Filter by

Speed @ Continuous Operating Torque

Continuous Operating Torque

Starting Torque

Mounting Position

Maximum Rotation Speed

Direction of Operation

Shaft Orientation

Radial Load Capacity

Motor Enclosure Type

Duty Cycle

Motor Type

Export Control Classification Number (ECCN)

RoHS

DFARS Specialty Metals

Compact DC Gearmotors

Drive low-speed, high-torque applications in small spaces. Gearmotors combine a motor and speed reducer to lower speed and increase torque. Wire for clockwise or counterclockwise rotation.

Use a motor speed control (not included) to adjust the motor speed. To convert AC power to DC power, see AC to DC transformers.

Use a torque-speed curve to confirm which motor will work for your application. Click on a part number and select “Product Detail” to view the curve for a motor.

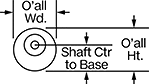

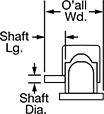

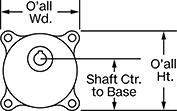

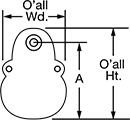

Round Face

|  |  |

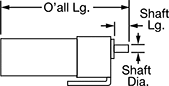

Overall | Shaft | Insulation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Speed @ Continuous Operating Torque | Power, hp | Full Load Current, amp | Lg. | Wd. | Ht. | Bearing Type | Dia. | Lg. | Ctr.-to-Base Lg. | Class | Max. Temp., ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12V DC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 rpm @ 175 in·ozf | 0.0001 | 0.2 | 4 1/4" | 2" | 2" | Plain | 1/4" | 3/4" | 1.33" | F | 311 | 6331K35 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 rpm @ 175 in·ozf | 0.0004 | 0.4 | 4 1/4" | 2" | 2" | Plain | 1/4" | 3/4" | 1.33" | F | 311 | 6331K34 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 rpm @ 140 in·ozf | 0.001 | 0.7 | 4 1/4" | 2" | 2" | Plain | 1/4" | 3/4" | 1.33" | F | 311 | 6331K33 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 rpm @ 47 in·ozf | 0.001 | 0.7 | 4 1/4" | 2" | 2" | Plain | 1/4" | 3/4" | 1.33" | F | 311 | 6331K32 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 83 rpm @ 16 in·ozf | 0.0012 | 0.7 | 4 1/4" | 2" | 2" | Plain | 1/4" | 3/4" | 1.33" | F | 311 | 6331K31 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

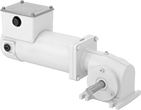

AC Gearmotors

Turn speed into torque with these AC-powered gearmotors—they combine a motor and a speed reducer into one. You can wire them for clockwise or counterclockwise rotation; instructions are included. The parallel shaft transmits motion inline with the motor.

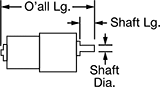

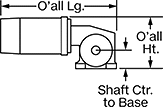

Base/Face Mount

|

|  |

Base/face-mount motors give you the flexibility to mount directly onto equipment or to the included base.

Totally Enclosed Nonventilated (TENV) Motor Enclosure—TENV (totally enclosed non-ventilated) enclosures are similar to TEFC motor enclosures, except they do not have a fan. They rely on air circulation from the motion of the motor for cooling.

Overall | Shaft | Insulation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Power, hp | Speed @ Continuous Operating Torque | Full Load Current, amp | Inverter Rated | Motor Enclosure Type | Lg. | Wd. | Ht. | Gear Type | Bearing Type | Dia. | Lg. | Ctr.-to-Base Lg. | Class | Max. Temp., ° F | Enclosure Rating | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

115/230V AC, Single Phase | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/15 | 8 rpm @ 345 in·lbf | 1/0.5 | No | Totally Enclosed Nonventilated (TENV) | 10 1/2" | 5" | 5 1/4" | Helical, Spur | Ball | 5/8" | 1 1/2" | 3 1/2" | F | 311 | IP43 | 4863N22 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/15 | 15 rpm @ 250 in·lbf | 1/0.5 | No | Totally Enclosed Nonventilated (TENV) | 10 1/2" | 5" | 5 1/4" | Helical, Spur | Ball | 5/8" | 1 1/2" | 3 1/2" | F | 311 | IP43 | 4863N23 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

