Straightedges

Use these highly accurate straightedges as a guide to scribe and cut straight lines and to check surface straightness. Accuracy is the straightness tolerance over the entire length of the straightedge.

Aluminum is lightweight.

Stainless steel is corrosion resistant.

| Lg. | Wd. | Thick. | Accuracy | Hole Dia. | Each | |

Square Edge | ||||||

|---|---|---|---|---|---|---|

Steel | ||||||

| 12" | 1 15/32" | 5/32" | -0.0005" to +0.0005" | __ | 0000000 | 000000 |

| 24" | 1 15/32" | 5/32" | -0.001" to +0.001" | __ | 0000000 | 000000 |

| 36" | 2 15/32" | 7/32" | -0.0015" to +0.0015" | 1/4" | 0000000 | 000000 |

| 48" | 2 15/32" | 7/32" | -0.002" to +0.002" | 1/4" | 0000000 | 000000 |

| 72" | 3 1/8" | 9/32" | -0.003" to +0.003" | 1/4" | 0000000 | 000000 |

Aluminum | ||||||

| 24" | 2" | 1/4" | -0.005" to +0.005" | 1/4" | 0000000 | 00000 |

| 36" | 2" | 1/4" | -0.005" to +0.005" | 1/4" | 0000000 | 00000 |

| 48" | 2" | 1/4" | -0.005" to +0.005" | 1/4" | 0000000 | 000000 |

| 60" | 2" | 1/4" | -0.005" to +0.005" | 1/4" | 0000000 | 000000 |

| 72" | 2" | 1/4" | -0.005" to +0.005" | 1/4" | 0000000 | 000000 |

| 96" | 2" | 1/4" | -0.005" to +0.005" | 1/4" | 0000000 | 000000 |

| 120" | 2" | 1/4" | -0.005" to +0.005" | 1/4" | 0000000 | 000000 |

Stainless Steel | ||||||

| 24" | 2 1/16" | 17/64" | -0.001" to +0.001" | __ | 00000000 | 000000 |

| 36" | 2 1/16" | 17/64" | -0.0015" to +0.0015" | 1/4" | 00000000 | 000000 |

| 48" | 2 9/16" | 17/64" | -0.002" to +0.002" | 1/4" | 00000000 | 000000 |

| 60" | 3 1/16" | 5/16" | -0.0025" to +0.0025" | 1/4" | 00000000 | 00000000 |

| 72" | 3 1/64" | 11/32" | -0.003" to +0.003" | 1/4" | 00000000 | 00000000 |

| 96" | 3 17/64" | 11/32" | -0.004" to +0.004" | 3/8" | 00000000 | 00000000 |

Beveled Edge | ||||||

Steel | ||||||

| 12" | 1 15/32" | 5/32" | -0.0005" to +0.0005" | __ | 0000000 | 000000 |

| 24" | 1 15/32" | 5/32" | -0.001" to +0.001" | __ | 0000000 | 000000 |

| 36" | 2 15/32" | 7/32" | -0.0015" to +0.0015" | 1/4" | 0000000 | 000000 |

| 48" | 2 15/32" | 7/32" | -0.002" to +0.002" | 1/4" | 000000 | 000000 |

| 72" | 3 5/32" | 9/32" | -0.003" to +0.003" | 1/4" | 0000000 | 000000 |

| 96" | 3 1/4" | 11/32" | -0.004" to +0.004" | 3/8" | 000000 | 00000000 |

| 120" | 3 17/64" | 11/32" | -0.005" to +0.005" | 3/8" | 000000 | 00000000 |

Stainless Steel | ||||||

| 24" | 2 1/16" | 17/64" | -0.001" to +0.001" | __ | 00000000 | 000000 |

| 36" | 2 1/16" | 17/64" | -0.0015" to +0.0015" | 1/4" | 00000000 | 000000 |

| 48" | 2 9/16" | 17/64" | -0.002" to +0.002" | 1/4" | 00000000 | 000000 |

| 60" | 3 1/16" | 5/16" | -0.0025" to +0.0025" | 1/4" | 00000000 | 00000000 |

| 72" | 3 1/64" | 11/32" | -0.003" to +0.003" | 1/4" | 00000000 | 00000000 |

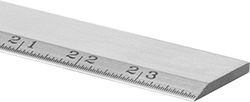

Straightedges with Graduations

Highly accurate, these straightedges work as a guide to scribe and cut straight lines and to check surface straightness. They have graduations, so you can take measurements as you go. Accuracy is the straightness tolerance over the entire length of the straightedge.

