Filter by

Cut Style

System of Measurement

Shank Diameter

Sold As

Finish

Component

Number of Milling Ends

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Insert Finish

Helix Angle

Grit Rating

Rake Angle Type

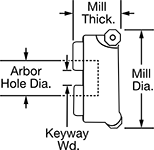

Holders for Replaceable Carbide-Insert Milling Cutters

|  |  |

Holder Shown with Octagon Inserts |

Insert Holders | Replacement Screws | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mill | ||||||||||||

Thk. | Dia. | Arbor Hole Dia. | Keyway Wd. | No. of Inserts Req. | Material | Heat Treatment | Each | Each | ||||

| 1 23/32" | 2" | 3/4" | 0.313" | 4 | Uncoated Steel | Hardened | 0000000 | 0000000 | 0000000 | 00000 | ||

| 1 7/8" | 3" | 1 1/4" | 0.5" | 5 | Uncoated Steel | Hardened | 0000000 | 000000 | 0000000 | 0000 | ||

| 1 7/8" | 3 1/2" | 1 1/2" | 0.625" | 5 | Uncoated Steel | Hardened | 0000000 | 000000 | 0000000 | 0000 | ||

| 1 7/8" | 4" | 1 1/2" | 0.625" | 6 | Uncoated Steel | Hardened | 0000000 | 000000 | 0000000 | 0000 | ||

| 1 61/64" | 5" | 1 1/2" | 0.625" | 6 | Uncoated Steel | Hardened | 0000000 | 000000 | 0000000 | 0000 | ||

| 1 61/64" | 6" | 1 1/2" | 0.625" | 8 | Uncoated Steel | Hardened | 0000000 | 000000 | 0000000 | 0000 | ||

Carbide Inserts for Replaceable Carbide-Insert Milling Cutters

|  |  |  |

Octagon | Round | Square |

Octagon | Round | Square | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Use On | Pkg. Qty. | Pkg. | Pkg. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Titanium Diboride (TiB2)-Coated Carbide | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum, Copper | 1 | 00000000 | 000000 | 00000000 | 000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum, Copper | 10 | 0000000 | 000000 | 00000000 | 000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Titanium Carbon Nitride (TiCN)-Coated Carbide | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Stainless Steel | 1 | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Stainless Steel | 10 | 00000000 | 000000 | 00000000 | 000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Titanium Aluminum Nitride (TiAlN)-Coated Carbide | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Hardened Steel, Tool Steel | 1 | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Hardened Steel, Tool Steel | 10 | 00000000 | 000000 | 00000000 | 000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Iron | 1 | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Iron | 10 | 00000000 | 000000 | 00000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Nickel, Titanium | 1 | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Nickel, Titanium | 10 | 00000000 | 000000 | 00000000 | 000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Steel | 1 | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Steel | 10 | 00000000 | 000000 | 00000000 | 000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Replaceable Carbide-Insert Face Milling Cutter Kits

