Mil. Spec. Compatible Connectors

Connectors secure with a quarter turn when mated, yet unlock and pull apart with minimal force. All have the same pin and socket configurations as MIL-DTL-26482, so they are compatible with other products that meet the same standard. They’re rated IP67 to protect against dust and temporary submersion. When mating connectors, the gender and housing lock location must be opposite. Poles are labeled with letters on the face of the connectors to ensure proper connection.

Crimpers (sold separately) are required for wire installation.

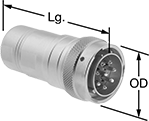

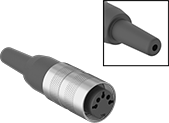

Mini Connectors

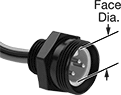

Often used to send power and signal to automated systems, motors, and pumps, these mini connectors carry higher currents than M5, M8, and M12 connectors. A threaded housing securely mates with other mini connectors and won’t come loose from shaking or vibration. They have a standard pole layout and housing thread size to reduce the chance you’ll mis-mate connectors.

Receptacles thread into panels and walls, so they work well in stationary or permanent installations. Receptacles with epoxy-coated zinc housing resist corrosion and weld-slag for use in harsh environments.

When mated, these connectors meet IP or NEMA ratings. IP67 rated connectors protect against dust and temporary submersion.

Caps protect connectors and maintain their IP and NEMA ratings when not in use.

Housing Thread | Mounting | 1 ft. Wire Lead Lg. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

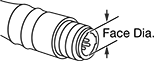

| Number of Poles | Face Dia. | Voltage | Current | Wire Lead Gauge | Color | Housing Material | Size | Type | Pipe Size | Thread Type | For Panel Cutout Dia. | Max. Temp., °F | Environmental Rating | Each | |

| 8 | 0.7" | 600V AC/600V DC | 7A | 16 | Black | Epoxy-Coated Zinc | 1"-16 | UNS | 1/2 | NPT | 0.88" | 220° | IP67 | 00000000 | 000000 |

Housing Thread | Mounting | 1 ft. Wire Lead Lg. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Poles | Face Dia. | Voltage | Current | Wire Lead Gauge | Color | Housing Material | Size | Type | Pipe Size | Thread Type | For Panel Cutout Dia. | Max. Temp., °F | Environmental Rating | Each | |

| 8 | 0.7" | 600V AC/600V DC | 7A | 16 | Black | Epoxy-Coated Zinc | 1"-16 | UNS | 1/2 | NPT | 0.88" | 220° | IP67 | 00000000 | 000000 |

Thread | ||||||

|---|---|---|---|---|---|---|

| For Face Dia. | Size | Type | Material | Temp. Range, °F | Each | |

Internal Thread | ||||||

| 0.7" | 1"-16 | UNS | Anodized Aluminum | 0° to 220° | 00000000 | 000000 |

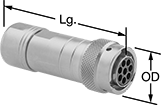

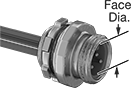

Harsh Environment Mini Connectors

Send higher current than M5, M8, and M12 connectors near tough industrial jobs, such as welding and metal machining. These mini connectors have a stainless steel housing or TPE cable that resists abrasion and cracking from exposure to water, chemicals, oil, coolant, or weld slag. They’re commonly used to send power and signal to automated systems, motors, and pumps. A threaded housing securely mates with other mini connectors to keep out contaminants and won’t come loose from shaking or vibration. They have a standard pole layout and housing thread size to reduce the chance you’ll mis-mate connectors.

When mated, these connectors meet IP67 and NEMA 6P for protection against dust, submersion, washdowns, and weather.

Receptacles thread into panels and walls, so they work well in stationary or permanent installations.

Caps protect connectors and maintain their IP and NEMA ratings when not in use.

Housing Thread | 1 ft. Wire Lead Lg. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

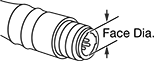

| Number of Poles | Face Dia. | Voltage | Current | Wire Lead Gauge | Housing Material | Size | Type | Type | For Panel Cutout Dia. | Max. Temp., °F | Environmental Rating | Mounting Pipe Size | Each | |

| 8 | 0.7" | 600V AC/600V DC | 7A | 16 | Stainless Steel | 1"-16 | UNS | NPT | 0.88" | 190° | IP67, NEMA 6P | 1/2 | 0000000 | 000000 |

Housing Thread | 1 ft. Wire Lead Lg. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Poles | Face Dia. | Voltage | Current | Wire Lead Gauge | Housing Material | Size | Type | Type | For Panel Cutout Dia. | Max. Temp., °F | Environmental Rating | Mounting Pipe Size | Each | |

| 8 | 0.7" | 600V AC/600V DC | 7A | 16 | Stainless Steel | 1"-16 | UNS | NPT | 0.88" | 190° | IP67, NEMA 6P | 1/2 | 0000000 | 000000 |

Thread | ||||||

|---|---|---|---|---|---|---|

| For Face Dia. | Size | Type | Material | Temp. Range, °F | Each | |

Internal Thread | ||||||

| 0.7" | 1"-16 | UNS | Stainless Steel | 0° to 220° | 00000000 | 000000 |

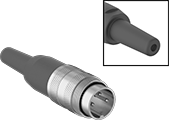

Micro M16 Connectors

Screw these micro M16 connectors together to securely connect equipment. They’re good for use with sensors, inspection cameras, servomotors, and actuators within industrial automation systems.

