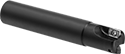

Replaceable Carbide-Insert Square End Mills for Manual Milling Machines

Use these tools with low-horsepower, manual milling machines. They have clamps for holding inserts that do not have a mounting hole. Replaceable carbide-insert end mills reduce waste and cost in high-volume jobs—when the cutting edges dull, replace the carbide inserts instead of the entire tool. End mills have a square cut style for milling square slots, pockets, and edges. All are noncenter-cutting for operations where the sides of the teeth do most of the work, such as shoulder milling, contouring, and finishing. They cannot be used for plunge cuts.

R8-shank end mills have internal threads on the tapered end for connecting to a drawbar.

Carbide inserts have a wear-resistant titanium-nitride (TiN) coating.

Shank Thread | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mill Dia. | Shank Dia. | Gender | Size | Overall Lg. | Cut Style | Material | Number of Inserts Required | End Mill Type | Each | |

Straight Shank | ||||||||||

| 3/4" | 3/4" | __ | __ | 3 7/8" | Square | Black-Oxide Steel | 1 | Noncenter Cutting | 0000000 | 000000 |

| 1" | 3/4" | __ | __ | 3 7/8" | Square | Black-Oxide Steel | 1 | Noncenter Cutting | 0000000 | 000000 |

| 1 1/4" | 3/4" | __ | __ | 3 7/8" | Square | Black-Oxide Steel | 2 | Noncenter Cutting | 0000000 | 000000 |

| 1 3/8" | 3/4" | __ | __ | 3 7/8" | Square | Black-Oxide Steel | 2 | Noncenter Cutting | 0000000 | 000000 |

| 1 1/2" | 3/4" | __ | __ | 3 7/8" | Square | Black-Oxide Steel | 3 | Noncenter Cutting | 0000000 | 000000 |

| 1 1/2" | 1" | __ | __ | 3 7/8" | Square | Black-Oxide Steel | 3 | Noncenter Cutting | 0000000 | 000000 |

| 2" | 3/4" | __ | __ | 3 7/8" | Square | Black-Oxide Steel | 3 | Noncenter Cutting | 0000000 | 000000 |

| 2" | 1" | __ | __ | 6 1/4" | Square | Black-Oxide Steel | 3 | Noncenter Cutting | 0000000 | 000000 |

R8 Taper Shank | ||||||||||

| 1" | __ | Female | 7/16"-20 | 5 7/8" | Square | Black-Oxide Steel | 1 | Noncenter Cutting | 0000000 | 000000 |

| 1 1/4" | __ | Female | 7/16"-20 | 5 7/8" | Square | Black-Oxide Steel | 2 | Noncenter Cutting | 0000000 | 000000 |

| 1 1/2" | __ | Female | 7/16"-20 | 5 7/8" | Square | Black-Oxide Steel | 3 | Noncenter Cutting | 0000000 | 000000 |

| 1 5/8" | __ | Female | 7/16"-20 | 5 7/8" | Square | Black-Oxide Steel | 3 | Noncenter Cutting | 0000000 | 000000 |

| 1 3/4" | __ | Female | 7/16"-20 | 5 7/8" | Square | Black-Oxide Steel | 3 | Noncenter Cutting | 0000000 | 000000 |

| 2" | __ | Female | 7/16"-20 | 5 7/8" | Square | Black-Oxide Steel | 3 | Noncenter Cutting | 0000000 | 000000 |

| 2 1/2" | __ | Female | 7/16"-20 | 5 7/8" | Square | Black-Oxide Steel | 5 | Noncenter Cutting | 0000000 | 000000 |

| 3" | __ | Female | 7/16"-20 | 5 7/8" | Square | Black-Oxide Steel | 5 | Noncenter Cutting | 0000000 | 000000 |

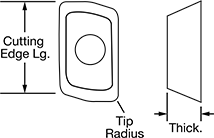

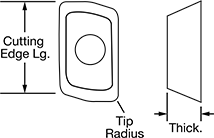

| Tip Radius | Insert Code | Insert Size | Thick. | For Use On | Each | |

Titanium Nitride (TiN) Coated | ||||||

|---|---|---|---|---|---|---|

| 1/64" | TPG-321 | 3/8" | 1/8" | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 00000000 | 000000 |

| 1/32" | TPG-322 | 3/8" | 1/8" | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 00000000 | 00000 |

| 3/64" | TPG-323 | 3/8" | 1/8" | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 00000000 | 00000 |

| 1/16" | TPG-324 | 3/8" | 1/8" | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 00000000 | 00000 |

| Tip Radius | Insert Code | Insert Size | Thick. | For Use On | Pkg. Qty. | Pkg. | |

