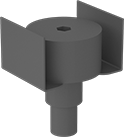

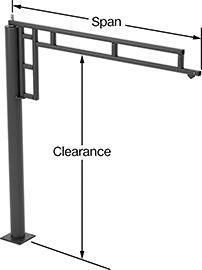

Floor-Mount Rotating Cranes

No need to pour a special foundation—you can install these cranes on a reinforced concrete floor. Also known as jib cranes, they rotate 360° to maximize floor space. Use Grade 5 steel Stud Anchors for Concrete (sold separately) to mount cranes to a minimum 6" deep reinforced concrete floor. Avoid any gaps, cracks, or expansion joints, and make sure your anchors are embedded at least 4 3/4" deep.

Blue painted steel cranes have tracks enclosed in the beams to keep debris from collecting on the track, allowing the trolley to move smoothly. The trolley has a mounting bar for your lifting device.

Rotation stops prevent cranes from turning past a certain point to protect surrounding structures. To install, weld the stop to the crane’s mast assembly. Since they’re welded, they’ll permanently limit the crane’s rotation.

Warning: Never use to lift people or items over people.

Capacity | Beam | Trolley | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| tons | lbs. | Clearance, ft. | Overall Ht. | Wd. | Ht. | Beam Style | Eye Dia. | Bar Dia. | Rotation | Fasteners Included | Mounting Hole Dia. | Specifications Met | Each | |

Blue Painted Steel | ||||||||||||||

6-ft. Span | ||||||||||||||

| __ | 150 | 8 | 8'8" | __ | __ | Enclosed | 1" | 0.5" | 360° | No | 1" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 000000000 | 000000000 |

| 1/8 | 250 | 10 | 11'1" | __ | __ | Enclosed | 0.505" | 0.5" | 360° | No | 3/4" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 000000000 | 00000000 |

8-ft. Span | ||||||||||||||

| __ | 150 | 10 | 11'1" | __ | __ | Enclosed | 0.505" | 0.5" | 360° | No | 1" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 000000000 | 00000000 |

| 1/8 | 250 | 8 | 9'1" | __ | __ | Enclosed | 0.505" | 0.5" | 360° | No | 1" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 000000000 | 00000000 |

| 1/8 | 250 | 10 | 11'1" | __ | __ | Enclosed | 0.505" | 0.5" | 360° | No | 1" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 000000000 | 00000000 |

| 1/4 | 500 | 8 | 9'4" | __ | __ | Enclosed | 1 1/8" | 0.75" | 360° | No | 1" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 000000000 | 00000000 |

| 1/2 | 1,000 | 10 | 11'4" | __ | __ | Enclosed | 1 1/4" | 1" | 360° | No | 1 1/4" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 000000000 | 00000000 |

10-ft. Span | ||||||||||||||

| __ | 150 | 10 | 11'1" | __ | __ | Enclosed | 0.505" | 0.5" | 360° | No | 1" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 000000000 | 00000000 |

| 1/8 | 250 | 8 | 9'4" | __ | __ | Enclosed | 0.505" | 0.5" | 360° | No | 1" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 000000000 | 00000000 |

| 1/8 | 250 | 10 | 11'4" | __ | __ | Enclosed | 0.505" | 0.5" | 360° | No | 1" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 000000000 | 00000000 |

| 1/4 | 500 | 8 | 9'4" | __ | __ | Enclosed | 3/4" | 0.75" | 360° | Yes | 3/4" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 000000000 | 00000000 |

12-ft. Span | ||||||||||||||

| 1/4 | 500 | 12 | 13'7" | __ | __ | Enclosed | 1 1/8" | 0.75" | 360° | No | 1 1/4" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 000000000 | 00000000 |

| 1/2 | 1,000 | 10 | 11'8" | __ | __ | Enclosed | 1" | 1" | 360° | Yes | 1" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 000000000 | 00000000 |

14-ft. Span | ||||||||||||||

| 1/4 | 500 | 12 | 13'8" | __ | __ | Enclosed | 1" | 1" | 360° | Yes | 1" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 000000000 | 00000000 |

| 1/2 | 1,000 | 10 | 11'10" | __ | __ | Enclosed | 1" | 1" | 360° | Yes | 1" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 000000000 | 00000000 |

