Fixturing for Parts Inspection

From towers and brackets to standoffs and supports, these components are the building blocks for your custom fixturing setup. They elevate parts so you can access a variety of angles for measuring and inspecting while protecting your measuring device from hitting the inspection table. You’ll often see them used with coordinate measuring machines (CMMs). They’re not for use in machining applications.

For technical drawings and 3-D models, click on a part number.

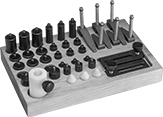

Kits come with a base set of clamps, standoffs, and other supports for positioning parts. Add other components, such as magnetic V-supports, to expand your starter toolkit for complex setups.

| Number of Pieces | Includes | Each | |

1/4"-20 Thread Size | |||

|---|---|---|---|

| 43 | 3 Hold-Down Clamps—1 9/16" Reach × 3" O'all Ht. 3 Hold-Down Clamps—2 5/16" Reach × 3" O'all Ht. 3 Standoffs—1/2" Dia. × 3/4" Ht. 3 Standoffs—1/2" Dia. × 2" Ht. 3 Standoffs—3/4" Dia. × 3/4" Ht. 3 Standoffs—3/4" Dia. × 2" Ht. 6 Standoffs—1/2" Dia. × 1" Ht. 6 Standoffs—3/4" Dia. × 1" Ht. 3 Pin Supports—1/2" Dia. × 1/2" Ht. 3 Pin Supports—3/4" Dia. × 1/2" Ht. 3 Cone Supports 1 Adjustable-Height Sleeve for Standoffs 2 Positioning Plates 1 Wood Stand | 0000000 | 0000000 |

| 63 | 3 Hold-Down Clamps—1 9/16" Reach × 3" O'all Ht. 3 Hold-Down Clamps—2 5/16" Reach × 3" O'all Ht. 2 Toggle Clamps with Mounting Plate 3 Standoffs—1/2" Dia. × 3/4" Ht. 3 Standoffs—1/2" Dia. × 2" Ht. 3 Standoffs—3/4" Dia. × 3/4" Ht. 3 Standoffs—3/4" Dia. × 2" Ht. 3 Standoffs—1" Dia. × 3/4" Ht. 3 Standoffs—1" Dia. × 2" Ht. 6 Standoffs—1/2" Dia. × 1" Ht. 6 Standoffs—3/4" Dia. × 1" Ht. 6 Standoffs—1" Dia. × 1" Ht. 1 Precision Adjustable-Height Standoff—1/2" Dia. 3 Pin Supports—1/2" Dia. × 1/2" Ht. 3 Pin Supports—3/4" Dia. × 1/2" Ht. 6 Cone Supports 2 Any-Angle Cone Supports 1 Adjustable-Height Sleeve for Standoffs 2 Positioning Plates 1 Wood Stand | 0000000 | 00000000 |

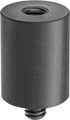

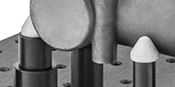

Standoffs raise the height of towers and angle brackets or extend the reach of supports and clamps. Screw them into one another for added length. Standoffs with adjustable height have a thumb screw to raise and lower components with precision.

| Dia. | Ht. | Thread Lg. | Material | Each | |

1/4"-20 Thread Size | |||||

|---|---|---|---|---|---|

Fixed Height | |||||

| 1/2" | 1/2" | 1/4" | Steel | 0000000 | 000000 |

| 1/2" | 3/4" | 1/4" | Steel | 0000000 | 00000 |

| 1/2" | 1" | 1/4" | Steel | 0000000 | 00000 |

| 1/2" | 2" | 1/4" | Steel | 0000000 | 00000 |

| 1/2" | 3" | 1/4" | Steel | 0000000 | 00000 |

| 3/4" | 1/2" | 1/4" | Steel | 0000000 | 00000 |

| 3/4" | 3/4" | 1/4" | Steel | 0000000 | 00000 |

| 3/4" | 1" | 1/4" | Steel | 0000000 | 00000 |

| 3/4" | 2" | 1/4" | Steel | 0000000 | 00000 |

| 3/4" | 3" | 1/4" | Steel | 0000000 | 00000 |

| 1" | 1/2" | 1/4" | Steel | 0000000 | 00000 |

| 1" | 3/4" | 1/4" | Steel | 0000000 | 00000 |

| 1" | 1" | 1/4" | Steel | 0000000 | 00000 |

| 1" | 2" | 1/4" | Steel | 0000000 | 00000 |

| 1" | 3" | 1/4" | Steel | 0000000 | 00000 |

Adjustable Height | |||||

| 1/2" | 1 7/16"-1 3/4" | 1/4" | Aluminum | 0000000 | 00000 |

Pin supports prop up your workpiece in two places, unlike standoffs and cone supports. Thread them horizontally into an angle bracket so the lip of a part, such as a flange, sits on the pin while the rest sits on the body. They’re especially helpful when you need to measure workpieces from underneath.