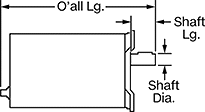

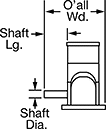

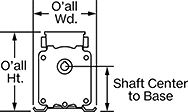

DC Gearmotors

|

|

|

Convert speed to torque to get the power you need—gearmotors are a motor and speed reducer in one. You can wire for clockwise or counterclockwise rotation; instructions are included. Gearmotors transmit motion inline with the motor.

To control motor speed, motor controls are also available. To convert AC power to DC power, see AC to DC transformers.

Gearmotors | Replacement Motor Brushes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Shaft | Insulation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Max. Rotation Speed, rpm | Power, hp | Speed @ Continuous Operating Torque | Radial Load Cap., lb. | Full Load Current, amp | Motor Enclosure Type | Lg. | Wd. | Ht. | Dia. | Lg. | Ctr.-to-Base Lg. | Class | Max. Temp., ° F | Certification | Each | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

90V DC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 1/20 | 8.7 rpm @ 293 in·lbf | 400 | 0.6 | Totally Enclosed Nonventilated (TENV) | 10 1/2" | 4" | 5 1/4" | 5/8" | 1 3/8" | 3 1/2" | F | 311 | UL Recognized Component | 4855N12 | 0000000 | 2 | 65705K222 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24 | 1/8 | 22 rpm @ 300 in·lbf | 322 | 1.16 | Totally Enclosed Nonventilated (TENV) | 12 1/4" | 4" | 5 1/4" | 5/8" | 1 3/8" | 3 1/2" | F | 311 | UL Recognized Component | 4855N14 | 000000 | 2 | 65705K212 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 31 | 1/8 | 31 rpm @ 220 in·lbf | 327 | 1.3 | Totally Enclosed Nonventilated (TENV) | 11 1/2" | 5" | 5 1/4" | 5/8" | 1 1/2" | 3 1/2" | F | 311 | UL Recognized Component | 6470K84 | 000000 | 1 | 65705K242 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 1/17 | 30 rpm @ 100 in·lbf | 171 | 0.8 | Totally Enclosed Nonventilated (TENV) | 8 3/4" | 4 1/2" | 5 1/2" | 1/2" | 1" | 3" | F | 311 | UL Recognized Component | 6470K71 | 000000 | 1 | 65705K242 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 44 | 1/4 | 42 rpm @ 280 in·lbf | 327 | 2.3 | Totally Enclosed Nonventilated (TENV) | 13 1/4" | 6" | 5 1/2" | 3/4" | 1 5/8" | 4" | F | 311 | UL Recognized Component | 6470K61 | 000000 | 1 | 59825K825 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 51 | 1/8 | 51 rpm @ 130 in·lbf | 277 | 1.3 | Totally Enclosed Nonventilated (TENV) | 11 1/2" | 5" | 6 1/4" | 5/8" | 1 1/2" | 3 1/2" | F | 311 | UL Recognized Component | 6470K88 | 000000 | 1 | 65705K242 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 55 | 1/20 | 49 rpm @ 55 in·lbf | 160 | 0.62 | Totally Enclosed Nonventilated (TENV) | 8 3/4" | 3 3/4" | 3 3/4" | 1/2" | 1" | 2.55" | F | 311 | UL Recognized Component | 4855N13 | 000000 | 2 | 65705K222 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 61 | 1/8 | 61 rpm @ 113 in·lbf | 267 | 1.3 | Totally Enclosed Nonventilated (TENV) | 11 1/2" | 5" | 5 1/4" | 5/8" | 1 1/2" | 3 1/2" | F | 311 | UL Recognized Component | 6470K85 | 000000 | 1 | 65705K242 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 62 | 1/4 | 62 rpm @ 220 in·lbf | 303 | 2.3 | Totally Enclosed Nonventilated (TENV) | 13 1/4" | 6" | 5 1/2" | 3/4" | 1 