Filter by

System of Measurement

Length

Thread Size

Shaft Diameter

End Type

Specifications Met

Minimum Hardness

Mount Type

Tolerance Rating

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Pull-Out Dowel Pins

Steel

Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg., mm | Dia. Tolerance, mm | Thread Size | Double Shear Breaking Strength, lbf | Min. Hardness | Specs. Met | 1-49 | 50-199 | 200-Up | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spring Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10 mm Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24 | 0.006 to 0.015 | M6 × 1 mm | Not Rated | Rockwell C52 | DIN 7979D-m6 | 97355A492 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 28 | 0.006 to 0.015 | M6 × 1 mm | Not Rated | Rockwell C52 | DIN 7979D-m6 | 97355A496 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 0.006 to 0.015 | M6 × 1 mm | Not Rated | Rockwell C52 | DIN 7979D-m6 | 97355A500 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 32 | 0.006 to 0.015 | M6 × 1 mm | Not Rated | Rockwell C52 | DIN 7979D-m6 | 97355A504 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36 | 0.006 to 0.015 | M6 × 1 mm | Not Rated | Rockwell C52 | DIN 7979D-m6 | 97355A505 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 0.006 to 0.015 | M6 × 1 mm | Not Rated | Rockwell C52 | DIN 7979D-m6 | 97355A506 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | 0.006 to 0.015 | M6 × 1 mm | Not Rated | Rockwell C52 | DIN 7979D-m6 | 97355A507 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | 0.006 to 0.015 | M6 × 1 mm | Not Rated | Rockwell C52 | DIN 7979D-m6 | 97355A515 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 70 | 0.006 to 0.015 | M6 × 1 mm | Not Rated | Rockwell C52 | DIN 7979D-m6 | 97355A518 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | 0.006 to 0.015 | M6 × 1 mm | Not Rated | Rockwell C52 | DIN 7979D-m6 | 97355A520 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12 mm Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24 | 0.007 to 0.018 | M6 × 1 mm | 24,000 | Rockwell C52 | DIN 7979D-m6 | 97355A531 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 0.007 to 0.018 | M6 × 1 mm | 24,000 | Rockwell C52 | DIN 7979D-m6 | 97355A535 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36 | 0.007 to 0.018 | M6 × 1 mm | 24,000 | Rockwell C52 | DIN 7979D-m6 | 97355A539 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 45 | 0.007 to 0.018 | M6 × 1 mm | 24,000 | Rockwell C52 | DIN 7979D-m6 | 97355A543 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | 0.007 to 0.018 | M6 × 1 mm | 24,000 | Rockwell C52 | DIN 7979D-m6 | 97355A547 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | 0.007 to 0.018 | M6 × 1 mm | 24,000 | Rockwell C52 | DIN 7979D-m6 | 97355A551 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

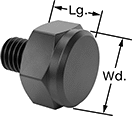

Single-End Studs

Shaft, mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg., mm | Thread Lg., mm | Lg. | Dia. | Dia. Tolerance | Tensile Strength | Hardness | Drive Style | Specs. Met | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M6 × 1 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 7.2 | 2.8 | 6 | -0.18 to 0 | Not Rated | Rockwell B75 | Slotted | DIN 427, ISO 2342 | 10 | 97493A158 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 7.2 | 4.8 | 6 | -0.18 to 0 | Not Rated | Rockwell B75 | Slotted | DIN 427, ISO 2342 | 10 | 97493A159 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 | 7.2 | 8.8 | 6 | -0.18 to 0 | Not Rated | Rockwell B75 | Slotted | DIN 427, ISO 2342 | 10 | 97493A125 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18 | 7.2 | 10.8 | 6 | -0.18 to 0 | Not Rated | Rockwell B75 | Slotted | DIN 427, ISO 2342 | 10 | 97493A161 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 7.2 | 12.8 | 6 | -0.18 to 0 | Not Rated | Rockwell B75 | Slotted | DIN 427, ISO 2342 | 10 | 97493A162 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 7.2 | 17.8 | 6 | -0.18 to 0 | Not Rated | Rockwell B75 | Slotted | DIN 427, ISO 2342 | 5 | 97493A163 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 7.2 | 22.8 | 6 | -0.18 to 0 | Not Rated | Rockwell B75 | Slotted | DIN 427, ISO 2342 | 10 | 97493A126 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

