About Ball and Roller Bearings

More

About Linear Bearings

More

Electrically Insulated Ball Bearings

Good for use in electric motors and power generators, these bearings have ceramic balls that insulate against stray current to prevent damage to the bearing. The ceramic balls generate less heat than steel balls, so they require lubrication less frequently.

Shielded bearings block out dust and other contaminants.

Sealed bearings block out dust and other contaminants better than open and shielded bearings but retain the most heat.

Radial Load Cap., lbs. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bearing Trade Number | For Shaft Dia., mm | For Housing ID, mm | Wd., mm | Ring Material | Dynamic | Static | Max. Speed, rpm | Lubrication | Temp. Range, °F | ABEC Rating | Each | |

Shielded | ||||||||||||

| 6203-2Z | 17 | 40 | 12 | Steel | 2,100 | 920 | 25,500 | Lubricated | -20° to 250° | ABEC-1 | 0000000 | 0000000 |

| 6204-2Z | 20 | 47 | 14 | Steel | 2,850 | 1,250 | 22,500 | Lubricated | -20° to 250° | ABEC-1 | 0000000 | 000000 |

| 6205-2Z | 25 | 52 | 15 | Steel | 3,100 | 1,500 | 19,500 | Lubricated | -20° to 250° | ABEC-1 | 0000000 | 000000 |

| 6206-2Z | 30 | 62 | 16 | Steel | 4,350 | 2,150 | 16,500 | Lubricated | -20° to 250° | ABEC-1 | 0000000 | 000000 |

| 6207-2Z | 35 | 72 | 17 | Steel | 5,750 | 2,900 | 13,500 | Lubricated | -20° to 250° | ABEC-1 | 0000000 | 000000 |

| 6208-2Z | 40 | 80 | 18 | Steel | 6,500 | 3,400 | 12,000 | Lubricated | -20° to 250° | ABEC-1 | 0000000 | 000000 |

| 6209-2Z | 45 | 85 | 19 | Steel | 8,400 | 5,700 | 11,800 | Lubricated | -20° to 245° | ABEC-1 | 0000000 | 000000 |

| 6210-2Z | 50 | 90 | 20 | Steel | 9,600 | 6,000 | 10,800 | Lubricated | -20° to 245° | ABEC-1 | 0000000 | 000000 |

| 6211-2Z | 55 | 100 | 21 | Steel | 11,400 | 7,300 | 9,600 | Lubricated | -20° to 245° | ABEC-1 | 0000000 | 000000 |

| 6306-2Z | 30 | 72 | 19 | Steel | 7,800 | 4,300 | 14,000 | Lubricated | -20° to 245° | ABEC-1 | 0000000 | 000000 |

| 6307-2Z | 35 | 80 | 21 | Steel | 9,100 | 5,300 | 12,600 | Lubricated | -20° to 245° | ABEC-1 | 0000000 | 000000 |

| 6308-2Z | 40 | 90 | 23 | Steel | 11,400 | 6,900 | 11,000 | Lubricated | -20° to 245° | ABEC-1 | 0000000 | 000000 |

| 6309-2Z | 45 | 100 | 25 | Steel | 14,800 | 9,200 | 9,700 | Lubricated | -20° to 245° | ABEC-1 | 0000000 | 000000 |

Sealed | ||||||||||||

| 6000-2RS | 10 | 26 | 8 | Steel | 1,050 | 440 | 32,000 | Lubricated | -40° to 210° | ABEC-1 | 0000000 | 000000 |

| 6001-2RS | 12 | 28 | 8 | Steel | 1,200 | 530 | 30,000 | Lubricated | -40° to 210° | ABEC-1 | 0000000 | 000000 |

| 6002-2RS | 15 | 32 | 9 | Steel | 1,300 | 640 | 24,000 | Lubricated | -40° to 210° | ABEC-1 | 0000000 | 000000 |

| 6003-2RS | 17 | 35 | 10 | Steel | 1,400 | 730 | 22,000 | Lubricated | -40° to 210° | ABEC-1 | 0000000 | 000000 |

| 6004-2RS | 20 | 42 | 12 | Steel | 2,200 | 1,100 | 19,000 | Lubricated | -40° to 210° | ABEC-1 | 0000000 | 000000 |

