Filter by

For Cutting

Length

Number of Mounting Holes

System of Measurement

Height

DIN Rail Trade Size

Handle Length

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Mounting Hole Diameter

REACH

RoHS

Width

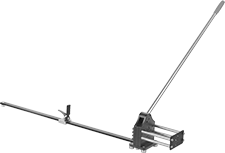

DIN-Rail Cutters

DIN 3 Rails with Bracket

Pull the lever on these cutters to make smooth cuts in steel and aluminum DIN rail without leaving a bur. To cut the same length over and over, slide the stop along the ruler and clamp in place. Cutters mount to your workbench.

Mounting Holes | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

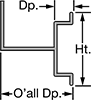

| For Cutting Trade Size (Height × Depth × Overall Depth) | Height | Width | Length | Handle Length | Ruler Length | Mounting Fasteners Included | Number of | Diameter | Each | |

| DIN 3 Rail (35 × 7.5 mm) DIN 3 Rail (35 × 15 mm) DIN 3 Rail with Bracket (35 × 7.5 × 58 mm) | 47" | 6" | 54" | 40" | 39"/100 cm | No | 4 | 0.39" | 0000000 | 000000000 |