Filter by

For Use With

Maximum Pressure Differential

Maximum Input Pressure

Measurement Unit

Connection Material

Minimum Pressure Differential

Maximum Pressure

Housing Material

Minimum Pressure

Export Control Classification Number (ECCN)

DFARS Specialty Metals

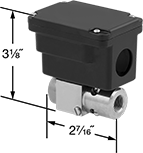

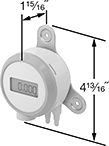

Differential Pressure Transmitters for Air

ABS Housing%20--%3e%3csvg%20version='1.1'%20id='Layer_1'%20xmlns='http://www.w3.org/2000/svg'%20xmlns:xlink='http://www.w3.org/1999/xlink'%20x='0px'%20y='0px'%20viewBox='0%200%20400%20400'%20style='enable-background:new%200%200%20400%20400;'%20xml:space='preserve'%3e%3cstyle%20type='text/css'%3e%20.st0{fill:%231A70A0;}%20.st1{opacity:0.5;}%20%3c/style%3e%3cg%3e%3cg%3e%3cpath%20class='st0'%20d='M200,56.9c38.35,0,74.4,14.93,101.51,42.05c27.11,27.11,42.05,63.17,42.05,101.51s-14.93,74.4-42.05,101.51%20S238.35,344.02,200,344.02s-74.4-14.93-101.51-42.05c-27.11-27.11-42.05-63.17-42.05-101.51s14.93-74.4,42.05-101.51%20S161.65,56.9,200,56.9%20M200,12.9C96.41,12.9,12.44,96.88,12.44,200.46c0,103.59,83.97,187.56,187.56,187.56%20c103.59,0,187.56-83.97,187.56-187.56C387.56,96.88,303.59,12.9,200,12.9L200,12.9z'/%3e%3c/g%3e%3cg%3e%3cg%20class='st1'%3e%3cpath%20class='st0'%20d='M235.49,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C190.89,163.58,214.53,158.88,235.49,152.24z%20M230.44,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C218.68,82.23,224.24,80.84,230.44,80.84z'/%3e%3c/g%3e%3cg%3e%3cpath%20class='st0'%20d='M214.08,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C169.48,163.58,193.11,158.88,214.08,152.24z%20M209.03,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C197.26,82.23,202.83,80.84,209.03,80.84z'/%3e%3c/g%3e%3c/g%3e%3c/g%3e%3c/svg%3e)

Mounting Holes | Connection | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pressure Differential, in. H₂O | Max. Input Pressure, in. H₂O | Input Voltage, V DC | For Tube ID | For DIN Rail Ht., mm | For No. of Wires | Mounting Hardware Included | Top Dia. (No. of) | Bottom Dia. (No. of) | Ht. | Wd. | Certification | Enclosure Rating | For Use With | Accuracy | Pipe | Fitting | Material | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4 to 20 mA Output Signal—Screw Terminals | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

