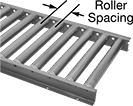

Roller Conveyors

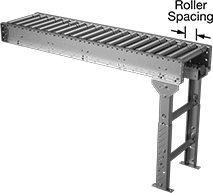

Mix and match conveyors and stands to design a conveyor system that moves parts exactly where they need to go. These conveyors have rollers that transfer items with flat or uneven bottoms, such as boxes or shipping tubes. They’re more durable and carry heavier loads than belt and skate wheel conveyors.

These conveyors don’t run on electricity, so their rollers require momentum from gravity, a push, or a powered conveyor to move. Since they’re not wired, they’re quick to set up and easy to maintain. This makes them handy if another conveyor unexpectedly shuts down or you need to extend an existing line in a pinch.

Curved and straight conveyors have connecting hooks to attach conveyor sections together.

Galvanized steel conveyors carry heavier loads than aluminum conveyors.

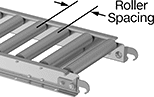

Note: Capacities are based on an evenly distributed load. The length of the material you’re conveying should be at least three times the roller spacing.

Wd. | 1 1/2" Roller Spacing | ||||||

|---|---|---|---|---|---|---|---|

| O'all | Between Frame | Lg., ft. | Frame Ht. | Cap. (No. of Stands Required) | No. of Stands Included | Each | |

1 3/8" Dia. Galvanized Steel Rollers—1/4" Round Axle | |||||||

| 12" | 10" | 7 | 2 1/2" | 120 lbs./ft. (2), 200 lbs./ft. (3) | None | 0000000 | 0000000 |

| 15" | 13" | 7 | 2 1/2" | 120 lbs./ft. (2), 200 lbs./ft. (3) | None | 0000000 | 000000 |

| 18" | 16" | 7 | 2 1/2" | 120 lbs./ft. (2), 200 lbs./ft. (3) | None | 0000000 | 000000 |

| 20" | 18" | 7 | 2 1/2" | 120 lbs./ft. (2), 200 lbs./ft. (3) | None | 0000000 | 000000 |

| 24" | 22" | 7 | 2 1/2" | 120 lbs./ft. (2), 200 lbs./ft. (3) | None | 0000000 | 000000 |

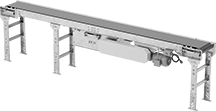

Motorized Roller Conveyors

Also known as line-shaft conveyors, these conveyors are driven by a drive shaft and round belts. Unlike belt conveyors, these have built-in accumulation, so packages can build up without crashing into one another or falling off the conveyor. The rollers are designed to smoothly transfer totes, packages, and other lightweight material. Shipping tubes, drums, and pails are less likely to get stuck in between rollers than between skate wheels.

Mix and match stands and conveyors to form straight lines, curve around obstacles, or create inclines. Only straight conveyor sections contain a motor, but they can power up to 60 ft. of conveyor extensions on either side. The motor can be reversed to send material in either direction.

Note: Capacities are based on an evenly distributed load. The length of the material you’re conveying should be at least three times the roller spacing.

For technical drawings and 3-D models, click on a part number.

Wd. | Roller | Ht. | 7 ft. Lg. | ||||||

|---|---|---|---|---|---|---|---|---|---|

| O'all | Between Frame | Spacing | Projection | Frame | O'all | Cap., lbs./ft. | Features | Each | |