5/8" | 4" | F | 311 | UL Recognized Component | 6470K62 | 000000 | 1 | 59825K825 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 70 | 1/17 | 60 rpm @ 56 in·lbf | 171 | 0.8 | Totally Enclosed Nonventilated (TENV) | 8 3/4" | 4 1/2" | 5 1/2" | 1/2" | 1" | 3" | F | 311 | UL Recognized Component | 6470K72 | 000000 | 1 | 65705K242 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 90 | 1/4 | 83 rpm @ 155 in·lbf | 267 | 2.3 | Totally Enclosed Nonventilated (TENV) | 13 1/4" | 6" | 5 1/2" | 3/4" | 1 5/8" | 4" | F | 311 | UL Recognized Component | 6470K63 | 000000 | 1 | 59825K825 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 94 | 1/8 | 94 rpm @ 77 in·lbf | 236 | 1.3 | Totally Enclosed Nonventilated (TENV) | 11 1/2" | 5" | 5 1/4" | 5/8" | 1 1/2" | 3 1/2" | F | 311 | UL Recognized Component | 6470K86 | 000000 | 1 | 65705K242 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | 1/17 | 100 rpm @ 36 in·lbf | 177 | 0.8 | Totally Enclosed Nonventilated (TENV) | 8 3/4" | 4 1/2" | 5 1/2" | 1/2" | 1" | 3" | F | 311 | UL Recognized Component | 6470K73 | 000000 | 1 | 65705K242 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 125 | 1/4 | 110 rpm @ 100 in·lbf | 256 | 2 | Totally Enclosed Nonventilated (TENV) | 13 1/4" | 6" | 5 1/2" | 3/4" | 1 5/8" | 4" | F | 311 | UL Recognized Component | 6470K64 | 000000 | 1 | 59825K825 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 150 | 1/17 | 150 rpm @ 24 in·lbf | 180 | 0.8 | Totally Enclosed Nonventilated (TENV) | 8 1/2" | 4 1/2" | 5 1/2" | 1/2" | 1" | 3" | F | 311 | UL Recognized Component | 6470K74 | 000000 | 1 | 65705K242 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 167 | 1/8 | 167 rpm @ 43 in·lbf | 197 | 1.3 | Totally Enclosed Nonventilated (TENV) | 11 1/2" | 5" | 5 1/4" | 5/8" | 1 1/2" | 3 1/2" | F | 311 | UL Recognized Component | 6470K87 | 000000 | 1 | 65705K242 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 173 | 1/4 | 165 rpm @ 70 in·lbf | 232 | 2 | Totally Enclosed Nonventilated (TENV) | 13 1/4" | 6" | 5 1/2" | 3/4" | 1 5/8" | 4" | F | 311 | UL Recognized Component | 6470K65 | 000000 | 1 | 59825K825 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 300 | 1/17 | 300 rpm @ 10 in·lbf | 180 | 0.8 | Totally Enclosed Nonventilated (TENV) | 8 1/2" | 4 1/2" | 5 1/2" | 1/2" | 1" | 3" | F | 311 | UL Recognized Component | 6470K75 | 000000 | 1 | 65705K242 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 393 | 1/4 | 360 rpm @ 40 in·lbf | 170 | 2.51 | Totally Enclosed Nonventilated (TENV) | 14 1/4" | 4" | 5 1/4" | 5/8" | 1 3/8" | 3 1/2" | F | 311 | UL Recognized Component | 4855N16 | 000000 | 2 | 65705K212 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 404 | 1/8 | 360 rpm @ 17 in·lbf | 200 | 1.1 | Totally Enclosed Nonventilated (TENV) | 9 3/4" | 3 3/4" | 3 3/4" | 1/2" | 1" | 2.55" | F | 311 | UL Recognized Component | 4855N15 | 000000 | 2 | 65705K212 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,800 | 1/20 | 20 rpm @ 100 in·lbf | 155 | 0.54 | Totally Enclosed Nonventilated (TENV) | 9 1/4" | 3 3/4" | 3 3/4" | 1/2" | 1" | 2 3/4" | F | 311 | UL Recognized Component | 4855N17 | 000000 | 1 | 65705K232 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

