Filter by

Diameter

Length

Material

Fencing Component

Flexibility

Wire Rope Construction

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Weight Capacity

Lubrication

Specifications Met

Recommended Pulley/Drum Diameter

Fencing Type

About Aluminum

Compare over 20 aluminum alloys to find the right material for you—all with material certificates for traceability.

Aluminum Wire

|  | |

Package | Coil | Spool |

Lg., ft. | Fabrication | Temper Designation | Specs. Met | Container Type | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

0.013" Diameter (-0.001" to 0.001" Tolerance) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | Cold Drawn | O | ASTM B211 | Package | 25 | 8904K87 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,735 | Cold Drawn | O | ASTM B211 | Spool | 1 | 8904K39 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6,940 | Cold Drawn | O | ASTM B211 | Spool | 1 | 8904K76 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 34,700 | Cold Drawn | O | ASTM B211 | Spool | 1 | 8904K45 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

0.016" Diameter (-0.001" to 0.001" Tolerance) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | Cold Drawn | O | ASTM B211 | Package | 25 | 8904K88 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,085 | Cold Drawn | O | ASTM B211 | Spool | 1 | 8904K37 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4,355 | Cold Drawn | O | ASTM B211 | Spool | 1 | 8904K77 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 21,790 | Cold Drawn | O | ASTM B211 | Spool | 1 | 8904K46 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

0.020" Diameter (-0.001" to 0.001" Tolerance) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | Cold Drawn | O | ASTM B211 | Package | 25 | 8904K89 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 680 | Cold Drawn | O | ASTM B211 | Spool | 1 | 8904K35 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2,725 | Cold Drawn | O | ASTM B211 | Spool | 1 | 8904K78 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13,635 | Cold Drawn | O | ASTM B211 | Spool | 1 | 8904K47 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

0.025" Diameter (-0.001" to 0.001" Tolerance) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | Cold Drawn | O | ASTM B211 | Package | 25 | 8904K91 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 430 | Cold Drawn | O | ASTM B211 | Spool | 1 | 8904K33 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,720 | Cold Drawn | O | ASTM B211 | Spool | 1 | 8904K79 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8,605 | Cold Drawn | O | ASTM B211 | Spool | 1 | 8904K48 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

0.032" Diameter (-0.001" to 0.001" Tolerance) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | Cold Drawn | O | ASTM B211 | Package | 10 | 8904K92 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 265 | Cold Drawn | O | ASTM B211 | Spool | 1 | 8904K31 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,075 | Cold Drawn | O | ASTM B211 | Spool | 1 | 8904K81 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5,380 | Cold Drawn | O | ASTM B211 | Spool | 1 | 8904K49 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

0.040" Diameter (-0.002" to 0.002" Tolerance) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | Cold Drawn | O | ASTM B211 | Package | 10 | 8904K93 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 165 | Cold Drawn | O | ASTM B211 | Spool | 1 | 8904K71 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 675 | Cold Drawn | O | ASTM B211 | Spool | 1 | 8904K82 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3,390 | Cold Drawn | O | ASTM B211 | Spool | 1 | 8904K51 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

0.051" Diameter (-0.002" to 0.002" Tolerance) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | Cold Drawn | O | ASTM B211 | Package | 10 | 8904K94 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 105 | Cold Drawn | O | ASTM B211 | Spool | 1 | 8904K72 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 425 | Cold Drawn | O | ASTM B211 | Spool | 1 | 8904K83 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2,130 | Cold Drawn | O | ASTM B211 | Spool | 1 | 8904K52 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

0.064" Diameter (-0.002" to 0.002" Tolerance) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | Cold Drawn | O | ASTM B211 | Package | 10 | 8904K95 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 67 | Cold Drawn | O | ASTM B211 | Spool | 1 | 8904K73 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 265 | Cold Drawn | O | ASTM B211 | Spool | 1 | 8904K84 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,340 | Cold Drawn | O | ASTM B211 | Spool | 1 | 8904K53 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

0.080" Diameter (-0.002" to 0.002" Tolerance) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2,025 | Cold Drawn | O | ASTM B211 | Coil | 1 | 8866K13 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

0.081" Diameter (-0.002" to 0.002" Tolerance) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | Cold Drawn | O | ASTM B211 | Package | 10 | 8904K96 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 42 | Cold Drawn | O | ASTM B211 | Spool | 1 | 8904K74 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 165 | Cold Drawn | O | ASTM B211 | Spool | 1 | 8904K85 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 840 | Cold Drawn | O | ASTM B211 | Spool | 1 | 8904K54 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

