | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ht. | Material | Color | Conveyor Mount. Fasteners Included | No. of Conveyor Mount. Holes | Lg. | Wd. | Floor Mount. Fasteners Included | No. of Floor Mount. Holes | Lg. | Wd. | Each | |

For 24" Overall Wd. | ||||||||||||

| 16" to 21" | Powder-Coated Steel | Green | Yes | 8 | 7/8" | 13/32" | No | 4 | 7/8" | 13/32" | 0000000 | 000000 |

| 20" to 25" | Powder-Coated Steel | Green | Yes | 8 | 7/8" | 13/32" | No | 4 | 7/8" | 13/32" | 0000000 | 00000 |

| 24" to 35" | Powder-Coated Steel | Green | Yes | 8 | 7/8" | 13/32" | No | 4 | 7/8" | 13/32" | 0000000 | 000000 |

| 34" to 45" | Powder-Coated Steel | Green | Yes | 8 | 7/8" | 13/32" | No | 4 | 7/8" | 13/32" | 0000000 | 000000 |

High-Capacity Large-Diameter Roller Conveyors

For more demanding shipping and assembly applications, these conveyors can carry heavy loads.

Lift gate conveyors can be lifted up to let workers quickly and safely pass through, so they don’t have to walk around or climb stairs over conveyors to navigate their facility. In constrained environments, these conveyors give you flexibility in conveyor placement.

Double-shielded bearings keep out dust and debris.

Note: Capacities are based on an evenly distributed load with at least one stand at each end for straight conveyors, and an additional stand in the center for curved conveyors. You can increase the capacity of a 10-ft. straight conveyor by adding a stand in the center. The length of the material you’re conveying should be at least three times the roller spacing.

Wd. | ||||||||

|---|---|---|---|---|---|---|---|---|

| O'all | Between Frame | Lg., ft. | Bearing Seal Type | Cap. (No. of Stands Required) | No. of Stands Included | Features | Each | |

3" Roller Spacing | ||||||||

2 1/2" Dia. Steel Rollers—11/16" Hex Axle | ||||||||

| 24" | 21" | 5 | Sealed | 800 lbs./ft. (2) | None | Connecting Plates | 00000000 | 0000000 |

| 24" | 21" | 10 | Sealed | 800 lbs./ft. (3), 375 lbs./ft. (2) | None | Connecting Plates | 0000000 | 00000000 |

4 1/2" Roller Spacing | ||||||||

2 1/2" Dia. Steel Rollers—11/16" Hex Axle | ||||||||

| 24" | 21" | 5 | Sealed | 800 lbs./ft. (2) | None | Connecting Plates | 0000000 | 000000 |

| 24" | 21" | 10 | Sealed | 800 lbs./ft. (3), 375 lbs./ft. (2) | None | Connecting Plates | 0000000 | 000000 |

6" Roller Spacing | ||||||||

2 1/2" Dia. Steel Rollers—11/16" Hex Axle | ||||||||

| 24" | 21" | 5 | Sealed | 800 lbs./ft. (2) | None | Connecting Plates | 00000000 | 000000 |

| 24" | 21" | 10 | Sealed | 800 lbs./ft. (3), 375 lbs./ft. (2) | None | Connecting Plates | 0000000 | 000000 |

3 1/2" Dia. Steel Rollers—1" Hex Axle | ||||||||

| 24 1/2" | 21" | 5 | Double Shielded | 2,200 lbs./ft. (2) | None | Connecting Plates | 00000000 | 00000000 |

| 24 1/2" | 21" | 10 | Double Shielded | 2,200 lbs./ft. (3), 1,100 lbs./ft. (2) | None | Connecting Plates | 00000000 | 00000000 |

Wd. | |||||||

|---|---|---|---|---|---|---|---|

| O'all | Between Frame | Radius | Cap. (No. of Stands Required) | No. of Stands Included | Features | Each | |

2 1/2" Dia. Steel Rollers—11/16" Hex Axle | |||||||

| 24" | 21" | 32 1/2" | 800 lbs./ft. (3) | None | Connecting Plates | 0000000 | 0000000 |

Wd. | 3" Roller Spacing | |||||||

|---|---|---|---|---|---|---|---|---|

| O'all | Between Frame | Lg., ft. | Opening Lg., ft. | Cap. (No. of Stands Required) | No. of Stands Included | Features | Each | |

2 1/2" Dia. Steel Rollers—11/16" Hex Axle | ||||||||

| 24" | 21" | 4 | 3 1/2 | 800 lbs./ft. (2) | None | Connecting Plates | 00000000 | 000000000 |

1.9" Diameter Conveyor Rollers

Replace damaged rollers or use multiple rollers to build a custom conveyor.