| 6006-2RZ | 30 | 55 | 13 | Steel | 3,100 | 1,850 | 16,000 | Lubricated | -40° to 210° | ABEC-1 | 0000000 | 000000 |

| 6008-2RZ | 40 | 68 | 15 | Steel | 4,000 | 2,450 | 12,000 | Lubricated | -40° to 210° | ABEC-1 | 0000000 | 000000 |

| 6202-2RS | 15 | 35 | 11 | Steel | 1,800 | 840 | 22,000 | Lubricated | -40° to 210° | ABEC-1 | 0000000 | 000000 |

| 6203-2RS | 17 | 40 | 12 | Steel | 2,200 | 1,050 | 20,000 | Lubricated | -40° to 210° | ABEC-1 | 0000000 | 000000 |

| 6204-2RS | 20 | 47 | 14 | Steel | 3,000 | 1,450 | 17,000 | Lubricated | -40° to 210° | ABEC-1 | 0000000 | 000000 |

| 6205-2RS | 25 | 52 | 15 | Steel | 3,300 | 1,750 | 15,000 | Lubricated | -40° to 210° | ABEC-1 | 0000000 | 000000 |

| 6206-2RZ | 30 | 62 | 16 | Steel | 4,550 | 2,500 | 15,000 | Lubricated | -40° to 210° | ABEC-1 | 0000000 | 000000 |

| 6207-2RZ | 35 | 72 | 17 | Steel | 6,050 | 3,400 | 13,000 | Lubricated | -40° to 210° | ABEC-1 | 0000000 | 000000 |

| 6208-2RZ | 40 | 80 | 18 | Steel | 7,300 | 4,250 | 11,000 | Lubricated | -40° to 210° | ABEC-1 | 0000000 | 000000 |

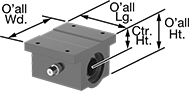

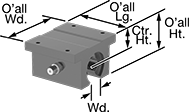

High-Speed Mounted Linear Sleeve Bearings

A ceramic liner makes high speeds as well as rapid acceleration and deceleration possible. Use these bearings with round end-supported shafts. All have end seals to keep lubricant in and dirt out. They are self-aligning, so they compensate for shaft misalignment. Note: Not for use with ceramic-coated aluminum or 300 series stainless steel shafts.

Overall | Mounting Holes | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Lg. | Wd. | Ht. | Center Ht. | Dynamic Load Capacity | Static Load Capacity, lbs. | Shaft Clearance | Temperature Range, ° F | For Shaft Material | No. of | Dia. | Each | |

Self Aligning with 2° Misalignment Capability | |||||||||||||

Ceramic-Lined 6061 Aluminum Bearings with 6061 Aluminum Housing | |||||||||||||

| 1/4" | 1 3/16" | 1 5/8" | 13/16" | 7/16" | 100 lbs. @ 100 fpm | 935 | 0.0005" to 0.0006" | -200° to 400° | Aluminum, Steel | 4 | 1/8" | 0000000 | 000000 |

| 3/8" | 1 5/16" | 1 3/4" | 15/16" | 1/2" | 150 lbs. @ 100 fpm | 1,600 | 0.0005" to 0.0006" | -200° to 400° | Aluminum, Steel | 4 | 1/8" | 0000000 | 00000 |

| 1/2" | 1 11/16" | 2" | 1 1/4" | 11/16" | 300 lbs. @ 100 fpm | 3,100 | 0.0005" to 0.0006" | -200° to 400° | Aluminum, Steel | 4 | 1/8" | 0000000 | 00000 |

| 5/8" | 1 15/16" | 2 1/2" | 1 5/8" | 7/8" | 450 lbs. @ 100 fpm | 4,600 | 0.0005" to 0.0006" | -200° to 400° | Aluminum, Steel | 4 | 3/16" | 0000000 | 00000 |

| 3/4" | 2 1/16" | 2 3/4" | 1 3/4" | 15/16" | 600 lbs. @ 100 fpm | 6,100 | 0.0005" to 0.0006" | -200° to 400° | Aluminum, Steel | 4 | 3/16" | 0000000 | 00000 |

