Filter by

Speed @ Continuous Operating Torque

Starting Torque

Continuous Operating Torque

Shaft Diameter

Voltage

Bearing Type

Motor Type

Face Shape

Direction of Operation

Motor Enclosure Type

Mounting Location

DFARS Specialty Metals

Duty Cycle

Efficiency

Enclosure Finish

Export Control Classification Number (ECCN)

Gear Type

Insulation Maximum Temperature

Maximum Rotation Speed

REACH

RoHS

Shaft Orientation

Wire Connection

Mounting Position

Enclosure Material

About Electric Motors

When replacing a motor, use the information on your motor’s nameplate to guide your selection.

More

Compact DC Gearmotors

Drive low-speed, high-torque applications in small spaces. Gearmotors combine a motor and speed reducer to lower speed and increase torque. Wire for clockwise or counterclockwise rotation.

Use a motor speed control (not included) to adjust the motor speed. To convert AC power to DC power, see AC to DC transformers.

Use a torque-speed curve to confirm which motor will work for your application. Click on a part number and select “Product Detail” to view the curve for a motor.

For technical drawings and 3-D models, click on a part number.

Round Face

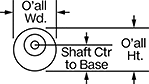

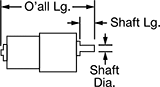

Overall | Shaft | Insulation | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Speed @ Continuous Operating Torque | Power, hp | Full Load Current, A | Lg. | Wd. | Ht. | Bearing Type | Dia. | Lg. | Center to Base | Class | Max. Temp., °F | Each | |

19.1 Volts DC | |||||||||||||

| 202 rpm @ 16 in.-oz. | 0.0036 | 0.6 | 3 3/4" | 1 3/8" | 1 3/8" | Plain | 0.19" | 3/4" | 0.95" | F | 311° | 0000000 | 0000000 |