Magnetic supports securely raise and hold metal parts, no clamps required.

| Dia. | Ht. | Thread Lg. | Max. Magnetic Pull, lbs. | Material | Each | |

1/4"-20 Thread Size | ||||||

|---|---|---|---|---|---|---|

| 1/2" | 1" | 1/4" | 9 | Steel | 0000000 | 000000 |

Magnetic V-supports have a notch to cradle metal cylindrical workpieces, like a spoon rest.

| Dia. | Ht. | V Wd. | V Dp. | V Angle | Thread Lg. | Max. Magnetic Pull, lbs. | Material | Each | |

1/4"-20 Thread Size | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1" | 1" | 1" | 1/4" | 120° | 1/4" | 16 | Steel | 0000000 | 0000000 |

Cone supports have a round pointed tip to minimize contact with your workpiece, so they’re often used to prop up delicate parts. They’re also useful for parts with irregular surfaces that slide off larger supports. Made of plastic, they’re nonmarring.

| Dia. | Ht. | Thread Lg. | Material | Each | |

1/4"-20 Thread Size | |||||

|---|---|---|---|---|---|

| 5/8" | 1/2" | 1/4" | Acetal Plastic | 0000000 | 000000 |

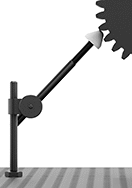

Cone supports have a round pointed tip to minimize contact with your workpiece, so they’re often used to prop up delicate parts. They’re also useful for parts with irregular surfaces that slide off larger supports. Made of plastic, they’re nonmarring. Any-angle cone supports have an arm that extends, retracts, and rotates 360°.

| Arm Lg. | Body Lg. | Arm Rotation | Thread Lg | Body Material | Cone Material | Each | |

1/4"-20 Thread Size | |||||||

|---|---|---|---|---|---|---|---|

| 4 1/4" | 4" | 360° | 1 1/8" | Steel | Acetal Plastic | 0000000 | 000000 |

Adjustable-height sleeves convert standoffs with a fixed height into standoffs with an adjustable height. Slide them over your 1/2" diameter standoff and move the sleeve up or down to set your desired height. Lock them in place with the thumb screw.

| For Standoff Dia. | Dia. | Ht. | Material | Includes | Each | |

1/4"-20 Thread Size | ||||||

|---|---|---|---|---|---|---|

| 1/2" | 1 1/8" | 2" | Acetal Plastic | 1/4"-20 Knurled Knob | 0000000 | 000000 |

Trays have slots to store and organize standoffs, supports, and other small components.

| Lg. | Wd. | Ht. | Material | Each | |

For 1/4"-20 Thread Size | |||||

|---|---|---|---|---|---|

| 17" | 8" | 1" | Acetal Plastic | 0000000 | 0000000 |

Clamps for Parts Inspection

With a light yet sturdy hold, these clamps help you keep workpieces in place hands-free for measuring and inspecting. Thread them right into your fixturing surface, whether it’s a plate, tower, or table. Because they apply less pressure than machining clamps, they won’t distort your parts, so you can take accurate measurements. While these clamps aren’t sturdy enough for use in machining, you can still use them for light fabrication work, such as laser engraving.

Hold-down clamps secure parts from the top.

Tension spring clamps are the most common type of clamp. Slide the arm down the shaft until it touches the top of your workpiece. Since you apply pressure directly, using too much force might move your part. Clamps with a rubber-coated tip are less likely to scrape parts than clamps with an uncoated tip.

Wire tension spring clamps have a slimmer profile than standard clamps, which means they don’t cover up as much of your workpiece. They’re often used to clamp small parts. Pull the wire arm away from the shaft, position your part, then release the arm so it moves back to cradle your part in place.

Clamps with a thumb screw give you more control over the pressure you apply on a workpiece than tension spring clamps. Twisting the screw moves the clamp up or down in small increments, so they’re less likely to dent or scratch your workpiece. The knurled head on the screw is slip resistant, letting you make precise turns with reliable grip.

Clamps with squeeze tabs on the back are best for supporting delicate parts. They have the lightest touch of any clamps we offer, because the tension is held in the tabs rather than the clamp itself. Press the tabs together like a clothespin and rotate the clamp where you need it.