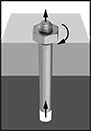

Vented Pull-Out Dowel Pins

Flat Shaft

Lg., mm | Dia. Tolerance, mm | Thread Size | Double Shear Breaking Strength, lbf | Min. Hardness | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Spring Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10 mm Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24 | 0.006 to 0.015 | M6 × 1 mm | Not Rated | Rockwell C52 | DIN 7979D-m6 | 98432A303 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 28 | 0.006 to 0.015 | M6 × 1 mm | Not Rated | Rockwell C52 | DIN 7979D-m6 | 98432A307 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 0.006 to 0.015 | M6 × 1 mm | Not Rated | Rockwell C52 | DIN 7979D-m6 | 98432A311 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36 | 0.006 to 0.015 | M6 × 1 mm | Not Rated | Rockwell C52 | DIN 7979D-m6 | 98432A315 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 0.006 to 0.015 | M6 × 1 mm | Not Rated | Rockwell C52 | DIN 7979D-m6 | 98432A319 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | 0.006 to 0.015 | M6 × 1 mm | Not Rated | Rockwell C52 | DIN 7979D-m6 | 98432A323 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | 0.006 to 0.015 | M6 × 1 mm | Not Rated | Rockwell C52 | DIN 7979D-m6 | 98432A327 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 70 | 0.006 to 0.015 | M6 × 1 mm | Not Rated | Rockwell C52 | DIN 7979D-m6 | 98432A332 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12 mm Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24 | 0.007 to 0.018 | M6 × 1 mm | 24,000 | Rockwell C52 | DIN 7979D-m6 | 98432A341 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 0.007 to 0.018 | M6 × 1 mm | 24,000 | Rockwell C52 | DIN 7979D-m6 | 98432A345 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36 | 0.007 to 0.018 | M6 × 1 mm | 24,000 | Rockwell C52 | DIN 7979D-m6 | 98432A349 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 0.007 to 0.018 | M6 × 1 mm | 24,000 | Rockwell C52 | DIN 7979D-m6 | 98432A353 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 45 | 0.007 to 0.018 | M6 × 1 mm | 24,000 | Rockwell C52 | DIN 7979D-m6 | 98432A357 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | 0.007 to 0.018 | M6 × 1 mm | 24,000 | Rockwell C52 | DIN 7979D-m6 | 98432A362 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | 0.007 to 0.018 | M6 × 1 mm | 24,000 | Rockwell C52 | DIN 7979D-m6 | 98432A366 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10 mm Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 0.006 to 0.015 | M6 × 1 mm | 101,000 | Rockwell C18 | DIN 7979C-m6 | 98432A133 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 0.006 to 0.015 | M6 × 1 mm | 101,000 | Rockwell C18 | DIN 7979C-m6 | 98432A137 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | 0.006 to 0.015 | M6 × 1 mm | 101,000 | Rockwell C18 | DIN 7979C-m6 | 98432A139 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | 0.006 to 0.015 | M6 × 1 mm | 101,000 | Rockwell C18 | DIN 7979C-m6 | 98432A141 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12 mm Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24 | 0.007 to 0.018 | M6 × 1 mm | 101,000 | Rockwell C18 | DIN 7979C-m6 | 98432A142 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 0.007 to 0.018 | M6 × 1 mm | 101,000 | Rockwell C18 | DIN 7979C-m6 | 98432A145 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | 0.007 to 0.018 | M6 × 1 mm | 101,000 | Rockwell C18 | DIN 7979C-m6 | 98432A146 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | 0.007 to 0.018 | M6 × 1 mm | 101,000 | Rockwell C18 | DIN 7979C-m6 | 98432A148 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel Headless Slotted Precision Shoulder Screws

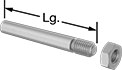

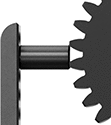

Threaded Taper Pins

Metric

Lg., mm | Large End Dia., mm | Rate of Taper | Thread Lg., mm | Thread Size | Min. Hardness | Breaking Strength, psi | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

12L14 Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6 mm Small End Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 45 | 6.5 | 1:50 | 19 | M6 | Rockwell B80 | 34,500 | DIN 7977, ISO 8737 | 5 | 92281A714 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | 6.6 | 1:50 | 19 | M6 | Rockwell B80 | 34,500 | DIN 7977, ISO 8737 | 5 | 92281A715 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 55 | 6.7 | 1:50 | 19 | M6 | Rockwell B80 | 34,500 | DIN 7977, ISO 8737 | 5 | 92281A716 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | 6.8 | 1:50 | 19 | M6 | Rockwell B80 | 34,500 | DIN 7977, ISO 8737 | 5 | 92281A717 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

