About Plastic

More

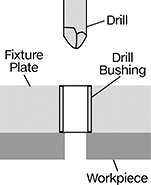

Press-Fit Drill Bushings

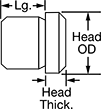

Also known as jig bushings, these drill bushings fit inside fixture plate holes to precisely guide drill bits, counterbores, reamers, and other cutting tools. They improve accuracy so your drilled holes and cuts are consistent from part to part. Known for their versatility, drill bushings are also used as spacers, shims, and machinery bushings.

Press into place with a manual or hydraulic press. Since these bushings are sized slightly larger than the hole for an extremely tight fit, they’ll stay put permanently. These are ANSI Type P bushings—also known as headless bushings—which means you don’t need to counterbore the hole to mount them flush.

Don't see the size you need? Additional sizes are available.

Tolerance | Each | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OD | Lg. | For Drill Bit Size | ID | OD | Lg. | Drill Bushing Type | Material | Hardness | 1-5 | 6-11 | 12-Up | |

1.75" ID | ||||||||||||

| 2" | 1 1/4" | 1 3/4" | 0.0003" to 0.0007" | 0.0019" to 0.0023" | -0.015" to 0.015" | P | Steel | Rockwell C61 | 00000000 | 000000 | 000000 | 000000 |

| 2" | 2" | 1 3/4" | 0.0003" to 0.0007" | 0.0019" to 0.0023" | -0.015" to 0.015" | P | Steel | Rockwell C61 | 00000000 | 00000 | 00000 | 00000 |

| 2" | 2 1/2" | 1 3/4" | 0.0003" to 0.0007" | 0.0019" to 0.0023" | -0.015" to 0.015" | P | Steel | Rockwell C61 | 0000000 | 00000 | 00000 | 00000 |

| 2" | 3" | 1 3/4" | 0.0003" to 0.0007" | 0.0019" to 0.0023" | -0.015" to 0.015" | P | Steel | Rockwell C61 | 00000000 | 00000 | 00000 | 00000 |

| 2 1/4" | 3/4" | 1 3/4" | 0.0003" to 0.0007" | 0.0021" to 0.0025" | -0.015" to 0.015" | P | Steel | Rockwell C61 | 00000000 | 00000 | 00000 | 00000 |

| 2 1/4" | 1" | 1 3/4" | 0.0003" to 0.0007" | 0.0021" to 0.0025" | -0.01" to 0.01" | P | Steel | Rockwell C61 | 000000000 | 00000 | 00000 | 00000 |

| 2 1/4" | 1 3/8" | 1 3/4" | 0.0003" to 0.0007" | 0.0021" to 0.0025" | -0.015" to 0.015" | P | Steel | Rockwell C61 | 00000000 | 00000 | 00000 | 00000 |

| 2 1/4" | 1 1/2" | 1 3/4" | 0.0003" to 0.0007" | 0.0021" to 0.0025" | -0.015" to 0.015" | P | Steel | Rockwell C61 | 00000000 | 00000 | 00000 | 00000 |

| 2 1/4" | 1 3/4" | 1 3/4" | 0.0003" to 0.0007" | 0.0021" to 0.0025" | -0.01" to 0.01" | P | Steel | Rockwell C61 | 000000000 | 00000 | 00000 | 00000 |

| 2 1/4" | 2" | 1 3/4" | 0.0003" to 0.0007" | 0.0021" to 0.0025" | -0.015" to 0.015" | P | Steel | Rockwell C61 | 00000000 | 00000 | 00000 | 00000 |

| 2 1/4" | 2 1/8" | 1 3/4" | 0.0003" to 0.0007" | 0.0021" to 0.0025" | -0.01" to 0.01" | P | Steel | Rockwell C61 | 000000000 | 00000 | 00000 | 00000 |

| 2 1/4" | 2 1/2" | 1 3/4" | 0.0003" to 0.0007" | 0.0021" to 0.0025" | -0.01" to 0.01" | P | Steel | Rockwell C61 | 000000000 | 00000 | 00000 | 00000 |

| 2 1/4" | 3" | 1 3/4" | 0.0003" to 0.0007" | 0.0021" to 0.0025" | -0.01" to 0.01" | P | Steel | Rockwell C61 | 000000000 | 00000 | 00000 | 00000 |

| 2 3/8" | 2" | 1 3/4" | 0.0003" to 0.0007" | 0.0021" to 0.0025" | -0.015" to 0.015" | P | Steel | Rockwell C61 | 00000000 | 00000 | 00000 | 00000 |

