About Sealant Flexibility

More

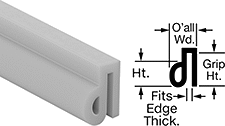

High-Temperature Chemical-Resistant Push-On Seals with Bulb on Side

Similar to standard silicone seals, fluorosilicone rubber seals can be used at high temperatures, but also withstand fuel and oil.

For technical drawings and 3-D models, click on a part number.

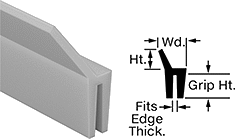

High-Temperature Chemical-Resistant Push-On Seals with Wiper

Made of fluorosilicone rubber, these seals withstand high temperatures like standard silicone without breaking down when exposed to fuel and oil.

For technical drawings and 3-D models, click on a part number.

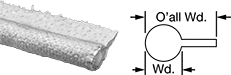

High-Temperature Chemical-Resistant Flange-Mount Rope Edge Seals

The PTFE coating on these fiberglass seals is slippery, so they are easier than the other seals to press fit into oven, furnace, and boiler doors. The PTFE resists most acids, alkalies, refrigerants, salts, and grease. The flange is also handy for positioning over uneven gaps.

Per Ft. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| O'all Wd. | Wd. | Flange Thick. | Core Material | Temp. Range, °F | For Use Outdoors | Color | Lengths, ft. | 1-24 | 25-Up | |

PTFE-Coated Fiberglass Fabric—Plain Backing | ||||||||||

| 1" | 3/8" | 1/8" | Fiberglass Fabric | -40° to 500° | No | White | 00000000 | 00000 | 00000 | |

| 1" | 1/2" | 1/8" | Fiberglass Fabric | -40° to 500° | No | White | 00000000 | 0000 | 0000 | |

| 1" | 3/4" | 1/8" | Fiberglass Fabric | -40° to 500° | No | White | 00000000 | 0000 | 0000 | |

| 1 1/2" | 3/4" | 1/8" | Fiberglass Fabric | -40° to 500° | No | White | 00000000 | 0000 | 0000 | |

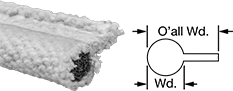

Ultra High-Temperature Chemical-Resistant Flange-Mount Rope Edge Seals

A ceramic cover makes these seals more chemical resistant than the seals with a silica cover. Seals resist acids (except hydrofluoric and phosphoric), diluted alkalies, most refrigerants, salts, and grease. The flange on these seals slides into a slot that is commonly found on oven, furnace, and boiler doors; it can be positioned to cover large gaps.

| O'all Wd. | Wd. | Flange Thick. | Core Material | Max. Temp., °F | For Use Outdoors | Color | 1 ft. | 10 ft. | 25 ft. | |

Ceramic Fabric—Plain Back | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 7/8" | 3/8" | 3/16" | Inconel 625 Nickel | 1700° | No | White | 0000000 | |||

| 1" | 1/2" | 3/16" | Inconel 625 Nickel | 1700° | No | White | 0000000 | |||

| 1 3/4" | 3/4" | 3/16" | Inconel 625 Nickel | 1700° | No | White | 0000000 | |||

| 2" | 1/2" | 3/16" | Inconel 625 Nickel | 1700° | No | White | 0000000 | |||

| 2" | 1" | 3/16" | Inconel 625 Nickel | 1700° | No | White | 0000000 | |||

| 3" | 1" | 3/16" | Inconel 625 Nickel | 1700° | No | White | 0000000 | |||

Self-Leveling Chemical-Resistant Sealants

Designed to withstand extreme environments, these fluoroelastomer sealants have excellent resistance to sulfuric acid, hydrochloric acid, nitric acid, gasoline, and oil. Thinner than non-sagging sealants, these flow easily into cracks and have a smooth finish.

Elongation and joint expansion/compression tolerance indicate flexibility—the higher the values are, the more joint movement sealants can sustain. These sealants are best suited to joints between similar materials that aren't exposed to wide temperature fluctuation. For high-wear applications, choose a harder sealant for the most abrasion resistance.

Sealants that cannot be sold to the regions listed exceed local regulatory limits on VOCs (volatile organic compounds).

Container | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Elongation | Joint Compression/ Expansion Tolerance | Tensile Strength, psi | Hardness | Temp. Range, °F | Color | For Joining | Cannot Be Sold To | Each | |

Fluoroelastomer | |||||||||||||

| 32 | Can | 5 min. | 3 days | 150% | -5% to 5% | 600 | Hard (Durometer 85A) | -40° to 400° | Gray | Metal, Masonry | __ | 00000000 | 0000000 |

| 32 | Can | 5 min. | 3 days | 450% | -15% to 15% | 750 | Medium Hard (Durometer 65A) | -40° to 400° | Gray | Metal, Masonry | Los Angeles County, CA; Orange County, CA; Riverside County, CA; San Bernardino County, CA | 00000000 | 000000 |

Viton® Fluoroelastomer | |||||||||||||

| 2.5 | Cartridge | 5 min. | 3 days | 400% | -25% to 25% | 1,000 | Medium Hard (Durometer 60A) | -40° to 400° | Black | Metal, Masonry | __ | 00000000 | 00000 |

| 11 | Cartridge | 5 min. | 3 days | 400% | -25% to 25% | 1,000 | Medium Hard (Durometer 60A) | -40° to 400° | Black | Metal, Masonry | __ | 00000000 | 000000 |

Chemical-Resistant Sealants

Designed to withstand extreme environments, these fluoroelastomer sealants have excellent resistance to harsh chemicals. They’re non-sagging, so they won't drip from vertical and overhead surfaces.

Elongation and joint expansion/compression tolerance indicate flexibility—the higher the values are, the more joint movement sealants can sustain. These sealants are best suited to joints between similar materials that aren't exposed to wide temperature fluctuation.

Viton® fluoroelastomer sealants resist sulfuric acid, hydrochloric acid, nitric acid, gasoline, fuels, and crude oil.

Aflas fluoroelastomer sealants stand up to hydroxides, industrial cleaning fluids, and other pH-basic chemicals in applications where traditional rubber caulk is ineffective.

Container | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Elongation | Joint Compression/ Expansion Tolerance | Tensile Strength, psi | Hardness | Temp. Range, °F | For Joining | Color | Each | |

Viton® Fluoroelastomer | ||||||||||||

| 2.5 | Cartridge | 5 min. | 3 days | 300% | -25% to 25% | 700 | Medium Hard (Durometer 65A) | -40° to 400° | Metal, Masonry | Black | 00000000 | 000000 |

| 11 | Cartridge | 5 min. | 3 days | 300% | -25% to 25% | 700 | Medium Hard (Durometer 65A) | -40° to 400° | Metal, Masonry | Black | 00000000 | 000000 |

Aflas Fluoroelastomer | ||||||||||||

| 11 | Cartridge | 5 min. | 3 days | 250% | -15% to 15% | 1,000 | Medium Hard (Durometer 65A) | -40° to 400° | Metal, Masonry | Black | 0000000 | 000000 |