DIN-Rail/Surface Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| -15 to 15 | 415 | 12 to 36 | 1/8" | 35 | 2 | No | 3/16", 2 | 5/32", 2 | 3 5/16" | 1 7/8" | CE Marked | NEMA 1 | Air | ±0.8% | Male | Barbed | Brass | 0 to 160 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| -10 to 10 | 415 | 12 to 36 | 1/8" | 35 | 2 | No | 3/16", 2 | 5/32", 2 | 3 5/16" | 1 7/8" | CE Marked | NEMA 1 | Air | ±0.8% | Male | Barbed | Brass | 0 to 160 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| -5 to 5 | 415 | 12 to 36 | 1/8" | 35 | 2 | No | 3/16", 2 | 5/32", 2 | 3 5/16" | 1 7/8" | CE Marked | NEMA 1 | Air | ±0.8% | Male | Barbed | Brass | 0 to 160 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| -2.5 to 2.5 | 415 | 12 to 36 | 1/8" | 35 | 2 | No | 3/16", 2 | 5/32", 2 | 3 5/16" | 1 7/8" | CE Marked | NEMA 1 | Air | ±0.8% | Male | Barbed | Brass | 0 to 160 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| -1 to 1 | 415 | 12 to 36 | 1/8" | 35 | 2 | No | 3/16", 2 | 5/32", 2 | 3 5/16" | 1 7/8" | CE Marked | NEMA 1 | Air | ±0.8% | Male | Barbed | Brass | 0 to 160 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| -0.5 to 0.5 | 415 | 12 to 36 | 1/8" | 35 | 2 | No | 3/16", 2 | 5/32", 2 | 3 5/16" | 1 7/8" | CE Marked | NEMA 1 | Air | ±0.8% | Male | Barbed | Brass | 0 to 160 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| -0.25 to 0.25 | 415 | 12 to 36 | 1/8" | 35 | 2 | No | 3/16", 2 | 5/32", 2 | 3 5/16" | 1 7/8" | CE Marked | NEMA 1 | Air | ±0.8% | Male | Barbed | Brass | 0 to 160 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| -0.1 to 0.1 | 415 | 12 to 36 | 1/8" | 35 | 2 | No | 3/16", 2 | 5/32", 2 | 3 5/16" | 1 7/8" | CE Marked | NEMA 1 | Air | ±0.8% | Male | Barbed | Brass | 0 to 160 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 0.1 | 415 | 12 to 36 | 1/8" | 35 | 2 | No | 3/16", 2 | 5/32", 2 | 3 5/16" | 1 7/8" | CE Marked | NEMA 1 | Air | ±0.8% | Male | Barbed | Brass | 0 to 160 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 0.25 | 415 | 12 to 36 | 1/8" | 35 | 2 | No | 3/16", 2 | 5/32", 2 | 3 5/16" | 1 7/8" | CE Marked | NEMA 1 | Air | ±0.8% | Male | Barbed | Brass | 0 to 160 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 0.5 | 415 | 12 to 36 | 1/8" | 35 | 2 | No | 3/16", 2 | 5/32", 2 | 3 5/16" | 1 7/8" | CE Marked | NEMA 1 | Air | ±0.8% | Male | Barbed | Brass | 0 to 160 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 1 | 415 | 12 to 36 | 1/8" | 35 | 2 | No | 3/16", 2 | 5/32", 2 | 3 5/16" | 1 7/8" | CE Marked | NEMA 1 | Air | ±0.8% | Male | Barbed | Brass | 0 to 160 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 2.5 | 415 | 12 to 36 | 1/8" | 35 | 2 | No | 3/16", 2 | 5/32", 2 | 3 5/16" | 1 7/8" | CE Marked | NEMA 1 | Air | ±0.8% | Male | Barbed | Brass | 0 to 160 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 5 | 415 | 12 to 36 | 1/8" | 35 | 2 | No | 3/16", 2 | 5/32", 2 | 3 5/16" | 1 7/8" | CE Marked | NEMA 1 | Air | ±0.8% | Male | Barbed | Brass | 0 to 160 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 10 | 415 | 12 to 36 | 1/8" | 35 | 2 | No | 3/16", 2 | 5/32", 2 | 3 5/16" | 1 7/8" | CE Marked | NEMA 1 | Air | ±0.8% | Male | Barbed | Brass | 0 to 160 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 25 | 415 | 12 to 36 | 1/8" | 35 | 2 | No | 3/16", 2 | 5/32", 2 | 3 5/16" | 1 7/8" | CE Marked | NEMA 1 | Air | ±0.8% | Male | Barbed | Brass | 0 to 160 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 50 | 415 | 12 to 36 | 1/8" | 35 | 2 | No | 3/16", 2 | 5/32", 2 | 3 5/16" | 1 7/8" | CE Marked | NEMA 1 | Air | ±0.8% | Male | Barbed | Brass | 0 to 160 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 100 | 415 | 12 to 36 | 1/8" | 35 | 2 | No | 3/16", 2 | 5/32", 2 | 3 5/16" | 1 7/8" | CE Marked | NEMA 1 | Air | ±0.8% | Male | Barbed | Brass | 0 to 160 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

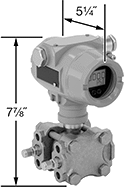

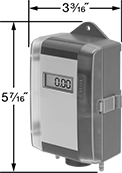

High-Accuracy Differential Pressure Transmitters

Aluminum Housing%20--%3e%3csvg%20version='1.1'%20id='Layer_1'%20xmlns='http://www.w3.org/2000/svg'%20xmlns:xlink='http://www.w3.org/1999/xlink'%20x='0px'%20y='0px'%20viewBox='0%200%20400%20400'%20style='enable-background:new%200%200%20400%20400;'%20xml:space='preserve'%3e%3cstyle%20type='text/css'%3e%20.st0{fill:%231A70A0;}%20.st1{opacity:0.5;}%20%3c/style%3e%3cg%3e%3cg%3e%3cpath%20class='st0'%20d='M200,56.9c38.35,0,74.4,14.93,101.51,42.05c27.11,27.11,42.05,63.17,42.05,101.51s-14.93,74.4-42.05,101.51%20S238.35,344.02,200,344.02s-74.4-14.93-101.51-42.05c-27.11-27.11-42.05-63.17-42.05-101.51s14.93-74.4,42.05-101.51%20S161.65,56.9,200,56.9%20M200,12.9C96.41,12.9,12.44,96.88,12.44,200.46c0,103.59,83.97,187.56,187.56,187.56%20c103.59,0,187.56-83.97,187.56-187.56C387.56,96.88,303.59,12.9,200,12.9L200,12.9z'/%3e%3c/g%3e%3cg%3e%3cg%20class='st1'%3e%3cpath%20class='st0'%20d='M235.49,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C190.89,163.58,214.53,158.88,235.49,152.24z%20M230.44,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C218.68,82.23,224.24,80.84,230.44,80.84z'/%3e%3c/g%3e%3cg%3e%3cpath%20class='st0'%20d='M214.08,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C169.48,163.58,193.11,158.88,214.08,152.24z%20M209.03,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C197.26,82.23,202.83,80.84,209.03,80.84z'/%3e%3c/g%3e%3c/g%3e%3c/g%3e%3c/svg%3e)

