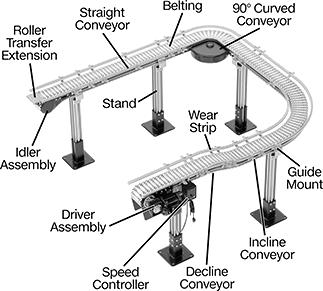

Modular Mini Chain Belt Conveyors

Build a mini conveyor in any shape you need. These conveyors have curved, straight, incline, and decline runs that you can quickly join together with the included brackets. They're often used in areas with limited floor space and applications that require frequent layout changes. To customize your conveyor, add on components, such as package stops and merge guides, with the built-in T-slots on the side. T-slot bolts are sold separately. These conveyors come with guides installed.

You'll need a drive assembly, an idler assembly, and a belt to complete your conveyor. To determine the belt length you need, multiply your conveyor’s length by 2.1. If you need a belt longer than what’s available, you can connect multiple together. Use a belt installation tool (sold separately) to pull out the pin, then line up two ends and push the pin in with the tool to connect them. You can also shorten a belt using the same tool.

Maximum run length is 70 ft. with two 90° curves. Adding more curved conveyors will reduce the run length.Incline and decline conveyors let you change elevation. For example, you could build a bridge over your existing conveyor line. To bring your conveyor back to its original height, use an incline or decline conveyor with the same climbing angle.

For technical drawings and 3-D models, click on a part number.

Conveyors with a 10° and 15° climbing angle require rough-surface belting (sold separately) so items won’t slip off.

Wd. | Ht. | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Belt | Frame | T-Slot | Conveyor Bed Lg. | Frame | Overall Range | Capacity, lbs./ft. | Number of Stands Included | Features | Each | |

10° Climbing Angle | ||||||||||

| 6" | 6" | 11 mm | 9 1/2" | 3" | 4 3/4"-6" | 40 | None | Pre-Installed Guides | 0000000 | 000000000 |

Conveyors with a 10° and 15° climbing angle require rough-surface belting (sold separately) so items won’t slip off.

Wd. | Ht. | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Belt | Frame | T-Slot | Conveyor Bed Lg. | Frame | Overall Range | Capacity, lbs./ft. | Number of Stands Included | Features | Each | |

10° Climbing Angle | ||||||||||

| 6" | 6" | 11 mm | 10" | 3" | 4 3/4"-6" | 40 | None | Pre-Installed Guides | 0000000 | 000000000 |

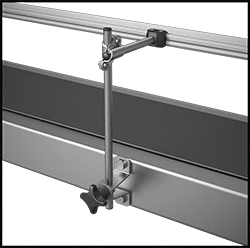

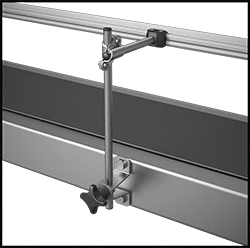

Mounting Rods with Clamp for Conveyors

A clamp at the end of the rod grips conveyor guides or other rods. Mount rods with brackets and connectors to create support arms.

Solid rods are sturdier than hollow rods, so they’re less likely to be knocked out of place by heavy objects on your conveyor. Instead of using bolts, tighten the clamps on style F around a guide rail by twisting the rod into the clamp.

For technical drawings and 3-D models, click on a part number.

| Lg. | Rod Dia. | For Channel Wd. | For Number of Lines | Material | Clamp Material | Each | ||

Solid | ||||||||

|---|---|---|---|---|---|---|---|---|

| F | 10" | 1/2" | 0.67" | 1 | Stainless Steel | Stainless Steel | 00000000 | 000000 |

Mounting Rods for Conveyors

Use brackets and connectors to create vertical and horizontal support arms.

Round rods are the most common. However, these rods might cause connectors to slip over time as vibration loosens their hold on the rod. Solid rods are sturdier than hollow rods, so they’re less likely to be knocked out of place by heavy objects on your conveyor.

Stainless steel mounting rods are the most corrosion resistant.

For technical drawings and 3-D models, click on a part number.

Graduated Mounting Rods for Conveyors

Graduated in 1/8" or 1 mm increments, these rods make it easy to align multiple brackets during installation.

Round rods are the most common. However, these rods might cause connectors to slip over time as vibration loosens their hold on the rod. Solid rods are sturdier than hollow rods, so they are less likely to be knocked out of place by heavy objects on your conveyor.

For technical drawings and 3-D models, click on a part number.

Thread | 1/2" Rod Dia. | ||||||

|---|---|---|---|---|---|---|---|

| Lg. | Graduation Marks (Numeric Increments) | Size | Lg. | Gender | Material | Each | |

Solid | |||||||

| 10" | 8ths (1") | 5/16"-18 | 0.89" | Female | Stainless Steel | 00000000 | 000000 |

Pivoting Mounting Rods for Conveyors

The pivoting joint on these rods makes angle mounting easy.

For technical drawings and 3-D models, click on a part number.

Thread | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Lg. | Rod Dia. | Range of Motion | Size | Lg. | Gender | Threading | Material | Each | |

Solid | |||||||||

| 10" | 5/8" | 180° | 5/16"-18 | 0.56" | Female | Threaded on One End | Stainless Steel | 00000000 | 000000 |

Graduated Pivoting Mounting Rods for Conveyors

To make aligning multiple brackets during installation easy, these rods have 1/8” graduation marks. They also have a pivoting joint, so you can adjust the angle of your mount.

For technical drawings and 3-D models, click on a part number.

Thread | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Lg. | Rod Dia. | Range of Motion | Size | Lg. | Gender | Threading | Material | Each | |

Solid | |||||||||

| 10" | 5/8" | 180° | 5/16"-18 | 0.72" | Female | Threaded on One End | Stainless Steel | 0000000 | 000000 |