Filter by

Diverting Valve Flow Pattern

Fitting Connection

For Use With

Body Material

Mounting Position

Maximum Pressure @ Temperature

Environment

U.S.–Mexico–Canada Agreement (USMCA) Qualifying

RoHS

DFARS Specialty Metals

Connection Port

Multiport Threaded Diverting Valves

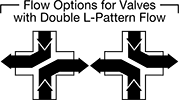

Double L-Pattern Flow

Mounting Holes | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Flow Shut-Off | Handle Style | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Valve Type | Temp. Range, ° F | Vacuum Rating | Seal Material | End-to-End Lg. | Mounting Fasteners Included | No. of | Thread Size | For Use With | Ht. | Lg. | Mounting Position | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female Side × NPT Female Side × NPT Female Side × NPT Female Side | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | No | T-Handle | Not Rated | 250 psi @ 70° F | Plug | -60 to 400 | Not Rated | Fluoroelastomer | 1 7/8" | No | 4 | 1/4"-20 | Air, Argon, Helium, Krypton, Neon, Oil, Water, Xenon | 2 7/8" | 3" | Any Angle, Horizontal, Vertical | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

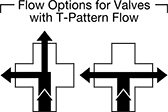

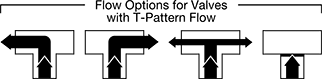

T-Pattern Flow

Mounting Holes | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Flow Shut-Off | Handle Style | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Valve Type | Temp. Range, ° F | Vacuum Rating | Seal Material | End-to-End Lg. | Mounting Fasteners Included | No. of | Thread Size | For Use With | Ht. | Lg. | Mounting Position | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female Side × NPT Female Side × NPT Female Side × NPT Female Side | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | No | T-Handle | Not Rated | 250 psi @ 70° F | Plug | -60 to 400 | Not Rated | Fluoroelastomer | 1 7/8" | No | 4 | 1/4"-20 | Air, Argon, Helium, Krypton, Neon, Oil, Water, Xenon | 2 7/8" | 3" | Any Angle, Horizontal, Vertical | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Diverting Valves with Barbed Fittings for Chemicals

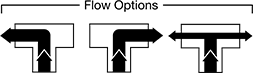

T-Pattern Flow

|  |

Mounting Holes | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Tube ID | Flow Shut-Off | Handle Style | Port Type | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Valve Type | Temp. Range, ° F | Vacuum Rating | Seal Material | End-to-End Lg. | Mounting Fasteners Included | No. of | Dia. | For Use With | Ht. | Lg. | Seat Material | Mounting Position | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PVDF Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Barbed × Barbed × Barbed | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" to 5/16" | Yes | Lever | Full | Not Rated | 15 psi @ 65° F | Plug | 35 to 100 | Not Rated | PVDF | 2 1/8" | No | 2 | 5/32" | Air, Butane, Carbon Dioxide, Chlorine, Citric Acid, Diesel Fuel, Ethanol, Ethylene Glycol, Gasoline, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Methanol (Methyl Alcohol), Nitric Acid, Nitrogen, Oxygen, Phosphoric Acid, Propane, Salt Water, Soap Solutions, Sulfuric Acid, Water | 1 1/2" | 2 1/8" | PVDF | Any Angle, Horizontal, Vertical | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" to 3/8" | Yes | Lever | Full | Not Rated | 15 psi @ 65° F | Plug | 35 to 100 | Not Rated | PVDF | 2 1/8" | No | 2 | 5/32" | Air, Butane, Carbon Dioxide, Chlorine, Citric Acid, Diesel Fuel, Ethanol, Ethylene Glycol, Gasoline, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Methanol (Methyl Alcohol), Nitric Acid, Nitrogen, Oxygen, Phosphoric Acid, Propane, Salt Water, Soap Solutions, Sulfuric Acid, Water | 1 1/2" | 2 1/8" | PVDF | Any Angle, Horizontal, Vertical | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" to 1/2" | Yes | Lever | Full | Not Rated | 15 psi @ 65° F | Plug | 35 to 100 | Not Rated | PVDF | 2 3/4" | No | 2 | 5/32" | Air, Butane, Carbon Dioxide, Chlorine, Citric Acid, Diesel Fuel, Ethanol, Ethylene Glycol, Gasoline, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Methanol (Methyl Alcohol), Nitric Acid, Nitrogen, Oxygen, Phosphoric Acid, Propane, Salt Water, Soap Solutions, Sulfuric Acid, Water | 2 1/16" | 2 3/4" | PVDF | Any Angle, Horizontal, Vertical | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" to 1/2" | Yes | Lever | Full | Not Rated | 15 psi @ 65° F | Plug | 35 to 100 | Not Rated | PVDF | 2 3/4" | No | 2 | 5/32" | Air, Butane, Carbon Dioxide, Chlorine, Citric Acid, Diesel Fuel, Ethanol, Ethylene Glycol, Gasoline, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Methanol (Methyl Alcohol), Nitric Acid, Nitrogen, Oxygen, Phosphoric Acid, Propane, Salt Water, Soap Solutions, Sulfuric Acid, Water | 2 1/16" | 2 3/4" | PVDF | Any Angle, Horizontal, Vertical | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sanitary Diverting Valves

