Belt Conveyors

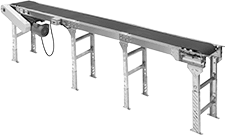

Move small, loose, and irregularly shaped material that might fall through or shift around roller or skate wheel conveyors. Material remains in the same location on the belt as it travels, making these conveyors ideal for inspecting products in an assembly line. These conveyors ship as sub-assemblies that require final assembly.

Reversible conveyors move material forward and back in applications such as loading and unloading trucks or returning empty containers back down the line.

Fixed-speed conveyors travel at 60 fpm, a common industry rate, to move material.

Variable-speed conveyors adjust from standard conveyor speeds down to 7 fpm, so they are often used to slow material flow for quality checks.

Three-phase motors balance power more evenly than single-phase motors, so they are good for heavy loads. While a conveyor with a single-phase motor may lag when a heavy load reaches the conveyor, a conveyor with a three-phase motor will continue smoothly.

Note: Capacities are based on an evenly distributed load.

For technical drawings and 3-D models, click on a part number.

Wd. | No. of Stands | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Lg., ft. | Belt | Frame | O'all Ht. | Cap., lbs. | Speed, fpm | Required | Included | Features | Each | |

120V AC—Single Phase (Plug In) | ||||||||||

| 15 | 12" | 17" | 34"-38" | 480 | 60 | 3 | 3 | On/Off Switch | 00000000 | 000000000 |

| 15 | 20" | 25" | 34"-38" | 435 | 60 | 3 | 3 | On/Off Switch | 00000000 | 00000000 |

| 15 | 24" | 29" | 34"-38" | 405 | 60 | 3 | 3 | On/Off Switch | 00000000 | 00000000 |

240/460V AC—Three Phase (Hardwire) | ||||||||||

| 15 | 12" | 17" | 34"-38" | 480 | 60 | 3 | 3 | __ | 00000000 | 00000000 |

| 15 | 20" | 25" | 34"-38" | 435 | 60 | 3 | 3 | __ | 00000000 | 00000000 |

| 15 | 24" | 29" | 34"-38" | 405 | 60 | 3 | 3 | __ | 00000000 | 00000000 |

Wd. | No. of Stands | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Lg., ft. | Belt | Frame | O'all Ht. | Cap., lbs. | Speed, fpm | Required | Included | Features | Each | |

120V AC—Single Phase (Plug In) | ||||||||||

| 15 | 12" | 17" | 34"-38" | 445 | 60 | 3 | 3 | On/Off Switch | 00000000 | 000000000 |

| 15 | 20" | 25" | 34"-38" | 400 | 60 | 3 | 3 | On/Off Switch | 00000000 | 00000000 |

| 15 | 24" | 29" | 34"-38" | 370 | 60 | 3 | 3 | On/Off Switch | 00000000 | 00000000 |

240/460V AC—Three Phase (Hardwire) | ||||||||||

| 15 | 12" | 17" | 34"-38" | 445 | 60 | 3 | 3 | __ | 00000000 | 00000000 |

| 15 | 20" | 25" | 34"-38" | 400 | 60 | 3 | 3 | __ | 00000000 | 00000000 |

| 15 | 24" | 29" | 34"-38" | 370 | 60 | 3 | 3 | __ | 00000000 | 00000000 |

Wd. | No. of Stands | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Lg., ft. | Belt | Frame | O'all Ht. | Cap., lbs. | Speed, fpm | Required | Included | Features | Each | |

90V DC—Single Phase (Plug In) | ||||||||||

| 15 | 12" | 17" | 34"-38" | 480 | 7-60 | 3 | 3 | On/Off Switch | 00000000 | 000000000 |

| 15 | 20" | 25" | 34"-38" | 435 | 7-60 | 3 | 3 | On/Off Switch | 00000000 | 00000000 |

| 15 | 24" | 29" | 34"-38" | 405 | 7-60 | 3 | 3 | On/Off Switch | 00000000 | 00000000 |

240/460V AC—Three Phase (Plug In) | ||||||||||

| 15 | 12" | 17" | 34"-38" | 480 | 7-60 | 3 | 3 | On/Off Switch | 00000000 | 00000000 |

| 15 | 20" | 25" | 34"-38" | 435 | 7-60 | 3 | 3 | On/Off Switch | 00000000 | 00000000 |

| 15 | 24" | 29" | 34"-38" | 405 | 7-60 | 3 | 3 | On/Off Switch | 00000000 | 00000000 |

Wd. | No. of Stands | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Lg., ft. | Belt | Frame | O'all Ht. | Cap., lbs. | Speed, fpm | Required | Included | Features | Each | |

