About Loc-Line and Snap-Loc Coolant Hose

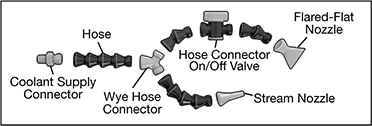

Assemble and disassemble Loc-Line and Snap-Loc coolant hose by snapping components together or pulling them apart. Assembly and separation tools (sold separately) are recommended.

To ensure compatibility, select the color and trade size that match your current system. A system’s trade size is equal to the ID of its hose.

1/4" Loc-Line Coolant Hose

Build a custom system to deliver coolant, cutting oil, water, or air in any direction. Once in position, hose stays put—there's no spring back or movement caused by vibration or heavy flow.

Assemble and disassemble by snapping components together or pulling them apart. Assembly pliers (sold separately) are recommended. To ensure compatibility, select the color and trade size that match your current system. These components fit Loc-Line hose with a 1/4” ID.

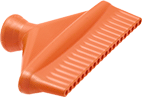

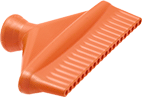

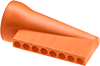

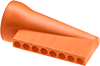

Nozzles direct flow.

Orifices | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Shape | Spray Pattern | Gender | No. of | Dia. | Ht. | Wd. | O'all Lg. | Material | Max. Flow Rate, gph | Max. Pressure, psi | Max. Temp., °F | Pkg. Qty. | Pkg. | |

| 20 | Straight | Stream | Female | 1 | 1/16" | __ | __ | 1 11/64" | Acetal Plastic | 250 | 30 | 170° | 4 | 00000000 | 00000 |

| 20 | Straight | Stream | Female | 1 | 1/8" | __ | __ | 1 11/64" | Acetal Plastic | 250 | 30 | 170° | 4 | 00000000 | 0000 |

| 20 | Straight | Stream | Female | 1 | 1/4" | __ | __ | 1 11/64" | Acetal Plastic | 250 | 30 | 170° | 4 | 00000000 | 0000 |

| 21 | 90° Elbow | Stream | Female | 1 | 1/16" | __ | __ | 63/64" | Acetal Plastic | 250 | 30 | 170° | 4 | 000000000 | 0000 |

| 21 | 90° Elbow | Stream | Female | 1 | 1/8" | __ | __ | 1 1/64" | Acetal Plastic | 250 | 30 | 170° | 4 | 00000000 | 0000 |

| 21 | 90° Elbow | Stream | Female | 1 | 1/4" | __ | __ | 1 3/32" | Acetal Plastic | 250 | 30 | 170° | 4 | 00000000 | 0000 |

| 22 | Straight | Flared Flat | Female | 1 | __ | 1/16" | 61/64" | 1" | Acetal Plastic | 250 | 30 | 170° | 2 | 00000000 | 0000 |

| 22 | Straight | Flat | Female | 1 | __ | 3/64" | 1" | 1" | Acetal Plastic | 250 | 30 | 170° | 2 | 00000000 | 0000 |

| 23 | Straight | Flat | Female | 1 | __ | 1/16" | 7/16" | 7/16" | Acetal Plastic | 250 | 30 | 170° | 4 | 00000000 | 0000 |

| 23 | Straight | Flat | Female | 1 | __ | 1/16" | 7/16" | 1 1/8" | Acetal Plastic | 250 | 50 | 170° | 4 | 000000000 | 0000 |

| 24 | Straight | Multiple Stream | Female | 5 | 1/16" | __ | __ | 7/16" | Acetal Plastic | 250 | 30 | 170° | 4 | 00000000 | 0000 |

| 24 | Straight | Multiple Stream | Female | 7 | 3/64" | __ | __ | 1" | Acetal Plastic | 250 | 30 | 170° | 4 | 000000000 | 0000 |

| 25 | Straight | Multiple Stream | Female | 16 | 3/64" | __ | __ | 1 1/2" | Acetal Plastic | 250 | 30 | 170° | 2 | 00000000 | 0000 |

