Filter by

For Cylinder ID

For Finish

DFARS Specialty Metals

Abrasive Material

Export Control Classification Number (ECCN)

REACH

Material

Grit Rating

Component

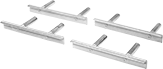

Easy-Adjust Rigid Cylinder Hones

Cylinder Hones | Cylinder Honing Stone Holders | Replacement Driver Shafts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Cylinder ID | Grit (For Finish) | Shank Dia. | Overall Lg. | Abrasive Lg. | Recommended Speed, rpm | No. of Stones | Shank Flexibility | Each | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Silicon Carbide Abrasive—For Steel, Stainless Steel, Titanium, Iron, Aluminum, Brass, Bronze, Copper, and Nickel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11/16" to 2 1/2" | 220 Grit (Smooth) | 0.25" | 8" | 1 1/8" | 1,500 | 2 | Flexible | 0000000 | 000000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 27/32" to 2" | 220 Grit (Smooth) | 0.25" | 8" | 1 1/8" | 1,500 | 3 | Flexible | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" to 3 1/8" | 400 Grit (Extra Smooth) | 0.25" | 8" | 1" | 1,500 | 3 | Flexible | 0000000 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" to 7" | 220 Grit (Smooth) | 0.25" | 13" | 3" | 1,200 | 3 | Flexible | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

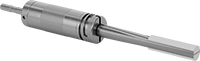

Rigid Cylinder Hones

Cylinder Hones | Replacement Driver Assemblies | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Cylinder ID | Abrasive Lg. | Shank Dia. | Overall Lg. | Recommended Speed, rpm | No. of Stones | Includes | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Silicon Carbide Abrasive—For Steel and Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" to 2 3/4" | 3 1/2" | 0.5" | 14" | 750 | 6 | Six Smooth-Finish (180 Grit) Stones Four Holders Six Wipers One Dressing Stick | 0000000 | 0000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" to 4 1/4" | 5" | 0.5" | 17" | 500 | 4 | Two Smooth-Finish (180 Grit) Stones Two Rough-Finish (80 Grit) Stones Four Holders Four Wipers One 1/2" Dia. Driver Extension One Dressing Stick | 0000000 | 000000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

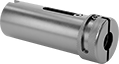

Rigid Cylinder Hones for Machine Tools

Drivers

|

For Cylinder ID | Shank Dia. | Overall Lg. | Each | ||

|---|---|---|---|---|---|

| 3/16" to 3" | 1/2" | 9" | 000000 | 000000000 |

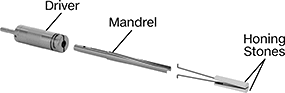

Honing Kits

Kits | Replacement Cylinder Honing Stones | Replacement Cylinder Honing Stone Truing Sleeves | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Cylinder ID | ||||||||||||||||

Actual | Nominal | For Cylinder ID Tolerance | Mandrel Lg. | Grit (For Finish) | Abrasive Lg. | Recommended Speed, rpm | No. of Stones | Includes | Each | No. of Pieces | Each | Each | ||||

| 0.177" to 0.209" | 3/16" | -0.001" to 0.001" | 4" | 220 Grit (Smooth) | 1" | 800 | 2 | One Mandrel Two Honing Stones One Truing Sleeve | 0000000 | 0000000 | 2 | 00000000 | 000000 | 00000000 | 0000000 | |

| 0.209" to 0.24" | 7/32" | -0.001" to 0.001" | 4" | 220 Grit (Smooth) | 1" | 800 | 2 | One Mandrel Two Honing Stones One Truing Sleeve | 0000000 | 000000 | 2 | 00000000 | 00000 | 00000000 | 000000 | |

| 0.24" to 0.302" | 1/4" | -0.001" to 0.001" | 3 1/4" | 220 Grit (Smooth) | 3/4" | 800 | 2 | One Mandrel Two Honing Stones One Truing Sleeve | 0000000 | 000000 | 2 | 00000000 | 00000 | 00000000 | 000000 | |

