Selecting an Immersion Heater

More

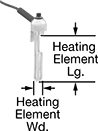

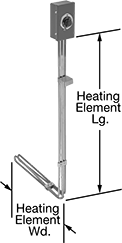

Hanging Immersion Heaters for Chemical Solutions

Hook these heaters on the side of small drums and pails to quickly and efficiently heat liquid through direct contact. All are for use in metal containers; they should not be used in plastic containers. An adjustable thermostat automatically turns the heater on when the temperature drops below the set temperature and off when it rises above the set temperature. Adjust the set temperature with the dial. The heating element is 316 stainless steel for excellent resistance to harsh chemicals.

Note: Immerse the heating element in liquid up to at least the minimum coverage level to prevent heater failure.

Heating Element | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Container Cap., gal. | Wattage, W | Watt Density, W/sq. in. | Voltage | Electrical Phase | Current, A | Dia. | Wd. | Min. Coverage | Overall Lg. | Temperature Control Method | NEMA Style | Cord Lg., ft. | For Use With | Each | |

With Adjustable Thermostat (70° to 212° F) | |||||||||||||||

6" Lg. 316 Stainless Steel Heating Element | |||||||||||||||

| 1 to 5 | 500 | 25 | 120V AC | Single | 4.3 | __ | 1 3/8" | 4 1/2" | 9 3/4" | Dial | 5-15 | 6 | Ammonium Hydroxide (0-3%) Ammonium Hydroxide (3-6%) Deionized Water Ethylene Glycol Motor Oil Water | 0000000 | 0000000 |

| 1 to 5 | 1,100 | 56 | 120V AC | Single | 9.6 | __ | 1 3/8" | 4 1/2" | 9 3/4" | Dial | 5-15 | 6 | Ammonium Hydroxide (0-3%) Ammonium Hydroxide (3-6%) Deionized Water Motor Oil Water | 0000000 | 000000 |

20" Lg. 316 Stainless Steel Heating Element | |||||||||||||||

| 5 to 10 | 500 | 12 | 120V AC | Single | 4.3 | __ | 1 3/8" | 18 1/2" | 23 1/2" | Dial | 5-15 | 6 | Ammonium Hydroxide (0-3%) Ammonium Hydroxide (3-6%) Deionized Water Ethylene Glycol Motor Oil Nitric Acid (0-3%) Nitric Acid (3-6%) Phosphoric Acid (0-3%) Phosphoric Acid (3-6%) Sodium Hydroxide (0-3%) Sodium Hydroxide (3-6%) Water | 0000000 | 000000 |

| 5 to 10 | 1,100 | 25 | 120V AC | Single | 9.6 | __ | 1 3/8" | 18 1/2" | 23 1/2" | Dial | 5-15 | 6 | Ammonium Hydroxide (0-3%) Ammonium Hydroxide (3-6%) Deionized Water Ethylene Glycol Motor Oil Nitric Acid (0-3%) Nitric Acid (3-6%) Phosphoric Acid (0-3%) Phosphoric Acid (3-6%) Sodium Hydroxide (0-3%) Sodium Hydroxide (3-6%) Water | 0000000 | 000000 |

With Adjustable Thermostat (70° to 250° F) | |||||||||||||||

14" Lg. 316 Stainless Steel Heating Element | |||||||||||||||

| 5 to 10 | 1,500 | 19 | 120V AC | Single | 13 | 13" | __ | 5" | 14 1/2" | Dial | 5-15 | 6 | Ammonium Hydroxide (0-3%) Ammonium Hydroxide (3-6%) Deionized Water Ethylene Glycol Motor Oil Phosphoric Acid (0-3%) Phosphoric Acid (3-6%) Water | 00000000 | 000000 |

| 5 to 10 | 1,500 | 23 | 120V AC | Single | 13 | 10 1/2" | __ | 5" | 14 1/2" | Dial | 5-15 | 6 | Ammonium Hydroxide (0-3%) Ammonium Hydroxide (3-6%) Deionized Water Ethylene Glycol Motor Oil Water | 00000000 | 000000 |

| 5 to 10 | 1,500 | 34 | 120V AC | Single | 13 | 7" | __ | 5" | 14 1/2" | Dial | 5-15 | 6 | Ammonium Hydroxide (0-3%) Ammonium Hydroxide (3-6%) Deionized Water Motor Oil Water | 00000000 | 000000 |