| 25 | Straight | Multiple Stream | Female | 16 | 1/16" | __ | __ | 1 17/32" | Acetal Plastic | 250 | 30 | 170° | 2 | 00000000 | 0000 |

| 25 | Straight | Multiple Stream | Female | 20 | 5/64" | __ | __ | 2 1/2" | Acetal Plastic | 250 | 30 | 170° | 2 | 00000000 | 00000 |

| 26 | 90° Elbow | Multiple Stream | Female | 6 | 3/32" | __ | __ | 3/4" | Acetal Plastic | 250 | 30 | 170° | 2 | 0000000 | 0000 |

| 27 | Tee | Stream | Female × Male | 1 | 5/64" | __ | __ | 1 21/64" | Acetal Plastic | 250 | 50 | 170° | 4 | 000000000 | 0000 |

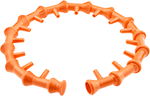

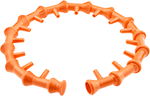

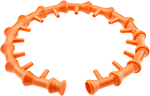

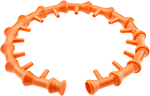

Style 28 is an assembly of 15 style 27 nozzles with a cap.

Orifices | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Gender | Spray Pattern | No. of | Dia. | OD | Bend Radius | Material | Max. Flow Rate, gph | Max. Pressure, psi | Max. Temp., °F | Pkg. Qty. | Pkg. | |

| 28 | Female | Multiple Stream | 15 | 5/64" | 3 5/8" | 1 1/4" | Acetal Plastic | 250 | 30 | 170° | 1 | 00000000 | 000000 |

1/2" Loc-Line Coolant Hose

Build a custom system to deliver coolant, cutting oil, water, or air in any direction. Once in position, hose stays put—there’s no spring back or movement caused by vibration or heavy flow.

Assemble and disassemble by snapping components together or pulling them apart. Assembly pliers (sold separately) are recommended. To ensure compatibility, select the color and trade size that match your current system. These components fit Loc-Line hose with a 1/2" ID.

Nozzles direct flow.

Orifices | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Shape | Spray Pattern | Gender | No. of | Dia. | Ht. | Wd. | O'all Lg. | Material | Max. Flow Rate, gph | Max. Pressure, psi | Max. Temp., °F | Pkg. Qty. | Pkg. | |

| 18 | Straight | Stream | Female | 1 | 1/4" | __ | __ | 1 15/32" | Acetal Plastic | 478 | 20 | 170° | 4 | 00000000 | 00000 |

| 18 | Straight | Stream | Female | 1 | 3/8" | __ | __ | 1 15/32" | Acetal Plastic | 478 | 20 | 170° | 4 | 00000000 | 0000 |

| 18 | Straight | Stream | Female | 1 | 1/2" | __ | __ | 1 15/32" | Acetal Plastic | 478 | 20 | 170° | 4 | 00000000 | 0000 |

| 19 | 90° Elbow | Stream | Female | 1 | 1/4" | __ | __ | 1 7/16" | Acetal Plastic | 478 | 20 | 170° | 4 | 000000000 | 0000 |

| 19 | 90° Elbow | Stream | Female | 1 | 3/8" | __ | __ | 1 1/2" | Acetal Plastic | 478 | 20 | 170° | 4 | 0000000 | 0000 |

| 19 | 90° Elbow | Stream | Female | 1 | 1/2" | __ | __ | 1 35/64" | Acetal Plastic | 478 | 20 | 170° | 4 | 0000000 | 0000 |

