High-Capacity Roller Conveyors

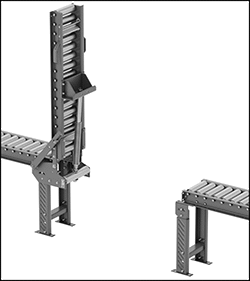

For moving heavy products on shipping and assembly lines, these have three times the load capacity of our standard roller conveyors. Whether you’re creating a straight line, a curve to route items around equipment, or a decline to lower them into a truck trailer, mixing and matching conveyors and stands lets you customize your system as needed. These conveyors have rollers that transfer items with flat or uneven bottoms, such as boxes or shipping tubes.

Because these conveyors don’t run on electricity, their rollers require momentum from gravity, a push, or a powered conveyor to move. Since they’re not wired, they’re quick to set up and easy to maintain. This makes them handy if another conveyor unexpectedly shuts down or you need to extend an existing line in a pinch. However, these high-capacity conveyors weigh about twice as much as standard ones, so they require more effort to move around.

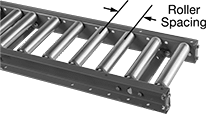

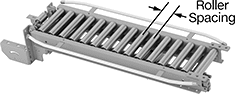

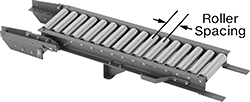

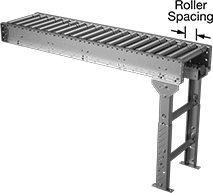

Choose a small roller spacing when conveying small items to prevent them from getting stuck between rollers. For large items, a large roller spacing helps minimize friction between your material and the rollers.

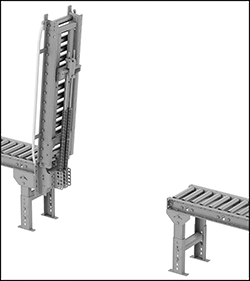

Lift gate conveyors can be raised up like a drawbridge, so you can quickly and safely pass through instead of walking around or using stairs to climb over. This gives you more flexibility in placing your conveyor, especially in cramped working environments. They’re spring loaded for easy lifting. Connect them to existing conveyors and a lift gate stand using their mounting plate.

Note: Capacities are based on an evenly distributed load. The length of the material you’re conveying should be at least three times the roller spacing.

For technical drawings and 3-D models, click on a part number.

Wd. | 3" Roller Spacing | |||||||

|---|---|---|---|---|---|---|---|---|

| O'all | Between Frame | Lg., ft. | Roller Projection | Frame Ht. | Cap. (No. of Stands Required) | No. of Stands Included | Each | |

1.9" Dia. Steel Rollers—7/16" Hex Axle | ||||||||

| 13" | 10" | 4 | 1/4" | 3 1/2" | 620 lbs./ft. (2) | None | 00000000 | 0000000 |

| 16" | 13" | 4 | 1/4" | 3 1/2" | 620 lbs./ft. (2) | None | 00000000 | 000000 |

| 18" | 15" | 4 | 1/4" | 3 1/2" | 620 lbs./ft. (2) | None | 00000000 | 000000 |

| 20" | 17" | 4 | 1/4" | 3 1/2" | 620 lbs./ft. (2) | None | 00000000 | 000000 |

| 24" | 21" | 4 | 1/4" | 3 1/2" | 620 lbs./ft. (2) | None | 00000000 | 000000 |

| 36" | 33" | 4 | 1/4" | 3 1/2" | 620 lbs./ft. (2) | None | 00000000 | 000000 |

| 40" | 37" | 4 | 1/4" | 3 1/2" | 620 lbs./ft. (2) | None | 00000000 | 000000 |

| 42" | 39" | 4 | 1/4" | 3 1/2" | 620 lbs./ft. (2) | None | 00000000 | 000000 |

Wd. | 3" Roller Spacing | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| O'all | Between Frame | Lg., ft. | Opening Lg., ft. | Roller Projection | Frame Ht. | Cap. (No. of Stands Required) | No. of Stands Included | Each | |