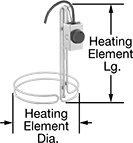

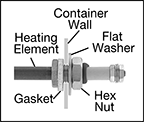

Bend-and-Stay Immersion Heaters with

Through-Wall Fittings for Chemical Solutions

Form these heaters into any shape and install them through container walls with the attached bulkhead fittings. They quickly and efficiently heat liquid through direct contact. All require a temperature switch or controller (sold separately) to regulate heat output. The Incoloy heating element has excellent resistance to harsh chemicals.

Note: Fully immerse the heating element in liquid to prevent heater failure.

Thread | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wattage, W | Watt Density, W/sq. in. | Current, A | Heating Element Lg. | Min. Bend Radius | For Hole Size | Size | Type | Gender | Wire Connection Type | Includes | For Use With | Each | |

120V AC, Single Phase | |||||||||||||

17/64" Dia. | |||||||||||||

| 250 | 30 | 2.1 | 11" | 15/16" | 15/32" | 7/16"-20 | UNF | Male | Screw Terminals | Flat Washers Gaskets Hex Nuts | Ammonium Hydroxide (0-3%), Ammonium Hydroxide (3-6%), Ethylene Glycol, Nitric Acid (0-3%), Nitric Acid (3-6%), Soap Solutions, Sodium Hydroxide (0-3%), Sodium Hydroxide (3-6%), Water | 0000000 | 0000000 |

| 350 | 30 | 2.9 | 15" | 15/16" | 15/32" | 7/16"-20 | UNF | Male | Screw Terminals | Flat Washers Gaskets Hex Nuts | Ammonium Hydroxide (0-3%), Ammonium Hydroxide (3-6%), Ethylene Glycol, Nitric Acid (0-3%), Nitric Acid (3-6%), Soap Solutions, Sodium Hydroxide (0-3%), Sodium Hydroxide (3-6%), Water | 0000000 | 000000 |

| 450 | 30 | 3.8 | 20" | 15/16" | 15/32" | 7/16"-20 | UNF | Male | Screw Terminals | Flat Washers Gaskets Hex Nuts | Ammonium Hydroxide (0-3%), Ammonium Hydroxide (3-6%), Ethylene Glycol, Nitric Acid (0-3%), Nitric Acid (3-6%), Soap Solutions, Sodium Hydroxide (0-3%), Sodium Hydroxide (3-6%), Water | 0000000 | 000000 |

| 650 | 30 | 5.4 | 27" | 15/16" | 15/32" | 7/16"-20 | UNF | Male | Screw Terminals | Flat Washers Gaskets Hex Nuts | Ammonium Hydroxide (0-3%), Ammonium Hydroxide (3-6%), Ethylene Glycol, Nitric Acid (0-3%), Nitric Acid (3-6%), Soap Solutions, Sodium Hydroxide (0-3%), Sodium Hydroxide (3-6%), Water | 0000000 | 000000 |

| 850 | 30 | 7.1 | 35" | 15/16" | 15/32" | 7/16"-20 | UNF | Male | Screw Terminals | Flat Washers Gaskets Hex Nuts | Ammonium Hydroxide (0-3%), Ammonium Hydroxide (3-6%), Ethylene Glycol, Nitric Acid (0-3%), Nitric Acid (3-6%), Soap Solutions, Sodium Hydroxide (0-3%), Sodium Hydroxide (3-6%), Water | 0000000 | 000000 |

| 1,000 | 30 | 8.3 | 41" | 15/16" | 15/32" | 7/16"-20 | UNF | Male | Screw Terminals | Flat Washers Gaskets Hex Nuts | Ammonium Hydroxide (0-3%), Ammonium Hydroxide (3-6%), Ethylene Glycol, Nitric Acid (0-3%), Nitric Acid (3-6%), Soap Solutions, Sodium Hydroxide (0-3%), Sodium Hydroxide (3-6%), Water | 0000000 | 000000 |

