Compare material, finish, length class, and decimal size equivalents.

About Reamers

More

Drill Bits

These jobbers'-length bits have the rigidity and length required for most applications.

Black-oxide and black-and-gold-oxide drill bits produce less friction than uncoated drill bits.

Drill bits with a split point keep centered without a pilot hole.

For technical drawings and 3-D models, click on a part number.

Shank | Each | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Drill Bit Size | Decimal Size Equivalent | Overall Lg. | Max. Drilling Dp. | Type | Size | Point Style | Specifications Met | For Use On | Each | |

Metric | ||||||||||

Black-and-Gold Oxide High-Speed Steel | ||||||||||

| 4.7 mm | 0.185" | 89mm | 58.3mm | Round | 4.7mm | Split | NAS907 Type B | Steel, Iron, Stainless Steel | 000000000 | 00000 |

| 4.8 mm | 0.189" | 89mm | 58.3mm | Round | 4.8mm | Split | NAS907 Type B | Steel, Iron, Stainless Steel | 000000000 | 0000 |

Short-Length Drill Bits

Also known as screw-machine and stub-length bits, these provide maximum rigidity for drilling straighter holes than jobbers'- and maintenance-length drill bits.

Black-oxide drill bits produce less friction than uncoated drill bits.

Titanium-nitride (TiN) coated drill bits last longer and can drill at higher speeds than uncoated and black-oxide drill bits.

Drill bits with a split point keep centered without a pilot hole.

For technical drawings and 3-D models, click on a part number.

Shank | Each | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Drill Bit Size | Decimal Size Equivalent | Overall Lg. | Max. Drilling Dp. | Type | Size | Point Style | Specifications Met | For Use On | Each | |

Metric | ||||||||||

Black-Oxide High-Speed Steel | ||||||||||

| 9.7 mm | 0.3819" | 89mm | 43mm | Round | 9.7mm | Split | DIN 1897 | Steel, Iron, Stainless Steel | 000000000 | 000000 |

| 10.0 mm | 0.3937" | 89mm | 22.9mm | Round | 10mm | Split | DIN 1897 | Steel, Iron, Stainless Steel | 00000000 | 00000 |

| 10.2 mm | 0.4016" | 89mm | 43mm | Round | 10.2mm | Split | DIN 1897 | Steel, Iron, Stainless Steel | 000000000 | 0000 |

| 10.5 mm | 0.4134" | 89mm | 43mm | Round | 10.5mm | Split | DIN 1897 | Steel, Iron, Stainless Steel | 000000000 | 00000 |

Titanium-Nitride (TiN) Coated High-Speed Steel | ||||||||||

| 10.0 mm | 0.3937" | 89mm | 43.2mm | Round | 10mm | Split | DIN 1897 | Steel, Hardened Steel, Tool Steel, Iron, Stainless Steel, Nickel, Aluminum, Brass, Bronze, Plastic | 0000000 | 00000 |

| 10.2 mm | 0.4016" | 89mm | 43.2mm | Round | 10.2mm | Split | DIN 1897 | Steel, Hardened Steel, Tool Steel, Iron, Stainless Steel, Nickel, Aluminum, Brass, Bronze, Plastic | 0000000 | 00000 |

| 10.5 mm | 0.4134" | 89mm | 26.2mm | Round | 10.5mm | Split | DIN 1897 | Steel, Hardened Steel, Tool Steel, Iron, Stainless Steel, Nickel, Aluminum, Brass, Bronze, Plastic | 0000000 | 00000 |

Short-Length Cobalt Steel Drill Bits

Also known as screw-machine and stub-length bits, these provide maximum rigidity for drilling straighter holes than jobbers'-length drill bits. Made of cobalt steel, which has better heat and wear resistance than high-speed steel, they can run up to 25% faster and have a longer tool life.

Drill bits with a split point keep centered without a pilot hole.

For technical drawings and 3-D models, click on a part number.

Shank | Each | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Drill Bit Size | Decimal Size Equivalent | Overall Lg. | Max. Drilling Dp. | Type | Size | Point Style | Specifications Met | For Use On | Each | |

Metric | ||||||||||

Uncoated Cobalt Steel | ||||||||||

| 10.0 mm | 0.3937" | 89mm | 23.1mm | Round | 10mm | Split | DIN 1897 | Steel, Hardened Steel, Tool Steel, Iron, Stainless Steel, Nickel | 00000000 | 000000 |

| 10.2 mm | 0.4016" | 89mm | 22.6mm | Round | 10.2mm | Split | DIN 1897 | Steel, Hardened Steel, Tool Steel, Iron, Stainless Steel, Nickel | 00000000 | 00000 |

Carbide Drill Bits

These jobbers'-length bits have the rigidity and length required for most applications. Made of solid carbide for the highest accuracy and longest tool life, they are harder, stronger, and more wear resistant than high-speed steel, cobalt steel, and carbide-tipped bits. They retain a sharp, hard edge at high temperatures for the best performance on hard and abrasive material. The four-facet point keeps the bit centered without a pilot hole. These bits require rigid toolholding to prevent breakage and should not be used in hand-held drilling applications.