1.9" Dia. Galvanized Steel Rollers—7/16" Hex Axle | |||||||||

| 16" | 13" | 3" | 1/4" | 5 1/2" | 36"-48" | 40 | Connecting Plates | 0000000 | 000000000 |

| 17" | 14" | 3" | 1/4" | 5 1/2" | 36"-48" | 40 | Connecting Plates | 00000000 | 00000000 |

| 19" | 16" | 3" | 1/4" | 5 1/2" | 36"-48" | 40 | Connecting Plates | 0000000 | 00000000 |

| 21" | 18" | 3" | 1/4" | 5 1/2" | 36"-48" | 40 | Connecting Plates | 00000000 | 00000000 |

| 25" | 22" | 3" | 1/4" | 5 1/2" | 36"-48" | 40 | Connecting Plates | 0000000 | 00000000 |

| 29" | 26" | 3" | 1/4" | 5 1/2" | 36"-48" | 40 | Connecting Plates | 00000000 | 00000000 |

| 31" | 28" | 3" | 1/4" | 5 1/2" | 36"-48" | 40 | Connecting Plates | 00000000 | 00000000 |

| 35" | 32" | 3" | 1/4" | 5 1/2" | 36"-48" | 40 | Connecting Plates | 0000000 | 00000000 |

| 41" | 38" | 3" | 1/4" | 5 1/2" | 36"-48" | 40 | Connecting Plates | 00000000 | 00000000 |

Conveyor Mount. Slot | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ht. | Conveyor Mount. Fasteners Included | No. of Conveyor Mount. Holes | Lg. | Wd. | Mount. Hole Ctr.-to-Ctr. | Floor Mount. Fasteners Included | No. of Floor Mount. Holes | Floor Mount. Hole Dia. | Each | |

For 16" Overall Wd. | ||||||||||

| 30 1/4" to 42 1/4" | Yes | 4 | 1" | 7/16" | 4" | No | 4 | 9/16" | 00000000 | 0000000 |

For 17" Overall Wd. | ||||||||||

| 30 1/4" to 42 1/4" | Yes | 4 | 1" | 7/16" | 4" | No | 4 | 9/16" | 00000000 | 000000 |

For 19" Overall Wd. | ||||||||||

| 30 1/4" to 42 1/4" | Yes | 4 | 1" | 7/16" | 4" | No | 4 | 9/16" | 00000000 | 000000 |

For 21" Overall Wd. | ||||||||||

| 30 1/4" to 42 1/4" | Yes | 4 | 1" | 7/16" | 4" | No | 4 | 9/16" | 00000000 | 000000 |

For 25" Overall Wd. | ||||||||||

| 30 1/4" to 42 1/4" | Yes | 4 | 1" | 7/16" | 4" | No | 4 | 9/16" | 00000000 | 000000 |

For 29" Overall Wd. | ||||||||||

| 30 1/4" to 42 1/4" | Yes | 4 | 1" | 7/16" | 4" | No | 4 | 9/16" | 00000000 | 000000 |

For 31" Overall Wd. | ||||||||||

| 30 1/4" to 42 1/4" | Yes | 4 | 1" | 7/16" | 4" | No | 4 | 9/16" | 00000000 | 000000 |

For 35" Overall Wd. | ||||||||||

| 30 1/4" to 42 1/4" | Yes | 4 | 1" | 7/16" | 4" | No | 4 | 9/16" | 00000000 | 000000 |

For 41" Overall Wd. | ||||||||||

| 30 1/4" to 42 1/4" | Yes | 4 | 1" | 7/16" | 4" | No | 4 | 9/16" | 00000000 | 000000 |

Stainless Steel Roller Conveyors

Conveyors are made of corrosion-resistant stainless steel, making them suitable for washdown applications.

Note: Capacities are based on an evenly distributed load with at least one stand at each end for straight conveyors, and an additional stand in the center for curved conveyors. You can increase the capacity of a 10-ft. straight conveyor by adding a stand in the center. The length of the material you’re conveying should be at least three times the roller spacing.

For technical drawings and 3-D models, click on a part number.