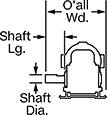

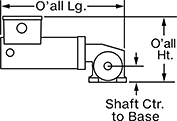

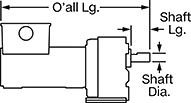

Right-Angle DC Gearmotors

A good solution for tight spaces, these gearmotors transmit motion at a 90° angle from the motor, so they’re positioned alongside your application when mounted. Gearmotors combine a motor and speed reducer to lower speed and increase torque.

To control motor speed, motor controls are also available. To convert AC power to DC power, see AC to DC transformers.

Electric Gearmotors

|

|

|

Gearmotors | Conduit Bodies | Replacement Motor Brushes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Shaft | Insulation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Power, hp | Speed @ Continuous Operating Torque | Radial Load Cap., lb. | Full Load Current, amp | Lg. | Wd. | Ht. | Dia. | Lg. | Ctr.-to-Base Lg. | Class | Max. Temp., ° F | Each | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

90V DC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/17 | 42 rpm @ 22 in·lbf | 185 | 0.9 | 8 3/4" | 4" | 3 3/4" | 1/2" | 1.3" | 1.3" | H | 356 | 59825K31 | 0000000 | 59825K11 | 000000 | 59825K537 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/17 | 62 rpm @ 19 in·lbf | 185 | 0.9 | 8 3/4" | 4" | 3 3/4" | 1/2" | 1.3" | 1.3" | H | 356 | 59825K32 | 000000 | 59825K11 | 00000 | 59825K537 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/17 | 116 rpm @ 16 in·lbf | 185 | 0.9 | 8 3/4" | 4" | 3 3/4" | 1/2" | 1.3" | 1.3" | H | 356 | 59825K33 | 000000 | 59825K11 | 00000 | 59825K537 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/17 | 222 rpm @ 10 in·lbf | 185 | 1 | 8 3/4" | 4" | 3 3/4" | 1/2" | 1.3" | 1.3" | H | 356 | 59825K34 | 000000 | 59825K11 | 00000 | 59825K537 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/17 | 445 rpm @ 5 in·lbf | 185 | 1 | 8 3/4" | 4" | 3 3/4" | 1/2" | 1.3" | 1.3" | H | 356 | 59825K35 | 000000 | 59825K11 | 00000 | 59825K537 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 42 rpm @ 80 in·lbf | 235 | 1.4 | 10 3/4" | 5 1/4" | 4 3/4" | 5/8" | 1.8" | 1.67" | H | 356 | 59825K36 | 000000 | 59825K12 | 00000 | 59825K825 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 62 rpm @ 70 in·lbf | 235 | 1.4 | 10 3/4" | 5 1/4" | 4 3/4" | 5/8" | 1.8" | 1.67" | H | 356 | 59825K37 | 000000 | 59825K12 | 00000 | 59825K825 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 122 rpm @ 45 in·lbf | 235 | 1.4 | 10 3/4" | 5 1/4" | 4 3/4" | 5/8" | 1.8" | 1.67" | H | 356 | 59825K38 | 000000 | 59825K12 | 00000 | 59825K825 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 237 rpm @ 25 in·lbf | 235 | 1.4 | 10 3/4" | 5 1/4" | 4 3/4" | 5/8" | 1.8" | 1.67" | H | 356 | 59825K39 | 000000 | 59825K12 | 00000 | 59825K825 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 475 rpm @ 13 in·lbf | 235 | 1.4 | 10 3/4" | 5 1/4" | 4 3/4" | 5/8" | 1.8" | 1.67" | H | 356 | 59825K49 | 000000 | 59825K12 | 00000 | 59825K825 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 60 rpm @ 135 in·lbf | 235 | 2.3 | 12 3/4" | 5 1/4" | 4 3/4" | 5/8" | 1.8" | 1.67" | H | 356 | 59825K51 | 000000 | 59825K12 | 00000 | 59825K825 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 79 rpm @ 125 in·lbf | 235 | 2.3 | 12 3/4" | 5 1/4" | 4 3/4" | 5/8" | 1.8" | 1.67" | H | 356 | 59825K52 | 000000 | 59825K12 | 00000 | 59825K825 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 120 rpm @ 90 in·lbf | 235 | 2.3 | 12 3/4" | 5 1/4" | 4 3/4" | 5/8" | 1.8" | 1.67" | H | 356 | 59825K53 | 000000 | 59825K12 | 00000 | 59825K825 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 233 rpm @ 50 in·lbf | 235 | 2.3 | 12 3/4" | 5 1/4" | 4 3/4" | 5/8" | 1.8" | 1.67" | H | 356 | 59825K54 | 000000 | 59825K12 | 00000 | 59825K825 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 465 rpm @ 30 in·lbf | 235 | 2.3 | 12 3/4" | 5 1/4" | 4 3/4" | 5/8" | 1.8" | 1.67" | H | 356 | 59825K55 | 000000 | 59825K12 | 00000 | 59825K825 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gearmotors with Hollow Body/Removable Shaft