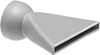

| 20 | Straight | Flat | Female | 1 | __ | 1/8" | 1 5/8" | 1 5/8" | Acetal Plastic | 478 | 20 | 170° | 2 | 00000000 | 0000 |

| 20 | Straight | Flat | Female | 1 | __ | 3/16" | 1 1/8" | 1 1/4" | Acetal Plastic | 478 | 20 | 170° | 2 | 00000000 | 0000 |

| 20 | Straight | Flared Flat | Female | 1 | __ | 7/64" | 2 29/64" | 2 1/2" | Acetal Plastic | 478 | 20 | 170° | 2 | 00000000 | 0000 |

| 20 | Straight | Flared Flat | Female | 1 | __ | 11/64" | 1 1/4" | 1 1/4" | Acetal Plastic | 478 | 20 | 170° | 2 | 00000000 | 0000 |

| 21 | Straight | Flat | Female | 1 | __ | 5/64" | 45/64" | 45/64" | Acetal Plastic | 478 | 20 | 170° | 4 | 0000000 | 0000 |

| 21 | Straight | Flat | Female | 1 | __ | 1/8" | 45/64" | 45/64" | Acetal Plastic | 478 | 20 | 170° | 4 | 000000000 | 0000 |

| 22 | Straight | Multiple Stream | Female | 5 | 1/8" | __ | __ | 45/64" | Acetal Plastic | 478 | 20 | 170° | 4 | 0000000 | 0000 |

| 22 | Straight | Multiple Stream | Female | 7 | 1/16" | __ | __ | 45/64" | Acetal Plastic | 478 | 20 | 170° | 4 | 000000000 | 0000 |

| 23 | Straight | Multiple Stream | Female | 20 | 5/64" | __ | __ | 2 1/2" | Acetal Plastic | 478 | 20 | 170° | 2 | 00000000 | 00000 |

| 24 | 90° Elbow | Multiple Stream | Female | 8 | 11/64" | __ | __ | 1 3/4" | Acetal Plastic | 478 | 20 | 170° | 2 | 0000000 | 0000 |

| 25 | Tee | Stream | Female × Male | 1 | 9/64" | __ | __ | 1 57/64" | Acetal Plastic | 478 | 30 | 170° | 4 | 000000000 | 0000 |

Style 26 is an assembly of 15 style 25 nozzles with a cap.

Orifices | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Gender | Spray Pattern | No. of | Dia. | OD | Bend Radius | Material | Max. Flow Rate, gph | Max. Pressure, psi | Max. Temp., °F | Pkg. Qty. | Pkg. | |

| 26 | Female | Multiple Stream | 15 | 9/64" | 4 1/2" | 1 3/4" | Acetal Plastic | 478 | 20 | 170° | 1 | 00000000 | 000000 |

3/4" Loc-Line Coolant Hose

Build a custom system to deliver coolant, cutting oil, water, or air in any direction. Once in position, hose stays put—there’s no spring back or movement caused by vibration or heavy flow.

Assemble and disassemble by snapping components together or pulling them apart. Assembly pliers (sold separately) are recommended. To ensure compatibility, select the color and trade size that match your current system. These components fit Loc-Line hose with a 3/4" ID.

Orifices | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Spray Pattern | Gender | No. of | Dia. | Ht. | Wd. | O'all Lg. | Material | Max. Flow Rate, gph | Max. Pressure, psi | Max. Temp., °F | Pkg. Qty. | Pkg. | |

| 12 | Stream | Female | 1 | 5/8" | __ | __ | 1 45/64" | Acetal Plastic | 1,140 | 10 | 170° | 4 | 00000000 | 00000 |

| 12 | Stream | Female | 1 | 3/4" | __ | __ | 1 45/64" | Acetal Plastic | 1,140 | 10 | 170° | 4 | 00000000 | 0000 |

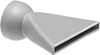

| 13 | Flared Flat | Female | 1 | __ | 3/16" | 3" | 2 3/32" | Acetal Plastic | 1,140 | 10 | 170° | 2 | 00000000 | 0000 |

1/4" Snap-Loc Coolant Hose

Build a custom system to deliver coolant, cutting oil, water, or air in any direction. Once in position, hose stays put—there’s no spring back or movement caused by vibration or heavy flow.

Assemble and disassemble by snapping components together or pulling them apart. Assembly and separation tools (sold separately) are recommended. To ensure compatibility, select the color and trade size that match your current system. These components fit Snap-Loc hose with a 1/4" ID.