Yellow Painted Steel | ||||||||||||||

8-ft. Span | ||||||||||||||

| 1 | 2,000 | 10 | 10'11" | 5 3/4" | 10 1/4" | Open | __ | __ | 360° | No | 15/16" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 00000000 | 00000000 |

10-ft. Span | ||||||||||||||

| 1 | 2,000 | 10 | 10'11" | 5 3/4" | 10 1/4" | Open | __ | __ | 360° | No | 15/16" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 00000000 | 00000000 |

12-ft. Span | ||||||||||||||

| 1 | 2,000 | 10 | 10'11" | 5 3/4" | 10 1/4" | Open | __ | __ | 360° | No | 15/16" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 00000000 | 00000000 |

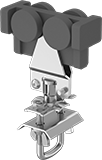

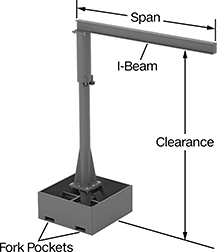

Movable Rotating Cranes

Transport these cranes anywhere they’re needed in your facility. Made with fork pockets in the base, they can be lifted and moved with a fork truck—saving you from taking your load to a mounted crane or having multiple cranes around your building. The first time you use these cranes, fill the base with concrete to keep them stable. Also known as jib cranes, they have an I-beam that rotates 360°, which makes it easy to position loads. The beam can accommodate most trolleys.

Warning: Never use to lift people or items over people.

Capacity | Overall | Beam | For Max. Fork | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| tons | lbs. | Clearance, ft. | Lg. | Wd. | Ht. | Wd. | Ht. | Fork Pocket Spacing Ctr.-to-Ctr. | For Min. Fork Lg. | Wd. | Ht. | Rotation | Specifications Met | Each | |

Blue Painted Steel | |||||||||||||||

8-ft. Span | |||||||||||||||

| 1/8 | 250 | 10 | 9'4" | 3'6" | 10'6" | 4" | 6" | 24" | 42" | 7 1/2" | 2 1/2" | 360° | ASME B30.11, CMAA Specification No. 74, OSHA Compliant 29 CFR 1910.179 | 0000000 | 000000000 |

| 1/4 | 500 | 10 | 9'4" | 3'6" | 10'6" | 4" | 6" | 24" | 42" | 7 1/2" | 2 1/2" | 360° | ASME B30.11, CMAA Specification No. 74, OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 |

| 1/2 | 1,000 | 10 | 9'3" | 3'6" | 10'10" | 4" | 10" | 24" | 42" | 7 1/2" | 2 1/2" | 360° | ASME B30.11, CMAA Specification No. 74, OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 |

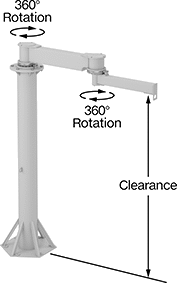

Articulating Cranes

Reach around corners and into tight spaces to precisely place loads. With two joints that each swivel 360°, these cranes are easier to maneuver around obstacles than our standard rotating cranes. They’re often used to move material around machinery, through doorways, and in other complex lifting jobs. Instead of swinging a load in a circle at a fixed distance, these cranes let you position it almost anywhere within their span.

Install with anchor bolts (sold separately) set in a reinforced concrete foundation.

Rotation stops (sold separately) prevent cranes from turning past a certain point to protect nearby machines and walls.

Warning: Never use to lift people or items over people.

Capacity | Overall | Beam | For Foundation | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| tons | lbs. | Clearance, ft. | Lg. | Wd. | Ht. | Wd. | Ht. | Eye Dia. | Rotation | Lg., ft. | Wd., ft. | Dp., ft. | Fasteners Included | Mounting Hole Dia. | Specifications Met | Each | |

Yellow Painted Steel | |||||||||||||||||

8-ft. Span | |||||||||||||||||

| 1/2 | 1,000 | 10 | 9'7" | 3'3" | 11'10" | 6" | 10" | 2 1/2" | 360° | 4 | 4 | 4 | No | 1" | ASME B30.11, CMAA Specification No. 74, OSHA Compliant 29 CFR 1910.179 | 0000000 | 0000000000 |