Titanium Nitride (TiN) Coated | |||||||

|---|---|---|---|---|---|---|---|

| 1/64" | TPG-321 | 3/8" | 1/8" | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 10 | 00000000 | 000000 |

| 1/32" | TPG-322 | 3/8" | 1/8" | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 10 | 00000000 | 00000 |

| 3/64" | TPG-323 | 3/8" | 1/8" | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 10 | 0000000 | 00000 |

| 1/16" | TPG-324 | 3/8" | 1/8" | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 10 | 00000000 | 00000 |

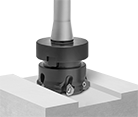

Replaceable Carbide-Insert Square End Mills

Pair carbide inserts with a holder to create end mills that reduce waste and cost in high-volume jobs. When the cutting edges dull, replace the inserts instead of the entire tool. These end mills are also known as indexable shoulder mills. All are noncenter cutting for operations where the sides of the teeth do most of the work, such as shoulder milling, contouring, and finishing. They can’t be used for plunge cuts. They have a square cut style for creating square slots, pockets, flat surfaces, and edges.

When choosing an end mill holder, consider the type of finish you want. The finer the finish, the more inserts you’ll need. More inserts mean tighter spacing, so you can machine at high speeds and remove material quickly while leaving a smooth surface. However, you’ll also need more machine power. Fewer inserts mean a coarser finish—the inserts are spaced apart to help with chip evacuation. A coarse finish is best for roughing applications, light machining, and cutting soft metals such as aluminum.

For shank mount holders, you’ll need two or three positive-rake inserts. Both the holders and inserts are designed to reduce vibration and keep thin workpieces from bending. However, the inserts have cutting edges only on one side. Chip breakers on the inserts keep long chips from forming, so they don't damage your tooling or restrict coolant flow.

For arbor mount holders, you’ll need four or more negative-rake inserts. Since the inserts have cutting edges on both sides, they last longer than positive-rake inserts. When all the edges on one side are dull, flip the insert over. These holders have a hole that passes coolant from your machine onto the workpiece, minimizing heat.

Insert Holders | Replacement Insert Screws | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mill Dia. | Shank Dia. | Overall Lg. | Number of Inserts Required | Cut Style | Material | End Mill Type | Each | Each | ||

Straight Shank | ||||||||||

For Coarse Finish | ||||||||||

| 3/8" | 3/8" | 2 3/8" | 2 | Square | Steel | Noncenter Cutting | 0000000 | 0000000 | 0000000 | 00000 |

| 1/2" | 1/2" | 2 3/4" | 2 | Square | Steel | Noncenter Cutting | 0000000 | 000000 | 0000000 | 0000 |

| 5/8" | 3/4" | 3 1/4" | 2 | Square | Steel | Noncenter Cutting | 0000000 | 000000 | 0000000 | 0000 |

| 1" | 1" | 4" | 2 | Square | Steel | Noncenter Cutting | 0000000 | 000000 | 0000000 | 0000 |

For Fine Finish | ||||||||||

| 3/4" | 3/4" | 3 23/64" | 3 | Square | Steel | Noncenter Cutting | 0000000 | 000000 | 0000000 | 0000 |

| 1 1/4" | 1 1/4" | 4" | 3 | Square | Steel | Noncenter Cutting | 0000000 | 000000 | 0000000 | 0000 |

| 1 1/2" | 1 1/4" | 4 1/2" | 3 | Square | Steel | Noncenter Cutting | 0000000 | 000000 | 0000000 | 0000 |

Insert Holders | Replacement Insert Screws | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mill Dia. | Arbor Hole Dia. | Keyway Wd. | Overall Lg. | Number of Inserts Required | Cut Style | Material | End Mill Type | Features | Each | Pkg. Qty. | Pkg. | ||

For Coarse Finish | |||||||||||||

| 2" | 3/4" | 0.322" | 1 9/16" | 4 | Square | Steel | Noncenter Cutting | Coolant Holes | 0000000 | 0000000 | 10 | 0000000 | 000000 |

| 3" | 1" | 0.385" | 1 3/4" | 5 | Square | Steel | Noncenter Cutting | Coolant Holes | 0000000 | 000000 | 10 | 0000000 | 00000 |

| 4" | 1 1/2" | 0.635" | 2" | 6 | Square | Steel | Noncenter Cutting | Coolant Holes | 0000000 | 000000 | 10 | 0000000 | 00000 |