Orifices | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Shape | Spray Pattern | Gender | No. of | Dia. | Ht. | Wd. | O'all Lg. | Material | Max. Flow Rate, gph | For Max. SSU Viscosity Grade | Max. Pressure, psi | Max. Temp., °F | Pkg. Qty. | Pkg. | |

| 11 | Straight | Stream | Female | 1 | 1/16" | __ | __ | 1 3/16" | Polypropylene Plastic | 240 | 200 | 39 | 200° | 4 | 0000000 | 00000 |

| 11 | Straight | Stream | Female | 1 | 1/8" | __ | __ | 1 3/16" | Polypropylene Plastic | 240 | 200 | 39 | 200° | 4 | 0000000 | 0000 |

| 11 | Straight | Stream | Female | 1 | 1/4" | __ | __ | 1 3/16" | Polypropylene Plastic | 240 | 200 | 39 | 200° | 4 | 0000000 | 0000 |

| 12 | 90° Elbow | Stream | Female | 1 | 1/8" | __ | __ | 1 5/64" | Polypropylene Plastic | 240 | 200 | 39 | 200° | 2 | 0000000 | 0000 |

| 12 | 90° Elbow | Stream | Female | 1 | 1/4" | __ | __ | 1 5/64" | Polypropylene Plastic | 240 | 200 | 39 | 200° | 2 | 0000000 | 0000 |

| 13 | Straight | Flared Flat | Female | 1 | __ | 3/64" | 15/16" | 1" | Polypropylene Plastic | 240 | 200 | 39 | 200° | 2 | 0000000 | 0000 |

| 14 | 90° Elbow | Multiple Stream | Female | 6 | 1/16" | __ | __ | 1 5/16" | Polypropylene Plastic | 500 | 200 | 30 | 200° | 2 | 0000000 | 0000 |

1/2" Snap-Loc Coolant Hose

Build a custom system to deliver coolant, cutting oil, water, or air in any direction. Once in position, hose stays put—there’s no spring back or movement caused by vibration or heavy flow.

Assemble and disassemble by snapping components together or pulling them apart. Assembly and separation tools (sold separately) are recommended. To ensure compatibility, select the color and trade size that match your current system. These components fit Snap-Loc hose with a 1/2" ID.

Orifices | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Shape | Spray Pattern | Gender | No. of | Dia. | Ht. | Wd. | O'all Lg. | Material | Max. Flow Rate, gph | For Max. SSU Viscosity Grade | Max. Pressure, psi | Max. Temp., °F | Pkg. Qty. | Pkg. | |

| 12 | Straight | Stream | Female | 1 | 1/4" | __ | __ | 1 47/64" | Polypropylene Plastic | 480 | 200 | 19 | 200° | 4 | 0000000 | 00000 |

| 12 | Straight | Stream | Female | 1 | 3/8" | __ | __ | 1 47/64" | Polypropylene Plastic | 480 | 200 | 19 | 200° | 4 | 0000000 | 0000 |

| 12 | Straight | Stream | Female | 1 | 1/2" | __ | __ | 1 47/64" | Polypropylene Plastic | 480 | 200 | 19 | 200° | 4 | 0000000 | 0000 |

| 13 | 90° Elbow | Multiple Stream | Female | 7 | 1/8" | __ | __ | 2 3/16" | Polypropylene Plastic | 2,000 | 200 | 20 | 200° | 2 | 0000000 | 0000 |

| 14 | Straight | Flared Flat | Female | 1 | __ | 1/8" | 2 3/32" | 2" | Polypropylene Plastic | 480 | 200 | 19 | 200° | 2 | 0000000 | 00000 |

3/4" Snap-Loc Coolant Hose

Build a custom system to deliver coolant, cutting oil, water, or air in any direction. Once in position, hose stays put—there’s no spring back or movement caused by vibration or heavy flow.

Assemble and disassemble by snapping components together or pulling them apart. To ensure compatibility, select the color and trade size that match your current system. These components fit Snap-Loc hose with a 3/4" ID.