Titanium-nitride (TiN) coated drill bits last longer and can drill at higher speeds than uncoated drill bits.

For technical drawings and 3-D models, click on a part number.

Shank | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Drill Bit Size | Decimal Size Equivalent | Overall Lg. | Max. Drilling Dp. | Type | Size | Point Style | For Use On | Each | |

Metric | |||||||||

Uncoated Carbide | |||||||||

| 7.0 mm | 0.2756" | 89mm | 43.2mm | Round | 7mm | Four Facet | Steel, Iron, Stainless Steel, Aluminum, Brass, Bronze, Plastic | 0000000 | 000000 |

Titanium-Nitride (TiN) Coated Carbide | |||||||||

| 7.0 mm | 0.2756" | 89mm | 54mm | Round | 7mm | Four Facet | Steel, Hardened Steel, Tool Steel, Iron, Stainless Steel, Nickel, Titanium, Fiberglass | 0000000 | 00000 |

Carbide Drill Bits with Coolant Holes

Holes in these bits allow coolant to be run through the tool for more efficient chip evacuation. Use them in CNC machines with coolant-through technology. Made of solid carbide for the highest accuracy and longest tool life, they are harder, stronger, and more wear resistant than high-speed steel, cobalt steel, and carbide-tipped bits. They retain a sharp, hard edge at high temperatures for the best performance on hard and abrasive material. A titanium aluminum nitride (TiAlN) coating gives them additional wear and temperature resistance. The four-facet point keeps the bit centered without a pilot hole. These bits require rigid toolholding to prevent breakage and should not be used in hand-held drilling applications.

Jobbers'-length drill bits have the rigidity and length required for most applications.

Maintenance-length drill bits are shorter and more rigid than jobbers'-length bits but longer than short-length bits. They hold up better than jobbers' bits when drilling in hard metal. Also known as mechanics' bits.

For technical drawings and 3-D models, click on a part number.

Shank | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Drill Bit Size | Decimal Size Equivalent | Overall Lg. | Max. Drilling Dp. | Type | Size | Point Style | No. of Coolant Holes | For Use On | Each | |

Metric—Maintenance Length | ||||||||||

Titanium-Aluminum-Nitride (TiAlN) Coated Carbide | ||||||||||

| 8.5 mm | 0.3346" | 89mm | 47mm | Round | 10mm | Four Facet | 2 | Steel, Hardened Steel, Tool Steel, Iron, Stainless Steel, Nickel, Titanium, Fiberglass | 00000000 | 0000000 |

| 9.0 mm | 0.3543" | 89mm | 47mm | Round | 10mm | Four Facet | 2 | Steel, Hardened Steel, Tool Steel, Iron, Stainless Steel, Nickel, Titanium, Fiberglass | 00000000 | 000000 |

| 9.5 mm | 0.374" | 89mm | 88.9mm | Round | 10mm | Four Facet | 2 | Steel, Hardened Steel, Tool Steel, Iron, Stainless Steel, Nickel, Titanium, Fiberglass | 00000000 | 000000 |

| 10.0 mm | 0.3937" | 89mm | 47mm | Round | 10mm | Four Facet | 2 | Steel, Hardened Steel, Tool Steel, Iron, Stainless Steel, Nickel, Titanium, Fiberglass | 0000000 | 000000 |

Carbide-Tipped Drill Bits

These jobbers'-length bits have the rigidity and length required for most applications. Made of carbide-tipped steel, which has better wear resistance than high-speed steel and cobalt steel, they maintain a sharper, harder edge at high temperatures for excellent performance on abrasive material, such as plastic. Because they aren’t as brittle as solid carbide bits, they can be used in less rigid setups, such as a hand-held drill.

For technical drawings and 3-D models, click on a part number.