Wd. | Roller | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| O'all | Between Frame | Lg., ft. | Spacing | Projection | Frame Ht. | Cap. (No. of Stands Required) | No. of Stands Included | Each | |

1 5/8" Dia. Stainless Steel Rollers—7/16" Hex Axle | |||||||||

| 18" | 16" | 7 | 3" | 5/16" | 2 1/2" | 120 lbs./ft. (2) | None | 0000000 | 000000000 |

| 24" | 22" | 7 | 3" | 5/16" | 2 1/2" | 120 lbs./ft. (2) | None | 0000000 | 00000000 |

| Replacement Bearing | 0000000 | Each | 000000 |

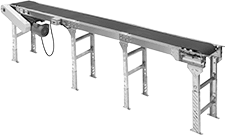

Belt Conveyors

Move small, loose, and irregularly shaped material that might fall through or shift around roller or skate wheel conveyors. Material remains in the same location on the belt as it travels, making these conveyors ideal for inspecting products in an assembly line. These conveyors ship as sub-assemblies that require final assembly.

Reversible conveyors move material forward and back in applications such as loading and unloading trucks or returning empty containers back down the line.

Fixed-speed conveyors travel at 60 fpm, a common industry rate, to move material.

Variable-speed conveyors adjust from standard conveyor speeds down to 7 fpm, so they are often used to slow material flow for quality checks.

Three-phase motors balance power more evenly than single-phase motors, so they are good for heavy loads. While a conveyor with a single-phase motor may lag when a heavy load reaches the conveyor, a conveyor with a three-phase motor will continue smoothly.

Note: Capacities are based on an evenly distributed load.

For technical drawings and 3-D models, click on a part number.

Wd. | No. of Stands | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Lg., ft. | Belt | Frame | O'all Ht. | Cap., lbs. | Speed, fpm | Required | Included | Features | Each | |

120V AC—Single Phase (Plug In) | ||||||||||

| 7 | 12" | 17" | 34"-38" | 495 | 60 | 2 | 2 | On/Off Switch | 00000000 | 000000000 |

| 7 | 20" | 25" | 34"-38" | 460 | 60 | 2 | 2 | On/Off Switch | 00000000 | 00000000 |

| 7 | 24" | 29" | 34"-38" | 445 | 60 | 2 | 2 | On/Off Switch | 00000000 | 00000000 |

240/460V AC—Three Phase (Hardwire) | ||||||||||

| 7 | 12" | 17" | 34"-38" | 495 | 60 | 2 | 2 | __ | 00000000 | 00000000 |

| 7 | 20" | 25" | 34"-38" | 460 | 60 | 2 | 2 | __ | 00000000 | 00000000 |

| 7 | 24" | 29" | 34"-38" | 445 | 60 | 2 | 2 | __ | 00000000 | 00000000 |

Wd. | No. of Stands | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Lg., ft. | Belt | Frame | O'all Ht. | Cap., lbs. | Speed, fpm | Required | Included | Features | Each | |

120V AC—Single Phase (Plug In) | ||||||||||

| 7 | 12" | 17" | 34"-38" | 460 | 60 | 2 | 2 | On/Off Switch | 00000000 | 000000000 |

| 7 | 20" | 25" | 34"-38" | 425 | 60 | 2 | 2 | On/Off Switch | 00000000 | 00000000 |

| 7 | 24" | 29" | 34"-38" | 410 | 60 | 2 | 2 | On/Off Switch | 00000000 | 00000000 |

240/460V AC—Three Phase (Hardwire) | ||||||||||

| 7 | 12" | 17" | 34"-38" | 460 | 60 | 2 | 2 | __ | 00000000 | 00000000 |

| 7 | 20" | 25" | 34"-38" | 425 | 60 | 2 | 2 | __ | 00000000 | 00000000 |

| 7 | 24" | 29" | 34"-38" | 410 | 60 | 2 | 2 | __ | 00000000 | 00000000 |

Wd. | No. of Stands | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Lg., ft. | Belt | Frame | O'all Ht. | Cap., lbs. | Speed, fpm | Required | Included | Features | Each | |

