About Shaft Collars

Shaft collars are useful for holding and positioning components on a shaft. They can also serve as mechanical stops and stroke limiters.

More

About Shaft Couplings

More

Clamping Precision Flexible Shaft Couplings

Designed to grip evenly around your shaft, these couplings provide more holding power than set screw couplings without marring the shaft. Tighten the clamping screws to secure.

Spiral couplings have long cuts in their body for flexibility to handle parallel, axial, and angular misalignment better than parallel couplings. However, they’re not as rigid. Often used for light duty encoder and stepper drive applications, they allow zero backlash (no play) and never need lubrication. They’re also known as helical beam couplings.

Aluminum couplings are lightweight with good corrosion resistance.

Misalignment Capability | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Overall Lg. | OD | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Axial | For Motion Type | Each | |

Spiral Cut | ||||||||||

7075 Aluminum | ||||||||||

| 1/8" × 3/32" | 3/4" | 1/2" | 10,000 | 5 | 0.005" | 2° | 0.005" | Forward/Reverse, Start/Stop | 00000000 | 0000000 |

| 5/32" × 3/32" | 3/4" | 1/2" | 10,000 | 5 | 0.005" | 2° | 0.005" | Forward/Reverse, Start/Stop | 00000000 | 000000 |

| 3/16" × 3/32" | 3/4" | 1/2" | 10,000 | 5 | 0.005" | 2° | 0.005" | Forward/Reverse, Start/Stop | 00000000 | 000000 |

| 1/4" × 3/32" | 3/4" | 3/4" | 10,000 | 20 | 0.006" | 3° | 0.006" | Forward/Reverse, Start/Stop | 00000000 | 000000 |

Set Screw Precision Flexible Shaft Couplings

Tighten the set screws to fasten these couplings to your shaft. Set screws bite into the shaft to hold the couplings in place. All are lightweight, corrosion-resistant aluminum.

Spiral couplings have long, continuous cuts in the body, making them flexible enough to handle parallel, axial, and angular misalignment. Often used for light duty encoder and stepper drive applications, they allow zero backlash (no play) and never need lubrication. They’re also known as helical beam couplings. Spiral couplings are less rigid than parallel couplings.

Misalignment Capability | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Overall Lg. | OD | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Axial | For Motion Type | Each | |

Spiral Cut | ||||||||||

7075 Aluminum | ||||||||||

| 1/4" × 3/32" | 3/4" | 3/4" | 10,000 | 20 | 0.006" | 3° | 0.006" | Forward/Reverse, Start/Stop | 00000000 | 000000 |

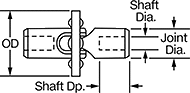

Precision Single U-Joints

A good choice when you need accurate and repeatable motion, these U-joints have zero backlash (no play), so there’s no motion lost when your shafts change direction. This keeps machines running smoothly. They’re single U-joints, so they connect and transfer torque between shafts that are misaligned at an angle.

Your shafts’ misalignment will affect the speed and torque the U-joint will be able to transmit. The more the shafts are misaligned, the less speed and torque the U-joint will be able to transmit.

Ball-bearing U-joints operate with less friction than pin-and-block joints, so they run at higher speeds. 303 stainless steel U-joints balance strength with good corrosion resistance. U-joints that connect with spring pins require you to drill holes through both the U-joint and your shafts. Spring pins are not included.

U-joints that don’t require lubrication are often used with optical devices and other sensitive equipment because they're less likely to attract dust and debris compared to lubricated U-joints. They’re also easier to maintain.

For Shaft | Torque | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Dp. | Joint Dia. | O'all Lg. | Max. Operating Angle | Max. Speed, rpm | Max. Torque, in.-lbs. | 5° Operating Angle | 10° Operating Angle | Shaft Mount Type | Lubrication | Each | |

Ball-Bearing Joint | ||||||||||||

303 Stainless Steel | ||||||||||||

| 3/32" | 11/32" | 3/16" | 1" | 30° | 4,000 | 1 | 0.9 in.-lbs. @ 1,500 rpm | 0.8 in.-lbs. @ 1,500 rpm | Spring Pin | Not Required | 00000000 | 000000 |

Clamping Shaft Collars

These metal collars are stronger than plastic shaft collars. They clamp evenly around the shaft to create a strong, mar-free hold. To use, slide onto your shaft and tighten the clamping screw to secure.

Black-oxide steel collars have some corrosion resistance. Aluminum collars are lightweight and have good corrosion resistance.

Set Screw Shaft Collars

Keep these shaft collars in place by tightening their set screw into the shaft. The tip of the screw digs in for a secure hold, but will mar the shaft’s surface. For maximum holding power, make sure the set screw material is harder than your shaft material. Use these shaft collars to position and retain power transmission components such as sprockets, pulleys, and bearings. You can also use them to limit the movement of a shaft.

Carbon steel collars are strong and wear resistant. Collars with a black-oxide finish have some corrosion resistance, but only in dry environments. Their dark color can be useful for matching other parts in your system. Collars with a zinc-plated finish have an outer layer of zinc that protects the steel from rust and extends the life of the collar. 303 stainless steel collars are corrosion resistant and highly machinable.

316 stainless steel collars are the most corrosion resistant while still being nearly as strong as steel collars. You can expose them to salt water, chlorine solutions, and chemicals without rusting.

Aluminum collars are lightweight and have good corrosion resistance.

Set Screw | ||||||

|---|---|---|---|---|---|---|

| For Shaft Dia. | OD | Wd. | Type | No. Included | Each | |

Black-Oxide 1215 Carbon Steel | ||||||

| 3/32" | 3/8" | 3/16" | Hex Socket | 1 | 000000 | 00000 |

Zinc-Plated 1215 Carbon Steel | ||||||

| 3/32" | 3/8" | 3/16" | Hex Socket | 1 | 0000000 | 0000 |

303 Stainless Steel | ||||||

| 3/32" | 3/8" | 3/16" | Hex Socket | 1 | 0000000 | 0000 |

316 Stainless Steel | ||||||

| 3/32" | 3/8" | 3/16" | Hex Socket | 1 | 0000000 | 00000 |

6061 Aluminum | ||||||

| 3/32" | 3/8" | 3/16" | Hex Socket | 1 | 000000 | 0000 |

Clamping Two-Piece Shaft Collars

These metal collars are stronger than plastic shaft collars. The two-piece design allows you to install them anywhere on a shaft without removing components or having access to the ends of the shaft. Collars clamp evenly around the shaft to create a strong, mar-free hold. Tighten the clamping screws to secure.

Black-oxide steel collars have some corrosion resistance. Aluminum collars are lightweight and have good corrosion resistance. 303 stainless steel collars have excellent corrosion resistance.