Housing Thread | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Poles | Face Dia. | Voltage | Current | For Wire Gauge | For Cable OD | Housing Material | Size | Pitch, mm | Temp. Range, °F | Environmental Rating | Specifications Met | Each | |

| 8 | 0.47" | 100V AC/ 100V DC | 5A | 20 | 0.16"-0.24" | Nickel-Plated Zinc | M16 | 0.75 | -40° to 210° | IP40 | UL Listed, IEC 61076-2-106 | 0000000 | 000000 |

Housing Thread | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Poles | Face Dia. | Voltage | Current | For Wire Gauge | For Cable OD | Housing Material | Size | Pitch, mm | Temp. Range, °F | Environmental Rating | Specifications Met | Each | |

| 8 | 0.47" | 100V AC/ 100V DC | 5A | 20 | 0.16"-0.24" | Nickel-Plated Zinc | M16 | 0.75 | -40° to 210° | IP40 | UL Listed, IEC 61076-2-106 | 0000000 | 000000 |

Housing Thread | Mounting Thread | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Poles | Face Dia. | Voltage | Current | For Wire Gauge | Housing Material | Size | Pitch, mm | Size | Pitch, mm | For Panel Cutout Dia. | Temp. Range, °F | Environmental Rating | Specifications Met | Each | |

| 8 | 0.47" | 100V AC/100V DC | 5A | 20 | Nickel-Plated Zinc | M16 | 0.75 | M18 | 0.75 | 0.71" | -40° to 210° | IP40 | UL Listed, IEC 61076-2-106 | 0000000 | 000000 |

Housing Thread | Mounting Thread | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Poles | Face Dia. | Voltage | Current | For Wire Gauge | Housing Material | Size | Pitch, mm | Size | Pitch, mm | For Panel Cutout Dia. | Temp. Range, °F | Environmental Rating | Specifications Met | Each | |

| 8 | 0.47" | 100V AC/100V DC | 5A | 20 | Nickel-Plated Zinc | M16 | 0.75 | M18 | 0.75 | 0.71" | -40° to 210° | IP40 | UL Listed, IEC 61076-2-106 | 0000000 | 000000 |

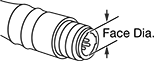

Micro M16 Wet-Location Connectors

Rated IP69K, these M16 connectors protect against dust, debris, and hot, high-pressure jets of water at high volumes. Screw them together to securely connect equipment, such as sensors, inspection cameras, servomotors, and actuators within industrial automation systems.

Housing Thread | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Poles | Face Dia. | Voltage | Current | For Wire Gauge | For Cable OD | Housing Material | Size | Pitch, mm | Temp. Range, °F | Specifications Met | Each | |

| 8 | 0.47" | 32V AC/32V DC | 7A | 20 | 0.23"-0.31" | Nickel-Plated Zinc | M16 | 0.75 | -40° to 210° | UL Listed, IEC 61076-2-106 | 0000000 | 000000 |

Housing Thread | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Poles | Face Dia. | Voltage | Current | For Wire Gauge | For Cable OD | Housing Material | Size | Pitch, mm | Temp. Range, °F | Specifications Met | Each | |

| 8 | 0.47" | 32V AC/32V DC | 7A | 20 | 0.23"-0.31" | Nickel-Plated Zinc | M16 | 0.75 | -40° to 210° | UL Listed, IEC 61076-2-106 | 0000000 | 000000 |

Housing Thread | Mounting Thread | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Poles | Face Dia. | Voltage | Current | For Wire Gauge | For Cable OD | Housing Material | Size | Pitch, mm | Size | Pitch, mm | For Panel Cutout Dia. | Temp. Range, °F | Specifications Met | Each | |

| 8 | 0.47" | 32V AC/32V DC | 7A | 20 | 0.23"-0.31" | Nickel-Plated Zinc | M16 | 0.75 | M18 | 0.75 | 0.71" | -40° to 210° | UL Listed, IEC 61076-2-106 | 0000000 | 000000 |

