About Shaft Collars

Shaft collars are useful for holding and positioning components on a shaft. They can also serve as mechanical stops and stroke limiters.

More

About Shaft Couplings

More

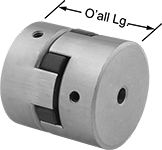

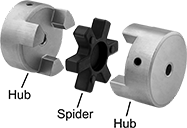

Set Screw Flexible Shaft Couplings

Each hub includes a set screw (unless noted), which bites into your shaft to hold the coupling in place. Also known as Lovejoy® couplings, these three-piece couplings have a spider-shaped cushion between two hubs to reduce shock and handle minor shaft misalignment.

Buna-N spiders provide good vibration damping and chemical resistance. Hytrel spiders provide fair vibration damping and excellent chemical resistance.

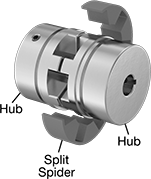

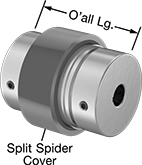

High-Torque Set Screw Flexible Shaft Couplings

The thick split spider on these couplings takes on twice as much torque as standard split spiders, while a set screw holds the hubs in place on your shaft. Also known as jaw couplings, use them to connect motors to pumps, mixers, and other high-torque equipment. You don’t need to lubricate them.

For a complete coupling, you’ll need two hubs, one split spider, and a split spider cover (all sold separately).

Hubs attach to the end of your shaft.

Split spiders cushion between the two hubs to dampen vibration, reduce shocks, and handle shaft misalignment, extending the life of bearings, seals, and motors. You can replace them without having to remove the hubs or move your shaft and equipment around, which reduces the risk of needing to realign the shaft. Spiders with medium-soft hardness are the most commonly used and are good for applications that start, stop, and reverse often. Those with medium hardness handle higher torque than those with medium-soft hardness, but they don’t reduce vibration as well.

Split spider covers hold the spider in place.

Urethane Split Spiders | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Steel Hubs | Misalignment Capability | Steel Split Spider Covers | |||||||||||||

| Overall Lg. | OD | For Motion Type | For Shaft Dia. | Each | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Temp. Range, °F | Color | Each | Each | |||

| 6 1/16" | 3 33/64" | Forward/Reverse, Start/Stop | 2 1/4" | 000000 | 0000000 | 6,000 | 7,065 | 0.038" | 2° | -60° to 212° | Red | 0000000 | 000000 | 0000000 | 0000000 |

Urethane Split Spiders | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Steel Hubs | Misalignment Capability | Steel Split Spider Covers | |||||||||||||

| Overall Lg. | OD | For Motion Type | For Shaft Dia. | Each | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Temp. Range, °F | Color | Each | Each | |||

| 6 1/16" | 3 33/64" | Forward/Reverse, Start/Stop | 2 1/4" | 000000 | 0000000 | 6,000 | 14,000 | 0.038" | 2° | -60° to 212° | Blue | 0000000 | 000000 | 0000000 | 0000000 |

Urethane Split Spiders | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Steel Hubs | Misalignment Capability | Steel Split Spider Covers | |||||||||||||

| Overall Lg. | OD | For Motion Type | For Shaft Dia. | Each | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Temp. Range, °F | Color | Each | Each | |||

| 6 1/16" | 3 33/64" | Forward/Reverse, Start/Stop | 2 1/4" | 000000 | 0000000 | 6,000 | 14,000 | 0.038" | 2° | -60° to 350° | White | 0000000 | 0000000 | 0000000 | 0000000 |

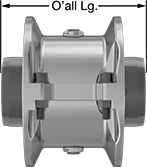

Shock-Absorbing Flexible Shaft Couplings

A strip of flexible spring steel wraps around the teeth of both hubs to absorb sharp, momentary load increases that can come from motor startups, emergency braking, or sudden impact with hard objects. When the shock load hits, the strip of spring steel (known as a grid) flexes to spread out the load. After the load passes, the grid straightens back out. They're commonly found in wire drawing and cutting machines, pulverizers, and mixers. Compared to spider couplings, jaw couplings, and other flexible shaft couplings, these handle higher torque while taking up less space. All have keyed bores to work with keyed shafts, which transmit higher torque with less slippage than round shafts.