1.9" Dia. Steel Rollers—7/16" Hex Axle | |||||||||

| 13" | 10" | 4 | 3 1/2 | 1/4" | 3 1/2" | 620 lbs./ft. (2) | None | 0000000 | 000000000 |

| 16" | 13" | 4 | 3 1/2 | 1/4" | 3 1/2" | 620 lbs./ft. (2) | None | 0000000 | 00000000 |

| 18" | 15" | 4 | 3 1/2 | 1/4" | 3 1/2" | 620 lbs./ft. (2) | None | 0000000 | 00000000 |

| 20" | 17" | 4 | 3 1/2 | 1/4" | 3 1/2" | 620 lbs./ft. (2) | None | 0000000 | 00000000 |

| 24" | 21" | 4 | 3 1/2 | 1/4" | 3 1/2" | 620 lbs./ft. (2) | None | 0000000 | 00000000 |

| 36" | 33" | 4 | 3 1/2 | 1/4" | 3 1/2" | 620 lbs./ft. (2) | None | 0000000 | 00000000 |

| 40" | 37" | 4 | 3 1/2 | 1/4" | 3 1/2" | 620 lbs./ft. (2) | None | 0000000 | 00000000 |

| 42" | 39" | 4 | 3 1/2 | 1/4" | 3 1/2" | 620 lbs./ft. (2) | None | 0000000 | 00000000 |

High-Capacity Large-Diameter Roller Conveyors

For more demanding shipping and assembly applications, these conveyors can carry heavy loads.

Lift gate conveyors can be lifted up to let workers quickly and safely pass through, so they don’t have to walk around or climb stairs over conveyors to navigate their facility. In constrained environments, these conveyors give you flexibility in conveyor placement.

Note: Capacities are based on an evenly distributed load with at least one stand at each end for straight conveyors, and an additional stand in the center for curved conveyors. You can increase the capacity of a 10-ft. straight conveyor by adding a stand in the center. The length of the material you’re conveying should be at least three times the roller spacing.

For technical drawings and 3-D models, click on a part number.

Wd. | 3" Roller Spacing | |||||||

|---|---|---|---|---|---|---|---|---|

| O'all | Between Frame | Lg., ft. | Opening Lg., ft. | Cap. (No. of Stands Required) | No. of Stands Included | Features | Each | |

2 1/2" Dia. Steel Rollers—11/16" Hex Axle | ||||||||

| 10" | 7" | 4 | 3 1/2 | 800 lbs./ft. (2) | None | Connecting Plates | 00000000 | 0000000 |

| 12" | 9" | 4 | 3 1/2 | 800 lbs./ft. (2) | None | Connecting Plates | 00000000 | 000000 |

| 18" | 15" | 4 | 3 1/2 | 800 lbs./ft. (2) | None | Connecting Plates | 00000000 | 000000 |

| 24" | 21" | 4 | 3 1/2 | 800 lbs./ft. (2) | None | Connecting Plates | 00000000 | 00000000 |

| 30" | 27" | 4 | 3 1/2 | 800 lbs./ft. (2) | None | Connecting Plates | 00000000 | 00000000 |

| 36" | 33" | 4 | 3 1/2 | 800 lbs./ft. (2) | None | Connecting Plates | 00000000 | 00000000 |

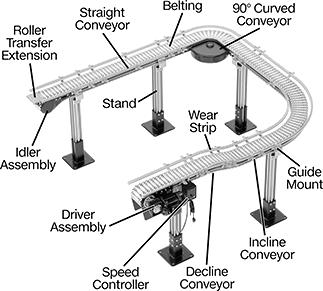

Motorized Roller Conveyors

Also known as line-shaft conveyors, these conveyors are driven by a drive shaft and round belts. Unlike belt conveyors, these have built-in accumulation, so packages can build up without crashing into one another or falling off the conveyor. The rollers are designed to smoothly transfer totes, packages, and other lightweight material. Shipping tubes, drums, and pails are less likely to get stuck in between rollers than between skate wheels.