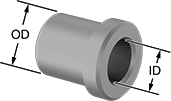

Press-Fit Drill Bushings with Head

A flanged head on these bushings acts as a stop, so they won’t press through your jig even under extreme drilling pressure. They’re ANSI Type H bushings, also known as headed bushings. The head adds support and protects the jig from damage caused by heavy use, so they’re often used in jigs made of thin or soft materials. These bushings guide your drill bit, reamer, or other cutting bit to create accurate, consistent holes from one workpiece to the next. They’re also used as spacers, shims, and machinery bushings. Made of hardened, ground steel, they hold their shape and resist wear, so they last for many cycles without needing to be replaced.

To install, fit the bushing into a hole in your jig. In a standard hole, the head will sit above the jig plate; to mount flush, install in a countersunk hole. A chamfered edge on the bottom of the bushing helps center the bushing in the hole. Once it’s centered, press the bushing into place with a hydraulic or lever press.

Don't see the size you need? Additional sizes are available.

Head | Tolerance | Each | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OD | Lg. | For Drill Bit Size | OD | Thick. | ID | OD | Lg. | Drill Bushing Type | Material | Hardness | 1-5 | 6-11 | 12-Up | |

1.75" ID | ||||||||||||||

| 2 1/4" | 3" | 1 3/4" | 2 31/64" | 3/8" | 0.0003" to 0.0007" | 0.0021" to 0.0025" | -0.01" to 0.01" | H | Steel | Rockwell C61 | 00000000 | 000000 | 000000 | 000000 |

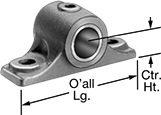

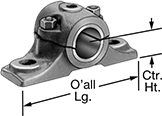

Mounted Sleeve Bearings

A reliable classic—these babbitt bearings are strong and corrosion resistant.

Bearings with split housing have a removable section for easy maintenance.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

Overall | Mounting | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Center Ht. | Ht. | Lg. | Wd. | Bearing Wd. | Hole Lg. | Hole Wd. | Hole Ctr.-to-Ctr. | Dynamic Radial Load Cap. | Temp. Range, °F | Alignment Style | Lubrication | Each | |

Babbitt Bearings with Solid Cast Iron Housing | ||||||||||||||

| 1 3/4" | 1 13/16" | 3 1/4" | 6 1/2" | 3 1/2" | 3 1/2" | 3/4" | 5/8" | 4 3/8" | 850 lbs. @ 30 rpm | 0° to 130° | Fixed Alignment | Required | 0000000 | 0000000 |

Babbitt Bearings with Split Cast Iron Housing | ||||||||||||||

| 1 3/4" | 1 1/2" | 3" | 6 3/4" | 3 1/2" | 3 1/2" | 3/4" | 1/2" | 5 1/4" | 850 lbs. @ 30 rpm | 0° to 130° | Fixed Alignment | Required | 0000000 | 000000 |

Low-Carbon Steel Round Tubes

Also known as mild steel, low-carbon steel is easy to machine, form, and weld. It's widely fabricated into parts that don’t require high strength, such as frames, supports, and conduit. This steel is manufactured to ASTM, SAE, or EN standards for quality and performance.

Seamless tubes are stronger than welded tubes.

DOM (drawn over mandrel) welded tubes are stronger than ERW (electric resistance welded) tubes.

Heat treatable tubes can be surface hardened. Tubes that are stress relieved minimize warping during machining.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

| OD | ID | Yield Strength, psi | Fabrication | Weld Method | Heat Treatable | Heat Treatment | Hardness | Specifications Met | 1/2 ft. Lg. | 1 ft. Lg. | 2 ft. Lg. | 3 ft. Lg. | 6 ft. Lg. | 8 ft. Lg. | |

1/8" Wall Thick. | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2" | 1 3/4" | 32,000 | Welded | ERW (Electric Resistance Welded) | No | __ | Rockwell B55 (Soft) | ASTM A513 Type 1 | 00000000 | ||||||

1/4" Wall Thick. | |||||||||||||||

| 2 1/4" | 1 3/4" | 65,000 | Welded | DOM (Drawn Over Mandrel) | No | Stress Relieved | Rockwell B80 (Medium) | ASTM A513 Type 5 | 00000000 | ||||||