0.114" Diameter (-0.002" to 0.002" Tolerance) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 21 | Cold Drawn | O | ASTM B211 | Spool | 1 | 8904K41 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 84 | Cold Drawn | O | ASTM B211 | Spool | 1 | 8904K42 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 420 | Cold Drawn | O | ASTM B211 | Spool | 1 | 8904K55 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,010 | Cold Drawn | O | ASTM B211 | Coil | 1 | 8866K12 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

0.125" Diameter (-0.002" to 0.002" Tolerance) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 830 | Cold Drawn | O | ASTM B211 | Coil | 1 | 8866K15 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

0.126" Diameter (-0.002" to 0.002" Tolerance) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | Cold Drawn | O | ASTM B211 | Spool | 1 | 8904K75 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 69 | Cold Drawn | O | ASTM B211 | Spool | 1 | 8904K86 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 330 | Cold Drawn | O | ASTM B211 | Spool | 1 | 8904K56 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

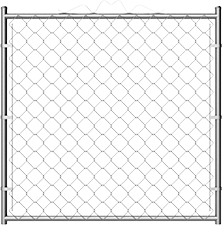

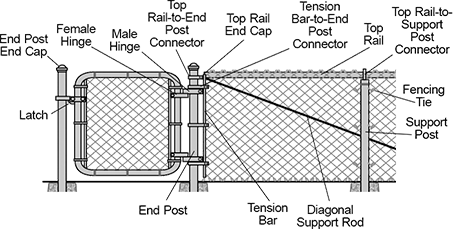

Chain Link Fencing

|

Diagonal Support Rods

|

11 ft. Long | ||||

|---|---|---|---|---|

Material | Each | |||

| Galvanized Steel | 5991T46 | 000000 | ||

Fasteners

|

Material | Pkg. Qty. | Pkg. | |||

|---|---|---|---|---|---|

| Galvanized Steel | 100 | 5991T44 | 000000 | ||

Barbed Wire Supports for End Posts

|

For Post Dia. | No. of Wires Held | Material | Each | |||

|---|---|---|---|---|---|---|

| 2 7/8" | 3 | Galvanized Steel | 5991T568 | 000000 | ||

Barbed Wire Supports for End Posts and Support Posts

|

For Post Dia. | No. of Wires Held | Material | Each | |||

|---|---|---|---|---|---|---|

| 2 3/8" | 3 | Galvanized Steel | 5991T564 | 000000 | ||

Barbed Wire Supports for Support Posts

|

For Post Dia. | No. of Wires Held | Material | Each | |||

|---|---|---|---|---|---|---|

| 1 7/8" | 3 | Galvanized Steel | 5991T562 | 000000 | ||

Wire Rope

Dia. | Wt. Cap., lb. | Wire Rope Construction | Recommended Pulley/Drum Dia. | Preformed | Specifications Met | Choose a Length, ft. | Per Ft. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16" | 90 | 7 × 7 Strand Core | 2 5/8" | Yes | ASTM A1023 | 25 , 50 , 100 , 300 , 500 | 3450T24 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16" | 95 | 7 × 7 Strand Core | 2 5/8" | Yes | MIL-DTL-83420 | 10 , 25 , 50 , 100 | 3450T11 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/32" | 150 | 7 × 7 Strand Core | 3 15/16" | Yes | ASTM A1023 | 25 , 50 , 100 , 300 , 500 | 3450T26 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/32" | 200 | 7 × 7 Strand Core | 3 15/16" | Yes | MIL-DTL-83420 | 10 , 25 , 50 , 100 | 3450T12 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 300 | 7 × 7 Strand Core | 5 1/4" | Yes | ASTM A1023 | 25 , 50 , 100 , 300 , 500 | 3450T28 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/32" | 500 | 7 × 7 Strand Core | 6 9/16" | Yes | ASTM A1023 | 25 , 50 , 100 , 300 , 500 | 3450T29 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 700 | 7 × 7 Strand Core | 7 7/8" | Yes | ASTM A1023 | 25 , 50 , 100 , 300 , 500 | 3450T31 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1,200 | 7 × 7 Strand Core | 10 1/2" | Yes | ASTM A1023 | 10 , 25 , 50 , 100 , 300 | 3450T32 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 2,600 | 7 × 7 Strand Core | 15 3/4" | Yes | ASTM A1023 | 50 , 100 , 300 | 3450T91 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Metal Twisted-Wire Fencing