Housing Thread | Mounting Thread | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Poles | Face Dia. | Voltage | Current | For Wire Gauge | For Cable OD | Housing Material | Size | Pitch, mm | Size | Pitch, mm | For Panel Cutout Dia. | Temp. Range, °F | Specifications Met | Each | |

| 8 | 0.47" | 32V AC/32V DC | 7A | 20 | 0.23"-0.31" | Nickel-Plated Zinc | M16 | 0.75 | M18 | 0.75 | 0.71" | -40° to 210° | UL Listed, IEC 61076-2-106 | 0000000 | 000000 |

Micro M12 Screw-Together Connectors

Because they tightly thread to M12 connections, these connectors won’t let contaminants in or come loose from vibration in rugged industrial environments and automated systems as they send power and signal or just power to your equipment. Their poles and keyways adhere to standard coding layouts, reducing the chance you’ll mismatch connectors.

A- and C-coded connectors send both power and signal, while K-, L-, S-, and T-coded connectors only send power. Choose A-coded connectors for AC and DC sensors, actuators, motors, light curtains, and other devices. They’re often used to connect equipment to IO Link controllers and within Profibus, DeviceNet, and other fieldbus systems.

Receptacles thread into panels and walls, making them best for stationary or permanent installations such as control panels. 90° elbow connectors run your cord along the side of equipment, so they fit behind machines and in tight spaces.

Connectors with screw terminals hold wire by tightening a screw. IP67 and IP68 rated connectors can withstand brief submersion. Add caps to protect connectors and maintain their IP and NEMA ratings when not in use.

Note: Sockets and female receptacles may have extra holes on their face that are not used.

Housing Thread | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Poles | Coding | Face Dia. | Voltage | Current | For Wire Gauge | For Cable OD | Housing Material | Size | Pitch, mm | Type | Max. Temp., °F | Environmental Rating | Each | |

| 8 | A | 0.3" | 30V AC/30V DC | 2A | 24-20 | 0.24"-0.31" | Polyurethane Rubber | M12 | 1 | Metric | 185° | IP67 | 0000000 | 000000 |

Housing Thread | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Poles | Coding | Voltage | Current | Face Dia. | For Wire Gauge | For Cable OD | Housing Material | Size | Pitch, mm | Type | Max. Temp., °F | Environmental Rating | Each | |

| 8 | A | 30V AC/30V DC | 2A | 0.3" | 24-20 | 0.24"-0.31" | Polyurethane Rubber | M12 | 1 | Metric | 185° | IP67 | 0000000 | 000000 |

Housing Thread | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Poles | Coding | Face Dia. | Voltage | Current | For Wire Gauge | For Cable OD | Housing Material | Size | Pitch, mm | Type | Max. Temp., °F | Environmental Rating | Each | |

| 8 | A | 0.3" | 30V AC/30V DC | 2A | 24-20 | 0.24"-0.31" | Polyurethane Rubber | M12 | 1 | Metric | 185° | IP67 | 0000000 | 000000 |

Housing Thread | Mounting | 1 ft. Wire Lead Lg. | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Poles | Coding | Face Dia. | Voltage | Current | Wire Lead Gauge | Housing Material | Size | Pitch, mm | Type | Thread Size | Pipe Size | Thread Pitch, mm | Type | For Panel Cutout Dia. | Temp. Range, °F | Environmental Rating | Each | |

| 8 | A | 0.3" | 60V AC/60V DC | 2A | 24 | Anodized Aluminum | M12 | 1 | Metric | 1/2"-14 | 1/2 | __ | NPT | 0.88" | -40° to 220° | IP67 | 0000000 | 000000 |

| 8 | A | 0.3" | 60V AC/60V DC | 2A | 24 | Anodized Aluminum | M12 | 1 | Metric | M20 | __ | 1.5 | Metric | 0.87" | -40° to 220° | IP67 | 0000000 | 00000 |

| 8 | A | 0.3" | 60V AC/60V DC | 2A | 24 | Nickel-Plated Brass | M12 | 1 | Metric | PG-9 | __ | __ | PG | 0.6" | -40° to 220° | IP67 | 0000000 | 00000 |

Housing Thread | Mounting | 1 ft. Wire Lead Lg. | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Poles | Coding | Face Dia. | Voltage | Current | Wire Lead Gauge | Housing Material | Size | Pitch, mm | Type | Thread Size | Pipe Size | Thread Pitch, mm | Type | For Panel Cutout Dia. | Temp. Range, °F | Environmental Rating | Each | |

| 8 | A | 0.3" | 60V AC/60V DC | 2A | 24 | Anodized Aluminum | M12 | 1 | Metric | 1/2"-14 | 1/2 | __ | NPT | 0.88" | -40° to 220° | IP67 | 0000000 | 000000 |

| 8 | A | 0.3" | 60V AC/60V DC | 2A | 24 | Anodized Aluminum | M12 | 1 | Metric | M20 | __ | 1.5 | Metric | 0.87" | -40° to 220° | IP67 | 0000000 | 00000 |

| 8 | A | 0.3" | 60V AC/60V DC | 2A | 24 | Nickel-Plated Brass | M12 | 1 | Metric | PG-9 | __ | __ | PG | 0.6" | -40° to 220° | IP67 | 0000000 | 00000 |

Shielded Micro M12 Screw-Together Connectors

Block signal interference from nearby devices, such as motors and transmitters, while maintaining a strong, stable connection for M12 threads. The shielding on these connectors maintains signal integrity and minimizes signal loss between equipment. The threaded housing creates a secure connection that withstands the shaking and vibrating of industrial automation.