Mounting Holes | Connection | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pressure Differential, psi | Max. Input Pressure, psi | Input Voltage, V DC | Pipe Size | For No. of Wires | Mounting Hardware Included | Dia. | No. of | Ht. | Wd. | Enclosure Rating | For Use With | Accuracy | Pipe | Fitting | Material | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4 to 20 mA Output Signal—Screw Terminals | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 1 | 350 | 9 to 30 | 1/4 | 2 | Yes | 5/32" | 4 | 3 1/8" | 2 7/16" | NEMA 4 | Air, Water | ±0.25% | NPT Female | Threaded | 17-4 PH Stainless Steel | 0 to 175 | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 2 | 350 | 9 to 30 | 1/4 | 2 | Yes | 5/32" | 4 | 3 1/8" | 2 7/16" | NEMA 4 | Air, Water | ±0.25% | NPT Female | Threaded | 17-4 PH Stainless Steel | 0 to 175 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 5 | 350 | 9 to 30 | 1/4 | 2 | Yes | 5/32" | 4 | 3 1/8" | 2 7/16" | NEMA 4 | Air, Water | ±0.25% | NPT Female | Threaded | 17-4 PH Stainless Steel | 0 to 175 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 10 | 350 | 9 to 30 | 1/4 | 2 | Yes | 5/32" | 4 | 3 1/8" | 2 7/16" | NEMA 4 | Air, Water | ±0.25% | NPT Female | Threaded | 17-4 PH Stainless Steel | 0 to 175 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 25 | 350 | 9 to 30 | 1/4 | 2 | Yes | 5/32" | 4 | 3 1/8" | 2 7/16" | NEMA 4 | Air, Water | ±0.25% | NPT Female | Threaded | 17-4 PH Stainless Steel | 0 to 175 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 50 | 350 | 9 to 30 | 1/4 | 2 | Yes | 5/32" | 4 | 3 1/8" | 2 7/16" | NEMA 4 | Air, Water | ±0.25% | NPT Female | Threaded | 17-4 PH Stainless Steel | 0 to 175 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

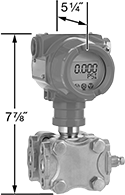

Easy-Setup Differential Pressure Transmitters

Mounting Holes | Connection | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pressure Differential | Max. Input Pressure, psi | Input Voltage, V DC | Pipe Size | Mounting Hardware Included | Dia. | No. of | Ht. | Wd. | Communication Protocol | Enclosure Rating | For Use With | Accuracy | Pipe | Fitting | Material | Housing Material | Temp. Range, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4 to 20 mA Output Signal—Screw Terminals | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 in. H₂O to 25 in. H₂O | 3,625 | 11 to 55 | 1/4 | No | 7/16" | 8 | 7 7/8" | 5 1/4" | HART | IP66, NEMA 4X | Air, Hydraulic Fluid, Water | ±0.075% | NPT Female | Threaded | Hastelloy Nickel | Aluminum | -40 to 185 | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 in. H₂O to 200 in. H₂O | 5,800 | 11 to 55 | 1/4 | No | 7/16" | 8 | 7 7/8" | 5 1/4" | HART | IP66, NEMA 4X | Air, Hydraulic Fluid, Water | ±0.075% | NPT Female | Threaded | Hastelloy Nickel | Aluminum | -40 to 185 | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 in. H₂O to 1,000 in. H₂O | 5,800 | 11 to 55 | 1/4 | No | 7/16" | 8 | 7 7/8" | 5 1/4" | HART | IP66, NEMA 4X | Air, Hydraulic Fluid, Water | ±0.075% | NPT Female | Threaded | Hastelloy Nickel | Aluminum | -40 to 185 | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 psi to 150 psi | 5,800 | 11 to 55 | 1/4 | No | 7/16" | 8 | 7 7/8" | 5 1/4" | HART | IP66, NEMA 4X | Air, Hydraulic Fluid, Water | ±0.075% | NPT Female | Threaded | Hastelloy Nickel | Aluminum | -40 to 185 | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 psi to 450 psi | 5,800 | 11 to 55 | 1/4 | No | 7/16" | 8 | 7 7/8" | 5 1/4" | HART | IP66, NEMA 4X | Air, Hydraulic Fluid, Water | ±0.075% | NPT Female | Threaded | Hastelloy Nickel | Aluminum | -40 to 185 | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 psi to 1,500 psi | 5,800 | 11 to 55 | 1/4 | No | 7/16" | 8 | 7 7/8" | 5 1/4" | HART | IP66, NEMA 4X | Air, Hydraulic Fluid, Water | ±0.075% | NPT Female | Threaded | Hastelloy Nickel | Aluminum | -40 to 185 | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

