Miniature Carbide Rounded-Edge Square End Mills

With a mill diameter of 3 mm or less, these end mills are great for precise, detailed work such as in electronics, mold making, and medical-device manufacturing. Often used for slotting and pocketing cuts in mold and die making, these end mills have a 90° profile and rounded corners, which reduce flute breakage and chipping. Also known as corner radius end mills. All are center cutting, allowing plunge cuts into a surface.

End mills with two flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts.

Made of solid carbide, these end mills are harder, stronger, and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the end mill from breaking.

An aluminum-chromium-nitride (AlCrN) coating provides excellent resistance to wear, high temperatures, and oxidation—even at high speeds. Great for difficult-to-machine materials like stainless steel, titanium, and tool steel.

Neck | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mill Dia., mm | Shank Dia., mm | Dia., mm | Lg., mm | Lg. of Cut, mm | Corner Cut Radius, mm | Overall Lg., mm | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Aluminum Chromium Nitride (AlCrN) Coated | ||||||||||||

2 Flute | ||||||||||||

| 1.8 | 6 | 1.75 | 5.4 | 2.7 | 0.15 | 50 | Equal | 30° | Aluminum, Brass, Bronze, Copper, Hardened Steel, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

Carbide Dovetail End Mills for O-Rings

Create dovetail grooves that allow O-rings to flex without falling out of place. Made of solid carbide, they are harder, stronger, and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the end mill from breaking.

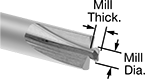

Mill | ||||||||

|---|---|---|---|---|---|---|---|---|

| For O-Ring Wd. | Dia. | Thick. | Shank Dia. | Overall Lg. | Flute Spacing | For Use On | Each | |

Uncoated | ||||||||

2 Flute—24° Chamfer Angle | ||||||||

| 1.78mm | 1.8mm | 1.3mm | 4.8mm | 63.5mm | Equal | Aluminum, Brass, Bronze, Fiberglass, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | 0000000 | 000000 |