For Fine Finish | |||||||||||||

| 2" | 3/4" | 0.322" | 1 9/16" | 5 | Square | Steel | Noncenter Cutting | Coolant Holes | 0000000 | 000000 | 10 | 0000000 | 00000 |

| 2 1/2" | 3/4" | 0.322" | 1 9/16" | 5 | Square | Steel | Noncenter Cutting | Coolant Holes | 0000000 | 000000 | 10 | 0000000 | 00000 |

| 2 1/2" | 3/4" | 0.322" | 1 9/16" | 7 | Square | Steel | Noncenter Cutting | Coolant Holes | 0000000 | 000000 | 10 | 0000000 | 00000 |

| 3" | 1" | 0.385" | 1 3/4" | 7 | Square | Steel | Noncenter Cutting | Coolant Holes | 0000000 | 000000 | 10 | 0000000 | 00000 |

| 4" | 1 1/2" | 0.635" | 2" | 8 | Square | Steel | Noncenter Cutting | Coolant Holes | 0000000 | 000000 | 10 | 0000000 | 00000 |

For Extra Fine Finish | |||||||||||||

| 3" | 1" | 0.385" | 1 3/4" | 9 | Square | Steel | Noncenter Cutting | Coolant Holes | 0000000 | 000000 | 10 | 0000000 | 00000 |

| 4" | 1 1/2" | 0.635" | 2" | 11 | Square | Steel | Noncenter Cutting | Coolant Holes | 0000000 | 000000 | 10 | 0000000 | 00000 |

Choose inserts that match the holder's mount type and the material you want to cut.

Uncoated inserts are best for general purpose milling and short production runs. Coated inserts are used for demanding, high-speed jobs in hard material. They’re harder and more wear resistant than uncoated carbide inserts.

Inserts sold individually come packed in a clear plastic case to protect cutting edges during shipment. Inserts sold in packs come factory sealed from the manufacturer for maximum traceability.

Each | Package | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Mill Dia. | Tip Radius | Cutting Edge Lg. | Insert Wd. | Thick. | Hole Dia. | Number of Cutting Edges | Rake Type | Finish | Features | Each | Pkg. Qty. | Pkg. | ||

For Shank Mount Holders | ||||||||||||||

For Use On Aluminum, Brass, Bronze, Copper, Plastic | ||||||||||||||

| 3/8", 1/2" | 1/64" | 0.23" | 0.16" | 3/32" | 1/16" | 2 | Positive | Uncoated | Chip Breakers | 0000000 | 000000 | 10 | 00000000 | 0000000 |

| 5/8", 3/4" | 1/64" | 0.39" | 0.268" | 9/64" | 1/8" | 2 | Positive | Uncoated | Chip Breakers | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 1", 1 1/4", 1 1/2" | 1/32" | 0.62" | 0.378" | 3/16" | 3/16" | 2 | Positive | Uncoated | Chip Breakers | 0000000 | 00000 | 10 | 00000000 | 000000 |

For Use On Aluminum, Brass, Bronze, Copper, Hardened Steel, Nickel, Stainless Steel, Steel, Titanium | ||||||||||||||

| 3/8", 1/2" | 1/64" | 0.23" | 0.16" | 3/32" | 1/16" | 2 | Positive | Aluminum Titanium Chromium Nitride (AlTiCrN) Coated | Chip Breakers | 0000000 | 00000 | 10 | 0000000 | 000000 |

| 5/8", 3/4" | 1/64" | 0.39" | 0.268" | 9/64" | 1/8" | 2 | Positive | Aluminum Titanium Chromium Nitride (AlTiCrN) Coated | Chip Breakers | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 1", 1 1/4", 1 1/2" | 1/32" | 0.62" | 0.378" | 3/16" | 3/16" | 2 | Positive | Aluminum Titanium Chromium Nitride (AlTiCrN) Coated | Chip Breakers | 0000000 | 00000 | 10 | 00000000 | 000000 |