Orifices | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Spray Pattern | Gender | No. of | Dia. | Ht. | Wd. | O'all Lg. | Material | Max. Flow Rate, gph | For Max. SSU Viscosity Grade | Max. Pressure, psi | Max. Temp., °F | Pkg. Qty. | Pkg. | |

| 6 | Stream | Female | 1 | 5/8" | __ | __ | 1 11/16" | Acetal Plastic | 1,080 | 200 | 9 | 200° | 4 | 0000000 | 00000 |

| 7 | Flared Flat | Female | 1 | __ | 1/8" | 2 29/32" | 3" | Polypropylene Plastic | 1,080 | 200 | 9 | 200° | 2 | 0000000 | 00000 |

1/4" Acid-Resistant Loc-Line Coolant Hose

Use this hose in areas exposed to acids, gasoline, alcohol, and other harsh chemicals. Build a custom system to deliver coolant, cutting oil, water, or air in any direction. Once in position, hose stays put—there’s no spring back or movement caused by vibration or heavy flow.

Assemble and disassemble by snapping components together or pulling them apart. Assembly pliers (sold separately) are recommended. To ensure compatibility, select the color and trade size that match your current system. These components fit Loc-Line hose with a 1/4" ID.

Orifices | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Spray Pattern | Gender | No. of | Dia. | Ht. | Wd. | O'all Lg. | Material | Max. Flow Rate, gph | Max. Pressure, psi | Max. Temp., °F | Pkg. Qty. | Pkg. | |

| 8 | Stream | Female | 1 | 1/16" | __ | __ | 1 11/64" | Polyester Plastic | 250 | 30 | 180° | 4 | 0000000 | 00000 |

| 8 | Stream | Female | 1 | 1/8" | __ | __ | 1 11/64" | Polyester Plastic | 250 | 30 | 180° | 4 | 0000000 | 0000 |

| 8 | Stream | Female | 1 | 1/4" | __ | __ | 1 11/64" | Polyester Plastic | 250 | 30 | 180° | 4 | 0000000 | 0000 |

| 9 | Flared Flat | Female | 1 | __ | 3/64" | 1" | 1" | Polyester Plastic | 250 | 30 | 180° | 2 | 0000000 | 0000 |

| 10 | Multiple Stream | Female | 16 | 3/64" | __ | __ | 1 5/8" | Polyester Plastic | 250 | 30 | 180° | 2 | 0000000 | 00000 |

| 10 | Multiple Stream | Female | 16 | 1/16" | __ | __ | 1 5/8" | Polyester Plastic | 250 | 30 | 180° | 2 | 0000000 | 00000 |

1/2" Acid-Resistant Loc-Line Coolant Hose

Use this hose in areas exposed to acids, gasoline, alcohol, and other harsh chemicals. Build a custom system to deliver coolant, cutting oil, water, or air in any direction. Once in position, hose stays put—there’s no spring back or movement caused by vibration or heavy flow.

Assemble and disassemble by snapping components together or pulling them apart. Assembly pliers (sold separately) are recommended. To ensure compatibility, select the color and trade size that match your current system. These components fit Loc-Line hose with a 1/2" ID.

Orifices | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Spray Pattern | Gender | No. of | Dia. | Ht. | Wd. | O'all Lg. | Material | Max. Flow Rate, gph | Max. Pressure, psi | Max. Temp., °F | Pkg. Qty. | Pkg. | |

| 7 | Stream | Female | 1 | 1/4" | __ | __ | 1 15/32" | Polyester Plastic | 478 | 20 | 180° | 4 | 0000000 | 00000 |

| 7 | Stream | Female | 1 | 3/8" | __ | __ | 1 15/32" | Polyester Plastic | 478 | 20 | 180° | 4 | 0000000 | 0000 |

| 7 | Stream | Female | 1 | 1/2" | __ | __ | 1 15/32" | Polyester Plastic | 478 | 20 | 180° | 4 | 0000000 | 0000 |

| 8 | Flared Flat | Female | 1 | __ | 11/64" | 1 1/4" | 1 1/4" | Polyester Plastic | 478 | 20 | 180° | 2 | 0000000 | 0000 |

Threaded Swivels for Hose Nozzles

To prevent hose from twisting, kinking, and wearing prematurely, these swivels rotate before and after installation as needed. Connect them to the threaded end of your dispensing hose.

