Filter by

Capacity

Material

Width

Maximum Temperature

Color

Lid Material

Depth

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Lid Type

RoHS

Space Saving Features

With Handle

Clarity

System of Measurement

Bottom ID

Bottom Inside Depth

Bottom Inside Width

Faucet Inlet Gender

Faucet Inlet Pipe Size

Round Plastic Batch Cans

A

Style A

A

| Capacity, gal. | Dia. | Ht. | Bottom ID | Thick. | Graduation Marks | Color | Clarity | Lid Type | Max. Temp., °F | Space Saving Features | Features | Each | |

Polyethylene Plastic | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 7 1/2 | 13 3/4" | 18" | 12 1/8" | 3/16" | 1 gal. | White | Semi-Clear | Loose Fitting | 140° | Stackable | Seamless | 0000000 | 0000000 |

High-Temperature Round Plastic Batch Cans

| Capacity, gal. | Dia. | Ht. | Bottom ID | Thick. | Graduation Marks | Color | Clarity | Lid Type | Max. Temp., °F | Space Saving Features | Features | Each | |

Polypropylene Plastic | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 7 1/2 | 13 3/4" | 18" | 12 1/8" | 3/16" | 1/2 gal., 2 L | White | Semi-Clear | Loose Fitting | 220° | Stackable | Seamless | 0000000 | 0000000 |

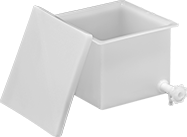

Rectangular Plastic Batch Cans with Faucet

A built-in faucet allows easy dispensing.

Bottom Inside | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Wd. | Dp. | Ht. | Wd. | Dp. | Thick. | Color | Clarity | Lid Type | Faucet Material | Seal Material | Max. Temp., °F | Space Saving Features | Features | Each | |

Polyethylene Plastic | ||||||||||||||||

| 7 1/2 | 18 1/4" | 13 1/4" | 10" | 16 1/2" | 11" | 1/4" | White | Semi-Clear | Loose Fitting | Polyethylene Plastic | PTFE Plastic | 175° | Stackable | Seamless | 0000000 | 0000000 |