About Hammers

More

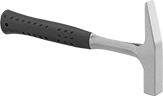

Blacksmiths' Hammers

Strike metal, concrete, and stone with the flat end of these hammers; the wedge-shaped end is for bending and shaping metal. They're also known as cross-peen hammers. For replacement handles, see Hickory Hammer Handles.

Hickory handles resist vibration. Steel handles are stronger than hickory handles but have less vibration resistance. Fiberglass handles resist breakage if you miss your mark.

Textured and ribbed grips provide slip resistance.

| Head Wt., lbs. | Face Dia. | Overall Lg. | Face Material | Handle Replaceable | Each | |

Hickory Handle—Plain Grip | ||||||

|---|---|---|---|---|---|---|

| 3 | 1 3/4" | 15" | Steel | Replaceable | 000000 | 000000 |

| 4 | 1 7/8" | 15" | Steel | Replaceable | 000000 | 00000 |

Steel Handle—Textured Grip | ||||||

| 2 | 1 3/8" | 14" | Steel | Nonreplaceable | 0000000 | 00000 |

| 3 | 1 3/4" | 16" | Steel | Nonreplaceable | 0000000 | 00000 |

Fiberglass Handle—Ribbed Grip | ||||||

| 3 | 1 5/8" | 14" | Steel | Replaceable | 0000000 | 00000 |

| 4 | 1 3/4" | 14" | Steel | Replaceable | 0000000 | 00000 |

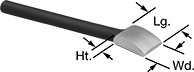

Nonsparking Blacksmiths' Hammers

The faces and head are made of aluminum-bronze that is Factory Mutual approved, so these tools inhibit sparking and are nonmagnetic and corrosion resistant. They satisfy OSHA requirements that specify nonsparking tools for locations where flammable vapors and combustible residues are present. Use the flat end of the head to strike metal, concrete, and stone; the wedge-shaped end is for shaping and bending metal. These tools are also known as cross-peen hammers. A textured grip provides slip resistance. For replacement handles, see Fiberglass Hammer Handles.

Warning: Do not use these tools in direct contact with acetylene.

| Head Wt., lbs. | Face Lg. | Face Wd. | Overall Lg. | Face Material | Handle Replaceable | Specifications Met | Each | |

Fiberglass Handle with Textured Grip | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1 1/2 | 1 5/16" | 1 5/16" | 14" | Aluminum-Bronze | Replaceable | FM Approved | 0000000 | 0000000 |

| 2 1/2 | 1 1/2" | 1 1/2" | 15" | Aluminum-Bronze | Replaceable | FM Approved | 0000000 | 000000 |

| 3 1/2 | 1 7/8" | 1 7/8" | 15" | Aluminum-Bronze | Replaceable | FM Approved | 0000000 | 000000 |

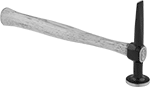

Riveting Hammers

Set solid rivets by hand. These tools are also known as paneing, setting, and seaming hammers. Use the flat end of the head to drive rivets and pins. The other end of the head has a wedge shape for creating corners and seams in sheet metal. For replacement handles, see Hickory Hammer Handles.

Hickory handles resist vibration. Steel handles are stronger than hickory handles but have less vibration resistance. Fiberglass handles combine the strength of steel with the vibration resistance of hickory.

Textured grips provide slip resistance.

| Head Wt., lbs. | Face Dia. | Face Lg. | Face Wd. | Overall Lg. | Face Material | Handle Replaceable | Each | ||

Hickory Handle with Plain Grip | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| A | 1/2 | 11/16" | __ | __ | 11" | Steel | Replaceable | 000000 | 000000 |

| A | 3/4 | 13/16" | __ | __ | 13 1/2" | Steel | Replaceable | 000000 | 00000 |

| A | 1 | 7/8" | __ | __ | 14" | Steel | Replaceable | 000000 | 00000 |

| B | 1 | __ | 13/16" | 13/16" | 13 1/2" | Steel | Replaceable | 000000 | 00000 |

Steel Handle with Textured Grip | |||||||||

| C | 3/4 | __ | 13/16" | 3/4" | 11" | Steel | Nonreplaceable | 000000 | 00000 |

| C | 1 1/4 | __ | 15/16" | 7/8" | 12" | Steel | Nonreplaceable | 000000 | 00000 |

Fiberglass Handle with Textured Grip | |||||||||

| D | 1 | 1" | __ | __ | 12 1/2" | Steel | Nonreplaceable | 0000000 | 00000 |

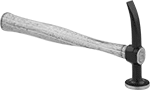

Sheet Metal Forming Hammers

Also known as body and fender tools, these hammers are excellent for forming and repairing dents in sheet metal components.

Hickory handles resist vibration.

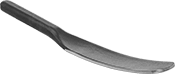

Place against the face of your workpiece and strike with a hammer. The blow will transfer to the workpiece without damaging the finish. Also known as dinging spoons, these tools are often used to smooth ridges and dings in sheet metal.

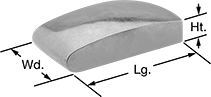

Style B have large, slightly curved faces for efficient finishing and shaping of sheet metal edges.

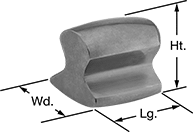

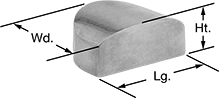

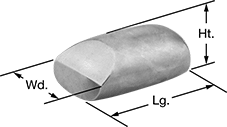

Place on the back side of your workpiece to act as a support when you strike it. Also known as dolly blocks.

A long handle lets you access hard-to-reach spots. Place the block on the back side of your workpiece to act as a support when you strike it. Also known as dolly blocks.

Block | |||||||

|---|---|---|---|---|---|---|---|

| Lg. | Wd. | Ht. | Overall Lg. | Wt., lbs. | Material | Each | |

| 3" | 2 1/2" | 1" | 14" | 4 1/4 | Steel | 0000000 | 000000 |