| 1,500 | 30 | 12.5 | 60" | 15/16" | 15/32" | 7/16"-20 | UNF | Male | Screw Terminals | Flat Washers Gaskets Hex Nuts | Ammonium Hydroxide (0-3%), Ammonium Hydroxide (3-6%), Ethylene Glycol, Nitric Acid (0-3%), Nitric Acid (3-6%), Soap Solutions, Sodium Hydroxide (0-3%), Sodium Hydroxide (3-6%), Water | 0000000 | 000000 |

5/16" Dia. | |||||||||||||

| 1,300 | 30 | 10.8 | 45" | 1 1/16" | 15/32" | 7/16"-20 | UNF | Male | Screw Terminals | Flat Washers Gaskets Hex Nuts | Ammonium Hydroxide (0-3%), Ammonium Hydroxide (3-6%), Ethylene Glycol, Nitric Acid (0-3%), Nitric Acid (3-6%), Soap Solutions, Sodium Hydroxide (0-3%), Sodium Hydroxide (3-6%), Water | 0000000 | 000000 |

240V AC, Single Phase | |||||||||||||

5/16" Dia. | |||||||||||||

| 850 | 30 | 3.5 | 31" | 1 1/16" | 15/32" | 7/16"-20 | UNF | Male | Screw Terminals | Flat Washers Gaskets Hex Nuts | Ammonium Hydroxide (0-3%), Ammonium Hydroxide (3-6%), Ethylene Glycol, Nitric Acid (0-3%), Nitric Acid (3-6%), Soap Solutions, Sodium Hydroxide (0-3%), Sodium Hydroxide (3-6%), Water | 0000000 | 000000 |

7/16" Dia. | |||||||||||||

| 1,500 | 30 | 6.3 | 41" | 1 1/2" | 11/16" | 5/8"-18 | UNF | Male | Screw Terminals | Flat Washers Gaskets Hex Nuts | Ammonium Hydroxide (0-3%), Ammonium Hydroxide (3-6%), Ethylene Glycol, Nitric Acid (0-3%), Nitric Acid (3-6%), Soap Solutions, Sodium Hydroxide (0-3%), Sodium Hydroxide (3-6%), Water | 0000000 | 000000 |

| 2,250 | 30 | 9.4 | 60" | 1 1/2" | 11/16" | 5/8"-18 | UNF | Male | Screw Terminals | Flat Washers Gaskets Hex Nuts | Ammonium Hydroxide (0-3%), Ammonium Hydroxide (3-6%), Ethylene Glycol, Nitric Acid (0-3%), Nitric Acid (3-6%), Soap Solutions, Sodium Hydroxide (0-3%), Sodium Hydroxide (3-6%), Water | 0000000 | 000000 |

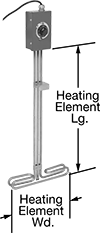

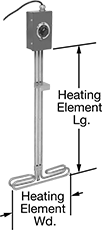

Hanging Immersion Heaters for Water

Sized to fit drums, these heaters have a bracket to hook on the side of drums and in bung openings. They quickly and efficiently heat liquid through direct contact. An adjustable thermostat automatically turns the heater on when the temperature drops below the set temperature and off when it rises above the set temperature. Adjust the set temperature with the dial. Heaters are for use in metal containers; they should not be used in plastic containers.

Hang-on heaters have a bracket to hook on the side of containers.

Bung-mount heaters have a bracket to secure them in drum openings.

Stainless steel heating elements have good corrosion resistance.

Note: Immerse the heating element in liquid up to at least the minimum coverage level to prevent heater failure.