| 0.302" to 0.365" | 5/16" | -0.001" to 0.001" | 4" | 220 Grit (Smooth) | 1 1/8" | 800 | 2 | One Mandrel Two Honing Stones One Truing Sleeve | 0000000 | 000000 | 2 | 00000000 | 00000 | 00000000 | 000000 | |

| 0.365" to 0.427" | 3/8" | -0.001" to 0.001" | 5" | 220 Grit (Smooth) | 1 1/2" | 800 | 2 | One Mandrel Two Honing Stones One Truing Sleeve | 0000000 | 000000 | 2 | 00000000 | 00000 | 00000000 | 000000 | |

| 0.427" to 0.49" | 7/16" | -0.001" to 0.001" | 5" | 220 Grit (Smooth) | 1 1/2" | 800 | 2 | One Mandrel Two Honing Stones One Truing Sleeve | 0000000 | 000000 | 2 | 00000000 | 00000 | 00000000 | 000000 | |

| 0.49" to 0.552" | 1/2" | -0.001" to 0.001" | 5 3/4" | 220 Grit (Smooth) | 1 15/16" | 600 | 2 | One Mandrel Two Honing Stones One Truing Sleeve | 0000000 | 000000 | 2 | 00000000 | 00000 | 00000000 | 000000 | |

| 0.552" to 0.615" | 9/16" | -0.001" to 0.001" | 5 3/4" | 220 Grit (Smooth) | 1 15/16" | 600 | 2 | One Mandrel Two Honing Stones One Truing Sleeve | 0000000 | 000000 | 2 | 00000000 | 00000 | 00000000 | 000000 | |

| 0.615" to 0.677" | 5/8" | -0.001" to 0.001" | 6" | 220 Grit (Smooth) | 2 1/2" | 400 | 2 | One Mandrel Two Honing Stones One Truing Sleeve | 0000000 | 000000 | 2 | 00000000 | 00000 | 00000000 | 000000 | |

| 0.677" to 0.74" | 11/16" | -0.001" to 0.001" | 6" | 220 Grit (Smooth) | 2 1/2" | 400 | 2 | One Mandrel Two Honing Stones One Truing Sleeve | 0000000 | 000000 | 2 | 00000000 | 00000 | 00000000 | 000000 | |

| 0.74" to 0.865" | 3/4" | -0.001" to 0.001" | 6 5/8" | 220 Grit (Smooth) | 3" | 400 | 2 | One Mandrel Two Honing Stones One Truing Sleeve | 0000000 | 000000 | 2 | 00000000 | 00000 | 00000000 | 000000 | |

| 0.865" to 0.99" | 7/8" | -0.001" to 0.001" | 7 1/8" | 220 Grit (Smooth) | 3 1/2" | 400 | 2 | One Mandrel Two Honing Stones One Truing Sleeve | 0000000 | 000000 | 2 | 00000000 | 00000 | 00000000 | 000000 | |

| 0.99" to 1.115" | 1" | -0.001" to 0.001" | 7 5/8" | 220 Grit (Smooth) | 3 1/2" | 400 | 2 | One Mandrel Two Honing Stones One Truing Sleeve | 0000000 | 000000 | 2 | 00000000 | 00000 | 00000000 | 000000 | |

| 1.115" to 1.24" | 1 1/8" | -0.001" to 0.001" | 7 5/8" | 220 Grit (Smooth) | 4" | 300 | 2 | One Mandrel Two Honing Stones One Truing Sleeve | 0000000 | 000000 | 2 | 00000000 | 00000 | 00000000 | 000000 | |

| 1.24" to 1.365" | 1 1/4" | -0.001" to 0.001" | 7 5/8" | 220 Grit (Smooth) | 4" | 300 | 2 | One Mandrel Two Honing Stones One Truing Sleeve | 0000000 | 000000 | 2 | 00000000 | 00000 | 00000000 | 000000 | |

| 1.365" to 1.49" | 1 3/8" | -0.001" to 0.001" | 7 5/8" | 220 Grit (Smooth) | 4" | 300 | 2 | One Mandrel Two Honing Stones One Truing Sleeve | 0000000 | 000000 | 2 | 00000000 | 00000 | 00000000 | 000000 | |