3/8" Wall Thick. | |||||||||||||||

| 2 1/2" | 1 3/4" | 65,000 | Welded | DOM (Drawn Over Mandrel) | No | __ | Rockwell B80 (Medium) | ASTM A513 Type 5 | 0000000 | ||||||

1/2" Wall Thick. | |||||||||||||||

| 2 3/4" | 1 3/4" | 65,000 | Welded | DOM (Drawn Over Mandrel) | No | __ | Rockwell B80 (Medium) | ASTM A513 Type 5 | 0000000 | ||||||

5/8" Wall Thick. | |||||||||||||||

| 3" | 1 3/4" | 70,000 | Welded | DOM (Drawn Over Mandrel) | No | __ | Rockwell B85 (Medium) | ASTM A513 Type 5 | 0000000 | ||||||

3/4" Wall Thick. | |||||||||||||||

| 3 1/4" | 1 3/4" | 35,000 | Seamless | __ | Yes | __ | Rockwell B60 (Medium) | ASTM A519 | 00000000 | ||||||

| OD | ID | Yield Strength, psi | Fabrication | Weld Method | Heat Treatable | Hardness | Specifications Met | Each | |

1" Lg. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

3/8" Wall Thick. | |||||||||

| 2 1/2" | 1 3/4" | 70,000 | Welded | DOM (Drawn Over Mandrel) | No | Rockwell B85 (Medium) | ASTM A513 Type 5 | 00000000 | 000000 |

3" Lg. | |||||||||

3/8" Wall Thick. | |||||||||

| 2 1/2" | 1 3/4" | 70,000 | Welded | DOM (Drawn Over Mandrel) | No | Rockwell B85 (Medium) | ASTM A513 Type 5 | 00000000 | 00000 |

932 Bearing Bronze Tubes

- Yield Strength: 18,000 psi

- Hardness: Rockwell B35 (Soft)

- Temper: M07

- Heat Treatable: No

- Specifications Met: ASTM B505

Offering excellent antifriction qualities, 932 bronze also offers good strength and wear resistance. It's also known as SAE 660 and is often used for bearings, bushings, and thrust washers.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

| OD | OD Tolerance Range | ID | ID Tolerance Range | Straightness Tolerance | Nonsparking Properties | 3" Lg. | 6 1/2" Lg. | 13" Lg. | |

1/8" Wall Thick. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 2" | 0.034" to 0.044" | 1 3/4" | -0.064" to -0.019" | .004" per inch | Nonsparking | 00000000 | |||

1/4" Wall Thick. | |||||||||

| 2 1/4" | 0.034" to 0.044" | 1 3/4" | -0.064" to -0.019" | .004" per inch | Nonsparking | 00000000 | |||

3/8" Wall Thick. | |||||||||

| 2 1/2" | 0.034" to 0.044" | 1 3/4" | -0.064" to -0.019" | .004" per inch | Nonsparking | 00000000 | |||

1/2" Wall Thick. | |||||||||

| 2 3/4" | 0.034" to 0.044" | 1 3/4" | -0.064" to -0.019" | .004" per inch | Nonsparking | 00000000 | |||

5/8" Wall Thick. | |||||||||

| 3" | 0.034" to 0.044" | 1 3/4" | -0.064" to -0.019" | .004" per inch | Nonsparking | 00000000 | |||

7/8" Wall Thick. | |||||||||

| 3 1/2" | 0.034" to 0.044" | 1 3/4" | -0.064" to -0.019" | .004" per inch | Nonsparking | 00000000 | |||

Oil-Filled 841 Bearing Bronze Tubes

- Yield Strength: 11,000 psi

- Hardness: Not Rated

- Temper: Not Rated

- Heat Treatable: No

- Specifications Met: ASTM B438

Powdered bronze is pressed and then impregnated with SAE 30 oil to make this material self-lubricating. Use it to make bearings and parts for hard-to-reach areas that would be difficult to access for lubrication, such as well pumps and turbine blades. These tubes are oversized on the outside and undersized on the inside to allow for finishing to the sizes listed.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Easy-to-Machine 936 Bearing Bronze Tubes

- Yield Strength: 21,000 psi

- Hardness: Rockwell B25 (Soft)

- Temper: M07

- Heat Treatable: No

- Specifications Met: ASTM B505

An easier-to-machine alternative to 932 bronze, 936 also has better corrosion resistance. It's also called modified SAE 64. Use it to machine bearings and bushings for oil pumps and gasoline engines.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

| OD | OD Tolerance Range | ID | ID Tolerance Range | Straightness Tolerance | 6" Lg. | 13" Lg. | |