Heating Element | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Container Cap., gal. | Wattage, W | Watt Density, W/sq. in. | Voltage | Electrical Phase | Current, A | Lg. | Wd. | Min. Coverage | Temp. Control Range, °F | Electrical Connection Type | NEMA Style | Cord Lg., ft. | Each | |

316 Stainless Steel Heating Element | ||||||||||||||

| 8 to 20 | 4,000 | 56 | 240V AC | Single | 16.7 | 26" | 13" | 4 1/2" | 60° to 250° | Plug | 6-30 | 6 | 00000000 | 0000000 |

| 8 to 20 | 6,000 | 65 | 240V AC | Single | 25 | 26" | 17" | 4 1/2" | 60° to 250° | Plug | 6-30 | 6 | 00000000 | 000000 |

Heating Element | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Container Cap., gal. | Wattage, W | Watt Density, W/sq. in. | Voltage | Electrical Phase | Current, A | Lg. | Wd. | Min. Coverage | Temp. Control Range, °F | For Bung Dia. | Wire Connection Type | Environmental Rating | Each | |

Steel Heating Element | ||||||||||||||

| 55 | 4,000 | 32 | 240V AC | Single | 16.7 | 36" | 19" | 7" | 60° to 250° | 2" | Screw Terminals | NEMA 1 | 00000000 | 0000000 |

321 Stainless Steel Heating Element | ||||||||||||||

| 55 | 4,000 | 32 | 240V AC | Single | 16.7 | 36" | 19" | 7" | 60° to 250° | 2" | Screw Terminals | NEMA 1 | 00000000 | 000000 |

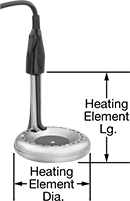

Drop-In Immersion Heaters for Water

Often used for temporary heating in sinks and pails, these heaters have a circular base that sits at the bottom of containers to quickly and efficiently heat liquid through direct contact. Remove them from the container after heating its contents. The heating element is Incoloy for excellent corrosion resistance.

Note: Immerse the heating element in liquid up to at least the minimum coverage level to prevent heater failure.

Floating Immersion Heaters for Water

Often used for freeze protection in outdoor containers, these heaters float on the water’s surface and automatically turn on when the water temperature drops below 45° F and turn off when it rises above 65° F. They are for use in metal containers. All have an Incoloy heating element for excellent corrosion resistance.

Clip-on heater guards (sold separately) prevent the heating element from contacting the sides of the container, allowing floating heaters be used in plastic containers.

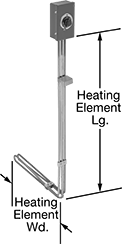

Hanging Immersion Heaters for Coolant

Use the attached bracket to hook these heaters on the side of drums and in bung openings. They quickly and efficiently heat liquid through direct contact. With a lower watt density than heaters for water or chemicals, these heaters can heat coolant without creating hot spots or damaging the heating element. An adjustable thermostat automatically turns the heater on when the temperature drops below the set temperature and off when it rises above the set temperature. Adjust the set temperature with the dial. Heaters are for use in metal containers; they should not be used in plastic containers.

Hang-on heaters have a bracket to hook on the side of containers.

Bung-mount heaters have a bracket to secure them in drum openings.

Stainless steel heating elements have good corrosion resistance.

Note: Immerse the heating element in liquid up to at least the minimum coverage level to prevent heater failure.

Heating Element | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Container Cap., gal. | Wattage, W | Watt Density, W/sq. in. | Voltage | Electrical Phase | Current, A | Lg. | Wd. | Min. Coverage | Temp. Control Range, °F | Electrical Connection Type | NEMA Style | Cord Lg., ft. | For Use With | Each | |

316 Stainless Steel Heating Element | |||||||||||||||

| 8 to 20 | 1,000 | 14 | 120V AC | Single | 8.3 | 26" | 13" | 4 1/2" | 60° to 250° | Plug | 5-15 | 6 | Ethylene Glycol, Water | 00000000 | 0000000 |

| 8 to 20 | 1,500 | 16 | 120V AC | Single | 12.5 | 26" | 17" | 4 1/2" | 60° to 250° | Plug | 5-15 | 6 | Ethylene Glycol, Water | 00000000 | 000000 |

Heating Element | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Container Cap., gal. | Wattage, W | Watt Density, W/sq. in. | Voltage | Electrical Phase | Current, A | Lg. | Wd. | Min. Coverage | Temp. Control Range, °F | For Bung Dia. | Wire Connection Type | Environmental Rating | For Use With | Each | |