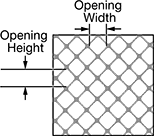

|  |

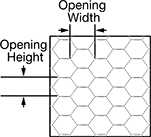

Opening | 25 ft. Long | 50 ft. Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ht., ft. | Ht. | Wd. | Wire Dia. | Flexibility | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hex Opening | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | 1" | 1 7/16" | 0.035" | Flexible | ——— | 0 | 9234T52 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 1" | 1 7/16" | 0.035" | Flexible | ——— | 0 | 9234T53 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 1" | 1 1/2" | 0.035" | Flexible | 9234T11 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 2" | 3 1/8" | 0.035" | Flexible | ——— | 0 | 9234T73 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 1" | 1 7/16" | 0.035" | Flexible | ——— | 0 | 9234T55 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 1" | 1 1/2" | 0.035" | Flexible | 9234T12 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 2" | 3 1/8" | 0.035" | Flexible | ——— | 0 | 9234T75 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 1" | 1 7/16" | 0.035" | Flexible | ——— | 0 | 9234T56 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 1" | 1 1/2" | 0.035" | Flexible | 9234T13 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 2" | 3 1/8" | 0.035" | Flexible | ——— | 0 | 9234T76 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 1" | 1 7/16" | 0.035" | Flexible | ——— | 0 | 9234T57 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 2" | 3 1/8" | 0.035" | Flexible | ——— | 0 | 9234T77 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 1" | 1 7/16" | 0.035" | Flexible | ——— | 0 | 9234T58 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 2" | 3 1/8" | 0.035" | Flexible | ——— | 0 | 9234T78 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extra-Flexible Wire Rope

Dia. | Wt. Cap., lb. | Wire Rope Construction | Recommended Pulley/Drum Dia. | Preformed | Specifications Met | Choose a Length, ft. | Per Ft. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/32" | 200 | 7 × 19 Strand Core | 2 7/16" | Yes | MIL-DTL-83420 | 10 , 25 , 50 , 100 , 300 | 3332T51 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/32" | 200 | 7 × 19 Strand Core | 2 7/16" | Yes | ASTM A1023 | 25 , 50 , 100 , 300 , 500 | 3450T37 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 400 | 7 × 19 Strand Core | 3 1/4" | Yes | MIL-DTL-83420 | 10 , 25 , 50 , 100 , 300 | 3332T52 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 400 | 7 × 19 Strand Core | 3 1/4" | Yes | ASTM A1023 | 25 , 50 , 100 , 300 , 500 | 3450T38 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/32" | 550 | 7 × 19 Strand Core | 4 1/16" | Yes | MIL-DTL-83420 | 10 , 25 , 50 , 100 , 300 | 3332T53 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/32" | 550 | 7 × 19 Strand Core | 4 1/16" | Yes | ASTM A1023 | 25 , 50 , 100 , 300 , 500 | 3450T39 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 800 | 7 × 19 Strand Core | 4 7/8" | Yes | MIL-DTL-83420 | 10 , 25 , 50 , 100 , 300 | 3332T54 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 800 | 7 × 19 Strand Core | 4 7/8" | Yes | ASTM A1023 | 10 , 25 , 50 , 100 , 300 | 3450T41 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/32" | 1,100 | 7 × 19 Strand Core | 5 11/16" | Yes | MIL-DTL-83420 | 5 , 10 , 25 , 50 , 100 | 3332T55 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/32" | 1,100 | 7 × 19 Strand Core | 5 11/16" | Yes | ASTM A1023 | 10 , 25 , 50 , 100 , 300 | 3450T42 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1,400 | 7 × 19 Strand Core | 6 1/2" | Yes | MIL-DTL-83420 | 5 , 10 , 25 , 50 , 100 | 3332T56 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1,400 | 7 × 19 Strand Core | 6 1/2" | Yes | ASTM A1023 | 10 , 25 , 50 , 100 , 300 | 3450T43 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 1,900 | 7 × 19 Strand Core | 8 1/8" | Yes | MIL-DTL-83420 | 5 , 10 , 25 , 50 , 100 | 3332T58 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 1,900 | 7 × 19 Strand Core | 8 1/8" | Yes | ASTM A1023 | 5 , 10 , 25 , 50 , 100 | 3450T45 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 2,800 | 7 × 19 Strand Core | 9 3/4" | Yes | MIL-DTL-83420 | 2 , 5 , 10 , 25 , 50 , 100 | 3332T59 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 2,800 | 7 × 19 Strand Core | 9 3/4" | Yes | ASTM A1023 | 5 , 10 , 25 , 50 , 100 | 3450T46 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

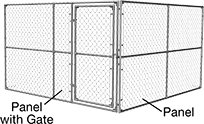

Chain Link Fence Panels

|  |