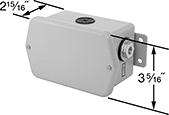

Differential Pressure Transmitters for Liquids

Steel Housing

Mounting Holes | Connection | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pressure Differential | Max. Input Pressure, psi | Input Voltage, V DC | Pipe Size | For No. of Wires | Mounting Hardware Included | Dia. | No. of | Ht. | Wd. | Enclosure Rating | For Use With | Accuracy | Pipe | Fitting | Material | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4 to 20 mA Output Signal—Screw Terminals | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 in. H₂O to 1 in. H₂O | 20 | 18 to 30 | 1/8 | 2 | No | 7/32" | 4 | 3 5/16" | 2 15/16" | IP56, NEMA 4 | Hydraulic Fluid, Water | ±1% | NPT Female | Threaded | Brass | 32 to 122 | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 in. H₂O to 3 in. H₂O | 20 | 18 to 30 | 1/8 | 2 | No | 7/32" | 4 | 3 5/16" | 2 15/16" | IP56, NEMA 4 | Hydraulic Fluid, Water | ±1% | NPT Female | Threaded | Brass | 32 to 122 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 in. H₂O to 5 in. H₂O | 20 | 18 to 30 | 1/8 | 2 | No | 7/32" | 4 | 3 5/16" | 2 15/16" | IP56, NEMA 4 | Hydraulic Fluid, Water | ±1% | NPT Female | Threaded | Brass | 32 to 122 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 in. H₂O to 10 in. H₂O | 20 | 18 to 30 | 1/8 | 2 | No | 7/32" | 4 | 3 5/16" | 2 15/16" | IP56, NEMA 4 | Hydraulic Fluid, Water | ±1% | NPT Female | Threaded | Brass | 32 to 122 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 in. H₂O to 25 in. H₂O | 20 | 18 to 30 | 1/8 | 2 | No | 7/32" | 4 | 3 5/16" | 2 15/16" | IP56, NEMA 4 | Hydraulic Fluid, Water | ±1% | NPT Female | Threaded | Brass | 32 to 122 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 psi to 1 psi | 20 | 18 to 30 | 1/8 | 2 | No | 7/32" | 4 | 3 5/16" | 2 15/16" | IP56, NEMA 4 | Hydraulic Fluid, Water | ±1% | NPT Female | Threaded | Brass | 32 to 122 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel Housing%20--%3e%3csvg%20version='1.1'%20id='Layer_1'%20xmlns='http://www.w3.org/2000/svg'%20xmlns:xlink='http://www.w3.org/1999/xlink'%20x='0px'%20y='0px'%20viewBox='0%200%20400%20400'%20style='enable-background:new%200%200%20400%20400;'%20xml:space='preserve'%3e%3cstyle%20type='text/css'%3e%20.st0{fill:%231A70A0;}%20.st1{opacity:0.5;}%20%3c/style%3e%3cg%3e%3cg%3e%3cpath%20class='st0'%20d='M200,56.9c38.35,0,74.4,14.93,101.51,42.05c27.11,27.11,42.05,63.17,42.05,101.51s-14.93,74.4-42.05,101.51%20S238.35,344.02,200,344.02s-74.4-14.93-101.51-42.05c-27.11-27.11-42.05-63.17-42.05-101.51s14.93-74.4,42.05-101.51%20S161.65,56.9,200,56.9%20M200,12.9C96.41,12.9,12.44,96.88,12.44,200.46c0,103.59,83.97,187.56,187.56,187.56%20c103.59,0,187.56-83.97,187.56-187.56C387.56,96.88,303.59,12.9,200,12.9L200,12.9z'/%3e%3c/g%3e%3cg%3e%3cg%20class='st1'%3e%3cpath%20class='st0'%20d='M235.49,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C190.89,163.58,214.53,158.88,235.49,152.24z%20M230.44,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C218.68,82.23,224.24,80.84,230.44,80.84z'/%3e%3c/g%3e%3cg%3e%3cpath%20class='st0'%20d='M214.08,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C169.48,163.58,193.11,158.88,214.08,152.24z%20M209.03,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C197.26,82.23,202.83,80.84,209.03,80.84z'/%3e%3c/g%3e%3c/g%3e%3c/g%3e%3c/svg%3e)

Mounting Holes | Connection | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pressure Differential, psi | Max. Input Pressure, psi | Input Voltage, V DC | Pipe Size | For No. of Wires | Mounting Hardware Included | Dia. | No. of | Ht. | Wd. | Certification | Enclosure Rating | For Use With | Accuracy | Pipe | Fitting | Material | Temp. Range, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4 to 20 mA Output Signal—Screw Terminals | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 5 | 50 | 10 to 35 | 1/4 | 2 | No | 1/4" | 2 | 2" | 1 7/16" | CE Marked | IP66, NEMA 4X | Diesel Fuel, Gasoline, Hydraulic Fluid, Water | ±0.5% | NPT Female | Threaded | 316 Stainless Steel | 0 to 200 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 10 | 50 | 10 to 35 | 1/4 | 2 | No | 1/4" | 2 | 2" | 1 7/16" | CE Marked | IP66, NEMA 4X | Diesel Fuel, Gasoline, Hydraulic Fluid, Water | ±0.5% | NPT Female | Threaded | 316 Stainless Steel | 0 to 200 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 25 | 120 | 10 to 35 | 1/4 | 2 | No | 1/4" | 2 | 2" | 1 7/16" | CE Marked | IP66, NEMA 4X | Diesel Fuel, Gasoline, Hydraulic Fluid, Water | ±0.5% | NPT Female | Threaded | 316 Stainless Steel | 0 to 200 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 50 | 250 | 10 to 35 | 1/4 | 2 | No | 1/4" | 2 | 2" | 1 7/16" | CE Marked | IP66, NEMA 4X | Diesel Fuel, Gasoline, Hydraulic Fluid, Water | ±0.5% | NPT Female | Threaded | 316 Stainless Steel | 0 to 200 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 100 | 500 | 10 to 35 | 1/4 | 2 | No | 1/4" | 2 | 2" | 1 7/16" | CE Marked | IP66, NEMA 4X | Diesel Fuel, Gasoline, Hydraulic Fluid, Water | ±0.5% | NPT Female | Threaded | 316 Stainless Steel | 0 to 200 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 150 | 750 | 10 to 35 | 1/4 | 2 | No | 1/4" | 2 | 2" | 1 7/16" | CE Marked | IP66, NEMA 4X | Diesel Fuel, Gasoline, Hydraulic Fluid, Water | ±0.5% | NPT Female | Threaded | 316 Stainless Steel | 0 to 200 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