Mix and match stands and conveyors to form straight lines, curve around obstacles, or create inclines. Only straight conveyor sections contain a motor, but they can power up to 60 ft. of conveyor extensions on either side. The motor can be reversed to send material in either direction.

Note: Capacities are based on an evenly distributed load. The length of the material you’re conveying should be at least three times the roller spacing.

For technical drawings and 3-D models, click on a part number.

Wd. | Roller | Ht. | 4 ft. Lg. | ||||||

|---|---|---|---|---|---|---|---|---|---|

| O'all | Between Frame | Spacing | Projection | Frame | O'all | Cap., lbs./ft. | Features | Each | |

1.9" Dia. Galvanized Steel Rollers—7/16" Hex Axle | |||||||||

| 16" | 13" | 3" | 1/4" | 5 1/2" | 36"-48" | 40 | Connecting Plates | 00000000 | 0000000 |

| 17" | 14" | 3" | 1/4" | 5 1/2" | 36"-48" | 40 | Connecting Plates | 00000000 | 000000 |

| 19" | 16" | 3" | 1/4" | 5 1/2" | 36"-48" | 40 | Connecting Plates | 00000000 | 000000 |

| 21" | 18" | 3" | 1/4" | 5 1/2" | 36"-48" | 40 | Connecting Plates | 00000000 | 000000 |

| 25" | 22" | 3" | 1/4" | 5 1/2" | 36"-48" | 40 | Connecting Plates | 00000000 | 000000 |

| 29" | 26" | 3" | 1/4" | 5 1/2" | 36"-48" | 40 | Connecting Plates | 00000000 | 000000 |

| 31" | 28" | 3" | 1/4" | 5 1/2" | 36"-48" | 40 | Connecting Plates | 00000000 | 000000 |

| 35" | 32" | 3" | 1/4" | 5 1/2" | 36"-48" | 40 | Connecting Plates | 00000000 | 000000 |

| 41" | 38" | 3" | 1/4" | 5 1/2" | 36"-48" | 40 | Connecting Plates | 00000000 | 000000 |

Conveyor Mount. Slot | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ht. | Conveyor Mount. Fasteners Included | No. of Conveyor Mount. Holes | Lg. | Wd. | Mount. Hole Ctr.-to-Ctr. | Floor Mount. Fasteners Included | No. of Floor Mount. Holes | Floor Mount. Hole Dia. | Each | |

For 17" Overall Wd. | ||||||||||

| 30 1/4" to 42 1/4" | Yes | 4 | 1" | 7/16" | 4" | No | 4 | 9/16" | 00000000 | 0000000 |

For 21" Overall Wd. | ||||||||||

| 30 1/4" to 42 1/4" | Yes | 4 | 1" | 7/16" | 4" | No | 4 | 9/16" | 00000000 | 000000 |

For 29" Overall Wd. | ||||||||||

| 30 1/4" to 42 1/4" | Yes | 4 | 1" | 7/16" | 4" | No | 4 | 9/16" | 00000000 | 000000 |

For 31" Overall Wd. | ||||||||||

| 30 1/4" to 42 1/4" | Yes | 4 | 1" | 7/16" | 4" | No | 4 | 9/16" | 00000000 | 000000 |

For 41" Overall Wd. | ||||||||||

| 30 1/4" to 42 1/4" | Yes | 4 | 1" | 7/16" | 4" | No | 4 | 9/16" | 00000000 | 000000 |

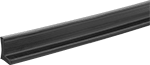

Cleats for Conveyor Belts

Use these cleats to convert any smooth conveyor belt into a belt for inclines. Cut cleats to the length you need with a utility knife.