| 1" | 2 13/16" | 3 1/4" | 2 3/16" | 1 3/16" | 1,000 lbs. @ 100 fpm | 11,000 | 0.0005" to 0.0006" | -200° to 400° | Aluminum, Steel | 4 | 3/16" | 0000000 | 000000 |

| 1 1/4" | 3 5/8" | 4" | 2 13/16" | 1 1/2" | 1,500 lbs. @ 100 fpm | 16,000 | 0.0005" to 0.0006" | -200° to 400° | Aluminum, Steel | 4 | 3/16" | 0000000 | 000000 |

| 1 1/2" | 4" | 4 3/4" | 3 1/4" | 1 3/4" | 2,000 lbs. @ 100 fpm | 22,000 | 0.0005" to 0.0006" | -200° to 400° | Aluminum, Steel | 4 | 1/4" | 0000000 | 000000 |

| 2" | 5" | 6" | 4 1/16" | 2 1/8" | 4,000 lbs. @ 100 fpm | 40,000 | 0.0005" to 0.0006" | -200° to 400° | Aluminum, Steel | 4 | 3/8" | 0000000 | 000000 |

High-Load Mounted Linear Sleeve Bearings

With two bearings mounted in one housing, these sleeve bearings can handle heavier loads than standard mounted linear sleeve bearings. All have an anodized aluminum housing that’s lightweight and stands up to corrosion. They also have a slippery, chemical-resistant PTFE liner, so there’s no need for added lubrication. Use these fixed-alignment bearings with round end-supported shafts where shaft misalignment is unlikely.

Overall, mm | Mounting Holes | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Diameter, mm | Shaft Clearance, mm | Length | Width | Height | Center Height, mm | Dynamic Load Capacity | Static Load Capacity, lbs. | Temperature Range, °F | For Shaft Material | Number of | Diameter, mm | Each | |

Fixed Alignment | |||||||||||||

PTFE-Lined Ceramic-Coated 6061 Aluminum Bearings with Anodized 6063 Aluminum Housing | |||||||||||||

| 12 | 0.0127 | 77 | 44 | 30 | 15 | 300 lbs. @ 100 fpm | 4,450 | -400° to 385° | Aluminum, Stainless Steel, Steel | 4 | 5 | 0000000 | 000000 |

| 16 | 0.0127 | 89 | 50 | 38.5 | 19 | 400 lbs. @ 100 fpm | 6,650 | -400° to 385° | Aluminum, Stainless Steel, Steel | 4 | 5 | 0000000 | 00000 |

| 25 | 0.0127 | 136 | 76 | 51.5 | 26 | 1,000 lbs. @ 100 fpm | 16,850 | -400° to 385° | Aluminum, Stainless Steel, Steel | 4 | 8 | 0000000 | 000000 |

High-Load High-Speed Mounted Linear Sleeve Bearings

With two bearings mounted in a single housing, these bearings have load capacities more than 10 times as high as standard mounted linear sleeve bearings. A ceramic liner helps them achieve high speeds as well as rapid acceleration and deceleration. Made of anodized aluminum, their housing is lightweight and corrosion resistant. These bearings are for fixed alignment, ideal for well-aligned shafts. Note: Not for use with ceramic-coated aluminum or 300 series stainless steel shafts.

Overall | Mounting Holes | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia., mm | Shaft Clearance, mm | Length, mm | Width, mm | Height, mm | Center Height, mm | Dynamic Load Capacity | Static Load Capacity, lbs. | Temperature Range, °F | Number of | Diameter, mm | Each | |

Fixed Alignment | ||||||||||||

Ceramic-Lined and -Coated 6061 Aluminum Bearings with Anodized 6063 Aluminum Housing | ||||||||||||

| 12 | 0.05 | 77 | 44 | 30 | 15 | 180 lbs. @ 100 fpm | 2,200 | -400° to 385° | 4 | 5 | 0000000 | 000000 |

| 20 | 0.05 | 100 | 54 | 41 | 21 | 390 lbs. @ 100 fpm | 5,200 | -400° to 385° | 4 | 6 | 0000000 | 00000 |

| 25 | 0.05 | 136 | 76 | 51.5 | 26 | 600 lbs. @ 100 fpm | 8,400 | -400° to 385° | 4 | 8 | 0000000 | 000000 |

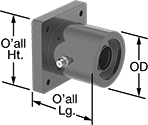

High-Speed Flange-Mounted Linear Sleeve Bearings

A ceramic liner makes high speeds as well as rapid acceleration and deceleration possible. The flange-mount design is good for vertical linear motion applications. Bearings are for use with round end-supported shafts and are self-aligning to compensate for shaft misalignment. End seals keep contaminants out.

