Filter by

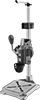

Mount Type

Body Material

Handle Position When Clamped

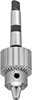

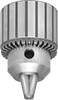

Drill Chuck Mount Type

Bit Shank Size

Holding Capacity

Machine Taper Number

DFARS Specialty Metals

Shank Type

Export Control Classification Number (ECCN)

Fabricating and Machining

Safety Equipment

Lighting

Building and Machinery Hardware