90V DC—Single Phase (Plug In) | ||||||||||

| 15 | 12" | 17" | 34"-38" | 445 | 7-60 | 3 | 3 | On/Off Switch | 00000000 | 000000000 |

| 15 | 20" | 25" | 34"-38" | 400 | 7-60 | 3 | 3 | On/Off Switch | 00000000 | 00000000 |

| 15 | 24" | 29" | 34"-38" | 370 | 7-60 | 3 | 3 | On/Off Switch | 00000000 | 00000000 |

240/460V AC—Three Phase (Plug In) | ||||||||||

| 15 | 12" | 17" | 34"-38" | 445 | 7-60 | 3 | 3 | On/Off Switch | 00000000 | 00000000 |

| 15 | 20" | 25" | 34"-38" | 400 | 7-60 | 3 | 3 | On/Off Switch | 00000000 | 00000000 |

| 15 | 24" | 29" | 34"-38" | 370 | 7-60 | 3 | 3 | On/Off Switch | 00000000 | 00000000 |

| Motor Enclosure Type | Number of Speeds | Each | |

120V AC—Single Phase (Plug In) | |||

|---|---|---|---|

| Totally Enclosed Fan Cooled (TEFC) | 1 | 00000000 | 0000000 |

240/460V AC—Three Phase (Hardwire) | |||

| Totally Enclosed Fan Cooled (TEFC) | 1 | 00000000 | 000000 |

| Totally Enclosed Fan Cooled (TEFC) | Variable | 00000000 | 000000 |

90V DC—Single Phase (Plug In) | |||

| Totally Enclosed Nonventilated (TENV) | Variable | 00000000 | 00000000 |

| Speed Ratio | Each | |

| 30:1 | 00000000 | 0000000 |

| Bore Dia. | Mounted Bearing Type | Each | |

| 1 3/16" | Two-Bolt Flange Mount | 00000000 | 000000 |

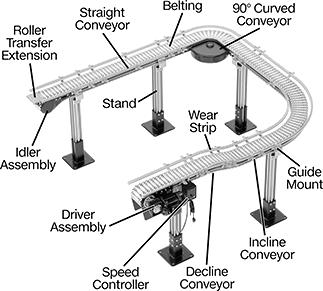

Modular Mini Chain Belt Conveyors

Build a mini conveyor in any shape you need. These conveyors have curved, straight, incline, and decline runs that you can quickly join together with the included brackets. They're often used in areas with limited floor space and applications that require frequent layout changes. To customize your conveyor, add on components, such as package stops and merge guides, with the built-in T-slots on the side. T-slot bolts are sold separately. These conveyors come with guides installed.

You'll need a drive assembly, an idler assembly, and a belt to complete your conveyor. To determine the belt length you need, multiply your conveyor’s length by 2.1. If you need a belt longer than what’s available, you can connect multiple together. Use a belt installation tool (sold separately) to pull out the pin, then line up two ends and push the pin in with the tool to connect them. You can also shorten a belt using the same tool.

Maximum run length is 70 ft. with two 90° curves. Adding more curved conveyors will reduce the run length.

For technical drawings and 3-D models, click on a part number.

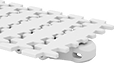

Attach belting to your conveyor to transport material. It’s driven by the conveyor’s motor. Tabs on the bottom keep it from lifting off the conveyor in curved sections.

To determine the belt length you need, multiply your conveyor’s length by 2.1. Belting is not included with any other components.

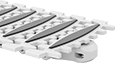

Rough-surface belting has pads on its chain links to grip material. If you’re conveying material at an incline or decline of 10° or higher, this belting will keep it from slipping.

15 ft. Lg. | |||||

|---|---|---|---|---|---|

| Belt Wd. | Thick. | Material | Temp. Range, °F | Each | |

Smooth Surface | |||||

| 3 1/4" | 5/32" | Acetal Plastic | 0° F to 140° | 0000000 | 0000000 |

| 6" | 5/32" | Acetal Plastic | 0° F to 140° | 0000000 | 000000 |

| 10 1/4" | 1/4" | Acetal Plastic | 0° F to 140° | 0000000 | 000000 |

Rough Surface | |||||

| 3 1/4" | 1/4" | Acetal Plastic | 0° F to 140° | 0000000 | 000000 |

| 6" | 9/32" | Acetal Plastic | 0° F to 140° | 0000000 | 000000 |

| 10 1/4" | 11/32" | Acetal Plastic | 0° F to 140° | 0000000 | 00000000 |