Fixturing for Parts Inspection

From towers and brackets to standoffs and supports, these components are the building blocks for your custom fixturing setup. They elevate parts so you can access a variety of angles for measuring and inspecting while protecting your measuring device from hitting the inspection table. You’ll often see them used with coordinate measuring machines (CMMs). They’re not for use in machining applications.

For technical drawings and 3-D models, click on a part number.

Cone supports have a round pointed tip to minimize contact with your workpiece, so they’re often used to prop up delicate parts. They’re also useful for parts with irregular surfaces that slide off larger supports. Made of plastic, they’re nonmarring.

| Dia. | Ht. | Thread Lg. | Material | Each | |

M8 × 1.25 mm Thread Size | |||||

|---|---|---|---|---|---|

| 16mm | 13mm | 7.7mm | Nylon Plastic | 0000000 | 000000 |

Trays have slots to store and organize standoffs, supports, and other small components.

| Lg. | Wd. | Ht. | Material | Each | |

For M8 Thread Size | |||||

|---|---|---|---|---|---|

| 432mm | 203mm | 25mm | Acetal Plastic | 0000000 | 0000000 |

Clamps for Parts Inspection

With a light yet sturdy hold, these clamps help you keep workpieces in place hands-free for measuring and inspecting. Thread them right into your fixturing surface, whether it’s a plate, tower, or table. Because they apply less pressure than machining clamps, they won’t distort your parts, so you can take accurate measurements. While these clamps aren’t sturdy enough for use in machining, you can still use them for light fabrication work, such as laser engraving.

Hold-down clamps secure parts from the top.

Tension spring clamps are the most common type of clamp. Slide the arm down the shaft until it touches the top of your workpiece. Since you apply pressure directly, using too much force might move your part.

For technical drawings and 3-D models, click on a part number.

Threaded Hole Location Gauges

Find the true center of threaded holes to precisely align and measure parts. Once you thread these gauges into a hole, their cylinder sticks out as a reliable reference point. They’re often used with a coordinate measuring machine (CMM) to pinpoint the coordinates of the cylinder’s exact center. You can then use those coordinates to measure distances between points or reference them for error-free assembly. Even without a CMM, you can use these gauges with a micrometer to measure accurate center-to-center distances.

For technical drawings and 3-D models, click on a part number.

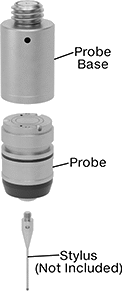

Modular Probes for CMMs

Swap out Renishaw probe styles to inspect different features on a part without having to recalibrate. These probes mount magnetically to a base that threads into your coordinate measuring machine (CMM), making mid-inspection changes quick. They’re also known as modules. It’s easy to tell different styles apart from their different end colors. To take 3D measurements, they record the coordinates of different points on your workpiece. Because this involves physically touching your workpiece, they’re more accurate than other automated measurement systems. They’re touch-trigger probes, the most common CMM probe type, which means they stop to record the coordinates of one point at a time. Use them to check distances, diameters, right angles, and the location of holes and grooves. However, they're not as good at checking complex features, flatness, or roundness.

All probes require a stylus as well as a base (sold separately for some probes).

Trigger force is the amount of force required for a probe to take a measurement and record it. Choose a probe with a force that is high enough to avoid false triggers from vibration but not so high it damages the workpiece and leads to inaccurate measurements.

SF series probes have a trigger force that works for most general purpose probing jobs where vibration is not an issue.

Bases house the system that sends a signal to record a measurement. They thread onto probe heads with an M8 connection on your CMM. TP20 probe bases have a magnetic proximity switch to prevent a probe from accidentally triggering when you’re attaching it or detaching it. However, probes attached to these bases can’t be used to inspect magnetic parts. TP20 NI probe bases aren’t affected by magnetic fields, so they can be used to inspect magnetic parts. However, because they don’t have a magnetic proximity switch, you’ll need to program your CMM to stop taking measurements when you’re changing out probes.

Installation tools make it easier to thread a probe base onto your CMM.

For technical drawings and 3-D models, click on a part number.

For Stylus | Trigger Force, N | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Pieces | Includes | Dia., mm | Thread Size | O'all Lg., mm | For Axis Measuring Direction | X- and Y-Axis | Z-Axis | End Color | Features | Manufacturer (Series) | Each | |

| 3 | Two 20 mm Lg. SF Probes One 19 mm Lg. TP20 Probe Base | 13 | M2 | 10-50 | ±X, ±Y, +Z | 0.08 | 0.75 | Black | Magnetic Proximity Switch | Renishaw (SF, TP20) | 0000000 | 000000000 |

| For Probe Manufacturer Series | Manufacturer | Manufacturer Model Number | Each | |

| TP20, TP20 NI | Renishaw | A-1042-1486 | 0000000 | 000000 |