A-coded, these connectors are often used to connect equipment to IO Link controllers and devices within Profibus, DeviceNet, and other fieldbus systems. They work with both AC and DC devices such as sensors, motors, and light curtains. Poles and keyways on their face adhere to standard coding layouts to reduce the chance you’ll mismatch connections.

Connectors with screw terminals have a screw that you tighten onto wire to connect. All meet IP ratings when either mated or capped. IP67 rated connectors are protected from dust and temporary submersion.

Add caps to protect connectors and maintain their IP ratings when not in use.

Note: They may have extra holes on the face that are not used.

Housing Thread | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Poles | Coding | Face Dia. | Voltage | Current | For Wire Gauge | For Cable OD | Housing Material | Size | Pitch, mm | Type | Temp. Range, °F | Environmental Rating | Each | |

| 8 | A | 0.3" | 30V AC/30V DC | 2A | 18 | 0.24" - 0.31" | Nickel-Plated Brass | M12 | 1 | Metric | -40° to 185° | IP67 | 0000000 | 000000 |

| For Thread Size | Material | Each | |

For Sockets with Internal Threads | |||

|---|---|---|---|

| M12 | Anodized Aluminum | 0000000 | 000000 |

Nano M8 Connectors

Also known as pico connectors, these are for low-current devices such as 8 mm and smaller proximity switches and photoelectric switches.

To view wiring diagrams, select a part number and click Product Detail.

Receptacles thread into panels and walls, so they work well in stationary or permanent installations.

IP67 rated connectors protect against dust and temporary submersion. Note: Sockets and female receptacles may have extra holes on the face that are not used.

Housing Thread | Mounting Thread | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Poles | Coding | Face Dia. | Voltage | Current, A | Wire Lead Gauge | Housing Material | Size | Pitch, mm | Size | Pitch, mm | For Panel Cutout Dia. | Temp. Range, °F | Environmental Rating | Each | |

| 8 | A | 0.2" | 30V AC/30V DC | 1.5 | 26 | Nickel-Plated Brass | M8 | 1 | M8 | 1 | 0.32" | -20° to 175° | IP67 | 0000000 | 000000 |

Housing Thread | Mounting Thread | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Poles | Coding | Face Dia. | Voltage | Current, A | Wire Lead Gauge | Housing Material | Size | Pitch, mm | Size | Pitch, mm | For Panel Cutout Dia. | Temp. Range, °F | Environmental Rating | Each | |

| 8 | A | 0.2" | 30V AC/30V DC | 1.5 | 26 | Nickel-Plated Brass | M8 | 1 | M12 | 1 | 0.48" | -20° to 175° | IP67 | 0000000 | 000000 |

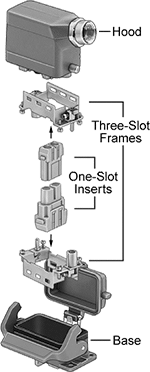

Multipurpose Build-Your-Own Latching Connectors

Combine power, USB, computer, and compressed air inserts to build a connector that sends signal, power, and data. A complete connector requires a hood, a base, two frames, and a male and female insert for each slot in the frame. The frames fit into the hood and base, and the inserts snap into the frame. Select components based on the number of slots needed. Once assembled, connectors are rated NEMA 4X, 12, and IP65 for protection against dirt, washdowns, and oil/coolant dripping.

Crimpers (sold separately) are required for wire installation for crimp-on connectors. They ratchet to ensure the correct pressure is applied to every crimp.

