Filter by

Material

Minimum Hardness

Sold As

Magnetic Properties

DFARS Specialty Metals

Export Control Classification Number (ECCN)

REACH

RoHS

Container Features

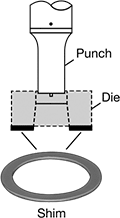

Shims for Dies

|

Restore your die to its original height for clean cuts in metal stamping. Dies shorten over time from wear and sharpening, which prevents your die punch from going all the way through and often causes annoying partial punches that require stopping to clear. Place these shims under your die to adjust its height, extend its life, and prevent jams.

You can stack multiple shims to achieve your exact thickness, but stacking more than four may cause them to shift. Remember, fewer shims are better, so a couple of thicker shims are more stable than a bunch of thin shims.

18-8 Stainless Steel—The choice for wet and outdoor environments, these shims resist rust. However, they’ll corrode or pit when exposed to salt water and chemicals.

Stress-Resistant Spring Steel—These shims are harder and hold their shape better than carbon steel. Use them for high-stress applications, such as leveling heavy machinery. They're best for dry environments since moisture will cause them to rust.

Thk. | Thk. Tolerance | OD Tolerance | ID | ID Tolerance | Min. Hardness | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 mm | -0.025 mm to 0.025 mm | -0.3 mm to 0 mm | 6 mm | -0.08 mm to 0.17 mm | Rockwell C40 | 25 | 99432A341 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 mm | -0.025 mm to 0.025 mm | -0.3 mm to 0 mm | 8 mm | -0.18 mm to 0.07 mm | Rockwell C40 | 25 | 99432A343 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

16 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 mm | -0.025 mm to 0.025 mm | -0.31 mm to 0 mm | 12 mm | -0.35 mm to 0 mm | Rockwell C40 | 25 | 99432A345 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

20 mm OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 mm | -0.025 mm to 0.025 mm | -0.32 mm to 0 mm | 16 mm | -0.5 mm to 0 mm | Rockwell C40 | 25 | 99432A347 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stress-Resistant Spring Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.005" | -0.0005" to 0.0005" | -0.01" to 0" | 0.17" | 0" to 0.01" | Rockwell C44 | 10 | 99432A340 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.015" | -0.00075" to 0.00075" | -0.01" to 0" | 0.17" | 0" to 0.01" | Rockwell C44 | 10 | 99432A342 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.032" | -0.0015" to 0.0015" | -0.02" to 0" | 0.17" | 0" to 0.02" | Rockwell C44 | 10 | 99432A401 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/16" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.005" | -0.0005" to 0.0005" | -0.01" to 0" | 0.23" | 0" to 0.01" | Rockwell C44 | 10 | 99432A344 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.015" | -0.00075" to 0.00075" | -0.01" to 0" | 0.23" | 0" to 0.01" | Rockwell C44 | 10 | 99432A346 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.032" | -0.0015" to 0.0015" | -0.02" to 0" | 0.23" | 0" to 0.02" | Rockwell C44 | 10 | 99432A409 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.005" | -0.0005" to 0.0005" | -0.01" to 0" | 0.285" | 0" to 0.01" | Rockwell C44 | 10 | 99432A348 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.015" | -0.00075" to 0.00075" | -0.01" to 0" | 0.285" | 0" to 0.01" | Rockwell C44 | 10 | 99432A350 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.032" | -0.0015" to 0.0015" | -0.02" to 0" | 0.285" | 0" to 0.02" | Rockwell C44 | 10 | 99432A417 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

7/16" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.005" | -0.0005" to 0.0005" | -0.01" to 0" | 0.31" | 0" to 0.01" | Rockwell C44 | 10 | 99432A352 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.015" | -0.00075" to 0.00075" | -0.01" to 0" | 0.31" | 0" to 0.01" | Rockwell C44 | 10 | 99432A354 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.032" | -0.0015" to 0.0015" | -0.02" to 0" | 0.31" | 0" to 0.02" | Rockwell C44 | 10 | 99432A425 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/2" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.005" | -0.0005" to 0.0005" | -0.01" to 0" | 0.35" | 0" to 0.01" | Rockwell C44 | 10 | 99432A356 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.015" | -0.00075" to 0.00075" | -0.01" to 0" | 0.35" | 0" to 0.01" | Rockwell C44 | 10 | 99432A358 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.032" | -0.0015" to 0.0015" | -0.02" to 0" | 0.35" | 0" to 0.02" | Rockwell C44 | 10 | 99432A433 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.005" | -0.0005" to 0.0005" | -0.01" to 0" | 0.47" | 0" to 0.01" | Rockwell C44 | 10 | 99432A360 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.015" | -0.00075" to 0.00075" | -0.01" to 0" | 0.47" | 0" to 0.01" | Rockwell C44 | 10 | 99432A362 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.032" | -0.0015" to 0.0015" | -0.02" to 0" | 0.47" | 0" to 0.02" | Rockwell C44 | 10 | 99432A441 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.005" | -0.0005" to 0.0005" | -0.01" to 0" | 0.595" | 0" to 0.01" | Rockwell C44 | 10 | 99432A364 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.015" | -0.00075" to 0.00075" | -0.01" to 0" | 0.595" | 0" to 0.01" | Rockwell C44 | 10 | 99432A366 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.032" | -0.0015" to 0.0015" | -0.02" to 0" | 0.595" | 0" to 0.02" | Rockwell C44 | 10 | 99432A449 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

7/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.005" | -0.0005" to 0.0005" | -0.01" to 0" | 5/8" | 0" to 0.01" | Rockwell C44 | 10 | 99432A368 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.015" | -0.00075" to 0.00075" | -0.01" to 0" | 5/8" | 0" to 0.01" | Rockwell C44 | 10 | 99432A372 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.032" | -0.0015" to 0.0015" | -0.02" to 0" | 5/8" | 0" to 0.02" | Rockwell C44 | 10 | 99432A457 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.005" | -0.0005" to 0.0005" | -0.01" to 0" | 3/4" | 0" to 0.01" | Rockwell C44 | 10 | 99432A374 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.015" | -0.00075" to 0.00075" | -0.01" to 0" | 3/4" | 0" to 0.01" | Rockwell C44 | 10 | 99432A376 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.032" | -0.0015" to 0.0015" | -0.02" to 0" | 3/4" | 0" to 0.02" | Rockwell C44 | 10 | 99432A465 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Shim Assortments for Dies

|

Keep a variety of shim ODs on hand to fit various die sizes. Restore your die to its original height for clean cuts in metal stamping. Dies shorten over time from wear and sharpening, which prevents your die punch from going all the way through and often causes annoying partial punches that require stopping to clear. Place these shims under your die to adjust its height, extend its life, and prevent jams.

You can stack multiple shims to achieve your exact thickness, but stacking more than four may cause them to shift. Remember, fewer shims are better, so a couple of thicker shims are more stable than a bunch of thin shims.

Stress-Resistant Spring Steel—These shims are harder and hold their shape better than carbon steel. Use them for high-stress applications, such as leveling heavy machinery. They're best for dry environments since moisture will cause them to rust.

Plastic Box—Labels in the lid make it easy to quickly find the right size.

No. of Pieces | OD | Thicknesses Included | Container Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Stress-Resistant Spring Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 450 | 1/4", 5/16", 3/8", 7/16", 1/2", 5/8", 3/4", 7/8", 1" | 0.005", 0.015" | Plastic Box | 99432A214 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||