Filter by

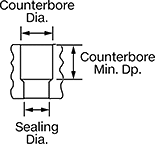

Counterbore Diameter

Sealing Diameter

Sleeve Material

Plug Connection Method

Material

Ball Material

For Use With

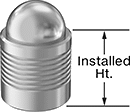

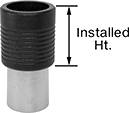

Installed Height

Minimum Counterbore Depth

DFARS Specialty Metals

Maximum Pressure

Pin Material

Finish

Sleeve Finish

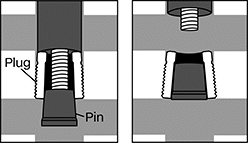

Push-In Bore Sealing Plugs

Counterbore | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Sealing Dia. | Dia. | Min. Dp. | Installed Ht. | Max. Pressure, psi | Max. Temp., ° F | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum Sleeve | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 5/32" | 0.113" | 1/8" | 2,100 | 300 | 5 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 5/32" | 0.149" | 5/32" | 3,000 | 300 | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/32" | 3/16" | 0.17" | 3/16" | 2,100 | 300 | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/32" | 3/16" | 0.208" | 7/32" | 3,000 | 300 | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 7/32" | 0.17" | 3/16" | 2,100 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 7/32" | 0.208" | 7/32" | 3,000 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/32" | 1/4" | 0.196" | 7/32" | 2,100 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/32" | 1/4" | 0.247" | 1/4" | 3,000 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 9/32" | 0.233" | 1/4" | 2,100 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 9/32" | 0.287" | 19/64" | 3,000 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/32" | 5/16" | 0.255" | 9/32" | 2,100 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/32" | 5/16" | 0.326" | 21/64" | 3,000 | 300 | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 11/32" | 0.275" | 5/16" | 2,100 | 300 | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 11/32" | 0.385" | 25/64" | 3,000 | 300 | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11/32" | 3/8" | 0.385" | 25/64" | 3,000 | 300 | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 13/32" | 0.308" | 23/64" | 2,100 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 13/32" | 0.425" | 7/16" | 3,000 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.3 mm | 3 mm | 2.9 mm | 3.18 mm | 3,000 | 300 | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.3 mm | 4 mm | 3.8 mm | 4 mm | 3,000 | 300 | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5.3 mm | 6 mm | 6.3 mm | 6.5 mm | 3,000 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6.2 mm | 7 mm | 7.3 mm | 7.5 mm | 3,000 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9.2 mm | 10 mm | 10.8 mm | 11 mm | 3,000 | 300 | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11 mm | 12 mm | 12.8 mm | 13 mm | 1,500 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel Sleeve | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.2 mm | 3 mm | 3.4 mm | 3.6 mm | 4,600 | 300 | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.3 mm | 4 mm | 3.8 mm | 4 mm | 4,600 | 300 | 5 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.3 mm | 5 mm | 5.3 mm | 5.5 mm | 4,600 | 300 | 5 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5.3 mm | 6 mm | 6.3 mm | 6.5 mm | 4,600 | 300 | 5 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6.4 mm | 7 mm | 7.3 mm | 7.5 mm | 4,600 | 300 | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7.4 mm | 8 mm | 8.3 mm | 8.5 mm | 4,600 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8.4 mm | 9 mm | 9.8 mm | 10 mm | 4,600 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9.4 mm | 10 mm | 10.8 mm | 11 mm | 4,600 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10.6 mm | 12 mm | 12.8 mm | 13 mm | 3,600 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12.7 mm | 14 mm | 14.5 mm | 15 mm | 3,600 | 300 | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14.7 mm | 16 mm | 16.5 mm | 17 mm | 3,600 | 300 | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16.7 mm | 18 mm | 18.5 mm | 19 mm | 3,600 | 300 | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18.7 mm | 20 mm | 21.5 mm | 22 mm | 3,600 | 300 | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20.7 mm | 22 mm | 24.5 mm | 25 mm | 3,600 | 300 | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel Sleeve | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16" | 3/32" | 0.081" | 3/32" | 5,500 | 300 | 5 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/32" | 1/8" | 0.113" | 1/8" | 5,500 | 300 | 5 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 5/32" | 0.13" | 5/32" | 5,500 | 300 | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/32" | 3/16" | 0.152" | 13/64" | 5,500 | 300 | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 7/32" | 0.187" | 7/32" | 5,500 | 300 | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/32" | 1/4" | 0.212" | 17/64" | 5,500 | 300 | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 9/32" | 1/4" | 9/32" | 5,500 | 300 | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/32" | 5/16" | 0.327" | 21/64" | 5,500 | 300 | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 11/32" | 0.385" | 25/64" | 5,500 | 300 | 1 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11/32" | 3/8" | 0.425" | 25/64" | 5,500 | 300 | 1 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 13/32" | 0.425" | 7/16" | 4,000 | 300 | 1 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13/32" | 7/16" | 0.503" | 33/64" | 4,000 | 300 | 1 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 15/32" | 0.504" | 33/64" | 4,000 | 300 | 1 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.2 mm | 3 mm | 3.4 mm | 3.6 mm | 5,500 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.3 mm | 4 mm | 3.8 mm | 4 mm | 5,500 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.3 mm | 5 mm | 5.3 mm | 5.5 mm | 5,500 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5.3 mm | 6 mm | 6.3 mm | 6.5 mm | 5,500 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6.4 mm | 7 mm | 7.3 mm | 7.5 mm | 5,500 | 300 | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7.4 mm | 8 mm | 8.3 mm | 8.5 mm | 5,500 | 300 | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8.4 mm | 9 mm | 9.8 mm | 10 mm | 5,500 | 300 | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9.4 mm | 10 mm | 10.8 mm | 11 mm | 5,500 | 300 | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10.6 mm | 12 mm | 12.8 mm | 13 mm | 4,100 | 300 | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12.7 mm | 14 mm | 14.5 mm | 15 mm | 4,100 | 300 | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