303 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6 mm Small End Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 45 | 6.5 | 1:50 | 19 | M6 | Rockwell B96 | 34,500 | DIN 7977, ISO 8737 | 5 | 92284A714 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | 6.6 | 1:50 | 19 | M6 | Rockwell B96 | 34,500 | DIN 7977, ISO 8737 | 5 | 92284A715 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 55 | 6.7 | 1:50 | 19 | M6 | Rockwell B96 | 34,500 | DIN 7977, ISO 8737 | 5 | 92284A716 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | 6.8 | 1:50 | 19 | M6 | Rockwell B96 | 34,500 | DIN 7977, ISO 8737 | 5 | 92284A717 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

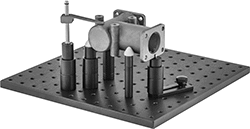

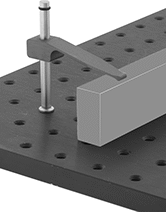

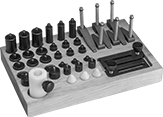

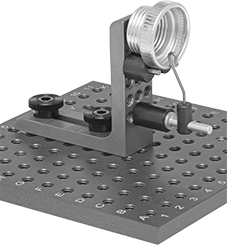

Fixturing for Parts Inspection

Kits

|

No. of Pieces | Includes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

M6 Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 42 | 2 Hold-Down Clamps—38 mm Reach × 38 mm O'all Ht. 4 Hold-Down Clamps—58 mm Reach × 75 mm O'all Ht. 3 Standoffs—13 mm Dia. × 20 mm Ht. 3 Standoffs—13 mm Dia. × 25 mm Ht. 3 Standoffs—13 mm Dia. × 50 mm Ht. 3 Standoffs—19 mm Dia. × 20 mm Ht. 3 Standoffs—19 mm Dia. × 25 mm Ht. 3 Standoffs—19 mm Dia. × 50 mm Ht. 3 Standoffs—25 mm Dia. × 20 mm Ht. 3 Standoffs—25 mm Dia. × 25 mm Ht. 3 Standoffs—25 mm Dia. × 50 mm Ht. 1 Adjustable-Height Standoff—13 mm Dia. 2 Pin Supports—13 mm Dia. × 25 mm Ht. 3 Cone Supports 1 Positioning Plate—35 mm Lg. 1 Positioning Plate—76 mm Lg. 1 Acetal Plastic Tray | 1409N51 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixture Towers

Tower, mm | Base, mm | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall Ht., mm | Lg. | Wd. | Lg. | Wd. | Number of Holes | Material | Includes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M6 Hole Thread Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 150 | 25 | 25 | 127 | 25 | 33 | Aluminum | Two M6 Knurled Knobs | 1409N73 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Angle Brackets

|  |

Slots, mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg., mm | Wd., mm | Ht., mm | Lg. | Wd. | Number of Holes | Material | Includes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M6 Hole Thread Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 76 | 25 | 76 | 44 | 7.8 | 18 | Aluminum | Two M6 Bolts | 1409N68 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Magnetic Supports

| |

Dia., mm | Ht., mm | Thread Lg., mm | Max. Magnetic Pull, lbf | Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

M6 × 1 mm Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13 | 25 | 6.2 | 9 | Steel | 1409N61 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Magnetic V-Supports

|  |

Dia., mm | Ht., mm | V Wd., mm | V Dp., mm | V Angle | Thread Lg., mm | Max. Magnetic Pull, lbf | Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

M6 × 1 mm Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13 | 25 | 13 | 3.6 | 120° | 6.3 | 9 | Steel | 1409N63 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

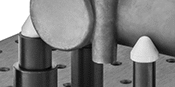

Cone Supports

|

|

Dia., mm | Ht., mm | Thread Lg., mm | Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

M6 × 1 mm Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 | 13 | 9.6 | Nylon | 1409N71 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Positioners

|  |

Slots, mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg., mm | Wd., mm | Thk., mm | Lg. | Wd. | Number of Holes | Material | Includes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M6 Hole Thread Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 75 | 25 | 10 | 30 | 6.5 | 1 | Steel | Two M6 Knurled Knobs | 1409N74 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Trays

|

Lg., mm | Wd., mm | Ht., mm | Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For M6 Thread | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 432 | 203 | 25 | Acetal | 1409N65 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

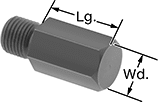

Threaded Locating and Support Buttons

|  |

Flat Head |

Thread | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg., mm | Wd., mm | Size | Lg., mm | Lg. Tolerance, mm | Shape | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel with Flat Head | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 10 | M6 × 1 mm | 11 | -0.2 to 0.2 | Hex | DIN 6320 | 3078N11 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