T-Pattern Flow

For Tube | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

ID | OD | Flow Shut-Off | Handle Style | Port Type | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Valve Type | Temp. Range, ° F | Seal Material | End-to-End Lg. | Surface Smoothness, μin | Food Industry Std. | For Use With | Ht. | Lg. | O-Ring Material | Seat Material | Mounting Position | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Quick Clamp × Quick Clamp × Quick Clamp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8" | 1 1/2" | No | Lever | Full | Not Rated | 55 psi @ 70° F | Plug | -20 to 300 | EPDM | 5 13/16" | 23 | 3-A Certified 51-01, FDA Compliant 21 CFR 177.2600 | Beverage, Food | 6 7/16" | 7 7/16" | EPDM | PTFE | Any Angle, Horizontal, Vertical | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/8" | 2" | No | Lever | Full | Not Rated | 55 psi @ 70° F | Plug | -20 to 300 | EPDM | 6 13/16" | 23 | 3-A Certified 51-01, FDA Compliant 21 CFR 177.2600 | Beverage, Food | 8 13/16" | 8 3/16" | EPDM | PTFE | Any Angle, Horizontal, Vertical | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/8" | 2 1/2" | No | Lever | Full | Not Rated | 55 psi @ 70° F | Plug | -20 to 300 | EPDM | 8 1/4" | 23 | 3-A Certified 51-01, FDA Compliant 21 CFR 177.2600 | Beverage, Food | 8 1/4" | 10 7/16" | EPDM | PTFE | Any Angle, Horizontal, Vertical | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Purity Air-Driven Diverting Valves for Food and Beverage

Air | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Tube OD | Diverting Valve Flow Pattern | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Pressure Range, psi | Connection | Max. Temp., ° F | Actuation Time, sec. | Valve Lg. | Port-to-Port Lg. | Interior Smoothness, Ra | Valve Type | For Use With | Seal Material | Food Industry Std. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel Body—Quick Clamp × Quick Clamp × Quick Clamp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Single Acting: Air-to-Divert/Spring Return | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

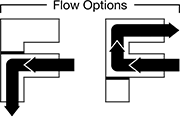

| 1" | L-Pattern, U-Pattern | 15 | 175 psi @ 190° F | 70 to 115 | 1/4 NPT Female | 190 | 2 | 3 7/16" | 2 1/4" | 23 | Plug | Beverage, Food | EPDM | 3-A Certified 53-06 | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | L-Pattern, U-Pattern | 54 | 75 psi @ 190° F | 70 to 115 | 1/4 NPT Female | 190 | 2 | 5 1/16" | 3 1/8" | 23 | Plug | Beverage, Food | EPDM | 3-A Certified 53-06 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | L-Pattern, U-Pattern | 119 | 70 psi @ 190° F | 70 to 115 | 1/4 NPT Female | 190 | 2 | 6 9/16" | 3 7/8" | 23 | Plug | Beverage, Food | EPDM | 3-A Certified 53-06 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||