1/4" Wall Thick. | |||||||

|---|---|---|---|---|---|---|---|

| 2 1/4" | 0.0312" to 0.0937" | 1 3/4" | -0.0937" to -0.0312" | 3/8" per 5 ft. | 00000000 | ||

3/8" Wall Thick. | |||||||

| 2 1/2" | 0.0312" to 0.0937" | 1 3/4" | -0.0937" to -0.0312" | 3/8" per 5 ft. | 00000000 | ||

1/2" Wall Thick. | |||||||

| 2 3/4" | 0.0312" to 0.0937" | 1 3/4" | -0.0937" to -0.0312" | 3/8" per 5 ft. | 00000000 | ||

5/8" Wall Thick. | |||||||

| 3" | 0.0312" to 0.0937" | 1 3/4" | -0.0937" to -0.0312" | 3/8" per 5 ft. | 00000000 | ||

Weldable 954 Bearing Bronze Tubes

- Yield Strength: 32,000 psi

- Hardness: Rockwell B85 (Medium)

- Temper: M07

- Heat Treatable: Yes

- Specifications Met: ASTM B505

954 bronze contains a minimum of 10% aluminum for strength and weldability. It is also known as aluminum bronze. It's widely used for bearings, bushings, valve bodies, and worm gears. The strength of this material increases with heat treating.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

| OD | OD Tolerance Range | ID | ID Tolerance Range | Straightness Tolerance | 6 1/2" Lg. | 13" Lg. | |

1/4" Wall Thick. | |||||||

|---|---|---|---|---|---|---|---|

| 2 1/4" | 0.055" to 0.145" | 1 3/4" | -0.155" to -0.055" | 1/4" per 5 ft. | 000000 | ||

3/8" Wall Thick. | |||||||

| 2 1/2" | 0.055" to 0.145" | 1 3/4" | -0.155" to -0.055" | 1/4" per 5 ft. | 0000000 | ||

1/2" Wall Thick. | |||||||

| 2 3/4" | 0.055" to 0.145" | 1 3/4" | -0.155" to -0.055" | 1/4" per 5 ft. | 0000000 | ||

5/8" Wall Thick. | |||||||

| 3" | 0.055" to 0.145" | 1 3/4" | -0.155" to -0.055" | 1/4" per 5 ft. | 0000000 | ||

Wear-Resistant Nylon Tubes

- Color: Off-White

- Temperature Range: -40° to 165° F

- Tensile Strength: 11,200-12,300 psi (Good)

- Impact Strength: 0.6-1.4 ft.-lbs./in. (Poor)

- Hardness: Rockwell R108-R121 (Hard)

- For Use Outdoors: No

- Specifications Met: ASTM D6779, FDA Compliant 21 CFR 177.1500, UL 94 HB

Because these wear-resistant nylon 6/6 tubes have a slippery surface that reduces friction, they’re often machined into bearings, gears, and valve seats.

Tubes with an oversized OD also have an undersized ID for finishing to the sizes listed.

5 ft. Lg. | |||

|---|---|---|---|

| OD | ID | Each | |

1/8" Wall Thick. | |||

| 2" | 1 3/4" | 0000000 | 000000 |

Oil-Filled Easy-to-Machine Wear-Resistant Cast Nylon Tubes

- Color: Green

- Temperature Range: 32° to 230° F

- Tensile Strength: 9,500-10,000 psi (Good)

- Impact Strength: 1.2-1.4 ft-lbs./in. (Poor)

- Hardness: Rockwell R110 (Hard)

- For Use Outdoors: Yes

- Specifications Met: ASTM D5989

Impregnated with oil, these tubes remain slippery over time. Use them to fabricate pulleys, bushings, and bearings for use in hard-to-reach areas where adding a lubricant would be difficult. Because they are made of cast nylon 6, they are easier to machine than standard nylon rods, plus they’re better electrical insulators. The OD is oversized and the ID is undersized for finishing to the sizes listed. This material is comparable to Nycast and Nyloil.

