How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Underground PVC Pipe Fittings for Drain, Waste, and Vent

With thinner walls than Schedule 40 fittings, these are lighter in weight and have more space on the inside for high-flow applications, such as underground gravity-flow sewer and storm drainage lines. They are also known as SDR 35 fittings. Made of PVC, they have good strength and corrosion resistance. All meet an ASTM specification and testing requirement for material quality, dimensions, and workmanship. Gasket-connect ends slip together and withstand slight shifts without cracking. Lubricate gasket-connect ends then insert unthreaded pipe using a pipe joiner (sold separately).

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

High-Polish Gasket Fittings for Stainless Steel Tubing

- For Use With: Air, Dairy, Water

- Temperature Range: See Gaskets

- Tubing:

Inch Butt-Weld Fittings and Quick-Clamp Fittings: Use with welded 304/304L or 316/316L stainless steel that meets ASTM 269 or ASTM 27

Metric Butt-Weld Fittings: Use with welded or seamless 316 stainless steel - Specifications Met:

304 Stainless Steel Adapters, Caps, and Nuts: 3-A Certified 63-04

Gaskets: See table

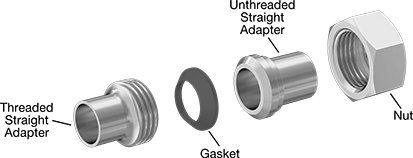

Join these fittings with a threaded nut and a gasket for a secure connection that grants you easy access to your line. Also known as bevel seat fittings, the fittings are beveled to fit snugly around the gasket, creating a vibration-resistant seal. Fittings are polished to a smooth finish on the interior to prevent product buildup and bacterial growth.

304 stainless steel fittings have very good corrosion resistance. They’re 3-A certified to meet sanitary design standards.

Note: For a complete connection, you’ll need a threaded straight adapter, an unthreaded straight adapter, a gasket, and a nut (all sold separately unless noted).

| For Tube OD | Material | Max. Pressure | Each | |

| 1" | 304 Stainless Steel | 400 psi @ 72° F | 000000000 | 00000 |

| 1 1/2" | 304 Stainless Steel | 400 psi @ 72° F | 000000000 | 00000 |

| 2" | 304 Stainless Steel | 400 psi @ 72° F | 000000000 | 00000 |

| 2 1/2" | 304 Stainless Steel | 400 psi @ 72° F | 000000000 | 00000 |

| 3" | 304 Stainless Steel | 400 psi @ 72° F | 000000000 | 00000 |

| 4" | 304 Stainless Steel | 400 psi @ 72° F | 000000000 | 00000 |

| For Tube OD | Nut Material | Max. Pressure | Each | |

| 1" | 304 Stainless Steel | 400 psi @ 72° F | 000000000 | 000000 |

| 1 1/2" | 304 Stainless Steel | 400 psi @ 72° F | 000000000 | 00000 |

| 2" | 304 Stainless Steel | 400 psi @ 72° F | 000000000 | 00000 |

| 2 1/2" | 304 Stainless Steel | 400 psi @ 72° F | 000000000 | 00000 |

| 3" | 304 Stainless Steel | 400 psi @ 72° F | 000000000 | 00000 |

| 4" | 304 Stainless Steel | 400 psi @ 72° F | 000000000 | 00000 |

| For Tube OD | ID | OD | Thick. | Temp. Range, °F | Color | Specifications Met | Each | |

Buna-N Rubber | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1" | 0.900" | 1.325" | 0.3" | -30° to 200° | Black | __ | 0000000 | 00000 |

| 1 1/2" | 1 3/8" | 1 7/8" | 0.33" | -30° to 200° | Black | __ | 0000000 | 0000 |

| 2" | 1.850" | 2 3/8" | 0.35" | -30° to 200° | Black | __ | 0000000 | 0000 |

| 2 1/2" | 2.340" | 2.950" | 0.35" | -30° to 200° | Black | __ | 0000000 | 0000 |