| Lg. | Wd. | Thick. | Front Graduation Marks (Numeric Increments) | Accuracy | Hole Dia. | Each | |

Inch—Beveled Edge | |||||||

|---|---|---|---|---|---|---|---|

Steel | |||||||

| 24" | 1 15/32" | 5/32" | 32nds (1") | -0.0005" to 0.0005" | __ | 0000000 | 0000000 |

| 36" | 2 15/32" | 7/32" | 32nds (1") | -0.0005" to 0.0005" | __ | 0000000 | 000000 |

Metric—Beveled Edge | |||||||

Steel | |||||||

| 300mm | 1 9/16" | 3/16" | Millimeters (1 cm) | -0.02mm to 0.02mm | 3/8" | 0000000 | 000000 |

| 500mm | 1 9/16" | 3/16" | Millimeters (1 cm) | -0.03mm to 0.03mm | 3/8" | 0000000 | 000000 |

| 1,000mm | 1 31/32" | 3/16" | Millimeters (1 cm) | -0.04mm to 0.04mm | 3/8" | 0000000 | 000000 |

Cutting Guides

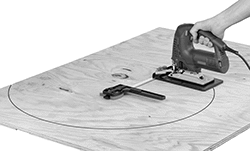

Clamp one of these guides onto your workpiece to make accurate cuts.

Style A guides are for making straight cuts. Use them with circular saws, jigsaws, and routers. They fit multiple workpiece sizes.

Style B guides are for making straight, beveled, and circular cuts. For straight or beveled cuts, attach a jigsaw or circular saw to the guide and use the slide like a T-square to keep your blade at a set distance from the edge as you cut. The guide has a range of 1" to 11 1/2" for jigsaws and 1" to 14" for circular saws. For circular cuts, use this guide like a compass and pencil to create a perfect circle between 6" and 24" in diameter. Drill a pilot hole in your workpiece at the center of the hole. One end of the guide fits into the pilot, and a jigsaw mounts to the other end. This keeps the blade at a fixed distance from the pivot as you cut. While cutting, use your free hand to ensure the saw stays in place.

For Max. Workpiece | |||||||

|---|---|---|---|---|---|---|---|

| Dia. | Wd. | Wd. | Cutting Pattern | Material | Includes | Each | |

| 24" | 14" | 5" | Circle, Straight | Plastic | Centering Pin | 0000000 | 000000 |

Electric Circular Saws for Metal

Make long, straight cuts into steel sheets, structural framing, and other metal components. These handheld saws are good for longer cuts than chop saws. At a low speed, they’ll cut without burrs or excessive heat—no coolant required. They’ll also produce fewer sparks than saws with abrasive wheels. To keep your workspace clean, all can either blow metal chips out of the way or collect them during cutting.

Evolution and Fein 6 99 08 120 00 1 saws have a high-torque motor that powers the blade more efficiently than our other saws. This makes them the best choice for cutting hard, thick metal.

Saws with a brake stop rotating soon after you release the trigger, so you can quickly reposition your workpiece and make the next cut.

| Manufacturer Model Number | Current | For Blade Dia. | For Arbor Hole Size | No-Load Speed, rpm | Max. Cutting Dp. | Max. Bevel Cut Angle (Tilt Direction) | Wt., lbs. | Features | Blade Location | Includes | Each | |

Evolution | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S210CCS | 15 A @ 120 V AC | 8 1/4" | 1" | 2,800 | 3" | __ | 24.7 | Chip Collector, Brake, Cut-Line Guide | Right Side | One 8 1/4" Dia. Ceramic-Tipped Steel Blade for Steel (50 Teeth) | 00000000 | 0000000 |

Fein Power Tools | ||||||||||||

| 6 99 08 120 00 0 | 13 A @ 120 V AC | 7 1/4" | 20 mm | 3,800 | 2 1/2" | 45° (Right) | 15 | Chip Collector, Brake, Laser Guide | Right Side | One 7 1/4" Dia. Carbide-Tipped Steel Blade for Steel (36 Teeth); Plastic Case | 00000000 | 000000 |

| 6 99 08 120 00 1 | 15 A @ 120 V AC | 9" | 1" | 2,300 | 3 1/2" | 45° (Right) | 21 | Chip Collector, Brake, Laser Guide | Right Side | One 9" Dia. Carbide-Tipped Steel Blade for Steel (48 Teeth); Plastic Case | 00000000 | 000000 |

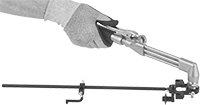

Plasma/Oxyacetylene Torch Cutting Guides

Insert a plasma or oxyacetylene torch in these guides for balance and stability when cutting straight, circular, and irregular shapes. They’re designed to cut as well as bevel at the same time.