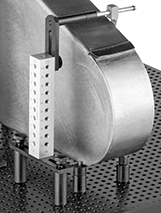

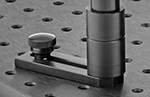

Clamps for Parts Inspection

Hold-Down Clamps

Clamps | Replacement Mounting Shafts | Replacement Clamp Arms | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Reach Lg., mm | Ht., mm | Thread Lg., mm | Material | Each | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tension Spring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M6 × 1 mm Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 21 | 50 | 6.2 | Aluminum | 1337N34 | 000000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 38 | 75 | 6.2 | Aluminum | 1337N32 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 58 | 75 | 6.2 | Aluminum | 1337N33 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Thumb Screw | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M6 × 1 mm Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 38 | 9.5 | Aluminum | 6203N14 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 76 | 63 | 6.4 | Aluminum | 6203N15 | 00000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 112 | 89 | 9.5 | Aluminum | 6203N16 | 000000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Squeeze Tabs | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M6 × 1 mm Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 83 | 76 | 9.5 | Plastic | 6203N22 | 00000 | 6203N19 | 000000 | 6203N17 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Side Clamps

Lg., mm | Wd., mm | Ht., mm | Thread Lg., mm | Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

M6 × 1 mm Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 77 | 66 | 13 | 19 | Plastic | 6203N24 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

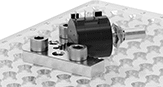

Positioning Clamps

|

Opening, mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Reach Lg., mm | Min. | Max. | Lg., mm | Wd., mm | Ht., mm | Thread Lg., mm | Material | Pair | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M6 × 1 mm Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 19 | 11 | 57 | 92 | 12.7 | 63 | 6.4 | Aluminum | 6203N26 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Threaded Hole Location Gauges

Thread Size | Thread Type | Hardness | Material | Each | ||

|---|---|---|---|---|---|---|

| M6 × 1 mm | Metric | Rockwell C60 | Tool Steel | 6648N18 | 0000000 |

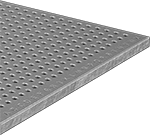

Fixture Plates

Fixture Plates

Quick-Change Adapters

Magnetic Mount | Bolt-On Mount | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg., mm | Wd., mm | Thk., mm | Max. Magnetic Pull, lbf | No. of Mounting Edges | Mounting Fasteners Included | No. of Mounting Holes | For Mounting Fastener Thread Size | Mounting Hole Ctr.-to-Ctr., mm | Material | Each | |||

| 180 | 30 | 13 | 3.5 | 1 | Yes | 2 | M6 | 147 | Anodized Aluminum | 6364N21 | 0000000 | ||

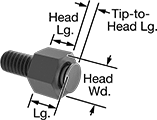

Swiveling Locating and Support Buttons

Head, mm | Thread | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Tip Dia., mm | Lg. | Wd. | Tip-to-Head Lg., mm | Lg., mm | Size | Lg., mm | Range of Motion | Head Lg. Tolerance, mm | Load Cap., lb. | Tip Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 8 | 10 | 2 | 10 | M6 × 1 mm | 12 | 28° | -0.05 to 0.05 | 2,050 | Stainless Steel | 1417N17 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

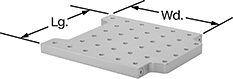

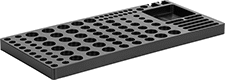

Quick-Change Fixture Plates

Fixture Plates

Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg., mm | Wd., mm | Thk., mm | Parallel Tolerance, mm | No. of | Ctr.-to-Ctr., mm | Max. Magnetic Pull, lbf | Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 Mounting Edge—M6 Hole Thread Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 180 | 180 | 13 | 0.127 | 81 | 20 | 3.5 | Anodized Aluminum | 6368N23 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 180 | 360 | 13 | 0.127 | 162 | 20 | 3.5 | Anodized Aluminum | 6368N24 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 360 | 360 | 13 | 0.127 | 324 | 20 | 3.5 | Anodized Aluminum | 6368N25 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 360 | 540 | 13 | 0.127 | 486 | 20 | 3.5 | Anodized Aluminum | 6368N26 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

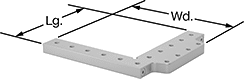

Corner Plates

Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg., mm | Wd., mm | Thk., mm | Parallel Tolerance, mm | No. of | Ctr.-to-Ctr., mm | Max. Magnetic Pull, lbf | Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 Mounting Edge—M6 Hole Thread Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 180 | 180 | 13 | 0.127 | 22 | 20 | 3.5 | Anodized Aluminum | 6368N31 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||