|  |

Side View of Gearmotor with Hollow Body and Shaft Removed | Gearmotor Shown with Hollow Body and Shaft Installed |

|

|

Gearmotors with a hollow body/removable shaft come assembled with a single-sided shaft for right-hand output. You can remove the shaft and turn it around for left-hand output, or you can replace it with a dual shaft (sold separately) to drive two processes at the same time. To monitor shaft rotation, you can pair this shaft with an encoder (not included).

Gearmotors | Conduit Bodies | Replacement Motor Brushes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Shaft | Insulation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Power, hp | Speed @ Continuous Operating Torque | Radial Load Cap., lb. | Full Load Current, amp | Lg. | Wd. | Ht. | Dia. | Lg. | Ctr.-to-Base Lg. | Class | Max. Temp., ° F | Each | Each | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

90V DC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 30 rpm @ 94 in·lbf | 300 | 1.28 | 10 1/4" | 5 1/4" | 4 3/4" | 5/8" | 1.6" | 1.45" | F | 311 | 59825K61 | 0000000 | 59825K68 | 000000 | 2 | 65705K212 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 40 rpm @ 82 in·lbf | 300 | 1.28 | 10 1/4" | 5 1/4" | 4 3/4" | 5/8" | 1.6" | 1.45" | F | 311 | 59825K62 | 000000 | 59825K68 | 00000 | 2 | 65705K212 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 60 rpm @ 64 in·lbf | 300 | 1.28 | 10 1/4" | 5 1/4" | 4 3/4" | 5/8" | 1.6" | 1.45" | F | 311 | 59825K63 | 000000 | 59825K68 | 00000 | 2 | 65705K212 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 180 rpm @ 27 in·lbf | 300 | 1.28 | 10 1/4" | 5 1/4" | 4 3/4" | 5/8" | 1.6" | 1.45" | F | 311 | 59825K64 | 000000 | 59825K68 | 00000 | 2 | 65705K212 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 60 rpm @ 120 in·lbf | 300 | 2.33 | 12 1/4" | 5 1/4" | 4 3/4" | 5/8" | 1.6" | 1.45" | F | 311 | 59825K65 | 000000 | 59825K69 | 00000 | 2 | 65705K212 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 90 rpm @ 100 in·lbf | 300 | 2.33 | 12 1/4" | 5 1/4" | 4 3/4" | 5/8" | 1.6" | 1.45" | F | 311 | 59825K66 | 000000 | 59825K69 | 00000 | 2 | 65705K212 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Washdown AC Gearmotors

IP rated, these gearmotors stand up to high-pressure washdowns. They combine a motor with a speed reducer to lower speed while increasing torque. Their parallel shaft transmits motion inline with the motor.

