Filter by

Maximum Pressure Differential

For Use With

Output Voltage

Measurement Unit

Width

Connection Material

Maximum Input Pressure

Maximum Pressure

Pipe Size

Material

Housing Material

Export Control Classification Number (ECCN)

REACH

RoHS

DFARS Specialty Metals

Minimum Pressure Differential

Differential Pressure Transmitters with Digital Display for Air

Nylon Housing%20--%3e%3csvg%20version='1.1'%20id='Layer_1'%20xmlns='http://www.w3.org/2000/svg'%20xmlns:xlink='http://www.w3.org/1999/xlink'%20x='0px'%20y='0px'%20viewBox='0%200%20400%20400'%20style='enable-background:new%200%200%20400%20400;'%20xml:space='preserve'%3e%3cstyle%20type='text/css'%3e%20.st0{fill:%231A70A0;}%20.st1{opacity:0.5;}%20%3c/style%3e%3cg%3e%3cg%3e%3cpath%20class='st0'%20d='M200,56.9c38.35,0,74.4,14.93,101.51,42.05c27.11,27.11,42.05,63.17,42.05,101.51s-14.93,74.4-42.05,101.51%20S238.35,344.02,200,344.02s-74.4-14.93-101.51-42.05c-27.11-27.11-42.05-63.17-42.05-101.51s14.93-74.4,42.05-101.51%20S161.65,56.9,200,56.9%20M200,12.9C96.41,12.9,12.44,96.88,12.44,200.46c0,103.59,83.97,187.56,187.56,187.56%20c103.59,0,187.56-83.97,187.56-187.56C387.56,96.88,303.59,12.9,200,12.9L200,12.9z'/%3e%3c/g%3e%3cg%3e%3cg%20class='st1'%3e%3cpath%20class='st0'%20d='M235.49,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C190.89,163.58,214.53,158.88,235.49,152.24z%20M230.44,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C218.68,82.23,224.24,80.84,230.44,80.84z'/%3e%3c/g%3e%3cg%3e%3cpath%20class='st0'%20d='M214.08,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C169.48,163.58,193.11,158.88,214.08,152.24z%20M209.03,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C197.26,82.23,202.83,80.84,209.03,80.84z'/%3e%3c/g%3e%3c/g%3e%3c/g%3e%3c/svg%3e)

Mounting Holes | Connection | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pressure Differential Range | Max. Input Pressure, in. H₂O | Input Voltage, V DC | For Tube ID | For No. of Wires | Mounting Hardware Included | Dia. | No. of | Ht. | Certification | Enclosure Rating | For Use With | Accuracy | Pipe | Fitting | Material | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4 to 20 mA, 0 to 5V DC, 0 to 10V DC Output Signal—Screw Terminals | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Surface Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

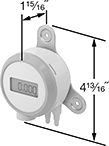

| 0 to 0.1 in. H₂O 0 to 0.15 in. H₂O 0 to 0.25 in. H₂O 0 to 0.5 in. H₂O | 99 | 10 to 36 | 1/8", 3/16", 1/4", 5 mm, 6 mm | 2, 3 | No | 3/16" | 3 | 4 13/16" | CE Marked | IP66, NEMA 4X | Air | ±1% | Male | Barbed | Nylon | -4 to 158 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 1 in. H₂O 0 to 2 in. H₂O 0 to 3 in. H₂O 0 to 5 in. H₂O | 166 | 10 to 36 | 1/8", 3/16", 1/4", 5 mm, 6 mm | 2, 3 | No | 3/16" | 3 | 4 13/16" | CE Marked | IP66, NEMA 4X | Air | ±1% | Male | Barbed | Nylon | -4 to 158 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 10 in. H₂O 0 to 15 in. H₂O 0 to 25 in. H₂O 0 to 28 in. H₂O | 166 | 10 to 36 | 1/8", 3/16", 1/4", 5 mm, 6 mm | 2, 3 | No | 3/16" | 3 | 4 13/16" | CE Marked | IP66, NEMA 4X | Air | ±1% | Male | Barbed | Nylon | -4 to 158 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Differential Pressure Transmitters with Electronic Switch Outputs

|

Configurable Analog Transmitter Output | Configurable Digital Switch Output | Mounting Holes | Connection | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pressure Differential, psi | Max. Input Pressure, psi | Input Voltage, V DC | Pipe Size | Ht. | Wd. | No. of | Signal | No. of | Signal Type | Mounting Hardware Included | Dia. | No. of | Enclosure Rating | For Use With | Accuracy | Pipe | Material | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5 Poles Micro M12 Plug In | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Glass-Filled Polyester Plastic Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 15 | 2,500 | 15 to 32 | 1/4 | 4 13/16" | 3" | 1 | 0 to 10V DC, 4 to 20 mA | 2 | PNP, NPN | No | 3/16" | 2 | IP65, IP67, NEMA 4X, NEMA 6 | Air, Hydraulic Fluid, Water | ±0.5% | NPT Female | 316L Stainless Steel | 14 to 158 | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 100 | 2,500 | 15 to 32 | 1/4 | 4 13/16" | 3" | 1 | 0 to 10V DC, 4 to 20 mA | 2 | PNP, NPN | No | 3/16" | 2 | IP65, IP67, NEMA 4X, NEMA 6 | Air, Hydraulic Fluid, Water | ±0.5% | NPT Female | 316L Stainless Steel | 14 to 158 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 500 | 2,500 | 15 to 32 | 1/4 | 4 13/16" | 3" | 1 | 0 to 10V DC, 4 to 20 mA | 2 | PNP, NPN | No | 3/16" | 2 | IP65, IP67, NEMA 4X, NEMA 6 | Air, Hydraulic Fluid, Water | ±0.5% | NPT Female | 316L Stainless Steel | 14 to 158 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||