| 3" | 2 7/8" | 3.475" | 0.35" | -30° to 200° | Black | __ | 0000000 | 0000 |

| 4" | 3.700" | 4 1/2" | 0.45" | -30° to 200° | Black | __ | 0000000 | 0000 |

PTFE Plastic | ||||||||

| 1" | 0.900" | 1.325" | 0.3" | -100° to 500° | White | 3-A Certified 20-27 | 0000000 | 0000 |

| 1 1/2" | 1 3/8" | 1 7/8" | 0.33" | -100° to 500° | White | 3-A Certified 20-27 | 0000000 | 0000 |

| 2" | 1.850" | 2 3/8" | 0.35" | -100° to 500° | White | 3-A Certified 20-27 | 0000000 | 0000 |

| 2 1/2" | 2.340" | 2.950" | 0.35" | -100° to 500° | White | 3-A Certified 20-27 | 0000000 | 0000 |

| 3" | 2 7/8" | 3.475" | 0.35" | -100° to 500° | White | 3-A Certified 20-27 | 0000000 | 0000 |

| 4" | 3.700" | 4 1/2" | 0.33" | -100° to 500° | White | 3-A Certified 20-27 | 0000000 | 0000 |

316 Stainless Steel/PTFE Plastic Blend | ||||||||

| 1" | 0.900" | 1.325" | 0.32" | -350° to 550° | Gray | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550, USP VI Certified | 0000000 | 00000 |

| 1 1/2" | 1 3/8" | 1 7/8" | 0.32" | -350° to 550° | Gray | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550, USP VI Certified | 0000000 | 00000 |

| 2" | 1.850" | 2 3/8" | 0.32" | -350° to 550° | Gray | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550, USP VI Certified | 0000000 | 00000 |

| 2 1/2" | 2.340" | 2.950" | 0.32" | -350° to 550° | Gray | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550, USP VI Certified | 0000000 | 00000 |

| 3" | 2 7/8" | 3.475" | 0.32" | -350° to 550° | Gray | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550, USP VI Certified | 0000000 | 00000 |

| 4" | 3.700" | 4 1/2" | 0.32" | -350° to 550° | Gray | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550, USP VI Certified | 0000000 | 00000 |

Ultra-High-Polish Gasket Fittings for Stainless Steel Tubing

- For Use With: Ammonia, Argon, Butane, Carbon Dioxide, Chloride, Fluoride, Fluorocarbon, Germane, Halide, Helium, Hydrogen, Krypton, Laser Gas, Natural Gas, Neon, Nitrogen, Oxygen, Silane, Sulfur Hexafluoride, Tungsten Hexafluoride, Xenon

- Temperature Range: -420° to 1000° F

- Tubing: Use with 316/316L stainless steel

- Compatible With: Swagelok® VCR

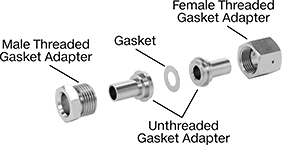

Polished to at least a 15 Ra finish on the inside, these fittings have an ultra-smooth interior surface that helps prevent contamination. Also known as ultra-high-purity fittings, they’re packed in a Class 100 clean room, cleaned, and double bagged. They are commonly used in semiconductor applications. Fittings use a metal gasket (sold separately), which generates fewer particles than a rubber gasket and creates a strong seal in high-pressure and ultra-high-vacuum applications. Fittings are 316 stainless steel for excellent corrosion resistance.

To assemble, place a gasket between the gasket ends before gently rotating the female-threaded fitting onto the male-threaded fitting. Tighten until 1/8 of a turn past finger tight.

Caps replace a female nut to close off the end of a line.

| For Tube OD | Material | Max. Pressure | Max. Vacuum | Environmental Rating | Each | |

| 1/8" | 316L Stainless Steel | 8,500 psi @ 72° F | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 000000 |

| 1/4" | 316L Stainless Steel | 5,100 psi @ 72° F | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 0000000 | 00000 |

| 1/2" | 316L Stainless Steel | 3,500 psi @ 72° F | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 0000000 | 00000 |

| 3/4" | 316L Stainless Steel | 3,350 psi @ 72° F | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 00000 |

| 1" | 316L Stainless Steel | 2,400 psi @ 72° F | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 00000 |

Plugs replace a male nut to close off the end of a line.