EPDM is more durable than Buna-N, and has better resistance to acids and weather. Attach cleats to the belt with the included fasteners.

| Ht. | Lg. | For Max. Belt Thick. | For Min. Pulley Dia. | Max. Temp., °F | Mount Type | Includes | Each | ||

Black EPDM Rubber | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| A | 1 1/4" | 48" | 0.430" | 3" | 300° | Bolt On | Mounting Fasteners | 0000000 | 000000 |

| A | 2" | 48" | 0.430" | 3" | 300° | Bolt On | Mounting Fasteners | 0000000 | 000000 |

| A | 3" | 48" | 0.430" | 3" | 300° | Bolt On | Mounting Fasteners | 0000000 | 000000 |

| A | 4" | 48" | 0.550" | 4" | 300° | Bolt On | Mounting Fasteners | 0000000 | 000000 |

Modular Mini Chain Belt Conveyors

Build a mini conveyor in any shape you need. These conveyors have curved, straight, incline, and decline runs that you can quickly join together with the included brackets. They're often used in areas with limited floor space and applications that require frequent layout changes. To customize your conveyor, add on components, such as package stops and merge guides, with the built-in T-slots on the side. T-slot bolts are sold separately. These conveyors come with guides installed.

You'll need a drive assembly, an idler assembly, and a belt to complete your conveyor. To determine the belt length you need, multiply your conveyor’s length by 2.1. If you need a belt longer than what’s available, you can connect multiple together. Use a belt installation tool (sold separately) to pull out the pin, then line up two ends and push the pin in with the tool to connect them. You can also shorten a belt using the same tool.

Maximum run length is 70 ft. with two 90° curves. Adding more curved conveyors will reduce the run length.

For technical drawings and 3-D models, click on a part number.

Wd. | Ht. | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Belt | Frame | T-Slot | Frame | Overall | Capacity, lbs./ft. | Number of Stands Included | Features | Each | |

4 ft. Conveyor Bed Lg. | |||||||||

| 3 1/4" | 3 1/4" | 11 mm | 3" | 4 3/4" | 40 | None | Pre-Installed Guides | 0000000 | 0000000 |

| 6" | 6" | 11 mm | 3" | 4 3/4" | 40 | None | Pre-Installed Guides | 0000000 | 000000 |

| 10 1/4" | 10 1/4" | 11 mm | 3" | 4 3/4" | 44 | None | Pre-Installed Guides | 0000000 | 000000 |

Magnetic Plates for Belt Conveyors

Keep ferrous objects in place as they move along your conveyor belt. These plates install under your conveyor belt to create a magnetic hold. Mount them with nonmagnetic fasteners.

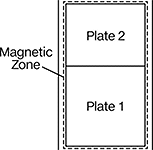

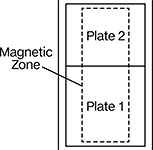

Conveyor plates with full magnetic coverage have a higher magnetic force than conveyor plates with partial magnetic coverage. They have a full magnetic zone throughout the plate, making them best for moving large objects. Position them side-by-side or end-to-end to cover the entire width or length of the belt. All have tapped holes for mounting.

Conveyor plates with partial magnetic coverage have a magnetic zone that runs down the center of the plate's length. They’re typically placed underneath the middle of the belt to pull small objects that are prone to shifting due to vibration, such as lids and fasteners, towards the center of the belt for secure conveying. If used with large objects, only a part of the object will be secured. When installing multiple plates down your conveyor run, be sure the poles are opposite of each other. All have mounting brackets for quick installation.

For technical drawings and 3-D models, click on a part number.

48" Lg. | |||||

|---|---|---|---|---|---|

| Wd. | Thick. | Max. Pull @ Distance | Bracket Material | Each | |

Full Magnetic Coverage | |||||

| 4 1/8" | 1 5/16" | 7 1/2 lbs. @ 1/8" | __ | 00000000 | 000000000 |

| 4 1/8" | 2 5/16" | 9 1/2 lbs. @ 1/8" | __ | 00000000 | 00000000 |

Partial Magnetic Coverage | |||||

| 1 5/8" | 1 5/32" | 2 1/2 lbs. @ 1/8" | Stainless Steel | 00000000 | 00000000 |

| 3" | 1 5/32" | 5 lbs. @ 1/8" | Stainless Steel | 00000000 | 00000000 |

| 3 5/8" | 1 29/32" | 5 3/4 lbs. @ 1/8" | Stainless Steel | 00000000 | 00000000 |

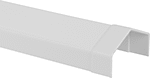

Protective Covers for Conveyors

Protect conveyed material from dust, debris, and other contaminants. All of these covers are FDA compliant for food and beverage conveying.