A complete coupling consists of two hubs as well as a grid and cover assembly (all sold separately). The grid and cover assembly includes a spring steel grid, aluminum cover, rubber seals, and grease for lubrication. When ordering, please choose components that have the same manufacturer series number, otherwise the grid will not fit.

Grid and Cover Assemblies | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Hubs | Misalignment Capability | Replacement Grids | Replacement Seal Kits | |||||||||||||

| O'all Lg. | OD | For Motion Type | Mfr. Series | For Shaft Dia. | Each | Parallel | Angular | Max. Speed, rpm | Max. Torque, in.-lbs. | Each | Each | Each | ||||

Black-Oxide Steel | ||||||||||||||||

For Keyed Shaft | ||||||||||||||||

| 7 7/8" | 6 11/32" | Continuous, Forward/Reverse, Start/Stop | Martin (1090T) | 2 1/4" | 000000 | 0000000 | 0.016" | 0.25° | 3,600 | 33,000 | 00000000 | 0000000 | 00000000 | 0000000 | 00000000 | 000000 |

| Additional Grease (14 fl. oz. Grease Gun Cartridge) | 0000000 | Each | 000000 |

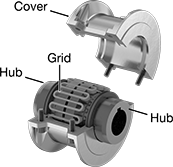

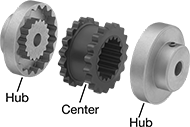

High-Speed Vibration-Damping Flexible Shaft Couplings

Use these gear-shaped couplings for high-speed and high-torque applications. A rubber center allows flexing so couplings can take on multiple types of misalignment while damping vibration and shock. With no metal-to-metal contact, there’s no need for lubrication. Fasten to your shafts by tightening the set screws, which bite into the shaft to hold it.

A complete coupling consists of two hubs and one center (each component sold separately).

Hubs have a keyway, except hubs for 1/4" and 3/8" shaft dia. do not have a keyway.

Centers | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Hubs | Misalignment Capability | ||||||||||||||

| O'all Lg. | OD | For Motion Type | Material | For Shaft Dia. | Each | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Axial | Temp. Range, °F | Material | Each | ||

| 4 7/16" | 5 29/64" | Continuous | Cast Iron | 2 1/4" | 0000000 | 000000 | 4,500 | 1,135 | 0.02" | 1° | 0.125" | -30° to 275° | TPE Rubber | 0000000 | 000000 |

| 5 11/16" | 7 1/2" | Continuous | Cast Iron | 2 1/4" | 000000 | 000000 | 3,600 | 2,875 | 0.025" | 1° | 0.125" | -30° to 275° | TPE Rubber | 0000000 | 000000 |

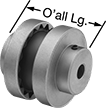

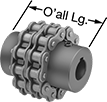

High-Torque Flexible Shaft Couplings

With a rugged roller-chain design, these couplings provide excellent torque and angular misalignment capacities. Lubrication is required. Fasten to your shaft by tightening the set screws, which bite into the shaft to hold it.

A complete coupling consists of two hubs and one roller chain (each component sold separately). Complete couplings meet ANSI B29.23M-1995.

Optional covers retain grease lubrication and provide protection from abrasion and corrosion.

Steel Roller Chain | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Steel Hubs | Misalignment Capability | Roller Chain | Orange Nylon Plastic Covers | |||||||||||||

| O'all Lg. | OD | OD with Cover | For Motion Type | For Shaft Dia. | Each | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | No. | Standard | Each | Each | |||

| 3 29/64" | 5" | 6 3/8" | Continuous | 2 1/4" | 0000000 | 000000 | 3,000 | 10,900 | 0.012" | 1.5° | 60-2 | ANSI | 0000000 | 000000 | 0000000 | 0000000 |

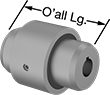

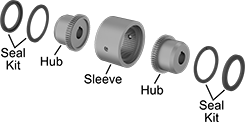

Ultra-High-Torque Flexible Shaft Couplings

With a rigid gear design, these steel couplings transmit more torque than other couplings of the same size. Lubrication is required. To install, heat the hubs to expand them slightly and fit them onto the shaft. When they cool, hubs shrink to fit the shaft tightly.

A complete coupling consists of two hubs, one sleeve, and one seal kit (each component sold separately).