Steel Heat Element | |||||||||||||||

| 55 | 1,000 | 8 | 120V AC | Single | 8.3 | 36" | 19" | 7" | 60° to 250° | 2" | Screw Terminals | NEMA 1 | Ethylene Glycol, Water | 00000000 | 0000000 |

321 Stainless Steel Heat Element | |||||||||||||||

| 55 | 1,000 | 8 | 120V AC | Single | 8.3 | 36" | 19" | 7" | 60° to 250° | 2" | Screw Terminals | NEMA 1 | Ethylene Glycol, Water | 00000000 | 000000 |

Bend-and-Stay Heaters for Ducts, Ovens, and Dryers

Form these flexible heaters into any shape to mount them through brackets, collars, and holes. They are also known as tubular heaters and can be used to heat air, liquids, and gases. All require a temperature switch or controller (sold separately) to regulate heat output.

Heating Element | Thread | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wattage, W | Watt Density, W/sq. in. | Current, A | Lg. | Material | Max. Heat Output, °F | Min. Bend Radius | Wire Connection Type | Size | Type | Mount. Fasteners Included | Each | |

120V AC, Single Phase | ||||||||||||

0.26" Dia. | ||||||||||||

| 250 | 27.8 | 2.1 | 16" | Incoloy | 1200° | 15/16" | Screw Terminals | 10-32 | UNF | No | 0000000 | 000000 |

| 350 | 28.6 | 2.9 | 20" | Incoloy | 1200° | 15/16" | Screw Terminals | 10-32 | UNF | No | 0000000 | 000000 |

| 450 | 27.5 | 3.8 | 25" | Incoloy | 1200° | 15/16" | Screw Terminals | 10-32 | UNF | No | 0000000 | 00000 |

| 500 | 26.6 | 4.2 | 28" | Incoloy | 1200° | 15/16" | Screw Terminals | 10-32 | UNF | No | 0000000 | 00000 |

| 650 | 29.5 | 5.4 | 32" | Incoloy | 1200° | 15/16" | Screw Terminals | 10-32 | UNF | No | 0000000 | 00000 |

| 750 | 30.8 | 6.3 | 36" | Incoloy | 1200° | 15/16" | Screw Terminals | 10-32 | UNF | No | 0000000 | 00000 |

| 850 | 29.7 | 7.1 | 40" | Incoloy | 1200° | 15/16" | Screw Terminals | 10-32 | UNF | No | 0000000 | 000000 |

| 1,000 | 29.9 | 8.3 | 46" | Incoloy | 1200° | 15/16" | Screw Terminals | 10-32 | UNF | No | 0000000 | 00000 |

| 1,100 | 29.9 | 9.2 | 50" | Incoloy | 1200° | 15/16" | Screw Terminals | 10-32 | UNF | No | 0000000 | 00000 |

| 1,200 | 29.4 | 10 | 55" | Incoloy | 1200° | 15/16" | Screw Terminals | 10-32 | UNF | No | 0000000 | 00000 |

| 1,350 | 30 | 11.3 | 60" | Incoloy | 1200° | 15/16" | Screw Terminals | 10-32 | UNF | No | 0000000 | 000000 |

| 1,500 | 30.6 | 12.5 | 65" | Incoloy | 1200° | 15/16" | Screw Terminals | 10-32 | UNF | No | 0000000 | 00000 |

0.315" Dia. | ||||||||||||

| 275 | 25.2 | 2.3 | 16" | Incoloy | 1200° | 1 1/16" | Screw Terminals | 10-32 | UNF | No | 0000000 | 00000 |

| 400 | 26.9 | 3.3 | 20" | Incoloy | 1200° | 1 1/16" | Screw Terminals | 10-32 | UNF | No | 0000000 | 000000 |

| 625 | 27.5 | 5.2 | 28" | Incoloy | 1200° | 1 1/16" | Screw Terminals | 10-32 | UNF | No | 0000000 | 00000 |