Overall | Mounting Holes | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Lg. | Wd. | Ht. | Flange Thick. | Bolt Circle Dia. | OD | Dynamic Load Capacity | Static Load Capacity, lbs. | Shaft Clearance | Temperature Range, ° F | For Shaft Material | No. of | Dia. | Each | |

Self Aligning with 2° Misalignment Capability | |||||||||||||||

Ceramic-Lined 6061 Aluminum Bearings with 6061 Aluminum Housing | |||||||||||||||

| 3/8" | 1 5/16" | 1 1/4" | 1 1/4" | 3/16" | 1 1/4" | 7/8" | 150 lbs. @ 100 fpm | 1,600 | 0.0005" | -200° to 400° | Aluminum, Stainless Steel, Steel | 4 | 5/32" | 0000000 | 000000 |

| 1/2" | 1 11/16" | 1 5/8" | 1 5/8" | 1/4" | 1 25/32" | 1 1/4" | 300 lbs. @ 100 fpm | 3,100 | 0.0005" | -200° to 400° | Aluminum, Stainless Steel, Steel | 4 | 3/16" | 0000000 | 00000 |

| 3/4" | 2 1/16" | 2 3/8" | 2 3/8" | 3/8" | 2 15/32" | 1 3/4" | 600 lbs. @ 100 fpm | 6,100 | 0.0005" | -200° to 400° | Aluminum, Stainless Steel, Steel | 4 | 7/32" | 0000000 | 00000 |

| 1" | 2 13/16" | 2 3/4" | 2 3/4" | 1/2" | 3" | 2 1/4" | 1,000 lbs. @ 100 fpm | 11,000 | 0.0005" | -200° to 400° | Aluminum, Stainless Steel, Steel | 4 | 9/32" | 0000000 | 00000 |

| 1 1/4" | 3 5/8" | 3" | 3" | 1/2" | 3 3/16" | 2 1/2" | 1,500 lbs. @ 100 fpm | 16,000 | 0.0005" | -200° to 400° | Aluminum, Stainless Steel, Steel | 4 | 9/32" | 0000000 | 000000 |

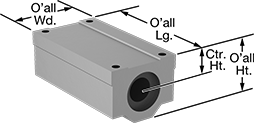

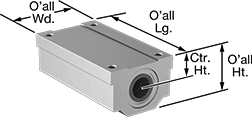

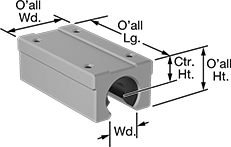

High-Speed Mounted Linear Sleeve Bearings for Support Rail Shafts

A ceramic liner makes high speeds as well as rapid acceleration and deceleration possible. Mount these bearings on a support rail shaft for applications requiring maximum rigidity. End seals keep contaminants out. These bearings are self-aligning to compensate for shaft misalignment. Note: Not for use with ceramic-coated aluminum or 300 series stainless steel shafts.

Overall | Mounting Holes | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Lg. | Wd. | Ht. | Center Ht. | Wd. | Dynamic Load Cap. | Static Load Cap., lbs. | Shaft Clearance | Temp. Range, ° F | For Shaft Material | No. of | Dia. | Each | |