Steel Sleeves | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Steel Hubs | Misalignment Capability | Seal Kits | |||||||||||||

| O'all Lg. | OD | For Motion Type | For Shaft Dia. | Each | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Axial | Each | Includes | Each | |||

| 4 3/4" | 5 1/2" | Continuous | 2 1/4" | 0000000 | 0000000 | 3,750 | 30,200 | 0.007" | 1° | 0.05" | 0000000 | 0000000 | Two Buna-N Rubber Lubrication Seals, Two Steel Snap Rings | 0000000 | 0000000 |

High-Grip Clamping Shaft Couplings

These couplings have the gripping strength to handle higher torque than most other couplings. Couplings clamp evenly around the shaft to create a mar-free hold. Slide onto the end of your shaft and tighten the clamping screws to secure. Good for high-torque applications, rigid couplings connect two shafts that are aligned, allowing for no relative movement between the shafts.

| For Shaft Dia. | Overall Lg. | OD | Max. Speed, rpm | Max. Torque, in.-lbs. | For Motion Type | Each | |

Steel | |||||||

|---|---|---|---|---|---|---|---|

For Round Shafts | |||||||

| 2 1/4" | 6 1/2" | 3 3/4" | 3,500 | 12,320 | Forward/Reverse, Start/Stop, Continuous | 000000 | 0000000 |

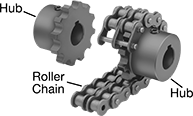

Two-Piece Shaft Coupling Bridges

When your shafts are not close enough to use standard couplings, these have the length to bridge the gap. Install them anywhere on a shaft without removing components or having access to the ends of the shaft. Tighten the clamping screws to secure. Good for high-torque applications, rigid couplings connect two shafts that are aligned, allowing for no relative movement between the shafts.

| For Shaft Dia. | Overall Lg. | OD | Max. Speed, rpm | Max. Torque, in.-lbs. | For Motion Type | Each | |

Cast Iron | |||||||

|---|---|---|---|---|---|---|---|

For Keyed Shafts | |||||||

| 2 1/4" | 9 5/16" | 5 3/4" | 3,180 | 12,000 | Forward/Reverse, Start/Stop, Continuous | 0000000 | 0000000 |

High-Grip Two-Piece Shaft Couplings

These couplings have the gripping strength to handle higher torque than most other couplings. Install them anywhere on a shaft without removing components or having access to the ends of the shaft. Tighten the clamping screws to secure. Good for high-torque applications, rigid couplings connect two shafts that are aligned, allowing for no relative movement between the shafts.

| For Shaft Dia. | Overall Lg. | OD | Max. Speed, rpm | Max. Torque, in.-lbs. | For Motion Type | Each | |

Steel | |||||||

|---|---|---|---|---|---|---|---|

For Round Shafts | |||||||

| 2 1/4" | 6 1/2" | 3 3/4" | 3,500 | 14,795 | Forward/Reverse, Start/Stop, Continuous | 0000000 | 0000000 |

Keyless Locking Shaft Couplings for Overhung Loads

Support the weight of a motor and transfer torque to another shaft at the same time with these couplings. Often used to hang motors from conveyor belts and other driven equipment, or to connect long sections of shafts, these couplings eliminate the need for support brackets. Use a torque arm to prevent hanging motors from spinning.

The clamping screws on the coupling face squeeze two outer collars against an inner ring, pressing it tight against shafts to lock them together. This ring-locking mechanism leaves no room for backlash, meaning that all of the turning force created by the motor is passed on to the second shaft. These couplings grip shafts of any shape, so you can install them onto existing keyways and splines without using a key.

To install these couplings, use a torque wrench to tighten each screw to the fastener tightening torque listed for each coupling size. To remove, gradually loosen each screw in sequence until you can slide the coupling on the shaft. Warning: Do not remove any clamping screws from the coupling until the outer collars are separated from the inner ring. The ring is under tension, and a sudden release of the collars can cause serious injury.