Easy-to-Machine Wear-Resistant Cast Nylon Tubes

- Color: Off-White

- Temperature Range: -20° to 200° F

- Tensile Strength: 10,000 psi (Good)

- Impact Strength: 1.5 ft.-lbs./in. (Poor)

- Hardness: Rockwell R110-R115 (Hard)

- For Use Outdoors: No

- Specifications Met: ASTM D5989, UL 94 HB, FDA Compliant 21 CFR 177.1500

These cast nylon 6 tubes are easier to machine than other standard nylon 6/6 rods. They’re also better electrical insulators. Use them to make pulleys, bushings, and bearings. These tubes have an oversized OD and an undersized ID for finishing to the sizes listed. This material is comparable to Nylatron and Nycast.

MDS-Filled Easy-to-Machine Wear-Resistant Cast Nylon Tubes

- Color: Black

- Maximum Temperature: 230° F

- Tensile Strength: 10,000 psi (Good)

- Impact Strength: 1.4 ft.-lbs./in. (Poor)

- Hardness: Rockwell R110 (Hard)

- For Use Outdoors: Yes

- Specifications Met: ASTM D5989

The addition of MDS gives these tubes exceptional wear resistance along with a self-lubricating surface. They're made of cast nylon 6, making them easier to machine and better electrical insulators than other MDS-filled nylon tubes. Tubes can be used to fabricate pulleys, bushings, and bearings installed in hard-to-reach areas where adding a lubricant would be difficult. The OD is oversized and the ID is undersized to allow for finishing to the sizes listed. This material is comparable to Nylatron and Nycast.

Heat-Stabilized Easy-to-Machine Wear-Resistant Cast Nylon Tubes

- Color: Blue

- Maximum Temperature: 250° F

- Tensile Strength: 10,000-13,500 psi (Good)

- Impact Strength: 1-2.5 ft.-lbs./in. (Poor)

- Hardness: Rockwell R110-R120 (Hard)

- For Use Outdoors: Yes

A good choice for making sprockets and pulleys, these cast nylon 6 tubes withstand higher temperatures and are easier to machine than standard nylon 6/6 tubes. This material is comparable to Nylatron and Nycast.

Slippery UHMW Polyethylene Tubes

These impact- and wear-resistant tubes offer 360° protection from scrapes and strikes to wires, cords, and anything that can slide through them. UHMW has a low-friction surface that resists sticking and binding.

Tight-tolerance tubes, also known as bushing stock, slide over rods and inside shafts to increase or decrease the diameter. Their precise sizing allows ascending sizes to fit inside each other to create a thicker wall.

- Color: White

- Temperature Range: -20° to 180° F

- Tensile Strength: 4,350-5,800 psi (Poor)

- Impact Strength: 16.8 ft.-lbs./in. (Excellent)

- Hardness: Durometer 65D-67D (Medium)

- For Use Outdoors: No

- Specifications Met: ASTM D4020

6" Lg. | |||||

|---|---|---|---|---|---|

| OD | OD Tolerance | ID | ID Tolerance | Each | |

1/4" Wall Thick. (-0.06" to 0") | |||||

| 2 1/4" | -0.030" to 0.000" | 1 3/4" | 0.000" to 0.030" | 0000000 | 000000 |

Wear-Resistant Easy-to-Machine Delrin® Acetal Resin Tubes

- Color: White or Black

- Temperature Range:

6" Lengths: 0° to 180° F

All other sizes: -20° to 180° F - Tensile Strength: 7,690 psi (Good)

- Impact Strength: 1-1.5 ft.-lbs./in. (Poor)

- Hardness: Rockwell R120-R122 (Hard)

- For Use Outdoors: No

- Specifications Met: See table

Easy to machine to close tolerances, these dimensionally stable tubes resist expanding when exposed to heat and moisture. They have a naturally slippery surface along with excellent wear resistance. Use them to make precision gears, bushings, and bearings. Delrin® acetal resin, also known as acetal homopolymer, is stronger and stiffer than acetal copolymer.

Tight-tolerance tubes that are 6” long are also known as bushing stock. You can slide them over rods to increase the OD, or into shafts to decrease the ID. Their precise sizing also allows ascending sizes to fit inside of each other to increase the wall thickness.

White | |||||||

|---|---|---|---|---|---|---|---|

| OD | OD Tolerance | ID | ID Tolerance | Specifications Met | Lg. | Each | |

1/8" Wall Thick. (-0.005" to 0.005") | |||||||

| 2" | -0.005" to 0.005" | 1 3/4" | -0.005" to 0.005" | ASTM D4181, FDA Compliant 21 CFR 177.2480, NSF/ANSI 51 | 6" | 0000000 | 0000000 |