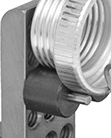

Side clamps don’t block access to the top of your workpiece like hold-down clamps. They push one side of your workpiece against another barrier, such as a standoff, support, or corner plate. Made of durable yet flexible plastic, the outer edge of the clamp slightly contracts when you pull the circular trigger—like drawing a bow.

Positioning clamps give you the most flexible setup of any clamps. They’re the best choice for curved or irregular shapes, such as cylinders. Both sliding pins on each arm have an O-ring that compresses when you push them tight against a workpiece. The O-ring cushions the pressure you apply, and it also gives grip while protecting parts from scratches. With an arm that rotates 360°, you can create movable supports. These clamps also have a magnetic flange to help secure metal parts.

For technical drawings and 3-D models, click on a part number.

Clamps | Replacement Mounting Shafts | Replacement Clamp Arms | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Reach | Ht. | Thread Lg. | Material | Tip Finish | Each | Each | Each | |||

Tension Spring | ||||||||||

1/4"-20 Thread Size | ||||||||||

| 13/16" | 1" | 1/4" | Aluminum | __ | 0000000 | 000000 | 000000 | 00 | 000000 | 00 |

| 13/16" | 2" | 1/4" | Aluminum | __ | 0000000 | 00000 | 000000 | 00 | 000000 | 00 |

| 1 9/16" | 2 3/4" | 1/4" | Aluminum | __ | 0000000 | 00000 | 000000 | 00 | 000000 | 00 |

| 1 9/16" | 2 3/4" | 1/4" | Aluminum | Rubber Coated | 0000000 | 00000 | 000000 | 00 | 000000 | 00 |

| 2 5/16" | 2 3/4" | 1/4" | Aluminum | __ | 0000000 | 00000 | 000000 | 00 | 000000 | 00 |

| 2 5/16" | 2 3/4" | 1/4" | Aluminum | Rubber Coated | 0000000 | 00000 | 000000 | 00 | 000000 | 00 |

| 3 7/16" | 3" | 1/4" | Aluminum | __ | 0000000 | 00000 | 000000 | 00 | 000000 | 00 |

Wire Tension Spring | ||||||||||

1/4"-20 Thread Size | ||||||||||

| 1 1/4" | 1" | 1/4" | Aluminum | __ | 0000000 | 00000 | 000000 | 00 | 000000 | 00 |

| 2" | 2" | 1/4" | Aluminum | __ | 0000000 | 00000 | 000000 | 00 | 000000 | 00 |

Thumb Screw | ||||||||||

1/4"-20 Thread Size | ||||||||||

| 1 9/16" | 1 1/2" | 3/8" | Aluminum | __ | 0000000 | 00000 | 000000 | 00 | 000000 | 00 |

| 3" | 2 1/2" | 1/4" | Aluminum | __ | 0000000 | 00000 | 000000 | 00 | 000000 | 00 |

| 4 3/8" | 3 1/2" | 3/8" | Aluminum | __ | 0000000 | 000000 | 000000 | 00 | 000000 | 00 |

Squeeze Tabs | ||||||||||

1/4"-20 Thread Size | ||||||||||

| 3 1/4" | 3" | 3/8" | Plastic | __ | 0000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 |

| Lg. | Wd. | Ht. | Thread Lg. | Material | Each | |

1/4"-20 Thread Size | ||||||

|---|---|---|---|---|---|---|

| 3 1/16" | 2 5/8" | 1/2" | 3/4" | Plastic | 0000000 | 000000 |

Opening | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Reach | Min. | Max. | Lg. | Wd. | Ht. | Thread Lg. | Material | Pair | |

1/4"-20 Thread Size | |||||||||

| 3/4" | 7/16" | 2 3/4" | 3 5/8" | 9/16" | 2 1/2" | 1/4" | Aluminum | 0000000 | 0000000 |

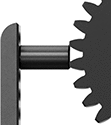

Threaded Hole Location Gauges

Find the true center of threaded holes to precisely align and measure parts. Once you thread these gauges into a hole, their cylinder sticks out as a reliable reference point. They’re often used with a coordinate measuring machine (CMM) to pinpoint the coordinates of the cylinder’s exact center. You can then use those coordinates to measure distances between points or reference them for error-free assembly. Even without a CMM, you can use these gauges with a micrometer to measure accurate center-to-center distances.

For technical drawings and 3-D models, click on a part number.

| Thread Size | Thread Type | Hardness | Material | Each | |

| 1/4"-20 | UNC | Rockwell C60 | Tool Steel | 0000000 | 0000000 |