Extraction tools (sold separately) make it easier to remove pins or sleeves from 17- and 20-pole power inserts.

| Number of Poles | Voltage | Current | For Wire Gauge | For Number of Frame Slots | Max. Temp., °F | Specifications Met | Each | |

Plug | ||||||||

|---|---|---|---|---|---|---|---|---|

Spring-Clamp Terminals | ||||||||

| 8 | 600V AC/600V DC | 16A | 20-14 | 1 | 255° | UL 94 V-0, DNV-GL Type Approved | 00000000 | 000000 |

Socket | ||||||||

Spring-Clamp Terminals | ||||||||

| 8 | 600V AC/600V DC | 16A | 20-14 | 1 | 255° | UL 94 V-0, DNV-GL Type Approved | 00000000 | 00000 |

| Extraction Tool for 20-Pole Inserts | 0000000 | Each | 000000 |

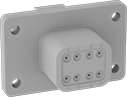

Panel-Mount Deutsch-Style DC Connectors

Install these connectors in panels, enclosures, and bulkheads to join equipment with compatible Deutsch-style DC connectors. They require a crimper (sold separately) for wire installation. Sealed with a silicone gasket and rated IP67, they block out dust, debris, and water. You can even safely submerse them for brief periods of time.

For an extra seal against dust and debris, add another gasket to the front or back of these connectors.

For Panel Cutout | Mounting | Crimp-On Connection | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Cable OD | For Wire Gauge | Current | Lg. | Wd. | Ht. | Color | Ht. | Wd. | Temperature Range, °F | Compatible With | Environmental Rating | Fasteners Included | Hole Dia. | No. of Holes | Each | |

8-Pole | ||||||||||||||||

| 0.05"-0.12" | 20, 19, 18, 17, 16 | 13A | 1.79" | 2.16" | 1.39" | Gray | 1.07" | 1.48" | -65° to 255° | Deutsch-Style Connectors | IP67 | No | 0.17" | 4 | 0000000 | 00000 |

| 0.09"-0.15" | 20, 19, 18, 17, 16, 15, 14 | 13A | 1.79" | 2.16" | 1.39" | Gray | 1.07" | 1.48" | -65° to 255° | Deutsch-Style Connectors | IP67 | No | 0.17" | 4 | 0000000 | 0000 |

| For Wire Gauge (Connector Insulation) | For Wire Type | For Pin-and-Sleeve Barrel Type | Ratcheting or Nonratcheting | Lg. | Material | Each | |

For Pin-and-Sleeve, D-Sub, and DT Deutsch-Style Connectors | |||||||

|---|---|---|---|---|---|---|---|

| 20-12 (Noninsulated) | Stranded | Open, Closed | Nonratcheting | 11" | Steel | 000000 | 000000 |

Mounting | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Number of Poles | Width | Height | Thickness | Color | Material | Hole Diameter | Number of Holes | Each | |

| 8 | 2.18" | 1.41" | 1/8" | Black | Rubber | 0.17" | 4 | 00000000 | 00000 |

| For Wire Gauge | Pkg. Qty. | Pkg. | |

| 20, 19, 18, 17, 16 | 10 | 0000000 | 00000 |

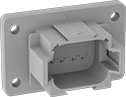

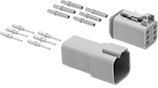

Deutsch-Style DC Connectors

Use these connectors in vehicles and other agricultural and construction equipment.

Connectors with a crimp-on connection require a crimper (sold separately) for wire installation.

Receptacles have snap-in pegs that secure them to circuit boards and relieve stress on the connector’s terminals when plugging and unplugging wires. Push the contacts through holes in your circuit board, then solder them on.

When mated, IP67 rated connectors create a dust- and watertight seal, even if briefly submersed.

Mated Housing | Crimp-On Connection | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Current | Lg. | Wd. | Ht. | Color | Temp. Range, °F | Compatible With | Environmental Rating | For Wire Gauge | Each | |

8-Pole | ||||||||||

| 13A | 1.5" | 0.9" | 1.4" | Gray | -65° to 255° | Deutsch-Style Connectors | IP67 | 20-14 | 0000000 | 000000 |

Mated Housing | Push-In and Solder Connection | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Current | Lg. | Wd. | Ht. | Color | Temp. Range, °F | Compatible With | Environmental Rating | Features | Each | |

8-Pole | ||||||||||

| 13A | 1.5" | 0.9" | 1.4" | Gray | -65° to 255° | Deutsch-Style Connectors | IP67 | Snap-In Pegs | 0000000 | 00000 |

| For Wire Gauge (Connector Insulation) | For Wire Type | For Pin-and-Sleeve Barrel Type | Ratcheting or Nonratcheting | Lg. | Material | Each | |

For Pin-and-Sleeve, D-Sub, and DT Deutsch-Style Connectors | |||||||

|---|---|---|---|---|---|---|---|

| 20-12 (Noninsulated) | Stranded | Open, Closed | Nonratcheting | 11" | Steel | 000000 | 000000 |

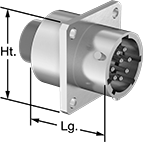

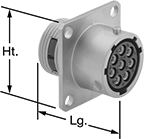

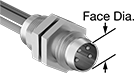

Servomotor M23 Connectors

with

Mounting Holes

Use these connectors with servomotor, servocontrollers, and servodrives in automated equipment and assembly lines. Rated NEMA 4X, IP67, and IP69K, they resist corrosion and protect against high-pressure, high-temperature washdowns. When mating connectors, the gender, housing thread location, and pole layout must be opposite. Poles are numbered on the face of the connector.