Overhung load capacity is the amount of downward force that a coupling can withstand from a motor or other object that it is supporting. To calculate the overhung load, measure the distance from the center of the coupling to the center of gravity of the motor. Multiply that distance by the combined weight of the motor and the portion of the shaft between the coupling and the motor. Do not exceed the overhung load capacity for a coupling.

| For Shaft Dia. | Overall Lg. | OD | Max. Speed, rpm | Max. Torque, in.-lbs. | Fastener Tightening Torque, in.-lbs. | Overhung Load Cap., in.-lbs. | For Motion Type | Each | |

Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 2 1/4" | 3 1/16" | 4 3/4" | 7,500 | 44,135 | 264 | 11,030 | Forward/Reverse, Start/Stop, Continuous | 0000000 | 0000000 |

Clamping Shaft Collars

These metal collars are stronger than plastic shaft collars. They clamp evenly around the shaft to create a strong, mar-free hold. To use, slide onto your shaft and tighten the clamping screw to secure.

Black-oxide steel collars have some corrosion resistance. Zinc-plated steel collars have moderate corrosion resistance. Aluminum collars are lightweight and have good corrosion resistance. 303 stainless steel collars have excellent corrosion resistance. 316 stainless steel collars have excellent corrosion and chemical resistance.

Clamping Screw | ||||||

|---|---|---|---|---|---|---|

| For Shaft Dia. | OD | Wd. | Type | No. Included | Each | |

Black-Oxide 1215 Carbon Steel | ||||||

| 2 1/4" | 3 1/4" | 3/4" | Socket Head Screw | 1 | 0000000 | 000000 |

Zinc-Plated 1215 Carbon Steel | ||||||

| 2 1/4" | 3 1/4" | 3/4" | Socket Head Screw | 1 | 0000000 | 00000 |

2024 Aluminum | ||||||

| 2 1/4" | 3 1/4" | 3/4" | Socket Head Screw | 1 | 0000000 | 00000 |

303 Stainless Steel | ||||||

| 2 1/4" | 3 1/4" | 3/4" | Socket Head Screw | 1 | 0000000 | 000000 |

316 Stainless Steel | ||||||

| 2 1/4" | 3 1/4" | 3/4" | Socket Head Screw | 1 | 0000000 | 000000 |

Extra-Grip Clamping Shaft Collars

With larger clamping screws than those found on standard clamping collars, these provide a stronger grip on your shaft without using additional screws. They clamp evenly around the shaft to create a strong, mar-free hold. To use, slide onto your shaft and tighten the clamping screw to secure. Collars are black-oxide steel, which offers some corrosion resistance.

Clamping Screw | Black-Oxide 1026 Carbon Steel | |||||

|---|---|---|---|---|---|---|

| For Shaft Dia. | OD | Wd. | Type | No. Included | Each | |

| 2 1/4" | 3 3/4" | 3/4" | Socket Head Screw | 1 | 0000000 | 000000 |

Quick-Release Clamping Shaft Collars

Installing and removing a collar is as easy as pushing down and lifting up a clamp lever. Collars clamp evenly around the shaft to create a strong, mar-free hold. All have a clamping screw to adjust lever tension. Made of anodized aluminum, they are lightweight with good corrosion resistance.

Clamping Screw | Black Anodized 6061 Aluminum | |||||

|---|---|---|---|---|---|---|

| For Shaft Dia. | OD | Wd. | Type | No. Included | Each | |

| 2 1/4" | 4 3/4" | 3/4" | Socket Head Screw | 1 | 00000000 | 0000000 |

Set Screw Shaft Collars

Keep these shaft collars in place by tightening their set screw into the shaft. The tip of the screw digs in for a secure hold, but will mar the shaft’s surface. For maximum holding power, make sure the set screw material is harder than your shaft material. Use these shaft collars to position and retain power transmission components such as sprockets, pulleys, and bearings. You can also use them to limit the movement of a shaft.

Carbon steel collars are strong and wear resistant. Collars with a black-oxide finish have some corrosion resistance, but only in dry environments. Their dark color can be useful for matching other parts in your system. Collars with a zinc-plated finish have an outer layer of zinc that protects the steel from rust and extends the life of the collar. 303 stainless steel collars are corrosion resistant and highly machinable.

316 stainless steel collars are the most corrosion resistant while still being nearly as strong as steel collars. You can expose them to salt water, chlorine solutions, and chemicals without rusting.

Aluminum collars are lightweight and have good corrosion resistance.

