About Shaft Collars

Shaft collars are useful for holding and positioning components on a shaft. They can also serve as mechanical stops and stroke limiters.

More

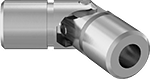

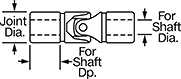

Single U-Joints

Connect and transfer torque between two shafts that are misaligned at an angle. Your shafts’ misalignment will affect the speed and torque these U-joints will be able to transmit. The more the shafts are misaligned, the less speed and torque they’ll be able to transmit.

Pin-and-block U-joints handle higher torque at lower speeds than other joint types such as those with needle bearings, making them a good choice for most applications. To extend their life by keeping lubricant in and contaminants out, use the grooves on their body to add a cover (sometimes called bellows or boots).

Steel U-joints are strong and handle more torque than zinc U-joints.

U-joints for keyed shafts connect to shafts with set screws. Unlike U-joints that use spring pins, there’s no drilling required.

For Shaft | Torque | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Dp. | Joint Dia. | Overall Lg. | Max. Operating Angle | Max. Speed, rpm | Max. Torque, in.-lbs. | 3° Operating Angle | 10° Operating Angle | Shaft Mount Type | Each | |

Pin-and-Block Joint | |||||||||||

Steel—For Keyed Shafts | |||||||||||

| 1 13/16" | 2 3/4" | 3" | 9 1/16" | 25° | 1,750 | 65,400 | 5,750 in.-lbs. @ 300 rpm | 1,940 in.-lbs. @ 300 rpm | Set Screw | 0000000 | 000000000 |

Clamping Shaft Collars

These metal collars are stronger than plastic shaft collars. They clamp evenly around the shaft to create a strong, mar-free hold. To use, slide onto your shaft and tighten the clamping screw to secure.

Black-oxide steel collars have some corrosion resistance.

Clamping Screw | ||||||

|---|---|---|---|---|---|---|

| For Shaft Dia. | OD | Wd. | Type | No. Included | Each | |

Black-Oxide 1215 Carbon Steel | ||||||

| 1 13/16" | 2 7/8" | 11/16" | Socket Head Screw | 1 | 0000000 | 000000 |

Set Screw Shaft Collars

Keep these shaft collars in place by tightening their set screw into the shaft. The tip of the screw digs in for a secure hold, but will mar the shaft’s surface. For maximum holding power, make sure the set screw material is harder than your shaft material. Use these shaft collars to position and retain power transmission components such as sprockets, pulleys, and bearings. You can also use them to limit the movement of a shaft.

Carbon steel collars are strong and wear resistant. Collars with a black-oxide finish have some corrosion resistance, but only in dry environments. Their dark color can be useful for matching other parts in your system. Collars with a zinc-plated finish have an outer layer of zinc that protects the steel from rust and extends the life of the collar. Aluminum collars are lightweight and have good corrosion resistance.

Clamping Two-Piece Shaft Collars

These metal collars are stronger than plastic shaft collars. The two-piece design allows you to install them anywhere on a shaft without removing components or having access to the ends of the shaft. Collars clamp evenly around the shaft to create a strong, mar-free hold. Tighten the clamping screws to secure.

Black-oxide steel collars have some corrosion resistance. Aluminum collars are lightweight and have good corrosion resistance. 303 stainless steel collars have excellent corrosion resistance.