Filter by

System of Measurement

Thread Size

Mount Type

Head Diameter

Material

Body Material

Head Material

Body Diameter

DFARS Specialty Metals

Export Control Classification Number (ECCN)

REACH

Finish

Body Length

Head Length

Maximum Head Movement

Minimum Spring Force

Thread Type

Hardness

Pitch

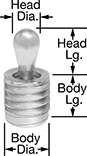

Threaded Spring Locating Pins

Pins | Installation Tools | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Body, mm | Head, mm | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Thread Size | Dia. | Lg. | Dia. | Lg. | Max. Head Movement, mm | Min. Spring Force | Max. Spring Force, lbf | Body Dia. Tolerance, mm | Body Material | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel Head | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M18 × 1.5 mm | 16 | 18 | 10 | 16 | 1.6 | Not Rated | 33 | -0.15 to 0.15 | Steel | 0000000 | 00000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M18 × 1.5 mm | 16 | 18 | 10 | 16 | 1.6 | Not Rated | 45 | -0.15 to 0.15 | Steel | 0000000 | 0000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Threaded Hole Location Gauges

Thread Size | Thread Type | Hardness | Material | Each | ||

|---|---|---|---|---|---|---|

| M18 × 1.5 mm | Metric | Rockwell C60 | Tool Steel | 0000000 | 0000000 |