Self Aligning with 2° Misalignment Capability | ||||||||||||||

Ceramic-Lined 6061 Aluminum Bearings with 6061 Aluminum Housing | ||||||||||||||

| 1/2" | 1 11/16" | 2" | 1 1/4" | 11/16" | 5/16" | 300 lbs. @ 100 fpm | 3,100 | 0.0005" to 0.0006" | -200° to 400° | Aluminum, Steel | 4 | 1/8" | 0000000 | 000000 |

| 5/8" | 1 15/16" | 2 1/2" | 1 5/8" | 7/8" | 3/8" | 450 lbs. @ 100 fpm | 4,600 | 0.0005" to 0.0006" | -200° to 400° | Aluminum, Steel | 4 | 3/16" | 0000000 | 00000 |

| 3/4" | 2 1/16" | 2 3/4" | 1 3/4" | 15/16" | 7/16" | 600 lbs. @ 100 fpm | 6,100 | 0.0005" to 0.0006" | -200° to 400° | Aluminum, Steel | 4 | 3/16" | 0000000 | 00000 |

| 1" | 2 13/16" | 3 1/4" | 2 3/16" | 1 3/16" | 9/16" | 1,000 lbs. @ 100 fpm | 11,000 | 0.0005" to 0.0006" | -200° to 400° | Aluminum, Steel | 4 | 3/16" | 0000000 | 000000 |

| 1 1/2" | 4" | 4 3/4" | 3 1/4" | 1 3/4" | 3/4" | 2,000 lbs. @ 100 fpm | 22,000 | 0.0005" to 0.0006" | -200° to 400° | Aluminum, Steel | 4 | 1/4" | 0000000 | 000000 |

High-Load High-Speed Mounted Linear Sleeve Bearings for Support Rail Shafts

With two bearings mounted in a single housing, these bearings have higher load capacities than standard ones. A ceramic liner helps them achieve high speeds as well as rapid acceleration and deceleration. Mount these bearings on a support rail shaft for applications requiring maximum rigidity. Made of ceramic-coated aluminum, their housing is lightweight and corrosion resistant. These bearings are for fixed alignment, ideal for well-aligned shafts. Note: Not for use with ceramic-coated aluminum or 300 series stainless steel shafts.

Overall, mm | Mounting Holes | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Diameter, mm | Length | Width | Height | Center Height, mm | Width, mm | Dynamic Load Capacity | Static Load Capacity, lbs. | Shaft Clearance, mm | Temperature Range, °F | For Shaft Material | Number of | Diameter, mm | Each | |

Fixed Alignment | ||||||||||||||

Ceramic-Lined 6061 Aluminum Bearings with Ceramic-Coated 6063 Aluminum Housing | ||||||||||||||

| 12 | 77 | 40 | 27.5 | 17 | 8.5 | 300 lbs. @ 100 fpm | 4,450 | 0.0127 to 0.0381 | -400° to 400° | Stainless Steel, Steel | 4 | 5 | 0000000 | 000000 |

| 16 | 89 | 45 | 33 | 20 | 10 | 400 lbs. @ 100 fpm | 6,650 | 0.0127 to 0.0381 | -400° to 400° | Stainless Steel, Steel | 4 | 5 | 0000000 | 000000 |

| 20 | 100 | 48 | 39 | 23 | 10 | 600 lbs. @ 100 fpm | 10,450 | 0.0127 to 0.0381 | -400° to 400° | Stainless Steel, Steel | 4 | 6 | 0000000 | 000000 |

| 25 | 136 | 60 | 47 | 27 | 11.5 | 1,000 lbs. @ 100 fpm | 16,850 | 0.0127 to 0.0381 | -400° to 400° | Stainless Steel, Steel | 4 | 6 | 0000000 | 000000 |

| 30 | 154 | 70 | 56 | 33 | 14 | 1,800 lbs. @ 100 fpm | 23,700 | 0.013 to 0.05 | -400° to 400° | Stainless Steel, Steel | 4 | 8 | 0000000 | 000000 |

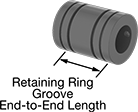

High-Speed Linear Sleeve Bearings

A ceramic liner makes high speeds as well as rapid acceleration and deceleration possible. Bearings are for use with round end-supported shafts. They have a fixed-alignment design for applications where shaft misalignment is unlikely. To install, slide bearings into a housing (not included) and secure with two retaining rings (sold individually).

