Filter by

Speed @ Continuous Operating Torque

Face Shape

Voltage Type

Maximum Rotation Speed

Shaft Diameter

Shaft Center-to-Base Length

Motor Enclosure Type

Bearing Type

Starting Torque

Continuous Operating Torque

Direction of Operation

Wire Connection

Efficiency

Shaft Type

Shaft Length

Motor Type

Mounting Position

U.S.–Mexico–Canada Agreement (USMCA) Qualifying

DFARS Specialty Metals

Export Control Classification Number (ECCN)

RoHS

REACH

Gear Type

Compact DC Gearmotors

Round Face

|  |  |

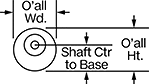

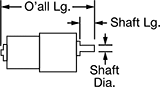

Overall | Shaft | Insulation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Speed @ Continuous Operating Torque | Power, hp | Full Load Current, amp | Lg. | Wd. | Ht. | Bearing Type | Dia. | Lg. | Ctr.-to-Base Lg. | Class | Max. Temp., ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12V DC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 536 rpm @ 124 in·ozf | 0.0769 | 6.4 | 6 1/4" | 2 1/8" | 2 3/4" | Ball | 1/4" | 3/4" | 1" | F | 311 | 2709K15 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

24V DC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 536 rpm @ 124 in·ozf | 0.0769 | 3.2 | 6 1/4" | 2 1/8" | 2 3/4" | Ball | 1/4" | 3/4" | 1" | F | 311 | 2709K16 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||