How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

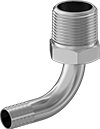

Stainless Steel Barbed Tube Fittings for Food and Beverage

- Temperature Range: -20° to 750° F

- Tubing: Use with soft or firm (Durometer 65A-90A) polyurethane rubber or PVC plastic

- Specifications Met: See table

Made of stainless steel, these fittings are more durable than plastic barbed tube fittings for food and beverage. They have single or multiple barbs that grip onto tubing.

Threaded connections can be taken apart for maintenance and repair.

| For Tube ID | Pipe Size | Material | Max. Pressure | Specifications Met | Each | |

NPT Threads | ||||||

|---|---|---|---|---|---|---|

| 1/4" | 1/8 | 303 Stainless Steel | 270 psi @ 72° F | ASTM A581, ASTM A582 | 0000000 | 00000 |

| 1/4" | 1/4 | 303 Stainless Steel | 270 psi @ 72° F | ASTM A581, ASTM A582 | 0000000 | 0000 |

| 1/4" | 3/8 | 303 Stainless Steel | 270 psi @ 72° F | ASTM A581, ASTM A582 | 0000000 | 0000 |

| 3/8" | 1/8 | 303 Stainless Steel | 270 psi @ 72° F | ASTM A581, ASTM A582 | 0000000 | 0000 |

| 3/8" | 1/4 | 303 Stainless Steel | 270 psi @ 72° F | ASTM A581, ASTM A582 | 0000000 | 0000 |

| 3/8" | 3/8 | 303 Stainless Steel | 270 psi @ 72° F | ASTM A581, ASTM A582 | 0000000 | 0000 |

| 3/8" | 1/2 | 303 Stainless Steel | 270 psi @ 72° F | ASTM A581, ASTM A582 | 00000000 | 00000 |

| 3/8" | 3/4 | 303 Stainless Steel | 270 psi @ 72° F | ASTM A581, ASTM A582 | 00000000 | 00000 |

| 1/2" | 1/4 | 303 Stainless Steel | 270 psi @ 72° F | ASTM A581, ASTM A582 | 00000000 | 00000 |

| 1/2" | 3/8 | 303 Stainless Steel | 270 psi @ 72° F | ASTM A581, ASTM A582 | 00000000 | 00000 |

| 1/2" | 1/2 | 303 Stainless Steel | 270 psi @ 72° F | ASTM A581, ASTM A582 | 0000000 | 00000 |

| 1/2" | 3/4 | 303 Stainless Steel | 270 psi @ 72° F | ASTM A581, ASTM A582 | 0000000 | 00000 |

| 6mm | 1/4 | 303 Stainless Steel, 304 Stainless Steel | 270 psi @ 72° F | ASTM A479, ASTM A581, ASTM A582 | 00000000 | 00000 |

| 8mm | 1/4 | 303 Stainless Steel, 304 Stainless Steel | 270 psi @ 72° F | ASTM A479, ASTM A581, ASTM A582 | 00000000 | 00000 |

| 12mm | 1/4 | 303 Stainless Steel, 304 Stainless Steel | 270 psi @ 72° F | ASTM A479, ASTM A581, ASTM A582 | 00000000 | 00000 |

| For Tube ID | Material | Max. Pressure | Specifications Met | Each | |

| 1/4" | 303 Stainless Steel | 270 psi @ 72° F | ASTM A581, ASTM A582 | 0000000 | 00000 |

| 9/32" | 303 Stainless Steel | 270 psi @ 72° F | ASTM A581, ASTM A582 | 00000000 | 0000 |

| 5/16" | 303 Stainless Steel | 270 psi @ 72° F | ASTM A581, ASTM A582 | 00000000 | 0000 |

| 3/8" | 303 Stainless Steel | 270 psi @ 72° F | ASTM A581, ASTM A582 | 0000000 | 0000 |

| 1/2" | 303 Stainless Steel | 270 psi @ 72° F | ASTM A581, ASTM A582 | 0000000 | 0000 |

| 6mm | 304 Stainless Steel | 270 psi @ 72° F | ASTM A479 | 00000000 | 0000 |

| 8mm | 304 Stainless Steel | 270 psi @ 72° F | ASTM A479 | 00000000 | 0000 |

| 12mm | 304 Stainless Steel | 270 psi @ 72° F | ASTM A479 | 00000000 | 0000 |

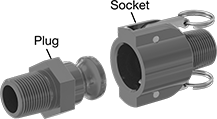

Plastic Cam-and-Groove Hose Couplings for Water

Made of polypropylene, these couplings are lighter in weight than metal cam-and-groove couplings and have good abrasion and corrosion resistance. A complete coupling consists of a plug and a socket (both sold separately) that allow you to quickly connect and disconnect medium-to large-diameter hose lines. To connect, insert the plug into the socket and press the levers down. The levers fit snugly into the groove on the plug’s body and force the plug against the gasket to form a tight seal. To disconnect, lift both levers and pull out the plug.

90° elbow sockets with barbed end are also known as CL couplers. Insert the barbed end into plastic or rubber hose and secure with a clamp.

Curved 90° elbow plugs and sockets are also called sweep elbows. Their rounded shape reduces flow disruption by minimizing back pressure on the seal and conserving momentum through the 90° turn. They’re particularly useful when there are solids suspended in the water.

Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size.

Warning: Relieve all pressure before disconnecting the couplings. Do not use cam-and-groove couplings with compressed air or gas.

- Maximum Pressure: 100 psi @ 72° F

- Temperature Range: -20° to 150° F

- Attachment Type: Use Worm-Drive Clamps or Band-and-Buckle Clamps

- Specifications Met: Fed. Spec. A-A-59326

Levers | |||||||

|---|---|---|---|---|---|---|---|

| Coupling Size | Socket ID | For Hose ID | No. of | Material | Pull Ring Material | Each | |

Polypropylene Plastic | |||||||

| 2 | 2 1/2" | 2" | 2 | 304 Stainless Steel | 304 Stainless Steel | 0000000 | 000000 |