Mill | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thick. | Dia. | Arbor Hole Dia. | Keyway Wd. | For Use On | Includes | Container Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Titanium Diboride (TiB2)-Coated Carbide Insert | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Octagonal Insert | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 23/32" | 2" | 3/4" | 0.313" | Aluminum, Copper | 10 Inserts, Cutter Body, Extra Screws, Two Wrenches | Plastic Case | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/8" | 3" | 1 1/4" | 0.5" | Aluminum, Copper | 10 Inserts, Cutter Body, Extra Screws, Two Wrenches | Plastic Case | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/8" | 4" | 1 1/2" | 0.625" | Aluminum, Copper | 10 Inserts, Cutter Body, Extra Screws, Two Wrenches | Plastic Case | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Square Insert | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 23/32" | 2" | 3/4" | 0.313" | Aluminum, Copper | 10 Inserts, Cutter Body, Extra Screws, Two Wrenches | Plastic Case | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/8" | 3" | 1 1/4" | 0.5" | Aluminum, Copper | 10 Inserts, Cutter Body, Extra Screws, Two Wrenches | Plastic Case | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/8" | 4" | 1 1/2" | 0.625" | Aluminum, Copper | 10 Inserts, Cutter Body, Extra Screws, Two Wrenches | Plastic Case | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Titanium Aluminum Nitride (TiAlN)-Coated Carbide Insert | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Octagonal Insert | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 23/32" | 2" | 3/4" | 0.313" | Hardened Steel, Tool Steel | 10 Inserts, Cutter Body, Extra Screws, Two Wrenches | Plastic Case | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 23/32" | 2" | 3/4" | 0.313" | Steel | 10 Inserts, Cutter Body, Extra Screws, Two Wrenches | Plastic Case | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/8" | 3" | 1 1/4" | 0.5" | Hardened Steel, Tool Steel | 10 Inserts, Cutter Body, Extra Screws, Two Wrenches | Plastic Case | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/8" | 3" | 1 1/4" | 0.5" | Steel | 10 Inserts, Cutter Body, Extra Screws, Two Wrenches | Plastic Case | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/8" | 4" | 1 1/2" | 0.625" | Hardened Steel, Tool Steel | 10 Inserts, Cutter Body, Extra Screws, Two Wrenches | Plastic Case | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/8" | 4" | 1 1/2" | 0.625" | Steel | 10 Inserts, Cutter Body, Extra Screws, Two Wrenches | Plastic Case | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Square Insert | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 23/32" | 2" | 3/4" | 0.313" | Steel | 10 Inserts, Cutter Body, Extra Screws, Two Wrenches | Plastic Case | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/8" | 3" | 1 1/4" | 0.5" | Steel | 10 Inserts, Cutter Body, Extra Screws, Two Wrenches | Plastic Case | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/8" | 4" | 1 1/2" | 0.625" | Steel | 10 Inserts, Cutter Body, Extra Screws, Two Wrenches | Plastic Case | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Holders for Replaceable Carbide-Insert Face Milling Cutters

Shank Mount

Insert Holders | Replacement Screws | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mill | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Thk. | Dia. | Shank Dia. | Helix Angle | No. of Inserts Req. | Material | Rake Angle Type | Each | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Coarse Grit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 9/16" | 1 1/2" | 1 1/4" | 45° | 2 | Nickel-Plated Steel | Negative | 00000000 | 0000000 | 10 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 9/16" | 1 1/2" | 1 1/4" | 45° | 3 | Nickel-Plated Steel | Negative | 00000000 | 000000 | 10 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 9/16" | 2" | 1 1/4" | 45° | 3 | Nickel-Plated Steel | Negative | 00000000 | 000000 | 10 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 9/16" | 2 1/2" | 1 1/4" | 45° | 4 | Nickel-Plated Steel | Negative | 00000000 | 000000 | 10 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Arbor Mount