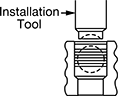

Installation Tools for Push-In Bore Sealing Plugs

|

|

For Counterbore Dia. | Dia. | Lg. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/32" | 3/8" | 5" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8", 3 mm | 3/8" | 5" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/32", 4 mm | 3/8" | 5" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 3/8" | 5" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/32", 5 mm | 3/8" | 5" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4", 6 mm | 3/8" | 5" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/32", 7 mm | 3/8" | 5" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16", 8 mm | 3/8" | 5" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11/32", 9 mm | 5/8" | 5" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 5/8" | 5" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13/32", 10 mm | 5/8" | 5" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 5/8" | 5" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15/32", 12 mm | 5/8" | 5" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8", 16 mm | 3/4" | 5" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11/16", 18 mm | 3/4" | 5" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25/32", 20 mm | 1" | 5" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8", 22 mm | 1" | 5" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Installation Tools for Push-In Bore Sealing Plugs, Sanitary RTD Probe Transmitters with Digital Display for Liquids and Gas Bore Sealing Plug Installation Tools

|  |

For Counterbore Dia. | Dia. | Lg. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16", 14 mm | 3/4" | 5" | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

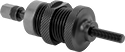

Installation Tools for Pull-Through Bore Sealing Plugs

Air Connection | Body | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Thread Size | Stroke Lg. | Operating Pressure, psi | Pulling Force, lbf | Wt., lb. | Pipe Size | Thread Type | Gender | Wd. | Dia. | Head Lg. | Overall Ht. | Each | |||

| 4-40, 6-32, 8-32, 10-24, 10-32, 1/4"-20, 1/4"-28, 5/16"-18, 5/16"-24, 3/8"-16, 3/8"-24, M2, M3, M4, M5, M6, M8, M10 | 0.04" to 0.28" | 75 to 100 | 5,000 | 4 | 1/4 | NPT | Female | 1" | 4 5/16" | 10 1/4" | 10 1/2" | 0000000 | 000000000 | ||

Pull-Through Bore Sealing Plugs

|  |

Sealing Dia. | Installed Ht. | Max. Pressure, psi | Max. Temp., ° F | Thread Size | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Aluminum Sleeve | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13/64" | 11/64" | 2,000 | 300 | 4-40 | 5 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 mm | 5 mm | 2,000 | 300 | M3 × 0.5 mm | 5 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 6.5 mm | 2,000 | 300 | M4 × 0.7 mm | 5 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 mm | 6.5 mm | 2,000 | 300 | M5 × 0.8 mm | 5 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide Steel Sleeve | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13/64" | 7/32" | 4,500 | 300 | 4-40 | 5 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15/64" | 1/4" | 4,500 | 300 | 6-32 | 5 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.5 mm | 4 mm | 4,500 | 300 | M2 × 0.4 mm | 5 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 8.5 mm | 4,500 | 300 | M4 × 0.7 mm | 5 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 mm | 10.5 mm | 4,500 | 300 | M6 × 1 mm | 5 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||