Since they’re inverter rated, you can adjust the speed with a motor speed control (not included). Wire these motors for clockwise or counterclockwise rotation; instructions are included.

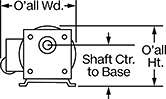

Round Face

|  |  |

Face Mount—Face-mount motors bolt directly to your equipment. They require a power cord (sold separately).

Totally Enclosed Nonventilated (TENV) Motor Enclosure—TENV (totally enclosed non-ventilated) enclosures are similar to TEFC motor enclosures, except they do not have a fan. They rely on air circulation from the motion of the motor for cooling.

IP69K Enclosure Rating—Motors rated IP69K protect against dust, debris, and high-temperature washdowns.

Overall | Shaft | Insulation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Power, hp | Speed @ Continuous Operating Torque | Full Load Current, amp | Motor Enclosure Type | Lg. | Wd. | Ht. | Dia. | Lg. | Ctr.-to-Base Lg. | Class | Max. Temp., ° F | Enclosure Rating | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

230V AC—Face Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 7 rpm @ 500 in·lbf | 0.5 | Totally Enclosed Nonventilated (TENV) | 10 3/4" | 5 1/4" | 5 1/4" | 3/4" | 1 5/8" | 3.45" | F | 311 | IP69K | 4862N23 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 12 rpm @ 500 in·lbf | 0.5 | Totally Enclosed Nonventilated (TENV) | 10 3/4" | 5 1/4" | 5 1/4" | 3/4" | 1 5/8" | 3.45" | F | 311 | IP69K | 4862N24 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 24 rpm @ 256 in·lbf | 0.5 | Totally Enclosed Nonventilated (TENV) | 10 3/4" | 5 1/4" | 5 1/4" | 3/4" | 1 5/8" | 3.45" | F | 311 | IP69K | 4862N25 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 47 rpm @ 128 in·lbf | 0.5 | Totally Enclosed Nonventilated (TENV) | 10 3/4" | 5 1/4" | 5 1/4" | 3/4" | 1 5/8" | 3.45" | F | 311 | IP69K | 4862N26 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 91 rpm @ 70 in·lbf | 0.5 | Totally Enclosed Nonventilated (TENV) | 10 3/4" | 5 1/4" | 5 1/4" | 3/4" | 1 5/8" | 3.45" | F | 311 | IP69K | 4862N27 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 178 rpm @ 34 in·lbf | 0.5 | Totally Enclosed Nonventilated (TENV) | 10 3/4" | 5 1/4" | 5 1/4" | 3/4" | 1 5/8" | 3.45" | F | 311 | IP69K | 4862N28 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 347 rpm @ 16 in·lbf | 0.5 | Totally Enclosed Nonventilated (TENV) | 10 3/4" | 5 1/4" | 5 1/4" | 3/4" | 1 5/8" | 3.45" | F | 311 | IP69K | 4862N29 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

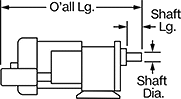

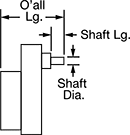

Constant-Speed AC Gearmotors

|  |  |

Achieve precise, constant speed for timing and positioning applications. Also known as synchronous gearmotors, these gearmotors use a frequency of 50/60 Hz to maintain speed and torque.