Bearings | External Retaining Rings | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Overall Lg. | For Housing ID | Retaining Ring Groove End-to-End Lg. | Dynamic Load Capacity | Static Load Capacity, lbs. | Shaft Clearance | Temperature Range, ° F | For Shaft Material | Each | Each | ||

Fixed Alignment | ||||||||||||

Ceramic-Lined 6061 Aluminum Bearings | ||||||||||||

| 1/4" | 3/4" | 0.5000" - 0.5005" | 0.517" | 70 lbs. @ 100 fpm | 935 | 0.0005" | -200° to 400° | Aluminum, Stainless Steel, Steel | 0000000 | 000000 | 0000000 | 00000 |

| 3/8" | 7/8" | 0.6250" - 0.6255" | 0.642" | 100 lbs. @ 100 fpm | 1,600 | 0.0005" | -200° to 400° | Aluminum, Stainless Steel, Steel | 0000000 | 00000 | 0000000 | 0000 |

| 1/2" | 1 1/4" | 0.8750" - 0.8755" | 0.969" | 250 lbs. @ 100 fpm | 3,100 | 0.0005" | -200° to 400° | Aluminum, Stainless Steel, Steel | 0000000 | 00000 | 0000000 | 0000 |

| 5/8" | 1 1/2" | 1.1250" - 1.1255" | 1.116" | 350 lbs. @ 100 fpm | 4,600 | 0.0005" | -200° to 400° | Aluminum, Stainless Steel, Steel | 0000000 | 00000 | 0000000 | 0000 |

| 3/4" | 1 5/8" | 1.2500" - 1.2505" | 1.178" | 450 lbs. @ 100 fpm | 6,100 | 0.0008" | -200° to 400° | Aluminum, Stainless Steel, Steel | 0000000 | 00000 | 0000000 | 0000 |

| 1" | 1 5/8" | 1.2500" - 1.2505" | 1.178" | 600 lbs. @ 100 fpm | 8,100 | 0.0008" | -200° to 400° | Aluminum, Stainless Steel, Steel | 0000000 | 00000 | 0000000 | 0000 |

| Each | Pkg. of 1 | |||||||||||

| 8mm | 25mm | 16 mm | 14mm | 100 lbs. @ 100 fpm | 1,550 | 0.0127mm to 0.0381mm | -200° to 400° | Stainless Steel, Steel | 0000000 | 00000 | 0000000 | 0000 |

| 12mm | 32mm | 22 mm | 20mm | 150 lbs. @ 100 fpm | 2,950 | 0.0127mm to 0.0381mm | -200° to 400° | Stainless Steel, Steel | 0000000 | 00000 | 0000000 | 0000 |

| 16mm | 36mm | 26 mm | 22mm | 200 lbs. @ 100 fpm | 4,450 | 0.0127mm to 0.0381mm | -200° to 400° | Stainless Steel, Steel | 0000000 | 00000 | 0000000 | 0000 |

| 20mm | 45mm | 32 mm | 28mm | 300 lbs. @ 100 fpm | 6,950 | 0.0127mm to 0.0381mm | -200° to 400° | Stainless Steel, Steel | 0000000 | 00000 | 0000000 | 0000 |

| 25mm | 58mm | 40 mm | 40mm | 500 lbs. @ 100 fpm | 11,250 | 0.0127mm to 0.0381mm | -200° to 400° | Stainless Steel, Steel | 0000000 | 00000 | 0000000 | 0000 |

| 30mm | 68mm | 47 mm | 48mm | 900 lbs. @ 100 fpm | 15,800 | 0.013mm to 0.05mm | -200° to 400° | Stainless Steel, Steel | 0000000 | 00000 | 0000000 | 0000 |

| Each | Each | |||||||||||

| 50mm | 100mm | 75 mm | 72mm | 2,000 lbs. @ 100 fpm | 38,750 | 0.013mm to 0.05mm | -200° to 400° | Stainless Steel, Steel | 0000000 | 00000 | 0000000 | 0000 |

High-Speed Ultra-Thin Linear Sleeve Bearings

Use these ultra-thin sleeve bearings in high-speed applications where clearance is a concern. They have a ceramic liner to achieve high speeds and allow rapid acceleration and deceleration. Pair them with round end-supported shafts. These fixed-alignment bearings are for use where shaft misalignment is unlikely. To install, slide them into a housing (not included).