For technical drawings and 3-D models, click on a part number.

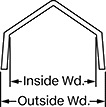

Outside | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Lg., ft. | Wd. | Ht. | Inside Wd. | Thick. | Color | UV Resistant | Specifications Met | Each | |

ABS Plastic | |||||||||

| 4 | 8" | 2 5/8" | 7 1/2" | 0.13" | Yellow | No | FDA Compliant 21 CFR 181.32 | 0000000 | 0000000 |

Ball Transfer Plates

These plates are designed to rest on a flat surface and are good for rotating and positioning heavy workpieces.

Note: The length and width of the material you're moving should be at least three times the ball spacing.

For technical drawings and 3-D models, click on a part number.

Overall | Frame | |||||||

|---|---|---|---|---|---|---|---|---|

| Lg. | Wd. | Ht. | Cap. per Ball, lbs. | Ball Dia. | Material | Color | Each | |

Steel Balls with Zinc-Plated Steel Housing | ||||||||

3" Ball Spacing | ||||||||

| 48" | 48" | 3" | 65 | 1" | Powder-Coated Steel | Blue | 0000000 | 000000000 |

4" Ball Spacing | ||||||||

| 48" | 48" | 3" | 65 | 1" | Powder-Coated Steel | Blue | 0000000 | 00000000 |

6" Ball Spacing | ||||||||

| 48" | 48" | 3" | 65 | 1" | Powder-Coated Steel | Blue | 0000000 | 000000 |

| Replacement Ball Transfer | 0000000 | Each | 00000 |

Covers for Ball Transfer Plates

Covers create a smooth surface so small and oddly shaped items won't get caught between ball transfers. Use them with Ball Transfer Plates.

For technical drawings and 3-D models, click on a part number.

Heavy Duty Flow Rails

All-steel construction and tightly spaced wheels with double ball bearings gives these rails the strength needed to handle heavy loads in confined spaces. Drill holes to mount or weld in place.

Note: Capacities are based on a fully supported rail.

For technical drawings and 3-D models, click on a part number.

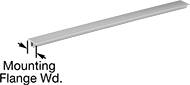

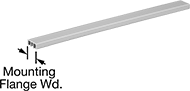

Holders for Tight-Seal Strip Brushes

Mount brushes by sliding them into a holder. Holders can be cut to size with a hacksaw.

Bolt-on holders can be drilled for mounting. Push-on holders have a top channel that grips the mounting surface.

For technical drawings and 3-D models, click on a part number.

For Backing | Holder | Mount. Flange | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wd. | Ht. | Wd. | Ht. | For Max. No. of Brushes | Wd. | Ht. | Thick. | Angle | Max. Temp., °F | 4-ft. Lg. | ||

