Filter by

System of Measurement

Thread Size

Shaft Diameter

Mount Type

Material

Shape

Thread Type

End Shape

Specifications Met

End Type

Shaft Type

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Pin Type

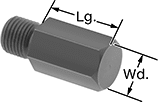

Single-End Studs

Shaft, mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg., mm | Thread Lg., mm | Lg. | Dia. | Dia. Tolerance | Tensile Strength | Hardness | Drive Style | Specs. Met | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M12 × 1.75 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 14 | 11 | 12 | -0.27 to 0 | Not Rated | Rockwell B75 | Slotted | DIN 427 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 16 | 14 | 12 | -0.27 to 0 | Not Rated | Rockwell B75 | Slotted | DIN 427 | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 14 | 21 | 12 | -0.27 to 0 | Not Rated | Rockwell B75 | Slotted | DIN 427 | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 14 | 26 | 12 | -0.27 to 0 | Not Rated | Rockwell B75 | Slotted | DIN 427 | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

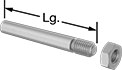

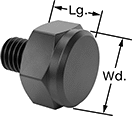

Threaded Taper Pins

Metric

Lg., mm | Large End Dia., mm | Rate of Taper | Thread Lg., mm | Thread Size | Min. Hardness | Breaking Strength, psi | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

12L14 Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12 mm Small End Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 85 | 13 | 1:50 | 28.75 | M12 | Rockwell B80 | 34,500 | DIN 7977, ISO 8737 | 1 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 90 | 13.1 | 1:50 | 28.75 | M12 | Rockwell B80 | 34,500 | DIN 7977, ISO 8737 | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 95 | 13.2 | 1:50 | 28.75 | M12 | Rockwell B80 | 34,500 | DIN 7977, ISO 8737 | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | 13.3 | 1:50 | 28.75 | M12 | Rockwell B80 | 34,500 | DIN 7977, ISO 8737 | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 110 | 13.5 | 1:50 | 28.75 | M12 | Rockwell B80 | 34,500 | DIN 7977, ISO 8737 | 1 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 120 | 13.7 | 1:50 | 28.75 | M12 | Rockwell B80 | 34,500 | DIN 7977, ISO 8737 | 1 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

14 mm Small End Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 85 | 14.9 | 1:50 | 31.75 | M12 | Rockwell B80 | 34,500 | DIN 7977, ISO 8737 | 1 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 90 | 15 | 1:50 | 31.75 | M12 | Rockwell B80 | 34,500 | DIN 7977, ISO 8737 | 1 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 95 | 15.1 | 1:50 | 31.75 | M12 | Rockwell B80 | 34,500 | DIN 7977, ISO 8737 | 1 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | 15.2 | 1:50 | 31.75 | M12 | Rockwell B80 | 34,500 | DIN 7977, ISO 8737 | 1 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 110 | 15.4 | 1:50 | 31.75 | M12 | Rockwell B80 | 34,500 | DIN 7977, ISO 8737 | 1 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 120 | 15.6 | 1:50 | 31.75 | M12 | Rockwell B80 | 34,500 | DIN 7977, ISO 8737 | 1 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

303 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12 mm Small End Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 85 | 13 | 1:50 | 28.75 | M12 | Rockwell B96 | 34,500 | DIN 7977, ISO 8737 | 1 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 90 | 13.1 | 1:50 | 28.75 | M12 | Rockwell B96 | 34,500 | DIN 7977, ISO 8737 | 1 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 95 | 13.2 | 1:50 | 28.75 | M12 | Rockwell B96 | 34,500 | DIN 7977, ISO 8737 | 1 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | 13.3 | 1:50 | 28.75 | M12 | Rockwell B96 | 34,500 | DIN 7977, ISO 8737 | 1 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 110 | 13.5 | 1:50 | 28.75 | M12 | Rockwell B96 | 34,500 | DIN 7977, ISO 8737 | 1 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 120 | 13.7 | 1:50 | 28.75 | M12 | Rockwell B96 | 34,500 | DIN 7977, ISO 8737 | 1 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

14 mm Small End Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 85 | 14.9 | 1:50 | 31.75 | M12 | Rockwell B96 | 34,500 | DIN 7977, ISO 8737 | 1 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 90 | 15 | 1:50 | 31.75 | M12 | Rockwell B96 | 34,500 | DIN 7977, ISO 8737 | 1 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 95 | 15.1 | 1:50 | 31.75 | M12 | Rockwell B96 | 34,500 | DIN 7977, ISO 8737 | 1 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | 15.2 | 1:50 | 31.75 | M12 | Rockwell B96 | 34,500 | DIN 7977, ISO 8737 | 1 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 110 | 15.4 | 1:50 | 31.75 | M12 | Rockwell B96 | 34,500 | DIN 7977, ISO 8737 | 1 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 120 | 15.6 | 1:50 | 31.75 | M12 | Rockwell B96 | 34,500 | DIN 7977, ISO 8737 | 1 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

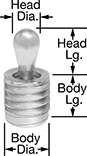

Threaded Spring Locating Pins

Pins | Installation Tools | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Body, mm | Head, mm | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Thread Size | Dia. | Lg. | Dia. | Lg. | Max. Head Movement, mm | Min. Spring Force | Max. Spring Force, lbf | Body Dia. Tolerance, mm | Body Material | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel Head | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 10 | 11.5 | 5 | 6 | 0.8 | Not Rated | 4.5 | -0.15 to 0.15 | Steel | 0000000 | 00000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 10 | 11.5 | 5 | 6 | 0.8 | Not Rated | 22 | -0.15 to 0.15 | Steel | 0000000 | 0000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 10 | 11.5 | 6 | 10 | 1 | Not Rated | 9 | -0.15 to 0.15 | Steel | 0000000 | 0000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 10 | 11.5 | 6 | 10 | 1 | Not Rated | 16 | -0.15 to 0.15 | Steel | 0000000 | 0000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

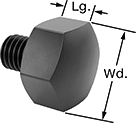

Threaded Locating and Support Buttons

|  |  |

Flat Head | Domed Head |