Power connectors deliver electricity to run a servomotor.

Clockwise

(12 Pole Shown)

Counterclockwise

(12 Pole Shown)

Low-Current | High-Current | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Poles | Pole Layout | No. of Poles | Current | Voltage | For Wire Gauge | No. of Poles | Current | Voltage | For Wire Gauge | For Cable OD | OD | For Panel Cutout Dia. | Each | |

Plug—External Thread | ||||||||||||||

| 8 | Clockwise | 4 | 8A | 300V AC/300V DC | 26-17 | 4 | 28A | 600V AC/600V DC | 18-14 | 0.27"-0.47" | 1" | __ | 0000000 | 000000 |

Socket—Internal Thread | ||||||||||||||

| 8 | Counterclockwise | 4 | 8A | 300V AC/300V DC | 26-17 | 4 | 28A | 600V AC/600V DC | 18-14 | 0.27"-0.47" | 1.1" | __ | 0000000 | 00000 |

Receptacle—External Thread | ||||||||||||||

| 8 | Clockwise | 4 | 8A | 300V AC/300V DC | 26-17 | 4 | 28A | 600V AC/600V DC | 18-14 | __ | __ | 1" | 0000000 | 00000 |

Receptacle with 4 Mounting Holes—External Thread | ||||||||||||||

| 8 | Clockwise | 4 | 8A | 300V AC/300V DC | 26-17 | 4 | 28A | 600V AC/600V DC | 18-14 | __ | __ | 0.79" | 0000000 | 00000 |

AMP Compact Connector Sets

Connectors come assembled with wire leads already installed so they can be quickly added to existing wiring systems. Each set includes one male plug and one female socket. A locking tab keeps them securely in place when mated.

Mated Housing | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Poles | Voltage | Current | Pin Dia. | Wire Lead Gauge | Color | Housing Material | Lg. | Wd. | Ht. | Temp. Range, °F | Each | |

6" Wire Lead Lg. | ||||||||||||

Plug × Socket | ||||||||||||

Tyco Universal MATE-N-LOK | ||||||||||||

| 8 | 600V AC/600V DC | 9.5A | 0.086" | 18 | White | Nylon Plastic | 1.7" | 2.05" | 0.62" | -65° to 255° | 0000000 | 000000 |

48" Wire Lead Lg. | ||||||||||||

Plug × Socket | ||||||||||||

Tyco Universal MATE-N-LOK | ||||||||||||

| 8 | 600V AC/600V DC | 9.5A | 0.086" | 18 | White | Nylon Plastic | 1.7" | 2.05" | 0.62" | -65° to 255° | 0000000 | 00000 |

Build-Your-Own AMP Compact Connectors

Configure a connector for your application—combine housings with pins and sleeves for different wire sizes.

Housings have a locking tab to form a secure connection when mated.

Mated Housing | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Number of Poles | Voltage | Current | For Pin Dia. | Color | Housing Material | Lg. | Wd. | Ht. | Temp. Range, °F | Pkg. Qty. | Pkg. | |

Pin Housings | ||||||||||||

Tyco Universal MATE-N-LOK | ||||||||||||

| 8 | 600V AC/600V DC | 9.5A | 0.084" | White | Nylon Plastic | 1.7" | 2.05" | 0.62" | -65° to 255° | 10 | 0000000 | 00000 |

Sleeve Housings | ||||||||||||

Tyco Universal MATE-N-LOK | ||||||||||||

| 8 | 600V AC/600V DC | 9.5A | 0.084" | White | Nylon Plastic | 1.7" | 2.05" | 0.62" | -65° to 255° | 5 | 0000000 | 00000 |

Weatherproof Molex Compact Connector Sets

A sealed polystyrene plastic housing protects connectors from weather. All come assembled with wire leads already installed so they can be quickly added to existing wiring systems. Each set includes one male plug and one female socket. A locking tab keeps them securely in place when mated.