90V DC—Single Phase (Plug In) | ||||||||||

| 7 | 12" | 17" | 34"-38" | 495 | 7-60 | 2 | 2 | On/Off Switch | 00000000 | 000000000 |

| 7 | 20" | 25" | 34"-38" | 460 | 7-60 | 2 | 2 | On/Off Switch | 00000000 | 00000000 |

| 7 | 24" | 29" | 34"-38" | 445 | 7-60 | 2 | 2 | On/Off Switch | 00000000 | 00000000 |

240/460V AC—Three Phase (Plug In) | ||||||||||

| 7 | 12" | 17" | 34"-38" | 495 | 7-60 | 2 | 2 | On/Off Switch | 00000000 | 00000000 |

| 7 | 20" | 25" | 34"-38" | 460 | 7-60 | 2 | 2 | On/Off Switch | 00000000 | 00000000 |

| 7 | 24" | 29" | 34"-38" | 445 | 7-60 | 2 | 2 | On/Off Switch | 00000000 | 00000000 |

Wd. | No. of Stands | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Lg., ft. | Belt | Frame | O'all Ht. | Cap., lbs. | Speed, fpm | Required | Included | Features | Each | |

90V DC—Single Phase (Plug In) | ||||||||||

| 7 | 12" | 17" | 34"-38" | 460 | 7-60 | 2 | 2 | On/Off Switch | 00000000 | 000000000 |

| 7 | 20" | 25" | 34"-38" | 425 | 7-60 | 2 | 2 | On/Off Switch | 00000000 | 00000000 |

| 7 | 24" | 29" | 34"-38" | 410 | 7-60 | 2 | 2 | On/Off Switch | 00000000 | 00000000 |

240/460V AC—Three Phase (Plug In) | ||||||||||

| 7 | 12" | 17" | 34"-38" | 460 | 7-60 | 2 | 2 | On/Off Switch | 00000000 | 00000000 |

| 7 | 20" | 25" | 34"-38" | 425 | 7-60 | 2 | 2 | On/Off Switch | 00000000 | 00000000 |

| 7 | 24" | 29" | 34"-38" | 410 | 7-60 | 2 | 2 | On/Off Switch | 00000000 | 00000000 |

| Motor Enclosure Type | Number of Speeds | Each | |

120V AC—Single Phase (Plug In) | |||

|---|---|---|---|

| Totally Enclosed Fan Cooled (TEFC) | 1 | 00000000 | 0000000 |

240/460V AC—Three Phase (Hardwire) | |||

| Totally Enclosed Fan Cooled (TEFC) | 1 | 00000000 | 000000 |

| Totally Enclosed Fan Cooled (TEFC) | Variable | 00000000 | 000000 |

90V DC—Single Phase (Plug In) | |||

| Totally Enclosed Nonventilated (TENV) | Variable | 00000000 | 00000000 |

| Speed Ratio | Each | |

| 30:1 | 00000000 | 0000000 |

| Bore Dia. | Mounted Bearing Type | Each | |

| 1 3/16" | Two-Bolt Flange Mount | 00000000 | 000000 |

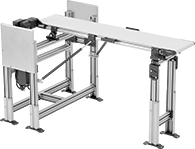

Easy-Access Ready-To-Run Mini Belt Conveyors

Run these conveyors right out of the box—they simply plug into an electrical outlet for power. The belts on these conveyors can move a wide range of small products, including electronic components, molded plastic parts, and other irregularly shaped parts that would catch on rollers and skate wheels. A good choice for quality checks, these conveyors have built-in speed controls and a flat belt surface that keeps objects steady as they move. Reverse the direction of travel with the flip of a switch. They’re small enough to fit in areas with limited space. Open the integrated lift gate for workers, dollies, and other equipment to safely pass through your line rather than going around the conveyor or over stairs. The height is adjustable to help you match existing setups. Continuous T-slots run along the sides of these conveyors for mounting side rails, guides, and custom equipment.

Note: Capacities are based on an evenly distributed load.

For technical drawings and 3-D models, click on a part number.