| 1.49" to 1.615" | 1 1/2" | -0.001" to 0.001" | 7 5/8" | 220 Grit (Smooth) | 4" | 300 | 2 | One Mandrel Two Honing Stones One Truing Sleeve | 0000000 | 000000 | 2 | 00000000 | 00000 | 00000000 | 000000 | |

| 1.615" to 1.74" | 1 5/8" | -0.001" to 0.001" | 7 5/8" | 220 Grit (Smooth) | 4" | 200 | 2 | One Mandrel Two Honing Stones One Truing Sleeve | 0000000 | 000000 | 2 | 00000000 | 00000 | 00000000 | 000000 | |

| 1.74" to 1.865" | 1 3/4" | -0.001" to 0.001" | 7 5/8" | 220 Grit (Smooth) | 4" | 100 | 2 | One Mandrel Two Honing Stones One Truing Sleeve | 0000000 | 000000 | 2 | 00000000 | 00000 | 00000000 | 000000 | |

| 1.865" to 1.99" | 1 7/8" | -0.001" to 0.001" | 7 5/8" | 220 Grit (Smooth) | 4" | 100 | 2 | One Mandrel Two Honing Stones One Truing Sleeve | 0000000 | 000000 | 2 | 00000000 | 00000 | 00000000 | 000000 | |

| 1.99" to 2.115" | 2" | -0.001" to 0.001" | 7 5/8" | 220 Grit (Smooth) | 4" | 100 | 2 | One Mandrel Two Honing Stones One Truing Sleeve | 0000000 | 000000 | 2 | 00000000 | 00000 | 00000000 | 000000 | |

| 2.115" to 2.24" | 2 1/8" | -0.001" to 0.001" | 7 5/8" | 220 Grit (Smooth) | 4" | 50 | 2 | One Mandrel Two Honing Stones One Truing Sleeve | 0000000 | 000000 | 2 | 00000000 | 00000 | 00000000 | 000000 | |

| 2.24" to 2.365" | 2 1/4" | -0.001" to 0.001" | 7 5/8" | 220 Grit (Smooth) | 4" | 50 | 2 | One Mandrel Two Honing Stones One Truing Sleeve | 0000000 | 000000 | 2 | 00000000 | 00000 | 00000000 | 000000 | |

| 2.365" to 2.49" | 2 3/8" | -0.001" to 0.001" | 7 5/8" | 220 Grit (Smooth) | 4" | 50 | 2 | One Mandrel Two Honing Stones One Truing Sleeve | 0000000 | 000000 | 2 | 00000000 | 00000 | 00000000 | 000000 | |

| 2.49" to 2.615" | 2 1/2" | -0.001" to 0.001" | 7 5/8" | 220 Grit (Smooth) | 4" | 50 | 2 | One Mandrel Two Honing Stones One Truing Sleeve | 0000000 | 000000 | 2 | 00000000 | 00000 | 00000000 | 000000 | |

| 2.615" to 2.74" | 2 5/8" | -0.001" to 0.001" | 7 5/8" | 220 Grit (Smooth) | 4" | 50 | 2 | One Mandrel Two Honing Stones One Truing Sleeve | 0000000 | 000000 | 2 | 00000000 | 00000 | 00000000 | 000000 | |

| 2.74" to 2.865" | 2 3/4" | -0.001" to 0.001" | 7 5/8" | 220 Grit (Smooth) | 4" | 50 | 2 | One Mandrel Two Honing Stones One Truing Sleeve | 0000000 | 000000 | 2 | 00000000 | 00000 | 00000000 | 000000 | |

| 2.865" to 2.99" | 2 7/8" | -0.001" to 0.001" | 7 5/8" | 220 Grit (Smooth) | 4" | 50 | 2 | One Mandrel Two Honing Stones One Truing Sleeve | 0000000 | 000000 | 2 | 00000000 | 00000 | 00000000 | 000000 | |

| 2.99" to 3.115" | 3" | -0.001" to 0.001" | 7 5/8" | 220 Grit (Smooth) | 4" | 50 | 2 | One Mandrel Two Honing Stones One Truing Sleeve | 0000000 | 000000 | 2 | 00000000 | 00000 | 00000000 | 000000 | |