Pin | Wire Lead | Mated Housing | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Poles | Voltage | Current | Wd. | Dp. | Gauge | Lg. | Color | Housing Material | Lg. | Wd. | Ht. | Max. Temp., °F | Environmental Rating | Specifications Met | Each | |

Plug × Socket | ||||||||||||||||

Molex MX150L | ||||||||||||||||

| 8 | 50V DC | 7A | 0.059" | 0.031" | 18 | 48" | Black | Polystyrene Plastic | 2.85" | 1.43" | 1.18" | 255° | IP67 | SAE J1128 | 0000000 | 000000 |

| 8 | 600V AC | 7A | 0.059" | 0.031" | 18 | 48" | Black | Polystyrene Plastic | 2.85" | 1.43" | 1.18" | 255° | IP67 | UL 1015 | 00000000 | 00000 |

| 8 | 600V AC | 13A | 0.059" | 0.031" | 14 | 48" | Black | Polystyrene Plastic | 2.85" | 1.43" | 1.18" | 255° | IP67 | UL 1015 | 00000000 | 00000 |

Build-Your-Own Amphenol Circuit Board Connectors

Attach wires to your circuit board with these Amphenol PV connectors. They push together, so they're easy to connect and disconnect yet still give you a strong, secure hold. Even after repeated use, they won’t lose their connection strength. First designed for use in solar power—the PV stands for photovoltaic—they’re also used in equipment ranging from small electronics to industrial robots.

For a complete connection, choose a plug and housing with the number of poles that matches the number of wires you need to connect. You’ll also need one sleeve for each wire.

Plugs have a friction clip to securely hold a housing when mated. An alignment key ensures the plug and housing are mated correctly, which is helpful when you can't get a good look during installation. To install a plug on your circuit board, push their contacts through the board's holes and solder them in place.

Crimpers (sold separately) are required to attach sleeves to your wires.

No. of | Push-In and Solder Connection | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Poles | Rows | Columns | For Hole Ctr.-to-Ctr. | Voltage | Current | Color | Housing Material | Ht. | Wd. | Dp. | Temp. Range, °F | Pkg. Qty. | Pkg. | |

Amphenol PV | ||||||||||||||

| 8 | 1 | 8 | 0.1" | 1,000V DC | 3A | Black | Nylon Plastic | 0.4" | 0.8" | 0.2" | -40° to 220° | 10 | 0000000 | 000000 |

| 8 | 2 | 4 | 0.1" | 1,000V DC | 3A | Black | Nylon Plastic | 0.4" | 0.4" | 0.3" | -40° to 220° | 10 | 0000000 | 00000 |

Build-Your-Own Molex Circuit Board Connectors

Connect wires to your circuit board with these Molex KK push-in connectors. A good choice for prototyping, they require less force to disassemble than Amphenol PV connectors. However, this means that they are less secure in more demanding applications.

For a complete connection, choose a plug and housing with the number of poles that matches the number of wires you need to connect. You’ll also need one sleeve for each wire.

Plugs have a friction clip to securely hold the housing when mated. They also have an alignment key that ensures the plug and housing are mated correctly, which is helpful when you can’t get a good look during installation. To install the plug on your circuit board, push the contacts through the board’s holes and solder them in place. The pins are gold-plated brass, so they resist corrosion better than tin- or nickel-plated pins. This means they’ll have a good, long-lasting electrical connection.

Insertion tools (sold separately) are helpful for assembling small wires.

Extraction tools (sold separately) release the locking mechanism on sleeves to remove them from housings.

Mated Housing | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For No. of Poles | For Hole Ctr.-to-Ctr. | For Max. Wire Gauge | Max. Voltage | Color | Housing Material | Ht. | Wd. | Dp. | Temp. Range, °F | Pkg. Qty. | Pkg. | |

Molex KK 254 | ||||||||||||

| 8 | 0.1" | 22 | 500V AC | White | Nylon Plastic | 0.62" | 0.8" | 0.19" | -40° to 175° | 25 | 0000000 | 00000 |

Mated Housing | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Poles | For Hole Ctr.-to-Ctr. | Voltage | Current | Color | Housing Material | Ht. | Wd. | Dp. | Pin Material | Temp. Range, °F | Pkg. Qty. | Pkg. | |

Molex KK 254 | |||||||||||||

| 8 | 0.1" | 500V AC | 4A | White | Nylon Plastic | 0.62" | 0.8" | 0.19" | Gold-Plated Brass | -40° to 175° | 5 | 0000000 | 00000 |

| For Wire Gauge | Each | |

| 30-22 | 0000000 | 000000 |

| For Wire Gauge | Each | |

| 30-22 | 0000000 | 000000 |

Build-Your-Own Molex Circuit Board Connectors with Locking Tab

Connect wires to circuit boards with Molex Mini-Fit push-in connectors. These connectors are easier to detach than Amphenol PV connectors, so they’re often used for prototyping. A complete connector consists of a sleeve housing, sleeves, and a circuit board plug (all sold separately). To assemble these connectors, crimp sleeves onto your wires, then place them inside a sleeve housing. Once you’ve wired the sleeve housing, slide it onto a circuit board plug.

