About Actuated On/Off Valves

More

About On/Off Valves

More

Multiport Threaded Diverting Valves

- Valve Type: Plug

- For Use With: Air, Argon, Helium, Krypton, Neon, Oil, Water, Xenon

- Seal Material: Fluoroelastomer Rubber

Divert the flow of compressed air and other media to multiple pieces of equipment. Turn the handle to direct flow to multiple outlet ports. Valves cannot shut off flow.

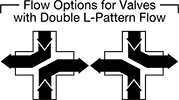

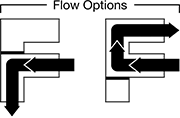

Valves with double L-pattern flow have two separate flow paths.

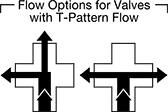

Valves with T-pattern flow direct flow from the inlet port to two of the three outlet ports at reduced capacity.

Mounting Holes | ||||||||

|---|---|---|---|---|---|---|---|---|

| Pipe Size | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Mounting Fasteners Included | No. of | Thread Size | Each | |

Double L-Pattern Flow | ||||||||

Brass Body | ||||||||

NPT Female × NPT Female × NPT Female × NPT Female | ||||||||

| 1/4 | 250 psi @ 70° F | -60° to 400° | 1 7/8" | No | 4 | 1/4"-20 | 00000000 | 0000000 |

T-Pattern Flow | ||||||||

Brass Body | ||||||||

NPT Female × NPT Female × NPT Female × NPT Female | ||||||||

| 1/4 | 250 psi @ 70° F | -60° to 400° | 1 7/8" | No | 4 | 1/4"-20 | 00000000 | 000000 |

Sanitary Diverting Valves

Designed to direct the flow of liquids in food, dairy, and chemical-processing facilities, these valves can be fully disassembled for clean-out-of-place (COP) processes. They connect to your line with quick-clamp sanitary fittings, also known as tri-clamp connections, which are easier to remove and sanitize than threaded connections. You’ll need a gasket and clamp to connect them to another quick-clamp fitting (not included). These valves are 3-A certified to meet sanitary design standards.

Made of 316 stainless steel, these valves won’t corrode from frequent washdowns with harsh cleaners. The O-rings and seals are made from EPDM, which holds up to water, detergents, chemicals, and steam. They’re also FDA compliant for direct contact with food.

When you open or close these valves, a tapered plug slides in or out to direct the flow. Unlike ball valves, this plug design doesn’t have crevices between the seal and the valve body where contaminants could be trapped. Any surfaces that liquids touch are polished to extreme smoothness, so there’s nowhere for bacteria to hide. Liquids with abrasives, such as a smoothie with seeds, should not be used with this valve—if the surface of the plug is scratched or the seal is damaged, your liquids can be contaminated.

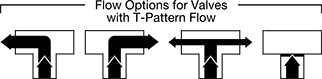

The T-pattern flow lets you direct liquids from the inlet to either outlet at full capacity, or to both outlets at reduced capacity. You can use any port as an inlet or an outlet—all three are full port and do not restrict flow. The long handle gives you plenty of leverage, so these valves are easy to open and close. The plug has a chrome plating to help it slide easily, and the seat is made from slippery PTFE to reduce friction from the handle, making sure these valves operate smoothly.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For Tube | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ID | OD | Flow Pattern | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Surface Smoothness | Specifications Met | Each | |

316 Stainless Steel Body | ||||||||||

Quick Clamp × Quick Clamp × Quick Clamp | ||||||||||

| 1 3/8" | 1 1/2" | T-Pattern | Not Rated | 55 psi @ 70° F | -20° to 300° | 5 13/16" | 23 microinch | 3-A Certified 51-01, FDA Compliant 21 CFR 177.2600 | 00000000 | 0000000 |

| 1 7/8" | 2" | T-Pattern | Not Rated | 55 psi @ 70° F | -20° to 300° | 6 13/16" | 23 microinch | 3-A Certified 51-01, FDA Compliant 21 CFR 177.2600 | 00000000 | 000000 |

| 2 3/8" | 2 1/2" | T-Pattern | Not Rated | 55 psi @ 70° F | -20° to 300° | 8 1/4" | 23 microinch | 3-A Certified 51-01, FDA Compliant 21 CFR 177.2600 | 00000000 | 00000000 |

Diverting Valves with Barbed Fittings for Chemicals

Barbed fittings on these valves grip onto tubing, providing a secure hold. To divert flow between ports in chemical-processing applications, they have a chemical-resistant seal and a PVDF body to withstand aggressive and corrosive solutions.