| For Shaft Diameter, mm | Overall Length, mm | For Housing ID, mm | Dynamic Load Capacity | Static Load Capacity, lbs. | Shaft Clearance, mm | Temperature Range, °F | For Shaft Material | Each | |

Fixed Alignment | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Ceramic-Lined 6061 Aluminum Bearings | |||||||||

| 6 | 22 | 12.000 - 12.018 | 70 lbs. @ 100 fpm | 760 | 0.038 | -200° to 400° | Stainless Steel, Steel | 0000000 | 000000 |

| 8 | 24 | 15.000 - 15.018 | 80 lbs. @ 100 fpm | 1,100 | 0.038 | -200° to 400° | Stainless Steel, Steel | 0000000 | 00000 |

| 10 | 26 | 17.000 - 17.018 | 250 lbs. @ 100 fpm | 1,500 | 0.038 | -200° to 400° | Stainless Steel, Steel | 0000000 | 00000 |

| 12 | 28 | 19.000 - 19.021 | 250 lbs. @ 100 fpm | 1,950 | 0.038 | -200° to 400° | Stainless Steel, Steel | 0000000 | 00000 |

| 14 | 28 | 21.000 - 21.021 | 300 lbs. @ 100 fpm | 2,250 | 0.038 | -200° to 400° | Stainless Steel, Steel | 0000000 | 00000 |

| 16 | 30 | 24.000 - 24.021 | 350 lbs. @ 100 fpm | 2,750 | 0.05 | -200° to 400° | Stainless Steel, Steel | 0000000 | 00000 |

| 25 | 40 | 35.000 - 35.025 | 600 lbs. @ 100 fpm | 5,800 | 0.05 | -200° to 400° | Stainless Steel, Steel | 0000000 | 00000 |

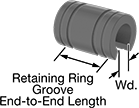

High-Speed Linear Sleeve Bearings for Support Rail Shafts

These bearings have a ceramic liner to help them achieve high speeds as well as rapid acceleration and deceleration. Mount them on support rail shafts for applications requiring maximum rigidity. To install, slide bearings into a housing (not included) and secure in place with two retaining rings (sold individually).

Fixed-alignment bearings are for use where shaft misalignment is unlikely.

Self-aligning bearings compensate for shaft misalignment.

Bearings | External Retaining Rings | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia., mm | Shaft Clearance | Overall Length, mm | Wd., mm | For Housing ID, mm | Retaining Ring Groove End-to-End Length, mm | Dynamic Load Capacity | Static Load Capacity, lbs. | Temperature Range, °F | For Shaft Material | Each | Pkg. Qty. | Pkg. | ||

Ceramic-Lined 6061 Aluminum Bearings | ||||||||||||||

| 12 | 0.001" | 32 | 7.6 | 22.0000 - 22.0210 | 22.6 | 150 lbs. @ 100 fpm | 2,200 | -400° to 400° | Stainless Steel, Steel | 0000000 | 000000 | 1 | 0000000 | 00000 |

| 25 | 0.001" | 58 | 13.2 | 40.0000 - 40.0250 | 43.7 | 500 lbs. @ 100 fpm | 8,400 | -400° to 400° | Stainless Steel, Steel | 0000000 | 00000 | 1 | 0000000 | 0000 |

Bearings | External Retaining Rings | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia., mm | Shaft Clearance | Overall Length, mm | Wd., mm | For Housing ID, mm | Retaining Ring Groove End-to-End Length, mm | Dynamic Load Capacity | Static Load Capacity, lbs. | Temperature Range, °F | For Shaft Material | Each | Pkg. Qty. | Pkg. | ||

Ceramic-Lined 6061 Aluminum Bearings | ||||||||||||||

| 12 | 0.001" | 32 | 7.6 | 22.0000 - 22.0210 | 22.6 | 150 lbs. @ 100 fpm | 2,200 | -400° to 400° | Stainless Steel, Steel | 0000000 | 000000 | 1 | 0000000 | 00000 |

| 25 | 0.001" | 58 | 13.2 | 40.0000 - 40.0250 | 43.7 | 500 lbs. @ 100 fpm | 8,400 | -400° to 400° | Stainless Steel, Steel | 0000000 | 00000 | 1 | 0000000 | 0000 |