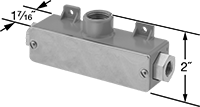

Differential Pressure Transmitters with Digital Display for Air

Nylon Housing%20--%3e%3csvg%20version='1.1'%20id='Layer_1'%20xmlns='http://www.w3.org/2000/svg'%20xmlns:xlink='http://www.w3.org/1999/xlink'%20x='0px'%20y='0px'%20viewBox='0%200%20400%20400'%20style='enable-background:new%200%200%20400%20400;'%20xml:space='preserve'%3e%3cstyle%20type='text/css'%3e%20.st0{fill:%231A70A0;}%20.st1{opacity:0.5;}%20%3c/style%3e%3cg%3e%3cg%3e%3cpath%20class='st0'%20d='M200,56.9c38.35,0,74.4,14.93,101.51,42.05c27.11,27.11,42.05,63.17,42.05,101.51s-14.93,74.4-42.05,101.51%20S238.35,344.02,200,344.02s-74.4-14.93-101.51-42.05c-27.11-27.11-42.05-63.17-42.05-101.51s14.93-74.4,42.05-101.51%20S161.65,56.9,200,56.9%20M200,12.9C96.41,12.9,12.44,96.88,12.44,200.46c0,103.59,83.97,187.56,187.56,187.56%20c103.59,0,187.56-83.97,187.56-187.56C387.56,96.88,303.59,12.9,200,12.9L200,12.9z'/%3e%3c/g%3e%3cg%3e%3cg%20class='st1'%3e%3cpath%20class='st0'%20d='M235.49,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C190.89,163.58,214.53,158.88,235.49,152.24z%20M230.44,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C218.68,82.23,224.24,80.84,230.44,80.84z'/%3e%3c/g%3e%3cg%3e%3cpath%20class='st0'%20d='M214.08,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C169.48,163.58,193.11,158.88,214.08,152.24z%20M209.03,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C197.26,82.23,202.83,80.84,209.03,80.84z'/%3e%3c/g%3e%3c/g%3e%3c/g%3e%3c/svg%3e)

Mounting Holes | Connection | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pressure Differential Range | Max. Input Pressure, in. H₂O | Input Voltage, V DC | For Tube ID | For No. of Wires | Mounting Hardware Included | Dia. | No. of | Ht. | Certification | Enclosure Rating | For Use With | Accuracy | Pipe | Fitting | Material | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4 to 20 mA, 0 to 5V DC, 0 to 10V DC Output Signal—Screw Terminals | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Surface Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 0.1 in. H₂O 0 to 0.15 in. H₂O 0 to 0.25 in. H₂O 0 to 0.5 in. H₂O | 99 | 10 to 36 | 1/8", 3/16", 1/4", 5 mm, 6 mm | 2, 3 | No | 3/16" | 3 | 4 13/16" | CE Marked | IP66, NEMA 4X | Air | ±1% | Male | Barbed | Nylon | -4 to 158 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 1 in. H₂O 0 to 2 in. H₂O 0 to 3 in. H₂O 0 to 5 in. H₂O | 166 | 10 to 36 | 1/8", 3/16", 1/4", 5 mm, 6 mm | 2, 3 | No | 3/16" | 3 | 4 13/16" | CE Marked | IP66, NEMA 4X | Air | ±1% | Male | Barbed | Nylon | -4 to 158 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 10 in. H₂O 0 to 15 in. H₂O 0 to 25 in. H₂O 0 to 28 in. H₂O | 166 | 10 to 36 | 1/8", 3/16", 1/4", 5 mm, 6 mm | 2, 3 | No | 3/16" | 3 | 4 13/16" | CE Marked | IP66, NEMA 4X | Air | ±1% | Male | Barbed | Nylon | -4 to 158 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polycarbonate Housing%20--%3e%3csvg%20version='1.1'%20id='Layer_1'%20xmlns='http://www.w3.org/2000/svg'%20xmlns:xlink='http://www.w3.org/1999/xlink'%20x='0px'%20y='0px'%20viewBox='0%200%20400%20400'%20style='enable-background:new%200%200%20400%20400;'%20xml:space='preserve'%3e%3cstyle%20type='text/css'%3e%20.st0{fill:%231A70A0;}%20.st1{opacity:0.5;}%20%3c/style%3e%3cg%3e%3cg%3e%3cpath%20class='st0'%20d='M200,56.9c38.35,0,74.4,14.93,101.51,42.05c27.11,27.11,42.05,63.17,42.05,101.51s-14.93,74.4-42.05,101.51%20S238.35,344.02,200,344.02s-74.4-14.93-101.51-42.05c-27.11-27.11-42.05-63.17-42.05-101.51s14.93-74.4,42.05-101.51%20S161.65,56.9,200,56.9%20M200,12.9C96.41,12.9,12.44,96.88,12.44,200.46c0,103.59,83.97,187.56,187.56,187.56%20c103.59,0,187.56-83.97,187.56-187.56C387.56,96.88,303.59,12.9,200,12.9L200,12.9z'/%3e%3c/g%3e%3cg%3e%3cg%20class='st1'%3e%3cpath%20class='st0'%20d='M235.49,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C190.89,163.58,214.53,158.88,235.49,152.24z%20M230.44,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C218.68,82.23,224.24,80.84,230.44,80.84z'/%3e%3c/g%3e%3cg%3e%3cpath%20class='st0'%20d='M214.08,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C169.48,163.58,193.11,158.88,214.08,152.24z%20M209.03,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C197.26,82.23,202.83,80.84,209.03,80.84z'/%3e%3c/g%3e%3c/g%3e%3c/g%3e%3c/svg%3e)