Set Screw | ||||||

|---|---|---|---|---|---|---|

| For Shaft Dia. | OD | Wd. | Type | No. Included | Each | |

Black-Oxide 1215 Carbon Steel | ||||||

| 2 1/4" | 3 1/4" | 15/16" | Hex Socket | 1 | 0000000 | 000000 |

Zinc-Plated 1215 Carbon Steel | ||||||

| 2 1/4" | 3 1/4" | 15/16" | Hex Socket | 1 | 0000000 | 00000 |

303 Stainless Steel | ||||||

| 2 1/4" | 3 1/4" | 15/16" | Hex Socket | 1 | 0000000 | 000000 |

316 Stainless Steel | ||||||

| 2 1/4" | 3 1/4" | 15/16" | Hex Socket | 1 | 0000000 | 000000 |

6061 Aluminum | ||||||

| 2 1/4" | 3 1/4" | 15/16" | Hex Socket | 1 | 0000000 | 00000 |

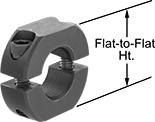

Clamping Two-Piece Shaft Collars

These metal collars are stronger than plastic shaft collars. The two-piece design allows you to install them anywhere on a shaft without removing components or having access to the ends of the shaft. Collars clamp evenly around the shaft to create a strong, mar-free hold. Tighten the clamping screws to secure.

Black-oxide steel collars have some corrosion resistance. Zinc-plated steel and chrome-plated steel collars have moderate corrosion resistance with a bright finish. Aluminum collars are lightweight and have good corrosion resistance. 303 stainless steel collars have excellent corrosion resistance. 316 stainless steel collars have excellent corrosion and chemical resistance.

Clamping Screw | ||||||

|---|---|---|---|---|---|---|

| For Shaft Dia. | OD | Wd. | Type | No. Included | Each | |

Black-Oxide 1215 Carbon Steel | ||||||

| 2 1/4" | 3 1/4" | 3/4" | Socket Head Screw | 2 | 0000000 | 000000 |

Zinc-Plated 1215 Carbon Steel | ||||||

| 2 1/4" | 3 1/4" | 3/4" | Socket Head Screw | 2 | 0000000 | 00000 |

Chrome-Plated 1215 Carbon Steel | ||||||

| 2 1/4" | 3 1/4" | 3/4" | Socket Head Screw | 2 | 0000000 | 00000 |

2024 Aluminum | ||||||

| 2 1/4" | 3 1/4" | 3/4" | Socket Head Screw | 2 | 00000000 | 00000 |

303 Stainless Steel | ||||||

| 2 1/4" | 3 1/4" | 3/4" | Socket Head Screw | 2 | 00000000 | 00000 |

316 Stainless Steel | ||||||

| 2 1/4" | 3 1/4" | 3/4" | Socket Head Screw | 2 | 0000000 | 000000 |

Keyway | Clamping Screw | |||||||

|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | OD | Wd. | Wd. | Dp. | Type | No. Included | Each | |

Black-Oxide 1215 Carbon Steel | ||||||||

| 2 1/4" | 3 1/4" | 3/4" | 1/2" | 7/32" | Socket Head Screw | 2 | 0000000 | 000000 |

Washdown Clamping Two-Piece Shaft Collars

Suitable for use in washdown applications, these plastic collars also offer good chemical resistance. The two-piece design allows you to install them anywhere on a shaft without removing components or having access to the ends of the shaft. Collars clamp evenly around the shaft to create a strong, mar-free hold. Tighten the clamping screws to secure.

Acetal collars have a naturally slippery surface and resist swelling when exposed to moisture.

Extra-Grip Clamping Two-Piece Shaft Collars

With larger screws than those found on standard clamping collars, these provide a stronger grip on your shaft without using additional screws. The two-piece design allows you to install them anywhere on a shaft without removing components or having access to the ends of the shaft. Collars clamp evenly around the shaft to create a strong, mar-free hold. Tighten the clamping screws to secure.

Black-oxide steel collars offer some corrosion resistance.