Oxyacetylene Torch Guides have a universal bushing that accepts all cutting torches.

Choose a Plasma Torch Guide that is compatible with your torch model number or measure the diameter of your torch head to find a compatible guide.

Cutting Dia. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Use With | Cutting Pattern | Min. | Max. | For Manufacturer | For Manufacturer Model Number | For Torch Head Dia. (Min) | For Torch Head Dia. (Max) | Each | |

| Oxyacetylene Torch | Circle, Left Curves, Right Curves, Straight | 2" | 36" | __ | __ | __ | __ | 0000000 | 0000000 |

| Plasma Torch | Circle, Left Curves, Right Curves, Straight | 3 1/4" | 39" | ESAB; Lincoln; Thermal Dynamics | Cutmaster 58, PT-27; LC-25, LC-40; SL-60 | 1.07" | 1.275" | 0000000 | 000000 |

| Plasma Torch | Circle, Left Curves, Right Curves, Straight | 3 1/4" | 39" | Hypertherm; Miller | HRT, MRT, PAC121, PAC125, RT60, RT80, T100, T60, T80; ICE 25 C | 0.75" | 1.005" | 0000000 | 000000 |

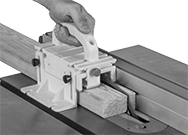

Push Blocks and Sticks

Keep hands safely away from table saw blades and router bits by using these tools to guide material during cuts.

Style A apply forward and downward pressure while guiding thin workpieces close to the fence on saw and router tables.

Style B apply downward, inward, and forward pressure to control cuts on a wide range of workpiece sizes. Adjust the handle and center leg for a balanced grip on the workpiece.

Router Guides

Make precise circular cuts with your router. These guides help you cut arcs at a specific distance from a set point—they’re often used to create the rounded edges of a workpiece.

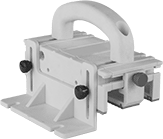

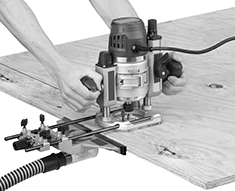

Style B guides include a baseplate that can mount to both fixed- and plunge-base routers. Securely tape the included pivot plate to the desired center point of your cut, then connect the pivot plate to the baseplate with the router guide. Once connected, the guide holds your router at the correct distance from the circle center. These guides can also be used to make straight cuts. An included adapter lets you attach a vacuum hose to control dust.

| Cutting Pattern | For Cut Dia. | For Cut Wd. | For Hose Dia. | Material | Mounting Hardware Included | Features | Includes | For Manufacturer | Each | |

| Circle, Straight | 8"-32" | 0"-8" | 1 3/8" | Steel | Yes | Adjustment Dial | Pivot Plate Baseplate Dust Hood Adapter for 1 1/4" and 1 1/2" Dia. Vacuum Hoses | Bosch | 00000000 | 000000 |

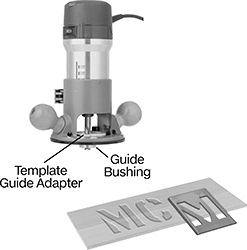

Router Guide Bushings

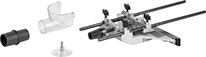

Control the distance between a template and router bit for making precise cuts. These kits are for use with pilotless router bits. To set the correct distance for the cut, choose from among the included bushing sizes. You can swap these router attachments in and out by hand.

Bosch guide bushings come ready to attach to Bosch routers—no need to swap out the baseplate.

Guide Bushings | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Bushing | Replacement Adapters | |||||||||||

| Manufacturer | Manufacturer Model No. | No. of Pieces | Sizes Included | Material | Includes | Container Type | Cutting Pattern | Each | Includes | Each | ||

| Bosch | RA1128 | 8 | 5/16", 7/16", 1/2", 5/8", 3/4" | Steel | Small Dovetail Guide Large Dovetail Guide 1/4" Radius Hinge Guide 5/8" Radius Hinge Guide General Purpose Guide Precision Guide Template Guide Adapter Threaded Template Guide Adapter | Plastic Case | Circle, Straight | 00000000 | 000000 | Template Guide Adapter Threaded Template Guide Adapter | 00000000 | 00000 |