Mounting Holes | Connection | Calibration Certificate Traceable to NIST | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pressure Differential Range | Max. Input Pressure, psi | Input Voltage, V DC | For Tube ID | For DIN Rail Ht., mm | For No. of Wires | Mounting Hardware Included | Dia. | No. of | Ht. | Wd. | Certification | Pressure Probe Cable Lg. | Enclosure Rating | For Use With | Accuracy | Fitting | Material | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4 to 20 mA, 0 to 5V DC, 0 to 10V DC Output Signal—Screw Terminals | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Surface Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| -5 to 5 in. H₂O -2.5 to 2.5 in. H₂O -1 to 1 in. H₂O -0.5 to 0.5 in. H₂O 0 to 0.5 in. H₂O 0 to 1 in. H₂O 0 to 2.5 in. H₂O 0 to 5 in. H₂O | 10 | 13 to 30 | 3/16" | — | 2, 3 | No | 3/16" | 2 | 5 7/16" | 3 3/16" | CE Marked | — | IP67 | Air | ±1% | Barbed | Brass | 32 to 122 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

DIN-Rail/Surface Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| -5 to 5 in. H₂O -2.5 to 2.5 in. H₂O -1 to 1 in. H₂O -0.5 to 0.5 in. H₂O 0 to 0.5 in. H₂O 0 to 1 in. H₂O 0 to 2.5 in. H₂O 0 to 5 in. H₂O | 10 | 13 to 30 | 3/16" | 35 | 2, 3 | No | 3/16" | 2 | 5 7/16" | 3 3/16" | CE Marked | 8" | IP67 | Air | ±1% | Barbed | Brass | 32 to 122 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Differential Pressure Transmitters with Electronic Switch Outputs

|

Configurable Analog Transmitter Output | Configurable Digital Switch Output | Mounting Holes | Connection | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pressure Differential, psi | Max. Input Pressure, psi | Input Voltage, V DC | Pipe Size | Ht. | Wd. | No. of | Signal | No. of | Signal Type | Mounting Hardware Included | Dia. | No. of | Enclosure Rating | For Use With | Accuracy | Pipe | Material | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5 Poles Micro M12 Plug In | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Glass-Filled Polyester Plastic Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 15 | 2,500 | 15 to 32 | 1/4 | 4 13/16" | 3" | 1 | 0 to 10V DC, 4 to 20 mA | 2 | PNP, NPN | No | 3/16" | 2 | IP65, IP67, NEMA 4X, NEMA 6 | Air, Hydraulic Fluid, Water | ±0.5% | NPT Female | 316L Stainless Steel | 14 to 158 | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 100 | 2,500 | 15 to 32 | 1/4 | 4 13/16" | 3" | 1 | 0 to 10V DC, 4 to 20 mA | 2 | PNP, NPN | No | 3/16" | 2 | IP65, IP67, NEMA 4X, NEMA 6 | Air, Hydraulic Fluid, Water | ±0.5% | NPT Female | 316L Stainless Steel | 14 to 158 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 500 | 2,500 | 15 to 32 | 1/4 | 4 13/16" | 3" | 1 | 0 to 10V DC, 4 to 20 mA | 2 | PNP, NPN | No | 3/16" | 2 | IP65, IP67, NEMA 4X, NEMA 6 | Air, Hydraulic Fluid, Water | ±0.5% | NPT Female | 316L Stainless Steel | 14 to 158 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Differential Pressure Transmitters with Dial Indicator for Liquids