Bolt On | ||||||||||||

Aluminum | ||||||||||||

| A | 1/8" | 1/8" | 3/4" | 7/32" | 1 | 3/4" | __ | 1/32" | __ | 212° | 0000000 | |

| A | 3/16" | 7/32" | 1" | 3/8" | 1 | 1" | __ | 1/16" | __ | 212° | 0000000 | |

| A | 5/16" | 5/16" | 1 1/4" | 15/32" | 1 | 1 1/4" | __ | 1/16" | __ | 212° | 0000000 | |

| A | 7/16" | 7/16" | 1 3/4" | 5/8" | 1 | 1 3/4" | __ | 1/16" | __ | 212° | 0000000 | |

| B | 3/16" | 7/32" | 15/16" | 3/8" | 2 | 7/32" | __ | 1/16" | __ | 212° | 0000000 | |

| B | 5/16" | 5/16" | 1 3/16" | 15/32" | 2 | 9/32" | __ | 1/16" | __ | 212° | 0000000 | |

| C | 1/8" | 1/8" | 7/32" | 7/8" | 1 | __ | 5/8" | 1/32" | __ | 212° | 0000000 | |

| C | 3/16" | 7/32" | 3/8" | 1 1/4" | 1 | __ | 7/8" | 1/16" | __ | 212° | 0000000 | |

| C | 5/16" | 5/16" | 7/16" | 1 1/4" | 1 | __ | 3/4" | 1/16" | __ | 212° | 0000000 | |

| C | 7/16" | 7/16" | 19/32" | 2 1/2" | 1 | __ | 1 13/16" | 1/16" | __ | 212° | 0000000 | |

| D | 1/8" | 1/8" | 7/32" | 3/4" | 1 | __ | 1/2" | 1/32" | __ | 212° | 0000000 | |

| D | 3/16" | 7/32" | 3/8" | 1" | 1 | __ | 5/8" | 1/16" | __ | 212° | 0000000 | |

| D | 5/16" | 5/16" | 15/32" | 1 1/2" | 1 | __ | 1 1/16" | 1/16" | __ | 212° | 0000000 | |

| D | 7/16" | 7/16" | 5/8" | 1 1/2" | 1 | __ | 7/8" | 1/16" | __ | 212° | 0000000 | |

| E | 3/16" | 7/32" | 11/16" | 2 3/8" | 1 | __ | 2" | 1/16" | __ | 212° | 0000000 | |

| E | 5/16" | 5/16" | 27/32" | 2 15/32" | 1 | __ | 2" | 1/16" | __ | 212° | 0000000 | |

| F | 3/16" | 7/32" | 3/8" | 13/32" | 1 | __ | 1 13/16" | 1/16" | 45° | 212° | 0000000 | |

| F | 5/16" | 5/16" | 7/16" | 1/2" | 1 | __ | 1 1/8" | 1/16" | 45° | 212° | 0000000 | |

| G | 3/16" | 7/32" | 3/8" | 3/8" | 1 | __ | 1" | 1/16" | 50° | 212° | 0000000 | |

| G | 5/16" | 5/16" | 7/16" | 15/32" | 1 | __ | 1 5/8" | 1/16" | 50° | 212° | 0000000 | |

Stainless Steel | ||||||||||||

| C | 3/16" | 7/32" | 9/32" | 1" | 1 | __ | 11/16" | 3/32" | __ | 600° | 0000000 | |

| C | 5/16" | 5/16" | 3/8" | 15/16" | 1 | __ | 19/32" | 1/16" | __ | 600° | 0000000 | |

Push On | ||||||||||||

PVC Plastic | ||||||||||||

| H | 1/8" | 1/8" | 5/16" | 1" | 1 | __ | 9/16" | __ | __ | 70° | 0000000 | |

Clamp-On Framing and Fittings

Fittings come in two pieces to clasp over rails, making assembly and disassembly quicker than our other framing. Use it to form temporary partitions, modular conveyors, and workstations. To assemble, clamp fittings onto the rail and tighten the included cap screw and nut. For permanent connections and added strength, fittings have a 5/32" hole to drill in an additional screw (not included).

For technical drawings and 3-D models, click on a part number.

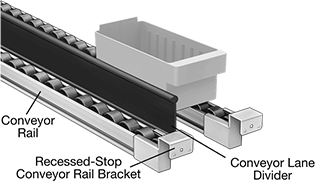

Conveyor rails slide directly into the conveyor rail mounting brackets.

Conveyor lane dividers guide and keep products separated on conveyor rail systems.

For Rail OD | ||||||

|---|---|---|---|---|---|---|

| Lg., ft. | Inch | Metric, mm | For Overall Wd. | Material | Each | |

| 4 | 1.08" | 28 | 1 9/16" | Black Plastic | 0000000 | 000000 |