Anodized aluminum swivels have good corrosion resistance and are lighter in weight than chrome-plated brass swivels. Chrome-plated brass swivels have comparable corrosion resistance to anodized aluminum swivels, but are softer, so they’re easier to thread together. They have a bright, shiny appearance.

Straight swivels rotate at the female connection point only. They are also known as inline swivels.

| Pipe Size | Connection | Max. Pressure | Temperature Range, °F | Lg. | Each | |

For Use With Gasoline, Hydraulic Fluid, and Coolant | ||||||

|---|---|---|---|---|---|---|

Anodized Aluminum | ||||||

| 1 1/4 × 1 1/4 | Threaded NPT Female × Threaded NPT Male | 150 psi @ 72° F | -65° to 250° | 4 1/2" | 0000000 | 0000000 |

| 1 1/2 × 1 1/2 | Threaded NPT Female × Threaded NPT Male | 150 psi @ 72° F | -65° to 250° | 5" | 0000000 | 000000 |

| 2 × 2 | Threaded NPT Female × Threaded NPT Male | 150 psi @ 72° F | -65° to 250° | 6 3/8" | 0000000 | 000000 |

Chrome-Plated Brass | ||||||

| 1 1/4 × 1 1/4 | Threaded NPT Female × Threaded NPT Male | 150 psi @ 72° F | -65° to 250° | 4 1/2" | 0000000 | 000000 |

| 1 1/2 × 1 1/2 | Threaded NPT Female × Threaded NPT Male | 150 psi @ 72° F | -65° to 250° | 5" | 0000000 | 000000 |

| 2 × 2 | Threaded NPT Female × Threaded NPT Male | 150 psi @ 72° F | -65° to 250° | 6 3/8" | 0000000 | 000000 |

Container | |||||

|---|---|---|---|---|---|

| Size, fl. oz. | Type | Max. Pressure for Fluids, psi | Temp. Range, °F | Each | |

For Use With Gasoline, Diesel Fuel, Hydraulic Oil, and Coolant | |||||

| 4 | Brush-Top Can | 10,000 | -100° to 600° | 00000000 | 000000 |

Barbed Swivels for Hose Nozzles

Slide the barbed end of these swivels into your dispensing hose and connect with a clamp. They rotate before and after installation as needed to prevent hose from twisting, kinking, and wearing prematurely. They are also known as inline swivels. Swivels are anodized aluminum, which is lightweight with good corrosion resistance.

Anodized Aluminum | |||||||

|---|---|---|---|---|---|---|---|

| For Hose ID | Pipe Size | Connection | Max. Pressure | Temperature Range, °F | Lg. | Each | |

For Use With Gasoline, Hydraulic Fluid, and Coolant | |||||||

| 1" | 1 | Barbed Male × Threaded NPT Male | 150 psi @ 72° F | -65° to 250° | 2 13/16" | 0000000 | 000000 |

| 1 1/4" | 1 1/4 | Barbed Male × Threaded NPT Male | 150 psi @ 72° F | -65° to 250° | 3 7/8" | 0000000 | 000000 |

| 1 1/2" | 1 1/2 | Barbed Male × Threaded NPT Male | 150 psi @ 72° F | -65° to 250° | 4 1/8" | 0000000 | 000000 |

| 2" | 2 | Barbed Male × Threaded NPT Male | 150 psi @ 72° F | -65° to 250° | 4 11/16" | 0000000 | 000000 |

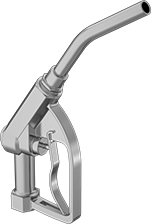

Coolant Hose Nozzles

Dispense and control the flow of coolant with these nozzles. They have a built-in check valve to reduce spillage when withdrawing the nozzle from the tank. Nozzles shut off manually, so you’ll have to release the trigger to stop the flow. They are brass for good corrosion resistance.

Warning: Do not leave nozzles unattended when in use.