Insert Holders | Replacement Screws | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mill | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Thk. | Dia. | Arbor Hole Dia. | Keyway Wd. | Helix Angle | No. of Inserts Req. | Material | Rake Angle Type | Each | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Coarse Grit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 9/16" | 2" | 3/4" | 0.313" | 45° | 3 | Nickel-Plated Steel | Negative | 00000000 | 0000000 | 10 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 9/16" | 2 1/2" | 3/4" | 0.313" | 45° | 4 | Nickel-Plated Steel | Negative | 00000000 | 000000 | 10 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 31/32" | 3" | 1" | 0.382" | 45° | 5 | Nickel-Plated Steel | Negative | 00000000 | 000000 | 10 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 31/32" | 4" | 1 1/2" | 0.626" | 45° | 5 | Nickel-Plated Steel | Negative | 00000000 | 000000 | 10 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 15/32" | 5" | 1 1/2" | 0.626" | 45° | 6 | Nickel-Plated Steel | Negative | 00000000 | 000000 | 10 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fine Grit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 9/16" | 2" | 3/4" | 0.313" | 45° | 4 | Nickel-Plated Steel | Negative | 00000000 | 000000 | 10 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 9/16" | 2 1/2" | 3/4" | 0.313" | 45° | 5 | Nickel-Plated Steel | Negative | 00000000 | 000000 | 10 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 31/32" | 3" | 1" | 0.382" | 45° | 6 | Nickel-Plated Steel | Negative | 00000000 | 000000 | 10 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 31/32" | 4" | 1 1/2" | 0.626" | 45° | 8 | Nickel-Plated Steel | Negative | 00000000 | 000000 | 10 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 15/32" | 5" | 1 1/2" | 0.626" | 45° | 10 | Nickel-Plated Steel | Negative | 00000000 | 00000000 | 10 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extra-Fine Grit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 9/16" | 2" | 3/4" | 0.313" | 45° | 5 | Nickel-Plated Steel | Negative | 00000000 | 000000 | 10 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 9/16" | 2 1/2" | 3/4" | 0.313" | 45° | 6 | Nickel-Plated Steel | Negative | 00000000 | 000000 | 10 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 31/32" | 3" | 1" | 0.382" | 45° | 8 | Nickel-Plated Steel | Negative | 00000000 | 000000 | 10 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 31/32" | 4" | 1 1/2" | 0.626" | 45° | 10 | Nickel-Plated Steel | Negative | 00000000 | 00000000 | 10 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 15/32" | 5" | 1 1/2" | 0.626" | 45° | 13 | Nickel-Plated Steel | Negative | 00000000 | 00000000 | 10 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbide Inserts for Replaceable Carbide-Insert Face Milling Cutters

|

|

Individual Carbide Insert Case |

|

|

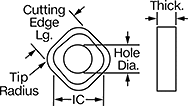

For Use On | For Mill Dia. | IC Dia. | Cutting Edge Lg. | Thk. | Hole Dia. | No. of Cutting Edges | Tip Radius | Rake Angle Type | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Aluminum Titanium Chromium Nitride (AlTiCrN)-Coated Carbide | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Cast Iron | 1 1/2", 2", 2 1/2", 3", 4", 5" | 1/2" | 0.51" | 7/32" | 3/16" | 8 | 1/32" | Negative | 1 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Cast Iron | 1 1/2", 2", 2 1/2", 3", 4", 5" | 1/2" | 0.51" | 7/32" | 3/16" | 8 | 1/32" | Negative | 10 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Hardened Steel, Steel | 1 1/2", 2", 2 1/2", 3", 4", 5" | 0.579" | 0.58" | 1/4" | 7/32" | 8 | 1/32" | Negative | 1 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Hardened Steel, Steel | 1 1/2", 2", 2 1/2", 3", 4", 5" | 0.579" | 0.58" | 1/4" | 7/32" | 8 | 1/32" | Negative | 10 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Stainless Steel, Titanium | 1 1/2", 2", 2 1/2", 3", 4", 5" | 1/2" | 0.51" | 7/32" | 3/16" | 8 | 1/32" | Negative | 1 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Stainless Steel, Titanium | 1 1/2", 2", 2 1/2", 3", 4", 5" | 1/2" | 0.51" | 7/32" | 3/16" | 8 | 1/32" | Negative | 10 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Diamondlike Carbon (DLC)-Coated Carbide | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum, Brass, Bronze, Copper, Plastic | 1 1/2", 2", 2 1/2", 3", 4", 5" | 0.579" | 0.58" | 1/4" | 7/32" | 8 | 1/32" | Negative | 1 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum, Brass, Bronze, Copper, Plastic | 1 1/2", 2", 2 1/2", 3", 4", 5" | 0.579" | 0.58" | 1/4" | 7/32" | 8 | 1/32" | Negative | 10 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||