Filter by

Temperature Setting

Measurement Unit

Electrical Connection

Housing Material

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Hot Plates for Metal Containers

|  |  | |

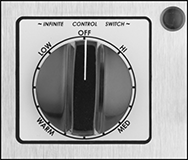

1 Heating Surface | 2 Heating Surfaces | Temperature Control Dial | NEMA 5-15 |

Heat metal containers on the coiled burners.

Heating Surface | Temp., ° F | Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of | Dia. | Wt. Cap., lb. | Setting | Adjustment Increment | Approx. Heat-Up Time, min. | Ht. | Wd. | Dp. | Housing Material | Wattage, W | Temp. Control Type | Plug No. of Blades | Electrical Connection | NEMA Style | Certification | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC—Plug | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 8" | 15 | 68 to 900 | 1 | 3 | 4 1/8" | 14" | 12 1/4" | Stainless Steel | 1,500 | Dial | 3 | Straight Blade | 5-15 | C-UL Listed, UL Classified, UL Listed | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 6" | 15 | 68 to 900 | 1 | 3 | 4 1/8" | 21 1/4" | 12 3/16" | Stainless Steel | 1,650 | Dial | 3 | Straight Blade | 5-15 | C-UL Listed, UL Classified, UL Listed | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hot Plates for Glass Containers

|  |  |

Style A | Style B | Style C |

|  | |

Style D | Style E |

NEMA 5-15 |

NEMA 6-15 |

Precisely control temperature while heating glass containers.

Note: Sand baths are not recommended. Metal foil and metal containers should not be used with these hot plates.

Style B—Style B has a hot surface warning light to protect against accidental burns.

Style E—Style E is ETL listed for conformance to ANSI/UL-499.

Aluminum Heating Surface—Aluminum hot plates maintain a uniform temperature across the entire heating surface while resisting warping and buckling at low temperatures.

Ceramic Heating Surface—Ceramic hot plates clean easily and resist acids and alkalies.

Hot Plates | Replacement Heating Elements | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Heating Surface | Temp. | Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style | Dia. | Wd. | Dp. | Material | Wt. Cap., lb. | Setting | Adjustment Increment | Approx. Heat-Up Time, min. | Dia. | Ht. | Wd. | Dp. | Housing Material | Wattage, W | Temp. Control Type | Plug No. of Blades | Electrical Connection | NEMA Style | Certification | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC—Plug | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 3 1/2" | — | — | Aluminum | Not Rated | 38° C to 371° C | 1° C | 5 | 3 1/2" | 3 3/4" | — | — | Stainless Steel | 325 | Dial | 3 | Straight Blade | 5-15 | — | 00000000 | 0000000 | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | — | 7" | 7" | Ceramic | Not Rated | 5° C to 550° C | 0.5° C | — | — | 4 9/16" | 8 11/16" | 12 15/16" | Aluminum | 1,582 | Dial | 3 | Straight Blade | 5-15 | TUV Rheinland Certified | 00000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | — | 6 1/4" | 6 1/4" | Aluminum | 20 | 38° C to 371° C | 1° C | 15 | — | 4 1/2" | 6 1/4" | 6 1/4" | Stainless Steel | 750 | Dial | 3 | Straight Blade | 5-15 | UL Listed | 0000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | — | 12" | 12" | Aluminum | 40 | 38° C to 371° C | 1° C | 15 | — | 6 1/4" | 12" | 12" | Stainless Steel | 1,600 | Dial | 3 | Straight Blade | 5-15 | C-UL Listed, UL Listed | 000000 | 00000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | — | 18" | 24" | Aluminum | 300 | 100° F to 550° F | 1° F | 24 | — | 5 1/4" | 18" | 24" | Stainless Steel | 1,500 | Dial | 3 | Straight Blade | 5-15 | ETL Listed | 0000000 | 00000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC—Hardwire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | — | 24" | 12" | Aluminum | 40 | 38° C to 371° C | 1° C | 15 | — | 6 1/4" | 24" | 12" | Stainless Steel | 3,200 | Dial | — | — | — | C-UL Listed, UL Listed | 000000 | 00000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

240V AC—Plug | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | — | 6 1/4" | 6 1/4" | Aluminum | 20 | 38° C to 371° C | 1° C | 15 | — | 4 1/2" | 6 1/4" | 6 1/4" | Stainless Steel | 750 | Dial | 3 | Straight Blade | 6-15 | — | 0000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | — | 18" | 24" | Aluminum | 300 | 100° F to 550° F | 1° F | 24 | — | 5 1/4" | 18" | 24" | Stainless Steel | 2,500 | Dial | 3 | Straight Blade | 6-15 | ETL Listed | 0000000 | 00000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

240V AC—Hardwire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | — | 24" | 12" | Aluminum | 40 | 38° C to 371° C | 1° C | 15 | — | 6 1/4" | 24" | 12" | Stainless Steel | 3,200 | Dial | — | — | — | C-UL Listed, UL Listed | 000000 | 00000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hot-Plate Bearing Heaters

|

Shown with Bearing |

Set one or more bearings flat on the plate. This heater has a thermostat that adjusts from 120° to 390° F and lights that indicate when the plate has reached the desired temperature. It’s housed in a metal case that minimizes heat loss and keeps dirt out of your bearings. In case of overheating, the heater will shut off.

For Bearing | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. ID | Max. Wd. | Max. Wt., lb. | Max. Temp., ° F | Temp. Accuracy, ° F | Wattage, W | Voltage, V AC | Freq., Hz | Wd. | Ht. | Dp. | Heater Material | Electrical Connection Permanence | Each | ||

| 4" | 2" | 9 | 390 | -18 to 18 | 1,000 | 120 | 50, 60 | 16" | 5" | 10" | Aluminum | Hardwire | 0000000 | 000000000 | |

Stirring Hot Plates for Glass Containers

| |

NEMA 5-15 |

A magnet embedded in the heating surface works with a magnetic stirring bar to stir liquids automatically. These hot plates have a hot surface warning light to protect against accidental burns. They are ceramic or ceramic coated, so they clean easily and resist acids and alkalies.

Ceramic-Coated Aluminum Heating Surface—Ceramic-coated aluminum hot plates maintain a uniform temperature across the entire heating surface while resisting warping and buckling at low temperatures.

Heating Surface | Temp., ° C | Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Wd. | Dp. | Material | Wt. Cap., lb. | Setting | Adjustment Increment | Ht. | Wd. | Dp. | Housing Material | Wattage, W | Temp. Control Type | Plug No. of Blades | Electrical Connection | NEMA Style | Certification | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC—Plug | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 7" | 7" | Ceramic | 40 | 5 to 550 | 0.5 | 4 9/16" | 8 11/16" | 12 15/16" | Aluminum | 1,582 | Dial | 3 | Straight Blade | 5-15 | TUV Rheinland Certified | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 10" | 10" | Ceramic | 45 | 5 to 500 | 0.5 | 4 5/8" | 11 9/32" | 15 13/16" | Aluminum | 1,650 | Dial | 3 | Straight Blade | 5-15 | TUV Rheinland Certified | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 5/16" | — | — | Ceramic-Coated Aluminum | 40 | 5 to 360 | 0.5 | 4 1/2" | 6 7/8" | 10 3/16" | Aluminum | 600 | Dial | 3 | Straight Blade | 5-15 | TUV Rheinland Certified | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||