Wd. | No. of Stands | 7 ft. Lg. | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Belt | Frame | O'all Ht. | Cap., lbs. | Required | Included | Voltage | Reversible | Features | Opening Lg. | Each | |

10-58 fpm | |||||||||||

| 6" | 6 5/8" | 24"-60" | 30 | 2 | 2 | 120V AC | Yes | On/Off Switch | 60" | 0000000 | 000000000 |

| 8" | 8 5/8" | 24"-60" | 30 | 2 | 2 | 120V AC | Yes | On/Off Switch | 60" | 00000000 | 00000000 |

| 12" | 12 5/8" | 24"-60" | 30 | 2 | 2 | 120V AC | Yes | On/Off Switch | 60" | 00000000 | 00000000 |

O'all | Mounting Holes | ||||||

|---|---|---|---|---|---|---|---|

| Lg. | Wd. | Mounting Fasteners Included | No. of | Dia. | Material | Each | |

| 3 3/16" | 1 3/4" | Yes | 2 | 9/32" | Zinc-Plated Steel | 0000000 | 000000 |

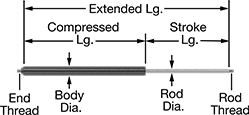

Body | Rod | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Extension Force, lbs. | Compression Force, lbs. | Extended Lg. | Compressed Lg. | Stroke Lg. | Max. Cycles per Minute | Max. Cycles | Dia. | Material | Dia. | Material | Temperature Range, °F | Each | |

M8 Rod and End Thread Size | |||||||||||||

| 25 | 33 | 33.94" | 17.8" | 16.14" | 6 | 25,000 | 0.85" | Steel | 0.39" | Steel | -22° to 176° | 00000000 | 000000 |

| 50 | 66 | 33.94" | 17.8" | 16.14" | 6 | 25,000 | 0.85" | Steel | 0.39" | Steel | -22° to 176° | 00000000 | 00000 |

Cleated Belt Conveyors for Inclines

The cleats on these conveyors prevent items from tumbling down as you move them along steep slopes. They are often used to bridge the gap between different elevations in your facility, such as between the floor and a shipping bin. These conveyors keep parts steady as they move, so they're great for moving small, loose, and irregularly shaped parts that might fall through or catch on roller and skate wheel conveyors. They come with an adjustable stand on the higher end and adjustable support bars on the lower end, so you can position the conveyor at the right height and angle for your application.

Note: Capacities are based on an evenly distributed load.

For technical drawings and 3-D models, click on a part number.

Wd. | Cleat | No. of Stands | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg., ft. | Belt | Frame | Ht. | Spacing | Side Rail Projection | O'all Ht. | Cap., lbs. | Speed, fpm | Climbing Angle | Required | Included | Reversible | Features | Each | |

Powder-Coated Steel Bed with PVC Plastic Belt | |||||||||||||||

120V AC—Single Phase (Plug In) | |||||||||||||||

| 7 | 12" | 16" | 1 1/2" | 12" | 3" | 55"-63" | 150 | 60 | 41°-45° | 1 | 1 | No | On/Off Switch | 0000000 | 000000000 |

| 7 | 16" | 20" | 1 1/2" | 12" | 3" | 55"-63" | 150 | 60 | 41°-45° | 1 | 1 | No | On/Off Switch | 0000000 | 00000000 |

| Wd. | Ht. | Wire Lead Lg. | Each | |

Hardwire | ||||

|---|---|---|---|---|

| 2 1/2" | 4 1/2" | 2 ft. | 00000000 | 0000000 |

| Motor Enclosure Type | Each | |

120V AC—Single Phase | ||

|---|---|---|

| Open Dripproof | 0000000 | 000000000 |

Holders for Tight-Seal Strip Brushes

Mount brushes by sliding them into a holder. Holders can be cut to size with a hacksaw.

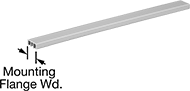

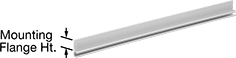

Bolt-on holders can be drilled for mounting. Push-on holders have a top channel that grips the mounting surface.