Keyway | Clamping Screw | |||||||

|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | OD | Wd. | Wd. | Dp. | Type | Number Included | Each | |

Black-Oxide 1026 Carbon Steel | ||||||||

| 2 1/4" | 3 3/4" | 3/4" | 1/2" | 1/4" | Socket Head Screw | 2 | 00000000 | 0000000 |

Clamping Screw | ||||||

|---|---|---|---|---|---|---|

| For Shaft Dia. | OD | Wd. | Type | Number Included | Each | |

Black-Oxide 1026 Carbon Steel | ||||||

| 2 1/4" | 3 3/4" | 3/4" | Socket Head Screw | 2 | 0000000 | 000000 |

Clamping Two-Piece Shaft Collars with Wrench Flats

Use a wrench to rotate your drive shaft without marring or gouging the shaft. Fasten one of these collars onto your shaft, position a wrench on the collar’s wrench flats, and then rotate the entire shaft/collar assembly to adjust the shaft. The two-piece design allows you to install these collars anywhere on a shaft without removing components or having access to the ends of the shaft. Tighten the clamping screws to secure.

Black-oxide steel collars have some corrosion resistance. Aluminum collars are lightweight and strong. 303 stainless steel collars have excellent corrosion resistance.

Set Screw Two-Piece Shaft Collars

Tighten the set screw to bite into an unhardened shaft for a secure hold. The two-piece design allows you to install these collars anywhere on a shaft without removing components or having access to the ends of the shaft. Clamping screws provide extra grip.

Carbon steel collars are strong and wear resistant. Their black-oxide finish is somewhat corrosion resistant, but only in dry environments. Their dark color can be useful for matching other parts in your system.

Set Screw | Clamping Screw | |||||||

|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | OD | Wd. | Type | No. Included | Type | No. Included | Each | |

Black-Oxide 1215 Carbon Steel | ||||||||

| 2 1/4" | 3 1/4" | 3/4" | Hex Socket | 1 | Socket Head Screw | 2 | 0000000 | 000000 |

Hinged Shaft Collars

Offering the benefits of a two-piece collar in a one-piece design, these collars swing open for positioning then close anywhere on your shaft. Tighten the clamping screw to secure. The screw is captive so it won’t fall out, making these collars good for use in tight areas where you can’t hold the screw in place. Collars clamp evenly around your shaft to create a strong, mar-free hold.

Black-oxide steel collars have some corrosion resistance.

Clamping Screw | Black-Oxide 1215 Carbon Steel | |||||

|---|---|---|---|---|---|---|

| For Shaft Dia. | OD | Wd. | Type | No. Included | Each | |

| 2 1/4" | 3 1/2" | 5/8" | Socket Head Screw | 1 | 00000000 | 000000 |

Flange-Mount Shaft Collars

Three tapped counterbored holes and three unthreaded holes provide mounting flexibility. Collars clamp evenly around the shaft to create a strong, mar-free hold. To use, slide onto your shaft and tighten the clamping screws to secure.

Collars with keyway have a standard ANSI keyway for use with keyed shafts, keys, and key stock.

Black-oxide steel collars are stronger than aluminum and stainless steel collars. They have some corrosion resistance. Aluminum collars are lightweight and have good corrosion resistance. 303 stainless steel collars have excellent corrosion resistance.

Flange | Keyway | Clamping Screw | Counterbored Mounting Holes | Unthreaded Mounting Holes | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | OD | Wd. | OD | Thick. | Wd. | Dp. | Type | No. Included | Mounting Fasteners Included | Thread Size | No. of | Dia. | No. of | Each | |

Black-Oxide 1117 Carbon Steel | |||||||||||||||

| 2 1/4" | 3 1/2" | 1 1/4" | 4 31/32" | 1/2" | 1/2" | 15/64" | Socket Head Screw | 2 | No | 5/16"-18 | 3 | 5/16" | 3 | 0000000 | 0000000 |

2024 Aluminum | |||||||||||||||

| 2 1/4" | 3 1/2" | 1 1/4" | 4 31/32" | 1/2" | 1/2" | 15/64" | Socket Head Screw | 2 | No | 5/16"-18 | 3 | 5/16" | 3 | 0000000 | 000000 |

303 Stainless Steel | |||||||||||||||

| 2 1/4" | 3 1/2" | 1 1/4" | 4 31/32" | 1/2" | 1/2" | 15/64" | Socket Head Screw | 2 | No | 5/16"-18 | 3 | 5/16" | 3 | 0000000 | 000000 |