For Arbor Mount Holders | ||||||||||||||

For Use On Aluminum, Brass, Bronze, Copper, Nickel, Stainless Steel, Steel | ||||||||||||||

| 2", 2 1/2", 3", 4" | 1/32" | 0.46" | 0.472" | 7/32" | 3/16" | 8 | Negative | Titanium Nitride (TiN) Coated | __ | 0000000 | 00000 | 5 | 0000000 | 000000 |

| 2", 2 1/2", 3", 4" | 1/16" | 0.46" | 0.472" | 7/32" | 3/16" | 8 | Negative | Titanium Nitride (TiN) Coated | __ | 0000000 | 00000 | 5 | 0000000 | 000000 |

For Use On Cast Iron | ||||||||||||||

| 2", 2 1/2", 3", 4" | 1/32" | 0.46" | 0.472" | 7/32" | 3/16" | 8 | Negative | Aluminum Oxide (Al2O3) Coated | __ | 0000000 | 00000 | 5 | 0000000 | 000000 |

For Use On Aluminum | ||||||||||||||

| 2", 2 1/2", 3", 4" | 1/32" | 0.46" | 0.472" | 7/32" | 3/16" | 8 | Negative | Titanium Diboride (TiB2) Coated | __ | 0000000 | 00000 | 5 | 0000000 | 000000 |

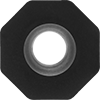

Replaceable Carbide-Insert Milling Cutters

Combine a cutter with carbide inserts (sold separately) to create a milling cutter, also known as indexable milling cutters. They remove metal at least two times faster than comparable high-speed steel milling cutters. When the cutting edges dull, replace the carbide inserts instead of the entire tool.

Use with an R8 shank arbor (sold separately).

Titanium-diboride (TiB2) coated inserts reduce friction in nonferrous metals and composites, so you can use them without lubrication in material like aluminum, fiberglass, and plastic. Titanium-carbonitride (TiCN) coated inserts have a hard, smooth finish that resists chipping and wear and prevents material from accumulating on the cutting edge. They’re especially good for use in aluminum. Titanium-aluminum-nitride (TiAlN) coated inserts dissipate heat better than other inserts, especially at high speeds. At high temperatures, the coating creates a layer of aluminum oxide that transfers heat to the chips, keeping the inserts cool, even when used without lubrication.

Use octagon inserts for general face milling. With eight cutting edges, they generate smooth cuts. Use round inserts for roughing and heavy cuts. Their shape makes them stronger than octagon and square inserts. Use square inserts to create a 90° corner when shoulder milling.

Inserts sold individually come packed in a clear plastic case to protect cutting edges during shipment. Inserts sold in packs come factory sealed from the manufacturer for maximum traceability.