Large-Diameter Conveyor Rollers

Steel rollers are stronger than aluminum rollers.

Roller | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Between Frame Wd. | Wd. | Gauge | Cap., lbs. | Overall Wd. | Bearing Seal Type | Temp. Range, °F | Each | |

7/16" Hex Axle | ||||||||

2" Dia. Steel Roller | ||||||||

| 21" | 20 9/16" | 12 | 300 | 22 1/8" | __ | -15° to 220° | 00000000 | 000000 |

2 1/2" Dia. Steel Roller | ||||||||

| 21" | 20 3/8" | 14 | 280 | 22 1/8" | __ | -15° to 220° | 00000000 | 00000 |

11/16" Hex Axle | ||||||||

2" Dia. Steel Roller | ||||||||

| 21" | 20 5/8" | 11 | 700 | 23" | Shielded | -10° to 225° | 0000000 | 000000 |

2 1/2" Dia. Steel Roller | ||||||||

| 21" | 20 7/16" | 11 | 645 | 23" | __ | -40° to 300° | 0000000 | 00000 |

Small-Diameter Conveyor Rollers

Galvanized steel rollers are strong and have some corrosion resistance.

Small-Diameter Corrosion-Resistant Conveyor Rollers

Made from stainless steel, these rollers are suitable for washdown applications.

Rollers with stainless steel bearings are more durable than rollers with plastic bearings.

1.9" Diameter Corrosion-Resistant Conveyor Rollers

Made from stainless steel, these rollers are suitable for washdown applications.

Sealed bearings keep out dirt and moisture for longer life.

Roller | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Between Frame Wd. | Wd. | Gauge | Cap., lbs. | Overall Wd. | Bearing Seal Type | Temp. Range, °F | Each | |

7/16" Hex Axle | ||||||||

1.9" Dia. Stainless Steel Roller | ||||||||

| 21" | 20 3/8" | 16 | 155 | 22" | Sealed | 10° to 150° | 0000000 | 0000000 |

Large-Diameter Corrosion-Resistant Conveyor Rollers

All stainless steel construction makes these rollers suitable for washdown applications. Shielded bearings block out dust and other contaminants.

Roller | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Between Frame Wd. | Wd. | Gauge | Cap., lbs. | Overall Wd. | Bearing Seal Type | Temp. Range, °F | Features | Each | |

7/16" Hex Axle | |||||||||

2 1/2" Dia. Stainless Steel Roller | |||||||||

| 21" | 20 7/8" | 14 | 170 | 22" | Shielded | 0° to 150° | __ | 00000000 | 0000000 |

11/16" Hex Axle | |||||||||

2 1/2" Dia. Stainless Steel Roller | |||||||||

| 21" | 20 7/8" | 11 | 400 | 22 1/2" | Shielded | 10° to 150° | Quiet-Rolling Bearings | 00000000 | 000000 |

1.9" Diameter Abrasion-Resistant Conveyor Rollers

The nonmarring roller surface protects material better than all-metal rollers.

PVC rollers are for light duty applications.

Polyethylene-coated rollers are nonstick.

Polyurethane-coated rollers are the most abrasion resistant.

Rollers with quiet-rolling bearings have maintenance-free, precision bearings to reduce conveyor noise.

Roller | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Between Frame Wd. | Wd. | Thick. | Gauge | Coating Thick. | Cap., lbs. | Overall Wd. | Temp. Range, °F | Features | Each | |

7/16" Hex Axle | ||||||||||

1.9" Dia. PVC Plastic Rollers—Gray | ||||||||||

| 21" | 20 7/8" | 1/8" | __ | __ | 25 | 22" | 14° to 175° | __ | 0000000 | 000000 |

1.9" Dia. Polyethylene-Coated Steel Rollers—White | ||||||||||

| 21" | 20 3/8" | __ | 16 | 0.08" | 125 | 22" | 10° to 150° | Quiet-Rolling Bearings | 0000000 | 00000 |