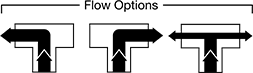

Valves with T-pattern flow can use any port as an inlet or an outlet. Turn the handle to direct flow from the inlet port to either outlet port at full capacity, direct flow to both outlet ports simultaneously at reduced capacity, or shut off flow completely.

- Valve Type: Plug

- For Use With: Air, Butane, Carbon Dioxide, Chlorine, Citric Acid, Diesel Fuel, Ethanol, Ethylene Glycol, Gasoline, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Methanol, Nitric Acid, Nitrogen, Oxygen, Phosphoric Acid, Propane, Salt Water, Soap Solutions, Sulfuric Acid, Water

- Seal Material: PVDF Plastic

- Seat Material: PVDF Plastic

Mounting Holes | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Tube ID | Port Type | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Mounting Fasteners Included | No. of | Dia. | Each | |

PVDF Plastic Body | |||||||||

Barbed × Barbed × Barbed | |||||||||

| 3/16" to 5/16" | Full | 15 psi @ 65° F | 35° to 100° | 2 1/8" | No | 2 | 5/32" | 0000000 | 000000 |

| 1/4" to 3/8" | Full | 15 psi @ 65° F | 35° to 100° | 2 1/8" | No | 2 | 5/32" | 0000000 | 00000 |

| 3/8" to 1/2" | Full | 15 psi @ 65° F | 35° to 100° | 2 3/4" | No | 2 | 5/32" | 0000000 | 00000 |

| 7/16" to 1/2" | Full | 15 psi @ 65° F | 35° to 100° | 2 3/4" | No | 2 | 5/32" | 0000000 | 00000 |

High-Purity Air-Driven Diverting Valves for Food and Beverage

- Valve Type: Plug

- For Use With: Beverage, Food

- Seal Material: EPDM Rubber

- Specifications Met: 3-A Certified 53-06

Often used in sanitary valve manifolds, these valves can be cleaned in place to eliminate the risk of cross contamination in food, beverage, and dairy lines. They are 3-A certified and electropolished to a 23 Ra finish for smooth internal surfaces that prevent product buildup and inhibit bacteria growth to maintain sanitary standards. All have sanitary quick-clamp fittings for easy disassembly. Valves operate on compressed air to automatically divert flow between ports more quickly than motor-driven valves. You must control the air to the actuator using either an electric pilot valve (not included) or a manual on/off valve (not included). Body is 316 stainless steel for excellent corrosion resistance. The actuator is secured to the valve body with a bracket for easy disassembly, maintenance, and repair.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

Air | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Flow Pattern | Flow Coefficient (Cv) | Max. Pressure | Pressure Range, psi | Connection | Max. Temp., °F | Actuation Time | Valve Lg. | Port-to-Port Lg. | Interior Smoothness | Each | |

316 Stainless Steel Body—Quick Clamp × Quick Clamp × Quick Clamp | ||||||||||||

Single Acting: Air-to-Divert / Spring Return | ||||||||||||

| 1" | L-Pattern, U-Pattern | 15 | 175 psi @ 190° F | 70 to 115 | 1/4 NPT Female | 190° | 2 sec. | 3 7/16" | 2 1/4" | 23 Ra | 0000000 | 000000000 |

| 2" | L-Pattern, U-Pattern | 54 | 75 psi @ 190° F | 70 to 115 | 1/4 NPT Female | 190° | 2 sec. | 5 1/16" | 3 1/8" | 23 Ra | 0000000 | 00000000 |

| 3" | L-Pattern, U-Pattern | 119 | 70 psi @ 190° F | 70 to 115 | 1/4 NPT Female | 190° | 2 sec. | 6 9/16" | 3 7/8" | 23 Ra | 0000000 | 00000000 |