Each | Package | ||||

|---|---|---|---|---|---|

| For Use On | Each | Pkg. Qty. | Pkg. | ||

Titanium Diboride (TiB2) Coated | |||||

| Aluminum, Copper | 00000000 | 000000 | 10 | 0000000 | 0000000 |

Titanium Carbon Nitride (TiCN) Coated | |||||

| Stainless Steel | 00000000 | 00000 | 10 | 00000000 | 000000 |

Titanium Aluminum Nitride (TiAlN) Coated | |||||

| Hardened Steel, Tool Steel | 00000000 | 00000 | 10 | 00000000 | 000000 |

| Iron | 00000000 | 00000 | 10 | 00000000 | 000000 |

| Nickel, Titanium | 00000000 | 00000 | 10 | 00000000 | 000000 |

| Steel | 00000000 | 00000 | 10 | 00000000 | 000000 |

Each | Package | ||||

|---|---|---|---|---|---|

| For Use On | Each | Pkg. Qty. | Pkg. | ||

Titanium Diboride (TiB2) Coated | |||||

| Aluminum, Copper | 00000000 | 000000 | 10 | 00000000 | 0000000 |

Titanium Carbon Nitride (TiCN) Coated | |||||

| Stainless Steel | 00000000 | 00000 | 10 | 00000000 | 000000 |

Titanium Aluminum Nitride (TiAlN) Coated | |||||

| Hardened Steel, Tool Steel | 00000000 | 00000 | 10 | 00000000 | 000000 |

| Iron | 00000000 | 00000 | 10 | 00000000 | 000000 |

| Nickel, Titanium | 00000000 | 00000 | 10 | 00000000 | 000000 |

| Steel | 00000000 | 00000 | 10 | 00000000 | 000000 |

Each | Package | ||||

|---|---|---|---|---|---|

| For Use On | Each | Pkg. Qty. | Pkg. | ||

Titanium Diboride (TiB2) Coated | |||||

| Aluminum, Copper | 00000000 | 000000 | 10 | 00000000 | 0000000 |

Titanium Carbon Nitride (TiCN) Coated | |||||

| Stainless Steel | 00000000 | 00000 | 10 | 00000000 | 000000 |

Titanium Aluminum Nitride (TiAlN) Coated | |||||

| Hardened Steel, Tool Steel | 00000000 | 00000 | 10 | 00000000 | 000000 |

| Iron | 00000000 | 00000 | 10 | 0000000 | 000000 |

| Nickel, Titanium | 00000000 | 00000 | 10 | 00000000 | 000000 |

| Steel | 00000000 | 00000 | 10 | 00000000 | 000000 |

Carbide Inserts for Replaceable Carbide-Insert Square End Mills

Pair these carbide inserts with a holder to create end mills that reduce waste and cost in high-volume jobs. When all the cutting edges dull, replace the inserts instead of the entire tool.

Choose inserts with a smaller tip radius to reduce vibration and create smaller chips, so chip evacuation is easier. Choose inserts with a larger tip radius for more aggressive machining—they have a stronger cutting edge, so they remove more material with each pass.

Use uncoated inserts for general purpose milling and short production runs. Coated inserts are best for demanding, high-speed jobs and hard materials. They’re harder and more wear resistant than uncoated carbide inserts.

Positive-rake inserts are designed to reduce vibration and keep thin workpieces from bending. They have cutting edges on only one side. Negative-rake inserts have cutting edges on both sides, so they last longer than positive-rake inserts. When all the edges on one side are dull, flip the insert over.

Inserts with chip breakers prevent long chips from forming, so they won’t block the flow of coolant or damage your tool.

Inserts sold individually come packed in a clear plastic case to protect cutting edges during shipment. Inserts sold in packs come factory sealed from the manufacturer for maximum traceability.

Each | Package | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Mill Dia. | For Manufacturer | For Manufacturer Series | Tip Radius | Cutting Edge Lg. | Insert Wd. | Thick. | Hole Dia. | Number of Cutting Edges | Rake Type | Finish | Features | Each | Pkg. Qty. | Pkg. | ||

For Shank Mount Holders | ||||||||||||||||

For Use On Aluminum, Brass, Bronze, Copper, Plastic | ||||||||||||||||

| 3/8", 1/2" | Sandvik Coromant | CoroMill 390 | 1/64" | 0.23" | 0.16" | 3/32" | 1/16" | 2 | Positive | Uncoated | Chip Breakers | 0000000 | 000000 | 10 | 00000000 | 0000000 |

| 5/8", 3/4" | Sandvik Coromant | CoroMill 390 | 1/64" | 0.39" | 0.268" | 9/64" | 1/8" | 2 | Positive | Uncoated | Chip Breakers | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 1", 1 1/4", 1 1/2" | Sandvik Coromant | CoroMill 390 | 1/32" | 0.62" | 0.378" | 3/16" | 3/16" | 2 | Positive | Uncoated | Chip Breakers | 0000000 | 00000 | 10 | 00000000 | 000000 |

For Use On Aluminum, Brass, Bronze, Copper, Hardened Steel, Nickel, Stainless Steel, Steel, Titanium | ||||||||||||||||

| 3/8", 1/2" | Sandvik Coromant | CoroMill 390 | 1/64" | 0.23" | 0.16" | 3/32" | 1/16" | 2 | Positive | Aluminum Titanium Chromium Nitride (AlTiCrN) Coated | Chip Breakers | 0000000 | 00000 | 10 | 0000000 | 000000 |

| 5/8", 3/4" | Sandvik Coromant | CoroMill 390 | 1/64" | 0.39" | 0.268" | 9/64" | 1/8" | 2 | Positive | Aluminum Titanium Chromium Nitride (AlTiCrN) Coated | Chip Breakers | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 1", 1 1/4", 1 1/2" | Sandvik Coromant | CoroMill 390 | 1/32" | 0.62" | 0.378" | 3/16" | 3/16" | 2 | Positive | Aluminum Titanium Chromium Nitride (AlTiCrN) Coated | Chip Breakers | 0000000 | 00000 | 10 | 00000000 | 000000 |