1.9" Dia. Polyurethane-Coated Steel Rollers—Orange | ||||||||||

| 21" | 20 1/2" | __ | 16 | 0.13" | 250 | 22 1/8" | -20° to 150° | __ | 00000000 | 000000 |

1.9" Dia. Polyurethane-Coated Steel Rollers—Black | ||||||||||

| 21" | 20 3/8" | __ | 16 | 0.08" | 125 | 22" | 10° to 150° | Quiet-Rolling Bearings | 0000000 | 000000 |

1.9" Diameter Dent-Resistant Conveyor Rollers

Rollers are made from thick, 12-ga. steel so they're less likely to dent than standard 16-ga. rollers.

Roller | |||||||

|---|---|---|---|---|---|---|---|

| For Between Frame Wd. | Wd. | Gauge | Cap., lbs. | Overall Wd. | Temp. Range, °F | Each | |

7/16" Hex Axle | |||||||

1.9" Dia. Steel Roller | |||||||

| 21" | 20 7/8" | 12 | 280 | 22" | -20° to 250° | 0000000 | 000000 |

1.9" Diameter Quiet-Rolling Conveyor Rollers

Rollers have maintenance-free, precision bearings to reduce conveyor noise.

Roller | |||||||

|---|---|---|---|---|---|---|---|

| For Between Frame Wd. | Wd. | Gauge | Cap., lbs. | Overall Wd. | Temp. Range, °F | Each | |

7/16" Hex Axle | |||||||

1.9" Dia. Galvanized Steel Roller | |||||||

| 21" | 20 3/32" | 16 | 180 | 22 1/4" | -20° to 165° | 0000000 | 000000 |

Tapered Conveyor Rollers for Curves

Improve tracking on curved sections of 1.9" diameter conveyors. Rollers taper from approximately 2 1/2" diameter on the outside to 1 5/8" on the inside.

Roller | |||||||

|---|---|---|---|---|---|---|---|

| For Between Frame Wd. | Wd. | Gauge | Cap., lbs. | Overall Wd. | Temp. Range, °F | Each | |

7/16" Hex Axle | |||||||

1 5/8"-2 1/2" Dia. Galvanized Steel Roller | |||||||

| 21" | 20 5/16" | 14 | 250 | 22" | -25° to 250° | 000000 | 0000000 |

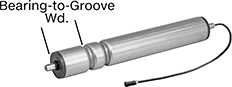

Round-Groove Conveyor Rollers

Rollers are grooved to accommodate round belts on line-shaft conveyors.

Rollers with two grooves can be used with motorized roller conveyors.

Roller | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Between Frame Wd. | For Belt Dia. | Wd. | Gauge | Cap., lbs. | Bearing-to-Groove Wd. | Groove Ctr.-to-Ctr. Wd. | O'all Wd. | Temp. Range, °F | Each | |

7/16" Hex Axle—1.9" Dia. Galvanized Steel Roller | ||||||||||

1 Groove | ||||||||||

| 21" | 3/16" | 20 19/32" | 16 | 265 | 2.75" | __ | 22 1/4" | -20° to 350° | 0000000 | 000000 |

2 Groove | ||||||||||

| 21" | 3/16" | 20 5/8" | 16 | 265 | 2.17" | 1.3" | 22 1/4" | -20° to 350° | 0000000 | 00000 |

| 21" | 3/16" | 20 7/8" | 16 | 225 | 2.50" | 1.3" | 22" | -40° to 212° | 0000000 | 00000 |

Motorized Round-Groove Conveyor Rollers

Also known as drive rollers, these connect to rollers with two grooves to power conveyors. The bearings are quiet-rolling to reduce conveyor noise and are shielded to keep out dirt and debris.

| For Between Frame Wd. | For Belt Dia. | Roller Wd. | Cap., lbs. | Wire Lead Lg. | Bearing-to-Groove Wd. | Groove Ctr.-to-Ctr. Wd. | O'all Wd. | Includes | Choose a Speed | Each | |

24V DC—Duty Cycle is Continuous with Up to 30 Starts and Stops per Minute | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

7/16" Hex Axle—1.9" Dia. Galvanized Steel Roller | |||||||||||

| 21" | 3/16" | 20.88" | 70 | 19" | 2.50" | 1.3" | 22" | Zone Control Card | 00000000 | 0000000 | |

120V AC (Single Phase)—Duty Cycle is 3 Seconds On, 2 Seconds Off | |||||||||||

7/16" Hex Axle—1.9" Dia. Zinc-Plated Steel Roller | |||||||||||

| 21" | 3/16" | 20 7/16" | 75 | 2" | 2.17" | 1.3" | 22 1/16" | Terminal Block | 0000000 | 000000 | |

Tapered Round-Groove Conveyor Rollers

Rollers taper from approximately 2 1/2" diameter on the outside to 1 5/8" on the inside so packages maintain their orientation on line-shaft conveyors.