Shank | Standard Point | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Drill Bit Size | Decimal Size Equivalent | Overall Lg. | Type | Size | For Use On | Max. Drilling Dp. | Point Angle | Each | |

Metric | |||||||||

Uncoated Carbide-Tipped Steel | |||||||||

| 4.2 mm | 0.1654" | 89mm | Round | 4.2mm | Steel, Iron, Titanium, Aluminum, Brass, Bronze, Plastic | 47mm | 118° | 00000000 | 000000 |

| 4.5 mm | 0.1772" | 89mm | Round | 4.5mm | Steel, Iron, Titanium, Aluminum, Brass, Bronze, Plastic | 47mm | 118° | 00000000 | 00000 |

Smooth-Finish Drill Bits for Wood

Bore clean, flat bottom holes in soft wood, veneer, and laminates. The center guide point prevents the bit from wandering. Also known as Forstner bits.

For technical drawings and 3-D models, click on a part number.

Drill Bits for Carbon Fiber, Fiberglass, and Graphite

These jobbers'-length bits have the rigidity and length required for most applications. They are designed to make clean holes in abrasive material. Their point keeps the bit centered without a pilot hole.

Diamond-coated drill bits are highly wear resistant for drilling in abrasive material. They last longer than uncoated bits.

For technical drawings and 3-D models, click on a part number.

Shank | ||||||||

|---|---|---|---|---|---|---|---|---|

| Drill Bit Size | Decimal Size Equivalent | Overall Lg. | Max. Drilling Dp. | Type | Size | Point Style | Each | |

Metric | ||||||||

Diamond-Coated Carbide | ||||||||

| 7.0 mm | 0.2756" | 89mm | 54mm | Round | 7mm | Brad | 0000000 | 000000 |

High-Speed Steel Multidiameter Drill Bits

Steps with progressively larger diameters let you drill a range of sizes with one bit. Also known as step drills.

Black-oxide drill bits produce less friction than uncoated drill bits.

For technical drawings and 3-D models, click on a part number.

Shank | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Drill Bit Size | Decimal Size Equivalent | No. of Sizes | Overall Lg. | For Max. Material Thick. | Type | Size | Point Style | For Use On | Each | |

Metric | ||||||||||

Black-Oxide High-Speed Steel | ||||||||||

| 6.0 mm, 8.0 mm, 10.0 mm, 12.0 mm, 14.0 mm, 16.0 mm, 18.0 mm, 20.0 mm, 22.0 mm, 24.0 mm, 26.0 mm, 28.0 mm, 30.0 mm, 32.0 mm | 0.2362", 0.315", 0.3937", 0.4724", 0.5512", 0.6299", 0.7087", 0.7874", 0.8661", 0.9449", 1.0236", 1.1024", 1.1811", 1.2598", 1.378" | 15 | 89mm | 2mm | 3-Flat | 9.53mm | Standard | Steel, Hardened Steel, Tool Steel, Iron, Nickel, Aluminum, Brass, Bronze, Plastic | 0000000 | 0000000 |

Cobalt Steel Hole-Starting Drill Bits

The short flute and length keep these bits straight for accurate placement when starting holes that will be drilled deeper with a longer bit. Also known as spotting drill bits. Cobalt steel bits are heat resistant and maintain their sharp edges when drilling hard material. They are for use in both hand-held drilling and machine-tool applications.

Bits with a 90° point angle are for centering and chamfering holes that will be followed by a smaller drill bit size.

For technical drawings and 3-D models, click on a part number.

Shank | 90° Point Angle | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Drill Bit Size | Decimal Size Equivalent | Overall Lg. | Max. Drilling Dp. | Type | Size | Point Style | For Use On | Each | |

Metric | |||||||||

Uncoated Cobalt Steel | |||||||||

| 10.0 mm | 0.3937" | 89mm | 25.4mm | Round | 10mm | Standard | Steel, Hardened Steel, Tool Steel, Iron, Stainless Steel, Nickel | 00000000 | 000000 |

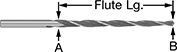

Metric Size Combination Drill Bit/Round-Shank Reamers for Taper-Pin Holes

The same tool drills and reams holes for taper pins. They have chip breakers on the cutting edge.

For technical drawings and 3-D models, click on a part number.

Reamer Dia. | Lg. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Taper Pin Number, mm | (A), mm | (B), mm | Flute, mm | Overall, mm | Number of Flutes | Flute Style | Spiral Direction | Rate of Taper | Point Angle | For Use On | Each | |

High-Speed Steel | ||||||||||||

| 2.5 | 3.4600 | 2.3300 | 56 | 89 | 2 | Spiral | Right Hand | 1" per 50" | 118° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 000000 |