Plugs have an alignment key that ensures the plug and housing are mated correctly, which is helpful when you can’t get a good look during installation. A locking tab holds the housing and plug together once they’re mated. To install the plug on your circuit board, push the contacts through the board’s holes and solder them in place. All plugs have gold-plated brass pins, which are more corrosion resistant than tin- or nickel-plated pins, so the electrical connection lasts longer. Plugs with snap-in pegs relieve stress on the terminal when plugging and unplugging wires.

Extraction tools release the locking mechanism on sleeves to remove them from housings.

Mated Housing | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For No. of Poles | For Hole Ctr.-to-Ctr. | For Max. Wire Gauge | Max. Voltage | Color | Housing Material | Ht. | Wd. | Dp. | Temp. Range, °F | Pkg. Qty. | Pkg. | |

Molex Mini-Fit Jr. | ||||||||||||

| 8 | 0.1" | 18 | 600V AC | White | Nylon Plastic | 0.93" | 0.71" | 0.57" | -40° to 220° | 25 | 0000000 | 000000 |

Mated Housing | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Poles | For Hole Ctr.-to.Ctr. | Voltage | Current | Color | Housing Material | Ht. | Wd. | Dp. | Pin Material | Temp. Range, °F | Features | Pkg. Qty. | Pkg. | |

Molex Mini-Fit Jr. | ||||||||||||||

| 8 | 0.1" | 600V AC | 9A | White | Nylon Plastic | 0.93" | 0.71" | 0.57" | Gold-Plated Brass | -40° to 220° | Locking Tab, Snap-In Pegs | 5 | 0000000 | 000000 |

| For Wire Gauge | Material | Each | |

| 30-14 | Metal | 0000000 | 000000 |

Micro M12 Screw-Together Ethernet Connectors

Unlike traditional RJ45 connectors found in data centers, these connectors stand up to rugged industrial environments since they tightly thread to devices with M12 connections, sealing out contaminants and resisting shaking loose from vibration. Use them to transfer high-speed data between sensors, switches, computers, IO modules, programmable logic controllers (PLCs), and other equipment. They can also power devices as they send data, so you don’t need a separate power cord. But, the device must be Power over Ethernet (PoE) compatible. These connectors are often used with EtherNet/IP, Profinet, and EtherCAT systems. Since they’re shielded, they block signal interference from nearby devices, maintaining their speed and data integrity. Poles and keyways on the face adhere to standard coding layouts to reduce the chance you’ll mismatch connections.

When choosing an Ethernet connector, make sure you match or exceed your network’s category industry designation. These connectors are backward compatible—for example, a Category 6 connector will work in a Category 5 network, but it’ll only run at the Category 5 speed.

A-coded and X-coded connectors send data faster than D-coded connectors, so they’re best for robotics and other systems that run multi-step programs.

Receptacles thread into a panel or wall, making them best for permanent installations such as control panels or hardwiring into equipment.

Connectors with a screw-on wire connection, also known as field wireable connectors, do not require special tools like crimpers or soldering irons to attach to cables.

IP rated connectors keep out dust and can be used in wet areas when mated or capped. IP67 connectors can be submerged temporarily.

Add caps to protect connectors and maintain their IP ratings when not in use.

Housing Thread | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Poles | Shielding | For Cable OD | For Cable Industry Designation | Transmission Speed | Housing Material | Size | Pitch, mm | Temperature Range, °F | Environmental Rating | Each | |

X-Code | |||||||||||

| 8 | Shielded | 0.2"-0.38" | Category 5E, Category 6, Category 6A | 10 Gb/s | Nickel-Plated Zinc | M12 | 1 | -40° to 185° | IP67 | 0000000 | 000000 |

Housing Thread | Mounting | 1ft. Lg. Wire Leads | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Poles | Wire Lead Gauge (No. of Wires) | Wire Insulation Material | Transmission Speed | Color | Housing Material | Size | Pitch, mm | For Panel Cutout Dia. | Pipe Size | Thread Type | Temperature Range, °F | Environmental Rating | Specifications Met | Each | |

A-Code | |||||||||||||||

| 8 | 24 (8) | PVC Plastic | Not Rated | Gray | Anodized Aluminum | M12 | 1 | 0.875" | 1/2 | NPT | -40° to 175° | IP67 | UL Listed, C-UL Listed | 0000000 | 000000 |

Housing Thread | Mounting | 1ft. Lg. Wire Leads | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Poles | Wire Lead Gauge (No. of Wires) | Wire Insulation Material | Transmission Speed | Color | Housing Material | Size | Pitch, mm | For Panel Cutout Dia. | Pipe Size | Thread Type | Temperature Range, °F | Environmental Rating | Specifications Met | Each | |

A-Code | |||||||||||||||

| 8 | 24 (8) | PVC Plastic | Not Rated | Gray | Anodized Aluminum | M12 | 1 | 0.875" | 1/2 | NPT | -40° to 175° | IP67 | UL Listed, C-UL Listed | 0000000 | 000000 |