10-ft. Span | |||||||||||||||||

| 1/2 | 1,000 | 10 | 11'7" | 3'3" | 11'10" | 6" | 10" | 2 1/2" | 360° | 4 | 4 | 4 | No | 1" | ASME B30.11, CMAA Specification No. 74, OSHA Compliant 29 CFR 1910.179 | 0000000 | 000000000 |

| Material | Lg. | Includes | Pkg. Qty. | Pkg. | |

| Steel | 48" | Leveling Nuts, Securing Nuts, Washers | 6 | 0000000 | 0000000 |

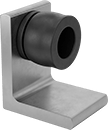

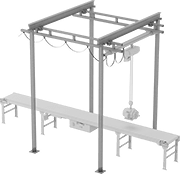

Workstation Cranes

Position your load anywhere inside the four posts of these cranes. Originally designed to service vehicles, these cranes offer the flexibility of overhead bridge cranes without requiring ceiling installation. They include two fixed beams, a moving beam that travels along them, a trolley, and four posts. The tracks are enclosed to keep debris from collecting.

These cranes are freestanding, and they don't require a foundation. Use steel stud anchors for concrete (not included) to mount them to a minimum 6" deep reinforced concrete floor.

Heavy duty cranes can handle daily use on your production line. They include a trolley and a cable travel system that keeps power cords out of the way as they move.

Warning: Never use to lift people or items over people.

Cap. | Overall | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| tons | lbs. | Fixed Beam Lg. | Moving Beam Lg., ft. | Clearance, ft. | Wd. | Ht. | Trolley Bar Dia. | Inside Wd. | Cable Lg., ft. | Cable Shape | Cable Wire Gauge | Fasteners Included | Mounting Hole Dia. | Specifications Met | Each | |

| 1/4 | 500 | 23' | 15 | 12 | 16'6" | 13'11" | 3/4" | 15'4" | 49 | Flat | 14 ga. | No | 7/8" | ASME B30.11, CMAA Specification No. 79 | 0000000 | 0000000000 |

| 1/2 | 1,000 | 11'6" | 10 | 12 | 11'6" | 14'3" | 1" | 10'4" | 30 | Flat | 14 ga. | No | 7/8" | ASME B30.11, CMAA Specification No. 79 | 0000000 | 000000000 |

| 1/2 | 1,000 | 23' | 15 | 12 | 16'6" | 14'3" | 1" | 15'4" | 49 | Flat | 14 ga. | No | 7/8" | ASME B30.11, CMAA Specification No. 79 | 0000000 | 000000000 |

| 1 | 2,000 | 11'6" | 10 | 12 | 11'7" | 14'7" | 1" | 10'4" | 30 | Flat | 14 ga. | No | 7/8" | ASME B30.11, CMAA Specification No. 79 | 0000000 | 000000000 |

| 1 | 2,000 | 23' | 15 | 12 | 16'7" | 14'9" | 1" | 15'4" | 49 | Flat | 14 ga. | No | 7/8" | ASME B30.11, CMAA Specification No. 79 | 0000000 | 000000000 |

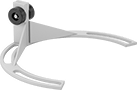

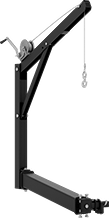

Hitch-Mount Hand-Winch Cranes

Save your back from loading toolboxes, generators, and other heavy items into your truck. These cranes slide right into your hitch—no need to modify your vehicle to mount them. Designed with an offset, you can lower the tailgate fully with the crane installed. Mount the crane to lift from the right or the left side of the truck depending on your task. Also known as davit cranes, they have a hand winch to raise the load, and an automatic brake holds the load securely when you release the handle.

Warning: Never use to lift people or items over people.

Capacity | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| tons | lbs. | Arm Lg. | Lift Lg. | O'all Ht. | Hook Style | Hook Material | Hook Movement | Hook Opening Wd. | Mounting Hole Dia. | No. of Mounting Holes | For Hitch Receiver Size | Includes | Specifications Met | Each | |

Black Powder-Coated Steel | |||||||||||||||

| 1/4 | 600 | 47" | 10' | 7' | Latching | Steel | Rigid | 7/8" | 25/32" | 1 | 2" Square | Hitch Pin, Mounting Bolts | ASME B30.11, CMAA Specification No. 74, OSHA Compliant 29 CFR 1910.179 | 0000000 | 0000000 |