For Arbor Mount Holders | ||||||||||||||||

For Use On Aluminum, Brass, Bronze, Copper, Nickel, Stainless Steel, Steel | ||||||||||||||||

| 2", 2 1/2", 3", 4" | Widia | VSM890-12 | 1/32" | 0.46" | 0.472" | 7/32" | 3/16" | 8 | Negative | Titanium Nitride (TiN) Coated | __ | 0000000 | 00000 | 5 | 0000000 | 000000 |

| 2", 2 1/2", 3", 4" | Widia | VSM890-12 | 1/16" | 0.46" | 0.472" | 7/32" | 3/16" | 8 | Negative | Titanium Nitride (TiN) Coated | __ | 0000000 | 00000 | 5 | 0000000 | 000000 |

For Use On Cast Iron | ||||||||||||||||

| 2", 2 1/2", 3", 4" | Widia | VSM890-12 | 1/32" | 0.46" | 0.472" | 7/32" | 3/16" | 8 | Negative | Aluminum Oxide (Al2O3) Coated | __ | 0000000 | 00000 | 5 | 0000000 | 000000 |

For Use On Aluminum | ||||||||||||||||

| 2", 2 1/2", 3", 4" | Widia | VSM890-12 | 1/32" | 0.46" | 0.472" | 7/32" | 3/16" | 8 | Negative | Titanium Diboride (TiB2) Coated | __ | 0000000 | 00000 | 5 | 0000000 | 000000 |

| Mill Dia. | Shank Dia. | Overall Lg. | Number of Inserts Required | Cut Style | Material | End Mill Type | Each | |

Straight Shank | ||||||||

|---|---|---|---|---|---|---|---|---|

For Coarse Finish | ||||||||

| 3/8" | 3/8" | 2 3/8" | 2 | Square | Steel | Noncenter Cutting | 0000000 | 0000000 |

| 1/2" | 1/2" | 2 3/4" | 2 | Square | Steel | Noncenter Cutting | 0000000 | 000000 |

| 5/8" | 3/4" | 3 1/4" | 2 | Square | Steel | Noncenter Cutting | 0000000 | 000000 |

| 1" | 1" | 4" | 2 | Square | Steel | Noncenter Cutting | 0000000 | 000000 |

For Fine Finish | ||||||||

| 3/4" | 3/4" | 3 23/64" | 3 | Square | Steel | Noncenter Cutting | 0000000 | 000000 |

| 1 1/4" | 1 1/4" | 4" | 3 | Square | Steel | Noncenter Cutting | 0000000 | 000000 |

| 1 1/2" | 1 1/4" | 4 1/2" | 3 | Square | Steel | Noncenter Cutting | 0000000 | 000000 |

| Mill Dia. | Arbor Hole Dia. | Keyway Wd. | Overall Lg. | Number of Inserts Required | Cut Style | Material | End Mill Type | Features | Each | |

For Coarse Finish | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 2" | 3/4" | 0.322" | 1 9/16" | 4 | Square | Steel | Noncenter Cutting | Coolant Holes | 0000000 | 0000000 |

| 3" | 1" | 0.385" | 1 3/4" | 5 | Square | Steel | Noncenter Cutting | Coolant Holes | 0000000 | 000000 |

| 4" | 1 1/2" | 0.635" | 2" | 6 | Square | Steel | Noncenter Cutting | Coolant Holes | 0000000 | 000000 |

For Fine Finish | ||||||||||

| 2" | 3/4" | 0.322" | 1 9/16" | 5 | Square | Steel | Noncenter Cutting | Coolant Holes | 0000000 | 000000 |

| 2 1/2" | 3/4" | 0.322" | 1 9/16" | 5 | Square | Steel | Noncenter Cutting | Coolant Holes | 0000000 | 000000 |

| 2 1/2" | 3/4" | 0.322" | 1 9/16" | 7 | Square | Steel | Noncenter Cutting | Coolant Holes | 0000000 | 000000 |

| 3" | 1" | 0.385" | 1 3/4" | 7 | Square | Steel | Noncenter Cutting | Coolant Holes | 0000000 | 000000 |

| 4" | 1 1/2" | 0.635" | 2" | 8 | Square | Steel | Noncenter Cutting | Coolant Holes | 0000000 | 000000 |

For Extra Fine Finish | ||||||||||

| 3" | 1" | 0.385" | 1 3/4" | 9 | Square | Steel | Noncenter Cutting | Coolant Holes | 0000000 | 000000 |

| 4" | 1 1/2" | 0.635" | 2" | 11 | Square | Steel | Noncenter Cutting | Coolant Holes | 0000000 | 000000 |