| For Tube OD | Material | Max. Pressure | Max. Vacuum | Environmental Rating | Each | |

| 1/8" | 316L Stainless Steel | 8,500 psi @ 72° F | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 00000 |

| 1/4" | 316L Stainless Steel | 5,100 psi @ 72° F | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 0000000 | 00000 |

| 1/2" | 316L Stainless Steel | 3,500 psi @ 72° F | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 0000000 | 00000 |

| 3/4" | 316L Stainless Steel | 3,350 psi @ 72° F | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 00000 |

| 1" | 316L Stainless Steel | 2,400 psi @ 72° F | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 00000 |

| For Tube OD | Nut Material | Max. Pressure | Max. Vacuum | Lg. | Each | |

Male | ||||||

|---|---|---|---|---|---|---|

| 1/8" | 316L Stainless Steel | 8,500 psi @ 72° F | 10 -11 torr @ 72° F | 1/2" | 00000000 | 00000 |

| 1/4" | 316L Stainless Steel | 5,100 psi @ 72° F | 10 -11 torr @ 72° F | 17/32" | 00000000 | 0000 |

| 1/4" | 316L Stainless Steel | 5,100 psi @ 72° F | 10 -11 torr @ 72° F | 23/32" | 0000000 | 0000 |

| 1/2" | 316L Stainless Steel | 3,500 psi @ 72° F | 10 -11 torr @ 72° F | 13/16" | 0000000 | 00000 |

| 3/4" | 316L Stainless Steel | 3,350 psi @ 72° F | 10 -11 torr @ 72° F | 1" | 00000000 | 00000 |

| 1" | 316L Stainless Steel | 2,400 psi @ 72° F | 10 -11 torr @ 72° F | 1 3/16" | 00000000 | 00000 |

Female | ||||||

| 1/8" | 316L Stainless Steel | 8,500 psi @ 72° F | 10 -11 torr @ 72° F | 17/32" | 00000000 | 0000 |

| 1/4" | 316L Stainless Steel | 5,100 psi @ 72° F | 10 -11 torr @ 72° F | 13/16" | 0000000 | 0000 |

| 1/2" | 316L Stainless Steel | 3,500 psi @ 72° F | 10 -11 torr @ 72° F | 7/8" | 0000000 | 00000 |

| 3/4" | 316L Stainless Steel | 3,350 psi @ 72° F | 10 -11 torr @ 72° F | 1 1/8" | 00000000 | 00000 |

| 1" | 316L Stainless Steel | 2,400 psi @ 72° F | 10 -11 torr @ 72° F | 1 11/32" | 00000000 | 00000 |

Retaining

Tabs

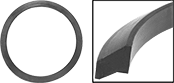

Nickel gaskets are softer than stainless steel gaskets, so they won’t wear down sealing surfaces as much, and they’re easier to tighten. They’re reactive to carbon monoxide and ozone, so they shouldn’t be used with those chemicals.

Hard and heat resistant, stainless steel gaskets can be used in a wider range of applications than nickel gaskets such as carbon monoxide and ozone. However, they’re harder to tighten than nickel gaskets, and they’ll wear down sealing surfaces more quickly.

Silver-plated stainless steel gaskets are softer than unfinished stainless steel gaskets, so they won’t wear down sealing surfaces as much, and they’re easier to tighten. However, they oxidize when exposed to air, and silver particles might flake off during assembly.

Gaskets with retaining tabs stay in place during installation, so you don’t have to hold the gasket while fastening fittings together. This also means they’re less likely to scratch or nick your fittings by rotating during installation.

| For Tube OD | Max. Vacuum | Environmental Rating | Each | |

Nickel Gasket | ||||

|---|---|---|---|---|

| 1/4" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 00000 |

| 1/2" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 0000 |

316L Stainless Steel Gasket | ||||

| 1/4" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 0000000 | 0000 |

| 1/2" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 0000000 | 0000 |

| 3/4" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 0000 |

| 1" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 0000 |

Silver-Plated 316L Stainless Steel Gasket | ||||

| 1/4" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 0000 |

| 1/2" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 0000 |

316L Stainless Steel Gasket with Retaining Tabs | ||||

| 1/4" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 0000 |

| 1/2" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 0000 |