Overall | Shaft | Insulation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Rotation Speed, rpm | Torque @ Max. Speed, in·lbf | Power, hp | Full Load Current, amp | Motor Enclosure Type | Lg. | Wd. | Ht. | Dia. | Lg. | Ctr.-to-Base Lg. | Class | Max. Temp., ° F | Certification | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

110V AC, Single Phase | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 6.9 | 1/200 | 0.2 | Totally Enclosed Nonventilated (TENV) | 1 1/2" | 2 1/4" | 2 1/2" | 1/4" | 0.26" | 1.99" | A | 221 | UL Recognized Component | 3867K1 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 6.9 | 1/200 | 0.2 | Totally Enclosed Nonventilated (TENV) | 1 1/2" | 2 1/4" | 2 1/2" | 1/4" | 0.26" | 1.99" | A | 221 | UL Recognized Component | 3867K3 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 6.9 | 1/200 | 0.2 | Totally Enclosed Nonventilated (TENV) | 1 1/2" | 2 1/4" | 2 1/2" | 1/4" | 0.26" | 1.99" | A | 221 | UL Recognized Component | 3867K7 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 6.9 | 1/200 | 0.2 | Totally Enclosed Nonventilated (TENV) | 1 1/2" | 2 1/4" | 2 1/2" | 1/4" | 0.26" | 1.99" | A | 221 | UL Recognized Component | 3867K9 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 6.1 | 1/200 | 0.2 | Totally Enclosed Nonventilated (TENV) | 1 1/2" | 2 1/4" | 2 1/2" | 1/4" | 0.26" | 1.99" | A | 221 | UL Recognized Component | 3867K12 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 3.5 | 1/200 | 0.2 | Totally Enclosed Nonventilated (TENV) | 1 1/2" | 2 1/4" | 2 1/2" | 1/4" | 0.26" | 1.99" | A | 221 | UL Recognized Component | 3867K16 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 2.6 | 1/200 | 0.2 | Totally Enclosed Nonventilated (TENV) | 1 1/2" | 2 1/4" | 2 1/2" | 1/4" | 0.26" | 1.99" | A | 221 | UL Recognized Component | 3867K18 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 1.8 | 1/200 | 0.2 | Totally Enclosed Nonventilated (TENV) | 1 1/2" | 2 1/4" | 2 1/2" | 1/4" | 0.26" | 1.99" | A | 221 | UL Recognized Component | 3867K23 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

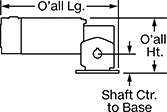

Washdown Right-Angle DC Gearmotors

|

|  |

Drive low-speed, high-torque applications in tight areas that are washed down. These gearmotors have an epoxy-coated enclosure and are rated IP55 to protect against water from low-pressure washdowns. They combine both a motor and speed reducer to lower speeds and increase torque. Since their shaft is at a 90° angle from their motor, they transmit motion alongside your application, so they take up less space than gearmotors with a shaft that's inline with their motor. They have a TENV (totally enclosed nonventilated) enclosure that is similar to a TEFC (totally enclosed fan cooled) enclosure, except it doesn't have a fan. It relies on cooling from the air circulation created by the motor's motion instead.

You can wire the shaft to rotate clockwise or counterclockwise; instructions are included. You can also switch the shaft's right-hand orientation to a left-hand orientation by removing the retaining covers, reversing the orientation, and then reassembling.

Gearmotors | Replacement Motor Brushes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Shaft | Insulation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Max. Rotation Speed, rpm | Power, hp | Speed @ Continuous Operating Torque | Full Load Current, amp | Motor Enclosure Type | Lg. | Wd. | Ht. | Dia. | Lg. | Ctr.-to-Base Lg. | Class | Max. Temp., ° F | Enclosure Rating | Certification | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