For technical drawings and 3-D models, click on a part number.

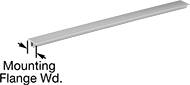

For Backing | Holder | Mount. Flange | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wd. | Ht. | Wd. | Ht. | For Max. No. of Brushes | Wd. | Ht. | Thick. | Angle | Max. Temp., °F | 7-ft. Lg. | ||

Bolt On | ||||||||||||

Aluminum | ||||||||||||

| A | 1/8" | 1/8" | 3/4" | 7/32" | 1 | 3/4" | __ | 1/32" | __ | 212° | 0000000 | |

| A | 3/16" | 7/32" | 1" | 3/8" | 1 | 1" | __ | 1/16" | __ | 212° | 0000000 | |

| A | 5/16" | 5/16" | 1 1/4" | 15/32" | 1 | 1 1/4" | __ | 1/16" | __ | 212° | 0000000 | |

| A | 7/16" | 7/16" | 1 3/4" | 5/8" | 1 | 1 3/4" | __ | 1/16" | __ | 212° | 0000000 | |

| B | 3/16" | 7/32" | 15/16" | 3/8" | 2 | 7/32" | __ | 1/16" | __ | 212° | 0000000 | |

| B | 5/16" | 5/16" | 1 3/16" | 15/32" | 2 | 9/32" | __ | 1/16" | __ | 212° | 0000000 | |

| C | 1/8" | 1/8" | 7/32" | 7/8" | 1 | __ | 5/8" | 1/32" | __ | 212° | 0000000 | |

| C | 3/16" | 7/32" | 3/8" | 1 1/4" | 1 | __ | 7/8" | 1/16" | __ | 212° | 0000000 | |

| C | 5/16" | 5/16" | 7/16" | 1 1/4" | 1 | __ | 3/4" | 1/16" | __ | 212° | 0000000 | |

| C | 7/16" | 7/16" | 19/32" | 2 1/2" | 1 | __ | 1 13/16" | 1/16" | __ | 212° | 0000000 | |

| D | 1/8" | 1/8" | 7/32" | 3/4" | 1 | __ | 1/2" | 1/32" | __ | 212° | 0000000 | |

| D | 3/16" | 7/32" | 3/8" | 1" | 1 | __ | 5/8" | 1/16" | __ | 212° | 0000000 | |

| D | 5/16" | 5/16" | 15/32" | 1 1/2" | 1 | __ | 1 1/16" | 1/16" | __ | 212° | 0000000 | |

| D | 7/16" | 7/16" | 5/8" | 1 1/2" | 1 | __ | 7/8" | 1/16" | __ | 212° | 0000000 | |

| E | 3/16" | 7/32" | 11/16" | 2 3/8" | 1 | __ | 2" | 1/16" | __ | 212° | 0000000 | |

| E | 5/16" | 5/16" | 27/32" | 2 15/32" | 1 | __ | 2" | 1/16" | __ | 212° | 0000000 | |

| F | 3/16" | 7/32" | 3/8" | 13/32" | 1 | __ | 1 13/16" | 1/16" | 45° | 212° | 0000000 | |

| F | 5/16" | 5/16" | 7/16" | 1/2" | 1 | __ | 1 1/8" | 1/16" | 45° | 212° | 0000000 | |

| G | 3/16" | 7/32" | 3/8" | 3/8" | 1 | __ | 1" | 1/16" | 50° | 212° | 0000000 | |

| G | 5/16" | 5/16" | 7/16" | 15/32" | 1 | __ | 1 5/8" | 1/16" | 50° | 212° | 0000000 | |

Push On | ||||||||||||

PVC Plastic | ||||||||||||

| H | 1/8" | 1/8" | 5/16" | 1" | 1 | __ | 9/16" | __ | __ | 70° | 0000000 | |