|

Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pressure Differential | Max. Input Pressure, psi | Input Voltage, V DC | Pipe Size | Mounting Hardware Included | Dia. | No. of | Ht. | Wd. | Enclosure Rating | Hazardous Location Rating | For Use With | Accuracy | Pipe Connection | Housing Material | Temp. Range, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4 to 20 mA, 0 to 5V DC Output Signal—Screw Terminals | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 in. H₂O to 25 in. H₂O | 1,500 | 9 to 35 | 1/4 | No | 3/16" | 2 | 2" | 4 7/16" | IP65, NEMA 4X | NEC Class I Division 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups F, G | Diesel Fuel, Gasoline, Hydraulic Fluid, Water | ±2% | NPT Female | Brass | -20 to 200 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 psi to 1 psi | 1,500 | 9 to 35 | 1/4 | No | 3/16" | 2 | 2" | 4 7/16" | IP65, NEMA 4X | NEC Class I Division 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups F, G | Diesel Fuel, Gasoline, Hydraulic Fluid, Water | ±2% | NPT Female | Brass | -20 to 200 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 psi to 5 psi | 1,500 | 9 to 35 | 1/4 | No | 3/16" | 2 | 2" | 4 7/16" | IP65, NEMA 4X | NEC Class I Division 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups F, G | Diesel Fuel, Gasoline, Hydraulic Fluid, Water | ±2% | NPT Female | Brass | -20 to 200 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 psi to 15 psi | 5,000 | 9 to 35 | 1/4 | No | 3/16" | 2 | 2 5/8" | 2 15/16" | IP65, NEMA 4X | NEC Class I Division 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups F, G | Diesel Fuel, Gasoline, Hydraulic Fluid, Water | ±2% | NPT Female | Brass | -20 to 200 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 psi to 30 psi | 5,000 | 9 to 35 | 1/4 | No | 3/16" | 2 | 2 5/8" | 2 15/16" | IP65, NEMA 4X | NEC Class I Division 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups F, G | Diesel Fuel, Gasoline, Hydraulic Fluid, Water | ±2% | NPT Female | Brass | -20 to 200 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 psi to 50 psi | 5,000 | 9 to 35 | 1/4 | No | 3/16" | 2 | 2 5/8" | 2 15/16" | IP65, NEMA 4X | NEC Class I Division 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups F, G | Diesel Fuel, Gasoline, Hydraulic Fluid, Water | ±2% | NPT Female | Brass | -20 to 200 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hazardous Location Easy-Setup Differential Pressure Transmitters

Mounting Holes | Connection | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pressure Differential | Max. Input Pressure, psi | Input Voltage, V DC | Pipe Size | Mounting Hardware Included | Dia. | No. of | Ht. | Wd. | Communication Protocol | Enclosure Rating | For Use With | Accuracy | Pipe | Fitting | Material | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4 to 20 mA Output Signal—Screw Terminals | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NEC Class I Divisions 1, 2 Groups A, B, C, D | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 in. H₂O to 25 in. H₂O | 3,625 | 11 to 55 | 1/4 | No | 7/16" | 8 | 7 7/8" | 5 1/4" | HART | IP66, NEMA 4X | Air, Diesel Fuel, Gasoline, Hydraulic Fluid, Water | ±0.075% | NPT Female | Threaded | Hastelloy Nickel | -40 to 185 | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 in. H₂O to 200 in. H₂O | 5,800 | 11 to 55 | 1/4 | No | 7/16" | 8 | 7 7/8" | 5 1/4" | HART | IP66, NEMA 4X | Air, Diesel Fuel, Gasoline, Hydraulic Fluid, Water | ±0.075% | NPT Female | Threaded | Hastelloy Nickel | -40 to 185 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 in. H₂O to 1,000 in. H₂O | 5,800 | 11 to 55 | 1/4 | No | 7/16" | 8 | 7 7/8" | 5 1/4" | HART | IP66, NEMA 4X | Air, Diesel Fuel, Gasoline, Hydraulic Fluid, Water | ±0.075% | NPT Female | Threaded | Hastelloy Nickel | -40 to 185 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 psi to 150 psi | 5,800 | 11 to 55 | 1/4 | No | 7/16" | 8 | 7 7/8" | 5 1/4" | HART | IP66, NEMA 4X | Air, Diesel Fuel, Gasoline, Hydraulic Fluid, Water | ±0.075% | NPT Female | Threaded | Hastelloy Nickel | -40 to 185 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 psi to 450 psi | 5,800 | 11 to 55 | 1/4 | No | 7/16" | 8 | 7 7/8" | 5 1/4" | HART | IP66, NEMA 4X | Air, Diesel Fuel, Gasoline, Hydraulic Fluid, Water | ±0.075% | NPT Female | Threaded | Hastelloy Nickel | -40 to 185 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 psi to 1,500 psi | 5,800 | 11 to 55 | 1/4 | No | 7/16" | 8 | 7 7/8" | 5 1/4" | HART | IP66, NEMA 4X | Air, Diesel Fuel, Gasoline, Hydraulic Fluid, Water | ±0.075% | NPT Female | Threaded | Hastelloy Nickel | -40 to 185 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Differential Pressure Transmitters with Dial Indicator for Air