90V DC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 42 | 1/8 | 42 rpm @ 80 in·lbf | 2.2 | Totally Enclosed Nonventilated (TENV) | 10 3/4" | 5 1/4" | 6 1/2" | 5/8" | 1 3/4" | 1.67" | F | 311 | IP55 | UL Recognized Component, CSA Certified | 4986N11 | 000000000 | 59825K825 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 62 | 1/4 | 62 rpm @ 135 in·lbf | 3.7 | Totally Enclosed Nonventilated (TENV) | 12 3/4" | 5 1/4" | 6 5/8" | 5/8" | 1 3/4" | 1.67" | F | 311 | IP55 | UL Recognized Component, CSA Certified | 4986N12 | 00000000 | 59825K825 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 125 | 1/4 | 125 rpm @ 90 in·lbf | 3.8 | Totally Enclosed Nonventilated (TENV) | 12 3/4" | 5 1/4" | 6 5/8" | 5/8" | 1 3/4" | 1.67" | F | 311 | IP55 | UL Recognized Component, CSA Certified | 4986N13 | 00000000 | 59825K825 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 250 | 1/4 | 250 rpm @ 50 in·lbf | 3.7 | Totally Enclosed Nonventilated (TENV) | 12 3/4" | 5 1/4" | 6 5/8" | 5/8" | 1 3/4" | 1.67" | F | 311 | IP55 | UL Recognized Component, CSA Certified | 4986N14 | 00000000 | 59825K825 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Washdown DC Gearmotors

|  |  |

Rated IP55 with an epoxy-coated enclosure, these gearmotors drive low-speed, high-torque applications in areas that are subject to low-pressure washdowns. They combine a motor with a speed reducer to lower speeds while increasing torque. Since their shaft is parallel to the motor, they transmit motion inline with the motor. They have a TENV (totally enclosed nonventilated) enclosure that is similar to a TEFC (totally enclosed fan cooled) enclosure, except it doesn't have a fan. It relies on cooling from the air circulation created by the motor's motion instead.

You can wire the shaft to rotate clockwise or counterclockwise; instructions are included.

Gearmotors | Replacement Motor Brushes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Shaft | Insulation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Max. Rotation Speed, rpm | Power, hp | Speed @ Continuous Operating Torque | Full Load Current, amp | Motor Enclosure Type | Lg. | Wd. | Ht. | Dia. | Lg. | Ctr.-to-Base Lg. | Class | Max. Temp., ° F | Enclosure Rating | Certification | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

90V DC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14 | 1/8 | 14 rpm @ 341 in·lbf | 1.5 | Totally Enclosed Nonventilated (TENV) | 11 3/4" | 6" | 6 3/4" | 3/4" | 1 5/8" | 4" | F | 311 | IP55 | UL Recognized Component, CSA Certified, CE Marked | 4938N11 | 000000000 | 59825K825 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 31 | 1/8 | 31 rpm @ 220 in·lbf | 1.6 | Totally Enclosed Nonventilated (TENV) | 12" | 5" | 6 3/8" | 5/8" | 1 1/2" | 3.13" | F | 311 | IP55 | UL Recognized Component, CSA Certified, CE Marked | 4938N12 | 00000000 | 59825K825 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 42 | 1/4 | 42 rpm @ 280 in·lbf | 2.6 | Totally Enclosed Nonventilated (TENV) | 13 3/4" | 6" | 6 3/4" | 3/4" | 1 5/8" | 4" | F | 311 | IP55 | UL Recognized Component, CSA Certified, CE Marked | 4938N15 | 00000000 | 59825K825 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 94 | 1/8 | 61 rpm @ 113 in·lbf | 1.6 | Totally Enclosed Nonventilated (TENV) | 12" | 5" | 6 3/8" | 5/8" | 1 1/2" | 3.13" | F | 311 | IP55 | UL Recognized Component, CSA Certified, CE Marked | 4938N13 | 00000000 | 59825K825 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 167 | 1/8 | 167 rpm @ 43 in·lbf | 1.6 | Totally Enclosed Nonventilated (TENV) | 12" | 5" | 6 3/8" | 5/8" | 1 1/2" | 3.13" | F | 311 | IP55 | UL Recognized Component, CSA Certified, CE Marked | 4938N14 | 00000000 | 59825K825 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 500 | 1/4 | 500 rpm @ 25 in·lbf | 2.4 | Totally Enclosed Nonventilated (TENV) | 13 3/4" | 6" | 6 3/4" | 3/4" | 1 5/8" | 4" | F | 311 | IP55 | UL Recognized Component, CSA Certified, CE Marked | 4938N116 | 00000000 | 59825K825 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||