Roller | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Between Frame Wd. | For Belt Dia. | Wd. | Gauge | Cap., lbs. | Bearing-to-Groove Wd. | Groove Ctr.-to-Ctr. Wd. | O'all Wd. | Temp. Range, °F | Each | |

7/16" Hex Axle | ||||||||||

1 5/8"-2 1/2" Dia. Galvanized Steel Roller | ||||||||||

| 21" | 3/16" | 20 5/16" | 14 | 250 | 2.80" | 1" | 22" | -25° to 250° | 0000000 | 0000000 |

1.9" Diameter V-Groove Conveyor Rollers

Also known as Poly-V rollers, these are designed for use with V-belts. They have sealed bearings to keep out dirt and moisture.

Roller | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Between Frame Wd. | For Belt Trade Size | Wd. | Gauge | Cap., lbs. | Overall Wd. | Hub Dia., mm | For No. of Belt Bands | Temp. Range, °F | Each | |

7/16" Hex Axle | ||||||||||

1.9" Dia. Galvanized Steel Roller | ||||||||||

| 21" | J | 19 1/4" | 16 | 155 | 22" | 43 | 2, 3, 4 | 10° to 150° | 00000000 | 000000 |

Ball Transfer Conveyors

Use these ball transfer conveyors alone or add them to High-Capacity Roller Conveyors to rotate and position material along a conveying line.

Note: Capacities are based on an evenly distributed load with a stand at each end. The length and width of the material you're conveying should be at least three times the ball spacing.

Wd. | Ball | Ht. | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Between Frame | O'all | Lg., ft. | Cap. per Ball, lbs. | Dia. | Projection | Frame | O'all | Features | Each | |

4" Ball Spacing | ||||||||||

Steel Ball with Zinc-Plated Steel Housing | ||||||||||

| 21" | 24" | 2 | 65 | 1" | 1/4" | 3 1/2" | 3 3/4" | Connecting Plates | 0000000 | 0000000 |

| 21" | 24" | 3 | 65 | 1" | 1/4" | 3 1/2" | 3 3/4" | Connecting Plates | 0000000 | 000000 |

3" Ball Spacing | ||||||||||

Steel Ball with Zinc-Plated Steel Housing | ||||||||||

| 21" | 24" | 2 | 65 | 1" | 1/4" | 3 1/2" | 3 3/4" | Connecting Plates | 000000 | 000000 |

| 21" | 24" | 3 | 65 | 1" | 1/4" | 3 1/2" | 3 3/4" | Connecting Plates | 0000000 | 000000 |

| Replacement Ball Transfer | 0000000 | Each | 00000 |

Conveyor Mount. Slot | Floor Mount. Slot | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ht. | Material | Color | Conveyor Mount. Fasteners Included | No. of Conveyor Mount. Holes | Lg. | Wd. | Floor Mount. Fasteners Included | No. of Floor Mount. Holes | Lg. | Wd. | Each | |

For 24" Overall Wd. | ||||||||||||

| 16"-21" | Powder-Coated Steel | Green | Yes | 8 | 7/8" | 13/32" | No | 4 | 7/8" | 13/32" | 0000000 | 000000 |

| 20"-25" | Powder-Coated Steel | Green | Yes | 8 | 7/8" | 13/32" | No | 4 | 7/8" | 13/32" | 0000000 | 00000 |

| 24"-35" | Powder-Coated Steel | Green | Yes | 8 | 7/8" | 13/32" | No | 4 | 7/8" | 13/32" | 0000000 | 000000 |

| 34"-45" | Powder-Coated Steel | Green | Yes | 8 | 7/8" | 13/32" | No | 4 | 7/8" | 13/32" | 0000000 | 000000 |