Aluminum Housing%20--%3e%3csvg%20version='1.1'%20id='Layer_1'%20xmlns='http://www.w3.org/2000/svg'%20xmlns:xlink='http://www.w3.org/1999/xlink'%20x='0px'%20y='0px'%20viewBox='0%200%20400%20400'%20style='enable-background:new%200%200%20400%20400;'%20xml:space='preserve'%3e%3cstyle%20type='text/css'%3e%20.st0{fill:%231A70A0;}%20.st1{opacity:0.5;}%20%3c/style%3e%3cg%3e%3cg%3e%3cpath%20class='st0'%20d='M200,56.9c38.35,0,74.4,14.93,101.51,42.05c27.11,27.11,42.05,63.17,42.05,101.51s-14.93,74.4-42.05,101.51%20S238.35,344.02,200,344.02s-74.4-14.93-101.51-42.05c-27.11-27.11-42.05-63.17-42.05-101.51s14.93-74.4,42.05-101.51%20S161.65,56.9,200,56.9%20M200,12.9C96.41,12.9,12.44,96.88,12.44,200.46c0,103.59,83.97,187.56,187.56,187.56%20c103.59,0,187.56-83.97,187.56-187.56C387.56,96.88,303.59,12.9,200,12.9L200,12.9z'/%3e%3c/g%3e%3cg%3e%3cg%20class='st1'%3e%3cpath%20class='st0'%20d='M235.49,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C190.89,163.58,214.53,158.88,235.49,152.24z%20M230.44,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C218.68,82.23,224.24,80.84,230.44,80.84z'/%3e%3c/g%3e%3cg%3e%3cpath%20class='st0'%20d='M214.08,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C169.48,163.58,193.11,158.88,214.08,152.24z%20M209.03,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C197.26,82.23,202.83,80.84,209.03,80.84z'/%3e%3c/g%3e%3c/g%3e%3c/g%3e%3c/svg%3e)

Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pressure Differential, in. H₂O | Max. Input Pressure, psi | Input Voltage, V DC | Pipe Size | For No. of Wires | Mounting Hardware Included | No. of Mounting Holes | Dia. | Certification | For Use With | Accuracy | Pipe | Fitting | Material | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4 to 20 mA Output Signal—Screw Terminals | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 0.5 | 10 | 10 to 35 | 1/8 | 2 | No | 3 | 5 1/2" | CE Marked | Air | ±2% | NPT Female | Threaded | Aluminum | 20 to 120 | 000000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 1 | 10 | 10 to 35 | 1/8 | 2 | No | 3 | 5 1/2" | CE Marked | Air | ±2% | NPT Female | Threaded | Aluminum | 20 to 120 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 2 | 2 | 10 to 35 | 1/8 | 2 | No | 3 | 5 1/2" | CE Marked | Air | ±2% | NPT Female | Threaded | Aluminum | 20 to 120 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 3 | 2 | 10 to 35 | 1/8 | 2 | No | 3 | 5 1/2" | CE Marked | Air | ±2% | NPT Female | Threaded | Aluminum | 20 to 120 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 6 | 10 | 10 to 35 | 1/8 | 2 | No | 3 | 5 1/2" | CE Marked | Air | ±2% | NPT Female | Threaded | Aluminum | 20 to 120 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 10 | 2 | 10 to 35 | 1/8 | 2 | No | 3 | 5 1/2" | CE Marked | Air | ±2% | NPT Female | Threaded | Aluminum | 20 to 120 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 20 | 11 | 10 to 35 | 1/8 | 2 | No | 3 | 5 1/2" | CE Marked | Air | ±2% | NPT Female | Threaded | Aluminum | 20 to 120 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 30 | 11 | 10 to 35 | 1/8 | 2 | No | 3 | 5 1/2" | CE Marked | Air | ±2% | NPT Female | Threaded | Aluminum | 20 to 120 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

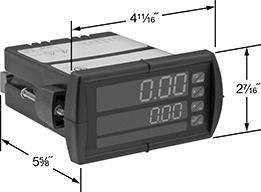

Pressure Transmitter Displays

Input | Display | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Input AC Voltage, V AC | Transmitter Power Supply, V DC | No. of Signal Inputs | Signal | Signal Selection | Relay Current @ Voltage | For DIN Panel Cutout Size | Enclosure Rating | Accuracy | Style | Color | Count | Wire Connection | Enclosure Material | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

With Lockout, USB Cable | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 85 to 265 | 24 | 1 | 0 to 20 mA, 4 to 20 mA 0 to 5V DC, 1 to 5V DC, 0 to 10V DC | Switch | — | 1/8 | IP65, NEMA 4X | 0.03% | Dual Line, LED | Red | -99,999 to 999,999 | Screw Terminal | Plastic | -40 to 149 | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

With Two SPDT (Single Pole, Double Throw) Relays, Alarm LED Indicator, Lockout, USB Cable | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 85 to 265 | 24 | 1 | 0 to 20 mA, 4 to 20 mA 0 to 5V DC, 1 to 5V DC, 0 to 10V DC | Switch | 3 amp @ 120V AC, 3 amp @ 240V AC | 1/8 | IP65, NEMA 4X | 0.03% | Dual Line, LED | Red | -99,999 to 999,999 | Screw Terminal | Plastic | -40 to 149 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||