| 650 | 32.8 | 5.4 | 25" | Incoloy | 1200° | 1 1/16" | Screw Terminals | 10-32 | UNF | No | 0000000 | 00000 |

| 750 | 28.1 | 6.3 | 32" | Incoloy | 1200° | 1 1/16" | Screw Terminals | 10-32 | UNF | No | 0000000 | 000000 |

| 975 | 28.2 | 8.1 | 40" | Incoloy | 1200° | 1 1/16" | Screw Terminals | 10-32 | UNF | No | 0000000 | 000000 |

| 1,300 | 29.2 | 10.8 | 50" | Incoloy | 1200° | 1 1/16" | Screw Terminals | 10-32 | UNF | No | 0000000 | 00000 |

240V AC, Single Phase | ||||||||||||

0.315" Dia. | ||||||||||||

| 850 | 27.7 | 3.5 | 36" | Incoloy | 1200° | 1 1/16" | Screw Terminals | 10-32 | UNF | No | 0000000 | 00000 |

| 1,150 | 28.3 | 4.8 | 46" | Incoloy | 1200° | 1 1/16" | Screw Terminals | 10-32 | UNF | No | 0000000 | 00000 |

| 1,450 | 29.3 | 6 | 55" | Incoloy | 1200° | 1 1/16" | Screw Terminals | 10-32 | UNF | No | 0000000 | 000000 |

| 1,600 | 29.4 | 6.7 | 60" | Incoloy | 1200° | 1 1/16" | Screw Terminals | 10-32 | UNF | No | 0000000 | 00000 |

| 1,750 | 29.5 | 7.3 | 65" | Incoloy | 1200° | 1 1/16" | Screw Terminals | 10-32 | UNF | No | 0000000 | 00000 |

0.43" Dia. | ||||||||||||

| 400 | 26.9 | 1.7 | 16" | Incoloy | 1200° | 1 1/2" | Screw Terminals | 10-32 | UNF | No | 0000000 | 000000 |

| 550 | 27.1 | 2.3 | 20" | Incoloy | 1200° | 1 1/2" | Screw Terminals | 10-32 | UNF | No | 0000000 | 00000 |

| 750 | 27.8 | 3.1 | 25" | Incoloy | 1200° | 1 1/2" | Screw Terminals | 10-32 | UNF | No | 0000000 | 00000 |

| 850 | 27.4 | 3.5 | 28" | Incoloy | 1200° | 1 1/2" | Screw Terminals | 10-32 | UNF | No | 0000000 | 000000 |

| 1,000 | 27.4 | 4.2 | 32" | Incoloy | 1200° | 1 1/2" | Screw Terminals | 10-32 | UNF | No | 0000000 | 000000 |

| 1,100 | 26.3 | 4.6 | 36" | Incoloy | 1200° | 1 1/2" | Screw Terminals | 10-32 | UNF | No | 0000000 | 00000 |

| 1,250 | 26.4 | 5.2 | 40" | Incoloy | 1200° | 1 1/2" | Screw Terminals | 10-32 | UNF | No | 0000000 | 000000 |

| 1,500 | 27.1 | 6.3 | 46" | Incoloy | 1200° | 1 1/2" | Screw Terminals | 10-32 | UNF | No | 0000000 | 000000 |

| 1,700 | 28 | 7.1 | 50" | Incoloy | 1200° | 1 1/2" | Screw Terminals | 10-32 | UNF | No | 0000000 | 000000 |

| 1,850 | 27.4 | 7.7 | 55" | Incoloy | 1200° | 1 1/2" | Screw Terminals | 10-32 | UNF | No | 0000000 | 000000 |

| 2,000 | 26.9 | 8.3 | 60" | Incoloy | 1200° | 1 1/2" | Screw Terminals | 10-32 | UNF | No | 0000000 | 000000 |

| 2,250 | 27.8 | 9.4 | 65" | Incoloy | 1200° | 1 1/2" | Screw Terminals | 10-32 | UNF | No | 0000000 | 000000 |

| Replacement Ceramic Insulators (Pkg. of 10) | 0000000 | Pkg. | 000000 |